В.Кондратьев Самолеты первой мировой войны

RAF SE.5/SE.5a

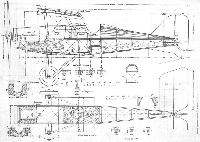

Цельнодеревянный одностоечный биплан с полотняной обшивкой. Разработан конструкторским коллективом фирмы "Ройял Эйркрафт Фэктори" под руководством X. П .Фоллэнда и Дж. П. Кенуорта. Создание этого истребителя, как и французского "Спада" S.VII, обусловлено появлением весной 1916 года 150-сильного авиадвигателя водяного охлаждения "Испано-Сюиза".

К началу осени проект машины был готов, а 22 ноября прототип, обозначенный SE.5, впервые поднялся в воздух. (SE - Scout Experimental - экспериментальный разведчик. Так поначалу в Великобритании называли не только легкие одноместные истребители-разведчики).

Стандартное вооружение машины состояло из одного синхронного "Виккерса" и одного несинхронного курсового "Льюиса", установленного над верхним крылом на так называемом "лафете Форстера", позволявшем сдвигать пулемет по направляющему рельсу назад-вниз для удобства перезарядки в полете.

SE.5 не отличался красотой и изяществом форм, однако он показал неплохие летные данные и в начале следующего, 1917 года был запущен в серию на заводе РАФ в Фарнборо. В марте первые серийные машины поступили в 56-й дивизион RFC, воевавший на западном фронте.

Было построено 59 экземпляров SE.5, после чего в апреле его сменила улучшенная версия машины,обозначенная SE.5a. Эта модификация начала поступать в строевые части в июне. До конца года на SE.5a перевооружили 24-й, 40-й, 41-й, 56-й, 68-й и 84-й дивизионы RFC. Всего же на "эсифайфах" воевали 24 английских, два американских и один австралийский авиадивизион.

Английские летчики высоко оценили машину за отличные скоростные данные, хорошую скороподъемность, выдающуюся прочность конструкции и удобную кабину, хотя горизонтальная маневренность была немного хуже, чем у "Ньюпора".

SE.5a производился в больших количествах до конца войны, а общий итог серийного выпуска достиг 5300 экземпляров. Еще несколько десятков машин собрано по английской лицензии на американской фирме "Кертисс". Американцы планировали построить для своих ВВС 1000 "эсифайфов", однако в связи с окончанием боевых действий заказ был аннулирован.

В 1919 году несколько экземпляров SE.5a попали в Россию в рамках английских военых поставок белогвардейцам генерала Деникина. По крайней мере, один из них впоследствии стал трофеем Красной армии. Еще 20 штук англичане передали полякам, которые использовали их в советско-польской войне 1920 г.

МОДИФИКАЦИИ

SE.5 - двигатель "Испано-Сюиза" 8А, 150 л.с. или его английская лицензионная версия Уолсли "Питон". Внешне самолет отличался короткими выхлопными патрубками, тонкими стойками тележки шасси и отсутствием заголовника за кабиной пилота.

SE.5a - двигатель "Испано-Сюиза" 8В, 200л.с.

ЛЕТНО-ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

S.E.5 S.E.5a

Размах, м 8,50 8,10

Длина, м 6,38 6,31

Высота, м 2,90 2,90

Площадь крыла, кв.м 23,10 22,90

Сухой вес, кг 634 640

Взлетный вес, кг 877 930

Двигатель "Испано-Сьюиза"

мощность, л.с. 150 200

Скорость максимальная, км/ч 196 212

Скорость подъема на высоту

2000м, мин.сек 7,48 6,00

Дальность полета, км 400 500

Потолок, м 5200 6700

Экипаж, чел 1 1

Показать полностью

А.Шепс Самолеты Первой мировой войны. Страны Антанты

RAF S.E.5 1915 г.

В начале 1915 года Англия получила из Франции техническую документацию на 8-цилиндровый V-образный мотор жидкостного охлаждения фирмы "Испано-Сьюиза". Этот компактный и достаточно мощный (150 л. с.) мотор и был установлен на один из лучших английских истребителей Первой мировой войны - S.E.5.

Эта машина - одностоечный биплан, в конструкции которого преобладало дерево и полотно. Кабина летчика размещалась в середине фюзеляжа. Посадка глубокая - в потоке оставалась одна голова. Капот двигателя обшивался металлом. Остальной фюзеляж - полотном. В конструкции каркаса фюзеляжа использовались стальные трубы и деревянный брус. Крылья также смешанной конструкции, двухлонжеронные, обтянуты полотном. Стойки бипланной коробки деревянные, на более поздних машинах - металлические. На обоих крыльях - элероны. Оперение обычной конструкции. Стабилизатор регулируемый. Руль поворота установлен на киле. Шасси жесткой конструкции, с резиновой амортизацией. В хвосте - неуправляемый костыль. Двигатель 8-цилиндровый, жидкостного охлаждения, рядный, V-образный, с лобовым радиатором. Винт деревянный, двухлопастной. Вооружение самолета состояло из двух пулеметов: синхронного 7,69-мм "Виккерс" и установленного на верхнем крыле 7,62-мм "Льюис".

Самолет строился в двух модификациях - S.E.5 и S.E.5a, причем последняя отличалась более мощным (200 л. с.) двигателем и незначительными деталями в хвостовом оперении. На последних машинах S.E.5а за кабиной пилота устанавливался заголовник.

Всего построено 5205 машин этого типа, которые состояли на вооружении 24 английских, двух американских и одной австралийской истребительных эскадрилий.

Показатели S.E.5 S.E.5a

Размеры, м:

Длина 6,36 6,36

размах крыльев 8,10 8,10

Высота 2,90 2,90

Площадь крыла, м2 22,9 22,90

Вес, кг:

максимальный взлетный 875 930

пустого 640 695

Двигатель: "Испано-Сьюиза"

мощность, л. с. 150 200

Скорость, км/ч 190 210

Дальность полета, км 400 500

Потолок практический, м 5200 6700

Экипаж, чел. 1

Вооружение 2 пулемета

Показать полностью

P.Hare Royal Aircraft Factory (Putnam)

S.E.5

Although it has occasionally been suggested that the design of this neat and attractive single-seater scout was carried out, at least in part, by Frank Goodden, it is doubtful whether his role extended beyond suggesting features he felt would be desirable, for H P Folland's style is clearly evident in every detail.

The S.E.5 was designed around the Hispano-Suiza V-8 engine, which, when it was first unveiled in mid-1915, was universally heralded as a significant advance in engine design. The use of this largely untried 200hp engine, with its reduction-geared propeller, was clearly intended from the start, because the sole armament originally envisaged for the S.E.5 was a Lewis gun mounted between the cylinder heads and firing through a hollow propeller shaft, an arrangement which obviated the need for synchronization gear, which the Allies had yet to perfect.

The original drawings show a compact and very conventional tractor biplane, its pilot seated unusually high to give him the best possible view past the upper wing. The vertical tail included both dorsal and ventral fin surfaces and a rudder which, save for its rounded corners, was a narrow parallelogram. The control wires to the rudder and elevators were routed wholly within the fuselage to reduce drag. To make the aircraft safe to be flown by inexperienced or inadequately trained pilots, the wings were given generous dihedral angle to afford a reasonable degree of stability, equally generous control surfaces being provided to allow good manoeuvrability. The tailplane incidence could be adjusted, via a control wheel in the cockpit, to trim the machine to fly 'hands off#.

One departure from convention, made in the interests of simplified construction, was the omission of compression ribs in the wing structure. Instead, some of the normal aerofoil ribs were formed from solid ply to carry the compression forces.

Three prototype S.E.5s were built, the first, A4561, being completed by November 1916. It differed from the original drawings in having the fin and rudder originally designed for the F.E. 10, an unbuilt project also designed around the Hispano engine. As no 200hp engine was available, a direct-drive unit of 150hp was installed in A4561, which was not fitted with any armament.

Frank Goodden took it up for its initial flight at about 10.00am on 22 November and, on landing after about ten minutes, exuberantly announced to the waiting spectators, 'She's a pixie!'. Capt Albert Ball, who was allowed to make a short flight the following day while on a visit to Farnborough, was less enthusiastic, comparing the new machine unfavourably with the lightness of the rotary-powered Nieuport which was then his usual mount. However, he was later to revise his opinion.

The second prototype, A4562, which appears to have been identical to the first, was test flown, again by Goodden, on 4 December. A heavy landing during subsequent testing necessitated a replacement undercarriage, and while it was in the workshop the machine was fitted with what would become the type's service armament. A belt-fed Vickers gun was mounted in the forward fuselage decking, offset to port and inclined at five degrees above the line of flight to lessen the effects of bullet drop and extend the effective range. The gun was synchronised to fire through the propeller disc by the recently developed Constantinesco gear. Since this gear could operate only a single gun at that time, a drum-fed Lewis gun was also fitted, on an overwing Foster mounting, firing above the propeller disc. Both an Aldis optical sight and a simple ring and bead were provided, the former directly in the pilot's line of sight and the latter fixed above the barrel of the Vickers gun.

The third prototype, A4563, had the 200hp geared engine for which the type had originally been designed, but otherwise differed little from the two previous examples. It made its first flight on 12 January, with Goodden in the cockpit, and, after suitable modification, eventually became the prototype S.E.5a.

On 28 January 1917 the port wing cellule of A4562 folded up in flight and its pilot, Frank Goodden, was killed in the resulting crash. A committee of investigation headed by Dr A P Thurston concluded that the wings had failed owing to the inadequate strength of the compression ribs, allied with unsatisfactory attachment of the interplane struts to the spars, which had allowed the former to become detached. The Factory staff quickly redesigned these components and the modifications were incorporated in all production machines, the first batch of which was already well advanced in the newly extended Farnborough workshops.

The first production S.E.5, A4845, was tested at Martlesham Heath in March 1917. It was criticised both for its poor lateral control at low speeds, and for its huge 'greenhouse' windscreen which, although it was designed to protect the pilot in his rather elevated position, tended to distort his view. Research carried out at the Factory established that the cause of the former deficiency was the sharp outward rake of the wingtips, and plans were made to modify this, thereby reducing the overall wingspan by about fifteen inches.

The first unit to be equipped with the S.E.5 was the newly formed 56 Squadron, whose pilots included Albert Ball. Before the CO, Maj Blomfield, would allow the pilots to begin operations, the greenhouse windscreens were removed by squadron personnel and replaced by small flat screens intended for Avros. This modification was eventually made to all S.E.5s, and in addition the pilot's seat was lowered and a faired headrest was fitted.

Later aircraft were fitted with long, straight exhaust pipes discharging aft of the cockpit, in place of the original 'T' shaped manifolds and stub exhausts. Radiator shutters, operated by the pilot, were added to assist in controlling engine temperature.

Only fifty or so machines had been completed when the decision was taken to fit all future machines with the 200hp engine, which was finally expected to become available in quantity. The shorter-span wings were also to be adopted at the same time, machines thus equipped being designated S.E.5a.

Powerplant: 150hp Hispano-Suiza V-8

Dimensions:

span 27ft 11in;

chord 5ft 0in;

gap 4ft 7in;

wing area 249 sq ft;

dihedral 5·;

length 20ft 11in;

height 9ft 5in.

Weights:

1,390lb (empty);

1,935lb (loaded)

Performance:

max speed 122mph at sea level;

ceiling 19,000ft;

endurance 2 1/2hrs.

S.E.5a

The third prototype S.E.5, A4563, which had been fitted with a 200hp geared Hispano-Suiza at the time of its first flight in January 1917, was subsequently modified in an effort to overcome the defects noted in the Martlesham Heath report on the type. It therefore had the shorter-span wings, an internal gravity petrol tank and water header tank within the centre-section, a lowered pilot's seat and a faired headrest. Although no criticism appears to have been made of the original two-bladed propeller, a four-bladed unit of slightly reduced diameter was substituted, in accordance with common Factory practice.

On 29 May Roderic Hill flew the modified aircraft to Martlesham Heath, where it received lightly favourable and enthusiastic reports. All production orders placed were therefore for the new type, now given the designation S.E.5a.

The aircraft industry was already swamped with work, and although Martin and Handasyde and the Air Navigation Company accepted orders, the majority went to companies previously engaged in other fields of engineering, including Wolseley Motors and Austin. Production was also undertaken by the Royal Aircraft Factory, and by the end of 1917 almost a thousand airframes had been produced.

Unfortunately, owing to problems with the geared engine, and consequent delays in manufacture, more than 400 machines were stockpiled awaiting engines. In an effort to forestall this eventuality an order had been placed with Wolseley for a number of direct-drive engines. However, because of a misunderstanding, instead of producing licence-built examples of the well-proven 150hp version which powered the S.E.5, the company set about developing an uprated version, intended to give the same output as the unreliable geared variant. By increasing the compression ratio from 4.5:1 to 5.6:1 it became possible to obtain 220hp at 2,000rpm, although this speed was rather high by the standards of the day. An example of this new engine, named the Viper, was tested in a production S.E.5a, after which its compression ratio was slightly reduced to 5.3:1. Although this lowered the nominal power output to 200hp, it gave a slightly enhanced performance at altitude and was adopted for production. A geared version, with the same rating but a lower propeller speed, was also produced, although in much smaller quantities.

To facilitate the installation of whichever of these engines was available, a new radiator, split into two separate banks each with its own shutters, was developed. This left a central vertical slot which could accommodate the different thrust lines of the various engines. The new radiator, which gave the machine a more purposeful, aggressive appearance, was fitted to all Wolseley-powered aircraft, stocks of the original one-piece radiator being used up on the Hispano-powered machines for which it had been designed. Hispano-powered S.E.5as also had small fairings over the ends of the projecting cylinder heads, while those with the Wolseley, which projected slightly less, did not. Machines with geared engines, of whatever make, were fitted with four-bladed propellers, and had a modified Foster mounting for their overwing Lewis guns to allow for the higher thrust line.

While the engine shortage was at its most acute a small number of S.E-.5as were fitted experimentally with the 200hp Sunbeam Arab, but this unit proved less reliable than the Hispano it was intended to replace, and was not adopted for mass production.

Complaints that the original steel-tube undercarriage lacked sufficient resilience for unprepared fields led to the development of a new type, with twin front legs in a narrow inverted vee, all encased in wooden fairings. Another, all-wood version was found to be equally successful and, being far simpler to produce, was adopted thereafter.

Overall, the S.E.5a was a great success, being strong, easy to fly, a stable gun platform, and possessing a performance at least equal to that of any adversary. Its success as a fighter, measured in terms of combat victories, was second only to that of its 'rival', the Sopwith Camel, but the Camel was a much trickier machine to fly and had an unenviable reputation for killing inexperienced pilots. Marshal of the Royal Air Force Lord Douglas of Kirtleside, who flew the type in 1917/18, said in his autobiography, 'Many of us felt that it was the best fighter in Britain in the First World War'. He described it as 'a very strong aeroplane', and 'the most beautiful aeroplane that has ever been built'.

Despite the S.E.5a's acknowledged success, the Factory continued to explore ways of enhancing its performance. In one experiment the S.E.5 A4862, which had remained at Farnborough and been converted to S.E.Sa configuration, had its nose covered by a blunt fairing, the car-type radiator being replaced by an underslung radiator beneath the fuselage. This appears to have been formed by mounting two Viper-type radiator blocks together, one above the other. As no significant improvement in performance resulted, the modification was not adopted, especially as the car-type installation was slightly easier to produce.

Various alternative tail surfaces were designed, including one with twin fins and rudders and another with a rounded vertical tail which gave the machine a vaguely Teutonic appearance. None of these was adopted, and, as no particular criticism appears to have been levelled at the aeroplane's existing tail surfaces or its control or stability, it can only be assumed that the installations were part of a programme of 'pure' research, in keeping with the Royal Aircraft Factory's redefined role. However, one tailplane modification which was adopted, although for relatively few machines, was the use of elevators of reduced chord. These were designed to increase manoeuvrability, but appear to have had little effect.

To facilitate pilot training a number of S.E.5as were converted to dual-control two-seaters. The main petrol tank was drastically reduced in size to make room for the second cockpit, which was positioned under the centre section, and no armament was carried.

Tests were carried out with a variable-pitch propeller, at least one machine being so equipped, but no real success was achieved during the existence of the Royal Aircraft Factory.

By the time of the Armistice 5,205 S.E.5as had been completed, the total reaching 5,269 before production finally ceased. After the war the type continued to serve with the United States Air Service and South African Air Force. Those belonging to the Royal Air Force were quickly disposed of, and a number found their way on to the civil register, at least one being powered, in the interests of economy, by an 80hp air-cooled Renault, with which the top speed fell to about 65mph.

Apart from pleasure and sporting use, the S.E.5a pioneered the art of 'skywriting' both in England and in the USA, a use which served to ensure that three examples would be preserved for posterity in England. Two more survive in the museums of the Australian and South African air services, and two American Eberhart-assembled examples are also extant.

Powerplant:

200hp Hispano-Suiza V-8

200hp Wolseley Viper V-8

200hp Wolseley Adder V

Dimensions:

span 26ft 7 1/2in;

chord 5ft 0in;

gap 4ft 7in;

wing area 245 sq ft;

dihedral 5·;

length 20ft 11in;

height 9ft 5in.

Weights:

1,531lb (empty);

2,0481b (loaded).

Performance: (Wolseley Viper)

max speed

136mph at sea level;

117mph at 15,000 ft;

ceiling 23,000ft.

S.E.5b

Early in 1918 A8947, the last of a batch of Farnborough-built machines, which had been ordered as an S.E.5 but completed as an S.E.5a, was modified to become the S.E.5b. New wings of unequal span and chord were fitted, the upper-wing ailerons being of narrow chord and hinged from an auxiliary spar. The interplane struts were raked outwards. The nose was streamlined, a large shallow spinner covered the propeller boss, and a retractable underslung radiator was provided to cool the 200hp geared Hispano-type engine.

Testing revealed that the induced drag of the large upper wing offset any advantage gained by the streamlining of the nose, and the anticipated improvements in performance were not realised.

Some time after the Armistice it was fitted with standard S.E.5a wings of equal span and chord, and was tested against a production S.E.5a with a nose radiator. The production machine was found superior in powered flight, the modified machine only bettering its performance when gliding with its radiator retracted.

Powerplant: 200hp Wolseley Viper V-8

Dimensions:

span

30ft 7in (upper);

26ft 6in (lower);

chord

6ft 0in (upper);

4ft 3in (lower);

wing area 278sqft;

length 20ft 10in;

height 9ft 6in.

S.E.5E

After the war the Eberhart Company in the USA assembled about sixty S.E.5as, largely from spare parts, for use by the US Air Service. These had plywood-covered fuselages and were powered by direct-drive 180hp Hispano-Suizas built under licence by the Wright Company.

The designation S.E.5E has frequently been applied to these machines.

Powerplant: 180hp Wright-built Hispano-Suiza V-8

Dimensions: As S.E.5a.

S.E.6

This was to have been a single-seater scout for which both the Rolls-Royce Falcon and the supercharged R.A.F.4d have been suggested as possible powerplants. It was to have had equal-span wings separated by 'N' struts. It is doubtful whether anything other than preliminary sketches were made, and no drawing connected with it has survived.

S.E.7

The S.E.7 appears to have been a radial-powered variant of the S.E.6, with which it is known to have shared its wings and tail surfaces. The projected engine was the R.A.F.8, for which a long-chord cowling was developed by windtunnel tests upon scale models.

The design was not completed, but it may have formed the basis for the S.R.2, designed by the Siddeley Deasy Company, of which Fred Green was then chief engineer and where the R.A.F.8 engine was developed into the Jaguar.

T.E.1

The T.E. classification was originally an abbreviation of 'Tatin Experimental', and was therefore reserved for aeroplanes with propellers behind their tails, but no machines of that type were built. In the case of the T.E.1 there is no record of what the 'T' stood for, the aircraft being a two-seat 'fighter' based upon a scaled-up S.E.5.

The drawings, completed early in 1917, show the machine with the now-universal variable-incidence tailplane and a steerable tailskid. Its intended armament was to have been a forward-firing Vickers gun fitted with the Constantinesco synchronisation gear, and a Scarff-ring-mounted Lewis for the observer. Power was to be provided by a 200hp Hispano-Suiza, or a variant thereof.

Three prototypes were ordered on 23 February, to be completed within three months, and three more examples were planned for later completion. The serials A8951-8956 were allotted to the six aircraft.

The first T.E.1 was approaching completion, slightly later than specified, when, on 11 June, work was suspended and was never resumed. The reason has not been discovered, but the emergence of the superb Bristol F.2B Fighter, coupled with the difficulties with production of the Hispano engine, must have influenced the War Office's decision.

Dimensions:

span 31ft 3in;

chord 5ft 8in;

wing area 327 sqft;

length 25ft 0in;

height 9ft 6in.

Weight:

(estimated) 2,300lb (loaded).

Performance: (estimated)

max speed 120mph;

endurance 4hrs.

Показать полностью

P.Lewis The British Fighter since 1912 (Putnam)

December, 1916, was an auspicious month for it saw the completion of two of the most successful designs in the annals of British single-seat fighters - the Royal Aircraft Factory’s S.E.5 and the Sopwith Camel. Both machines were destined to play outstanding parts in the turbulent air fighting over the Western Front and their names were to form a glowing part of the legend of the first great War in the Air.

The Farnborough S.E.5 was next in the line of Scouting Experimentals after the S.E.4a and its fin and rudder outline immediately indicated the hand of H. P. Folland again as the designer. Frank Goodden and J. Kenworthy contributed to the overall design and involved also were F. M. Green as design engineer, S. W. Hiscocks as his assistant, H. Grinsted as stressman, with W. S. Farren responsible for the aerodynamic and stability calculations. The S.E.5’s trim, well-balanced outline stamped it undeniably as a thoroughbred and the machine lived up fully to the promise it inspired.

The machine’s wooden airframe was a normal structure with fabric covering and was centred around the 150 h.p. Hispano-Suiza engine with a flat frontal radiator. The single-bay wings were set with pronounced stagger and carried four ailerons, and the tailplane embodied the refinement of variable incidence controllable during flight.

The prototype A4561 took off for the first time during December, 1916, and was soon modified with revised exhausts and increased windscreen area to the rear. The prototype’s life, however, was short as the wings failed late in January, 1917, during testing by Frank Goodden who was killed in the resulting crash. Modifications were made and the S.E.5 went on to make its great name in the hands of squadron pilots, the first unit to receive the type being No. 56 Squadron, R.F.C., during March, 1917. The armament of the S.E.5 comprised a Vickers gun mounted to port on the front decking and a Lewis gun on a Foster mounting which carried it on top of the upper centresection. The first production S.E.5s were delivered complete with a large windscreen over the front and sides of the cockpit but this was quickly replaced by a small screen of simple, flat form in the interest of visibility from the cockpit.

<...>

By mid-1917 a revised version of the S.E.5, the S.E.5a, had started to reach the squadrons, No. 56 being the first to receive it. The new machine was powered by the geared 200 h.p. Hispano-Suiza and embodied minor alterations in the fore-fuselage. The higher-powered engine suffered from lack of reliability but the S.E.5a soon vindicated itself and established a first-class reputation amongst its pilots. The machine went into service with alternative engines which included the Hispano-Suiza of 220 h.p. and 240 h.p., the 200 h.p. Wolseley Viper W.4A and the 200 h.p. Wolseley Adder W.4B.

<...>

As the War progressed through its final year two further Scouting Experimental designs were indulged in by the Royal Aircraft Factory designers. One, the S.E.5b, was built as a modification of an S.E.5 - A8947 - for comparative tests with the standard S.E.5a. The 200 h.p. Hispano-Suiza was streamlined into the nose, assisted by a large spinner, and a semi-retractable radiator of reduced area was installed underneath the engine to effect a considerable saving in drag. New unequal-span wings were fitted and the machine was tested also with normal S.E.5a wings, in which guise the designation S.E.5c was at times applied to it. The S.E.5b was given the standard S.E.5 armament of one Vickers gun and one Lewis gun.

The other S.E. design, the S.E.6, remained an incomplete project but would have been a single-seat biplane to the same requirement as the Martinsyde F.3 with the useful power of the 275 h.p. Rolls-Royce Falcon III.

After barely six years, the busy period of aeroplane design activity at the Royal Aircraft Factory came to an end but the organization could look back with satisfaction on time spent in developing a useful range of machines. Particularly noteworthy were its Scouting Experimentals, each of which had been in the forefront of advanced design and construction techniques, culminating in the outstandingly successful S.E.5 and S.E.5a.

Показать полностью

F.Mason The British Fighter since 1912 (Putnam)

R.A.F. S.E.5 and S.E.5A

Genesis of the Royal Aircraft Factory’s excellent S.E.5 design lay entirely in the Hispano-Suiza engine, designed by the Swiss engineer Marc Birkigt, a 150hp V-eight liquid-cooled in-line engine of which the War Office ordered fifty examples from France, as well as negotiating a manufacturing licence, in mid-1915. Being thus a Service-sponsored engine, it was not unnatural that the Royal Aircraft Factory should be instructed to produce a suitable fighter design, for its power-weight ratio of about 0.33 bhp/lb compared favourably with most fighter engines extant, such as the 110hp Clerget which returned a figure of 0.28 bhp/lb. Leading the project at Farnborough was the chief engineer, Maj F M Green, with Henry Folland, assisted by John Kenworthy, being responsible for the principal design; Maj Frank Goodden, the Factory’s chief pilot, was also closely involved.

The design was entirely new, although it has been suggested that some of its inspiration lay in the Martinsyde RG, for the compact front fuselage was superficially reminiscent of that aeroplane; the remainder of the aircraft was a natural progression from the S.E.4A.

Fundamental to the design was that it should be relatively simple to fly, yet represent a worthwhile advance in performance, armament and agility over fighters such as the D.H.2 which, it should be remembered, was still in service at the end of 1916. For ease of manufacture, the structure was simple and straightforward with wings of parallel chord, a wooden box-girder fuselage, and tail surfaces little changed from the S.E.4A. The single-bay, staggered wings were built around two spruce spars with internal wire bracing, and with ailerons on upper and lower wings. A large car-type radiator was located immediately forward of the engine, and the fuel tank was mounted on the top longerons directly behind; the tank was initially cowled by an extension of the top engine cowling panel, but the panel was omitted on production aircraft. Early aircraft also featured a small gravity fuel tank above the upper wing, offset to port of the centreline.

After long delays, the fifty Hispano-Suiza engines, ordered the previous year, began delivery in August 1916, and manufacture of three prototype S.E.5s started the following month. These aircraft possessed sharply raked wingtips and short exhaust manifolds each with a single central outlet.

In the morning of 22 November Frank Goodden flew the first prototype S.E.5, A4561, at Farnborough, and expressed delight with the new fighter, a view not shared by Capt Albert Ball dso, who flew the aircraft a day or so later. The second prototype, A4562, was flown on 4 December and soon afterwards went to France for brief operational trials with No 60 Squadron (giving rise to some incorrect impressions that ‘the S.E.5 equipped the Squadron from january 1917 onwards’). The judgement was more reasoned than that of Ball, speaking of the S.E.5 as being comparable with the Nieuport 17 and Spad VII, though more stable and simpler to fly. It was, the report stated, likely to be much steadier in gun firing.

On 28 January the first S.E.5 prototype crashed near Farnborough, killing the Factory’s popular chief pilot, Frank Goodden. The official findings were convoluted, suggesting that the propeller had ‘burst’, and that the ensuing vibration had caused the wing structure to fail. In fact it seems most likely that wing structure collapse occurred in the first instance during aerobatics. Be that as it may, the design was modified to incorporate strengthened rear spars, shortened wings with reduced rake, and strengthened strut/spar joints. The result was an immensely strong airframe that became a hallmark of the S.E.

A preliminary order for 24 S.E.5s had already been received by the Factory, these aircraft being fitted - for the most part - with the imported Hispano engines. However, these aircraft had progressed too far to include the new wing changes. They were issued to No 56 Squadron at London Colney, near St Albans, commanded by Maj R G Blomfield, and used for training before being changed for the strengthened aircraft which were taken to France the following month. Among those pilots who joined the Squadron during the training period was Capt Albert Ball, posted in as a flight commander; he had not yet become reconciled with the S.E.5, and obtained permission to continue flying a Nieuport.

Early production S.E.5s featured semi-enclosed cockpits intended to give protection from the slipstream for the pilot while attempting to load the Lewis gun, or clear stoppages on the Vickers; it was, however, much disliked by the pilots, and was replaced by a small rigid windscreen which became a standard fitting.

Meanwhile licence production of the Hispano-Suiza engine had been undertaken by the Wolseley Motors company, but this had got off to a slow start. The Air Board had sanctioned the purchase of 8,000 engines from the Mayen company in France although, once again, these would not start arriving in Britain until late in 1917 (and were to be found to have poorly manufactured components). A geared version of the 150hp Hispano-Suiza had been developed which produced a nominal 200 bhp; this was tested in the third S.E.5 prototype, A4563, early in 1917, and underwent operational trials with Nos 56 and 84 Squadrons in France. It was readily distinguishable by the higher propeller line and a slightly deeper fuselage forward of the cockpit, the aircraft being re-termed the S.E.5A.

The S.E.5A became the subject of all production contracts placed from March 1917 onwards, and featured a number of other refinements, such as the addition of a streamlined headrest fairing behind the cockpit (although a number of pilots had this removed as they considered it to restrict their rearward vision).

Nor were the early Wolseley-built engines satisfactory, and weaknesses in components led to fairly frequent engine failures. By the time these had been rectified, production of Hispano-Suiza engines was running some six months behind schedule, as were examples of a high-compression version of the 150hp engine, developed by Wolseley and named the Viper.

Despite these difficulties, S.E.5As began re-equipping No 56 Squadron in June, and No 60 Squadron the following month, the majority of their aircraft being produced by Martinsyde at Brooklands. In August No 84 Squadron at Lilbourne in Northamptonshire, commanded by Maj William Sholto Douglas (later Marshal of the Royal Air Force Lord Douglas of Kirtleside, gcb, mc, dfc), received the S.E.5A and moved to France in September. By the end of the year Nos 24, 32, 40, 41, 56, 60 and 84 Squadrons had been re-equipped and were serving in France, a most disappointing number bearing in mind that almost 3,000 aircraft had been on order for almost six months, and only 828 had been delivered. Altogether sixteen squadrons had been expected to be flying the S.E.5A by December 1917.

Added to the engine troubles were problems with the gun interrupter gear (although the Constantinesco equipment was elsewhere considered to be reliable); it was found that the hydraulic system of the interrupter was incompatible with some batches of the Wolseley-built Hispanos - a weakness not finally overcome until February 1918. Nevertheless, by the spring of that year the S.E.5A was generally considered to be over its troubles and to be the best British fighter of the day. It was faster, though less manoeuvrable than the Sopwith Camel, and capable of withstanding considerable damage in combat. Some of the best-known pilots of the RFC and RAF of the First World War flew the aircraft. Maj Edward(‘Mick’) Mannock vc, DSO**, mc*, scored 54 of his 73 victories while flying S.E.SAs with Nos 40, 70 and 85 Squadrons; Lt-Col W A Bishop vc, dso*, mc, dfc, shot down 27 enemy aircraft out of his total score of 72 victories while with Nos 60 and 85 Squadrons. Other high-scoring S.E.5A pilots included Maj J T B McCudden vc, dso*, mc*, dfc, Capt A W Beauchamp-Proctor vc, dso, mc*, dfc, Capt G E H McElroy mc**, dfc*, Capt JIT Jones dso, mc, dfc*, mm, and Lieut A P F Rhys Davids dso, mc*.

The S.E.5A had undergone a number of improvements, including the strengthening of the undercarriage; the forward member of the V-struts, previously a single tubular member, was now doubled, the two steel tubes being faired over with ply or sheet metal. Increasing numbers of aircraft were fitted with direct-drive Wolseley Viper engines but, being heavier than the Hispano, were generally disliked. A geared development, the Adder, also appeared, but this was even heavier.

S.E.5As were issued to Home Defence units but were regarded as unsuitable as interceptors owing to the length of time needed to warm up their engines before take-off. After the first German daylight raids over southeast England in June 1917, No 56 Squadron was ordered back from France (in spite of objections by Trenchard) to Bekesboume in Kent. After having kicked its heels for a fortnight, without so much as seeing a German raider, the Squadron returned to France. Four other Home Defence Squadrons became operational on S.E.5As, but all had been replaced with Camels by the end of the War.

S.E.5As did not fight on the Italian Front, but three Squadrons, Nos 17, 47 and 150, flew the aircraft in Macedonia. In Palestine, Nos 111 and 145 Squadrons’ S.E.s were heavily engaged during General Allenby’s final offensive through Palestine in the late summer of 1918, both in the ground attack role (using 201b Cooper bombs) and in patrols over the enemy aerodromes to discourage German pilots from taking off. No 72 Squadron served in Mesopotamia until February 1919 when its duties were taken over by No 30, also flying S.E.5 As.

Like the Camel, the S.E.5A did not survive long in the peacetime RAF, the last squadron aircraft being withdrawn from Nos 56 and 81 in January 1920. Small numbers served in Canada and Australia.

It had been planned to build 1,000 aircraft in America for the Air Service, and a contract to that effect had been agreed with the Curtiss company; this was cancelled at the end of the War, and only one Curtiss-built example was completed. 57 others, known as S.E.5Es, were however built from components shipped out from Britain in 1922-23 and these served as advanced trainers.

One other version appeared in Britain as the S.E.5B, a much-modified S.E.5A, A8947. In this a Viper engine, with a much cleaned-up mounting and cowling, was fitted, together with sesquiplane wings and outward-raked interplane struts. The car-type radiator was replaced by a chin-mounted unit and the propeller fitted with a large spinner. To provide a performance comparison, the larger wings were afterwards replaced by standard components while retaining the improved engine installation (in a version known as the S.E.5C) but, although this returned the best performance figures of any S.E.5 variant, it appeared much too late to warrant putting it into production.

Type: Single-engine, single-seat, single-bay biplane fighting scout.

Manufacturers: The Royal Aircraft Factory, Farnborough, Hampshire; The Austin Motor Co Ltd, Birmingham; The Air Navigation Co Ltd, Addlestone; Martinsyde Ltd, Brooklands; Vickers Ltd, Crayford and Weybridge, Surrey; Wolseley Motors Ltd, Birmingham.

Powerplant: S.E.5: 150hp Hispano-Suiza; also 200hp Wolseley W.4A Viper. S.E.5A: 200hp Hispano-Suiza; 220hp Hispano-Suiza; 240hp Hispano-Suiza; 200hp Wolseley W.4A Viper; 200hp Wolseley W.4B Viper.

Structure: Wooden box-girder, wire-braced and fabric-covered; twin spruce spar wings, fabric-covered and with ailerons on upper and lower wings; variable incidence tailplane.

Dimensions: Span, 28ft 0in (early S.E.5s), 26ft 7 1/2 in (late S.E.5s and S.E.SAs); length, 21ft 4in (S.E.5), 20ft 11in (S.E.5A); height, 9ft 5in (S.E.5), 9ft 6in (S.E.5A); wing area, 249 sq ft (early S.E.5s), 244 sq ft (late S.E.5s and S.E.SAs).

Weights: S.E.5A (200hp Hispano-Suiza). Tare, 1,400lb; all-up, 1,953lb.

Performance: S.E.5A (200hp Hispano-Suiza). Max speed, approx 135 at sea level; climb to 10,000ft, 10 min 20 sec; service ceiling, 22,000ft; endurance: 3 hr.

Armament: One fixed, synchronized 0.303in Vickers machine gun with Constantinesco interrupter gear on nose, offset to port, with 400 rounds; and one Lewis gun on Foster mounting above upper wing centre section with four 97-round drums. Four 20lb Cooper bombs could be carried on racks under the fuselage.

Prototypes: Three S.E.5 prototypes, A4561-A4563 (first flown by Maj Frank Goodden on 22 November 1916 at Farnborough). One S.E.5B, A8947 (a modified S.E.5).

Production: 48 S.E.5s (excluding prototypes; all built by Royal Aircraft Factory: A4845- A4868 and A8898-A8947); 5,180 S.E.SAs built in Britain (Royal Aircraft Factory, 200: B4851-B4900, C1051-C1150 and D7001-D7050; Martinsyde, 500: B1-B200, D3911-D4010, E3154-E3253 and F5249-F5348; Vickers, 2,165: B501-B700, C5301-C5450, C9486-C9635, D201-D450, D3426-D3575, D5951-D6200, D8431-D8580, E1251-E1400, E3904-E4103, F551-F615, F5449-F5698 and F8946-F9145; Austin, 1,550: B8231-B8580*, C8661-C9310, E5637-E5936, F7951-F8200; Air Navigation Co, 336: C1751-C1950, E5937-E6036 and H674-H710 approx; Wolseley, 400: C6351-C6500, D6851-D7000 and F851-F950. *Some of these aircraft may not have been completed.)

Summary of RFC and RAF Service: S.E.5s served with Nos 56 and 60 Squadrons in France. S.E.SAs served with Nos 1, 24, 29, 32, 40, 41, 56, 60, 64, 68, 74, 84, 85 and 92 Squadrons in France; S.E.SAs served with Nos 17,47 and 150 Squadrons in Greece; S.E.SAs served with Nos 30, 72, 111 and 145 Squadrons in the Middle East; and S.E.SAs served with Nos 50, 61, 81, 87, 93, 94 and 143 Squadrons in the United Kingdom (not all operationally).

Показать полностью

W.Green, G.Swanborough The Complete Book of Fighters

ROYAL AIRCRAFT FACTORY S.E.5 UK

Second only to the Sopwith Camel in reputation as the RFC's outstanding fighter of World War I, the S.E.5 was designed under the direction of H.P. Folland. Of classic tractor biplane configuration, the S.E.5 was initiated to take advantage of the new Hispano-Suiza engine that began test-running in Spain in February 1915 and was in production in France a few weeks later. Two versions of the engine became available during 1916, the basic direct-drive 150 hp unit and a geared version producing 200 hp. Examples of both were included in the British orders placed in France and, subsequently, with Wolseley for licence-built examples (as the 150 hp Python and 200 hp Adder respectively). The S.E.5 was intended, from the outset, to be powered by the 200 hp geared engine and to be armed with a 0.303-in (7,7-mm) Lewis machine gun firing through a hollow propeller shaft, but, in the event, early aircraft had to use the 150 hp Hispano 8Aa, and had an armament of one Vickers gun in the front fuselage, offset to port, with interrupter gear, and a Lewis on a Foster mount above the centre section. Unarmed, the first of three prototypes of the S.E.5 flew on 22 November 1916. It was a compact single-bay biplane with equi-span wings featuring raked tips, a similarly-raked tailplane, triangular fin and almost rectangular rudder, with a small ventral fin and a V-strut undercarriage. A large windscreen was provided over the front of the cockpit. All major components were of conventional wood construction, with fabric covering. Of two further prototypes, one was similarly powered and first flew on 4 December 1916, whereas the other introduced the 200 hp engine and became, effectively, the prototype for the S.E.5a (which see). Production of the S.E.5 was ordered "off the drawing board” with a first batch of 24 built by the RAF at Farnborough, where the first was completed in March 1917. A second batch of 50 followed on, but at least 15 of these were to emerge as S.E.5a’s, and some S.E.5s in service were also modified to have 200 hp engines. In service with the RFC in France by early 1917, production S.E.5s were modified in various ways, particularly by removal of the windscreen. Other changes tried out on S.E.5s to improve the lateral control were consolidated in the S.E.5a.

Max speed, 122 mph (196 km/h) at 3,000 ft (915 m), 98 mph (158 km/h) at 15,000 ft (4 570 m).

Time to 6,500 ft (1980 m), 8 min.

Service ceiling, 19,000 ft (5 790 m).

Endurance, 2.5 hrs.

Empty weight, 1,399 lb (635 kg).

Loaded weight, 1,935 lb (878 kg).

Span, 27 ft 11 in (8,51 m).

Length, 20 ft 11 in (6,38 m).

Height, 9 ft 5 in (2,87 m).

Wing area, 249.8 sq ft (23,20 m2).

ROYAL AIRCRAFT FACTORY S.E.5a UK

The third prototype of the S.E.5 flew at Farnborough on 12 January 1917 powered by a 200 hp geared Hispano-Suiza 8B water-cooled eight-cylinder V-type engine, but otherwise similar to the 150 hp-engined earlier prototypes. While production deliveries of the 200 hp engine were awaited, airframe modifications were introduced in the light of early experience with the first production batch of S.E.5s. In particular, the wing rear spars were shortened at the tips to provide greater strength, this serving to blunt the previously raked tips and reduce overall span by 15 1/2 in (39,4 cm). At the same time, lateral control was improved by shortening the levers on the ailerons. With a small Avro-type windscreen in place of the S.E.5's voluminous structure, a small fabric-covered head fairing behind the cockpit, the blunt wings and the standard Vickers + Lewis gun armament, the version with 200 hp engine became the subject of large-scale production as the S.E.5a, starting with part of the second batch S.E.5s already ordered from the RAF. Two hundred more were built at Farnborough itself and, in addition, by the time the war came to an end in November 1918, some 5,125 S.E.5a’s had been built by five companies in less than 18 months: Austin (1,550), Bleriot & Spad (560), Martinsyde (400), Vickers (2,215) and Wolseley (400). Production of the 200 hp Hispano (in several sub-variants, and including licence-production by Wolseley as the W.4B Adder I, II and III) failed to keep pace with this prodigious output, and numerous operational difficulties with the engine enhanced the problem. Consequently, many S.E.5a's were fitted (without change of designation) with the 200 hp direct-drive Wolseley W.4A Viper, a derivative of the French engine. At least six S.E.5a's were flown with the 200 hp Sunbeam Arab I (geared) or Arab II (direct drive) water-cooled eight-cylinder engine in trials at Farnborough, and some production aircraft received high-compression versions of the French-built Hispano-Suiza engine, increasing maximum output to 220 hp. Twenty-two squadrons of the RFC and the US Air Service were flying the S.E.5a by the time of the Armistice, but this brought an end to planned large-scale production by Curtiss in the US when only one of 1,000 on order had been completed (in addition to 56 assembled from British components). Service use continued on a small scale for only a short time after the end of the war, in Australia, Canada and South Africa as well as with the RAF. The following data refer to the S.E.5a with the 200 hp Hispano-Suiza engine.

Max speed, 126 mph (203 km/h) at 10,000 ft (3 050 m), 116 mph (187 km/h) at 15,000 ft (4 570 m).

Time to 10,000 ft (3 050 m), 13.25 min.

Service ceiling, 17,000 ft (5180 m).

Endurance, 2.25 hrs.

Empty weight, 1,531 lb (694 kg).

Loaded weight, 2,048 lb (929 kg).

Span, 26 ft 7 1/2 in (8,11 m).

Length, 20 ft 11 in (6,37 m).

Height, 9 ft 6 in (2,89 m).

Wing area, 245.8 sq ft (22,83 m2).

ROYAL AIRCRAFT FACTORY S.E.5B UK

The final aircraft built at Farnborough against contracts for 74 S.E.5s placed in 1917 was used early the following year for an experimental programme aimed at improving the performance and fighting ability of the type. Fitted with a 200 hp Hispano-Suiza 8B engine and armed with the Lewis and Vickers gun combination of the standard S.E.5a, it had new single-bay wings of unequal span and chord. In addition, a retractable radiator was provided in the forward fuselage, and a large, shallow, propeller spinner was fitted, to combine with a re-profiled cowling and give better streamlining of the fuselage. The head-fairing behind the cockpit was also improved. Tests in 1918 revealed little performance gain or handling benefit, with the extra drag of the big upper wing offsetting gains from the more streamlined fuselage. Standard S.E.5a wings were fitted to the S.E.5b in 1919, as well as a modified horizontal tail, for comparative testing at Martlesham Heath, and this aircraft made an appearance at the RAF Pageant at Hendon in 1920.

Loaded weight, 1,950 lb (885 kg).

Span, 30 ft 7 in (9,32 m).

Length, 20 ft 10 in (6,35 m).

Height, 9 ft 6 in (2,89 m).

Wing area, 278 sqft (25,83 m2).

Показать полностью

J.Bruce British Aeroplanes 1914-1918 (Putnam)

S.E.5 and 5a

IN the year 1915 there appeared a new French aero-engine, designed by M. Marc Birkigt and made by the Hispano-Suiza company. It was an eight-cylinder water-cooled vee unit with each bank of cylinders cast in aluminium as a one-piece block; it delivered 150 h.p. for a weight of only 445 lb.

In the summer of 1915, one of these engines was inspected in Paris by Lieutenant-Colonel H. R. M. Brooke-Popham. On his recommendation, a British order for fifty engines was placed in August 1915, and negotiations were begun for the manufacture of the Hispano-Suiza in Britain. These negotiations involved the parent Hispano-Suiza company in Barcelona as well as the French firms who were manufacturing the engine under contract, and cost a great deal of time. British production of the Hispano-Suiza did not begin until the spring of 1916.

With the promise of this compact and workmanlike engine being available, the design staff at Farnborough began work on the design of a new single-seat fighter which was given the designation S.E.5. Their aim was to produce an aeroplane which could be flown with reasonable safety by pilots who had had only the sketchy flying training of the period. This presupposed a certain degree of inherent stability, and the design was revised after early wind-tunnel tests had shown that the original conception would not have been sufficiently stable.

The design work was largely done by H. P. Folland, assisted by J. Kenworthy and Major Frank W. Goodden. Much of the later success of the S.E.5 is attributable to careful designing, particularly in the matter of detail design, at which Mr Folland excelled.

The machine’s basic structure was typical of the war period. The fuselage was a wire-braced box girder composed of wooden longerons and spacers: plywood was applied to the fuselage sides below the engine bearers, and extended as far aft as the front spar of the lower mainplanes. A flat car-type radiator was mounted at the nose, and the short exhaust manifolds had a single central outlet. The main fuel tank was mounted on top of the upper longerons behind the engine; the tank was shaped to the contour of the fuselage top-decking. On the prototype S.E.5 the tank was covered by an extension of the engine cowling, but it was left uncowled in production machines. There was a gravity tank mounted externally above the centre-section well out to port. The undercarriage was a simple structure consisting of two steel tube vees.

The wings had spruce spars and were braced internally by wire. There were no conventional compression struts: in their place were certain ribs which were made solid. The single-bay interplane bracing was supplemented by two auxiliary mid-bay flying wires on each side. The incidence of the tailplane could be varied in flight; and a rather unusual feature was the location of the elevator cable runs within the fuselage and tailplane. The vertical tail assembly was a characteristic structure of highly practical design.

The fifty Hispano-Suiza engines which had been ordered in 1915 were delivered between August and December, 1916. One of the first was installed in the prototype S.E.5, A.4561, which first flew in December, 1916. This machine was later flown with modified exhausts and side extensions of the windscreen. In its first flights the S.E.5 gave every indication of being a satisfactory aircraft, but structural failure of the wings brought about the destruction of the prototype at the end of January, 1917. In the crash Frank Goodden lost his life, a life which could ill be spared from Britain’s aeronautical effort of the time.

Production had already been initiated, but was suspended while the crash was investigated. The shape of the wing-tip was re-designed to be much less sharply raked, modified strut-to-spar joints were fitted, and stronger lift-bracing was introduced. Construction of the first production batch of S.E.5s was too far advanced for the new wing-tip shape to be used, but the rear spars were reinforced and the other modifications incorporated. The machines of the second batch of S.E.5s had the modified wings of reduced span which became standard on all subsequent S.E.5s and 5a’s. Some machines were fitted with an improved gravity tank which was mounted within the leading edge of the upper centre-section; this arrangement also became standard.

The modifications proved to be entirely satisfactory, and in service the S.E.5 airframe gained a reputation for great structural strength which inspired confidence in combat.

The armament fitted to the production machines consisted of two machine-guns. A Vickers gun was mounted in front of the cockpit on the port side and with its breech mechanism enclosed within the top decking; and a Lewis gun was carried above the centre-section on a Foster mounting. The latter weapon could slide back along a curved rail until it was nearly vertical; in this position it could be reloaded and could also be fired upwards. It has been said that the Lewis gun was fitted to the S.E.5 in this way because Captain Albert Ball, V.C., had scored several successes with the Foster-mounted Lewis on his Nieuport Scout, and had exploited its ability to fire upwards.

The Vickers gun on the S.E.5 was synchronised to fire through the revolving airscrew by means of the Constantinesco hydraulic synchronising gear. This gun-gear gave a good deal of trouble before it became understood. Frequently the Vickers gun would not fire at all or, if it did, an S.E. pilot might find that he had shot his own airscrew off. Major J. T. B. McCudden experienced these troubles, despite meticulous personal attention to his guns. Describing his combat experiences at a time as late as September, 1917, he wrote: “My word! You cannot realise what it is to get on the Huns’ tails time after time, and then have your guns let you down.”

The first production S.E.5s were completed in March, 1917, and were delivered to No. 56 Squadron. That unit had been formed at Gosport in June, 1916, from a nucleus provided by No. 28 Squadron, and moved to London Colney during the following month. Major R. G. Blomfield assumed command early in February, 1917, and on the 26th of that month Captain Albert Ball was posted to the squadron as a Flight Commander. No. 56 Squadron received its first S.E.5 on March 13th, 1917, and by April 5th its establishment of the new machines was complete. On that date an advance party went to France, and two days later the complete squadron arrived at Vert Galand aerodrome.

In one or two features the early production S.E.5 was not satisfactory for operational use, and Major Blomfield kept his squadron grounded for two weeks to allow some essential modifications to be made. The machines delivered to No. 56 Squadron had a cumbersome transparent windshield which extended forward over the breech of the Vickers gun. It may have been hoped that this “greenhouse” (as it was called by the pilots) would facilitate the clearing of gun stoppages; but all it did was to interfere seriously with the pilot’s forward view, and it could have been a danger in a crash. Major Blomfield had the greenhouses replaced by a small flat Triplex windscreen which was adopted as a standard fitting on all S.E.5s.

Experience showed that it was better to have the fire of the Lewis gun converging with that of the Vickers at about 50 yards range instead of being parallel to it. The Foster mounting was therefore raised slightly at the rear end.

The S.E.5s of No. 56 Squadron made their first patrol on April 22nd, 1917, when five machines led by Ball patrolled between Lievin and Croisilles. An Albatros two-seater which they pursued escaped destruction only because strict orders had been issued that no S.E.5 was to cross the lines in any circumstances.

Captain Ball scored his first victory on an S.E.5 on April 23rd, when he shot down a green Albatros scout in flames from 13,000 feet over Cambrai. Ball did not at first like the S.E.5, for it was less responsive than the sensitive Nieuport Scout which he had been flying. His dislike of the S.E. was so great that he asked for, and obtained, a Nieuport for his personal use in No. 56 Squadron. However, after being saved from death on April 26 th, 1917, by the speed and double fire-power of the S.E.5, realised its true worth and used his Nieuport only once more over the lines.

Convincing proof of the S.E.5’s great structural strength was provided on April 28th, 1917. Lieutenant G. C. Maxwell had engaged a group of Albatros scouts over Fontaine when his machine was struck by anti-aircraft fire. His engine was damaged and his elevator controls rendered almost totally ineffective. With little control over his S.E., Maxwell glided down and hit the ground near Combles at about 140 m.h.p. The engine and its bearers broke off, but the remainder of the aircraft bounced on for nearly a hundred yards and was completely wrecked. Maxwell was quite uninjured.

In S.E.5 airframes various experimental versions of the 150 h.p. Hispano-Suiza engine were flown. In September, 1917, engines with compression ratios increased to 5-3 to 1 and 5-6 to 1 were fitted; the latter engine developed 192 h.p. Finally, in December, 1917, a Wolseley Viper engine was tested in an S.E.5. According to the official records of the performance trials, all these installations were made in S.E.5s with the long-span wings.

The Hispano-Suiza engine underwent development during 1916, and a geared version was produced which developed 200 h.p. The second S.E.5 prototype was fitted with one of these engines. This first installation was very similar to that of the 150 h.p. Hispano-Suiza, and could be distinguished only by its higher thrust-line and left-hand airscrew. The aeroplane itself had the original form of S.E.5 wings with reinforced rear spars. The third prototype, A.4563, was also fitted with the 200 h.p. Hispano-Suiza, but the radiator was provided with shutters and a four-bladed airscrew was used. The shorter-span wings were fitted, and the exhausts were the L-shaped manifolds which had been used on most of the first production S.E.5s. This aircraft was used operationally in France by Squadrons Nos. 56 and 84.

This modified version of the aircraft was designated S.E.5a, and all subsequent machines were of this type. The first production S.E.5a was delivered to No. 56 Squadron in June, 1917, and thereafter the type gradually replaced the S.E.5. No. 56 Squadron was completely re-equipped with the new type by August, 1917. The S.E.5a fuselage forward of the cockpit was a little deeper than that of the S.E.5, and long horizontal exhaust pipes were standard fittings. In No. 56 Squadron these long pipes were not liked at first; they were cut off just behind the rear exhaust stub and replaced by short pipes welded on at an outwards angle. Later, however, the long pipes were again used.

Unfortunately, the 200 h.p. Hispano-Suiza engine was dogged by ill-luck; consequently the S.E.5a was not so immediately effective as it might have been. Really large-scale production was still some way off, owing to difficulties in obtaining engines. At the insistence of the Admiralty, the Air Board had ordered 8,000 Hispano-Suiza engines in November, 1916, principally from the Mayen concern in France. This firm built a large factory for the purpose, using some £2 million advanced by the British Government, but the first engines did not come off the lines until late in 1917.

Meanwhile, production of the 200 h.p. engine was undertaken in England by the Wolseley company; and other Hispano-Suiza engines made in France by Brasier were fitted to S.E.5a’s.

The Wolseley-built engines were not at first successful. On May 7th, 1917, Sir William Weir, the Controller of Aeronautical Supplies, had to report that a 200 h.p. Hispano-Suiza engine made by Wolseley had broken four successive crankshafts after an average run of only four hours. Trials of this engine continued, and production went ahead after eleven modifications had been introduced, but the delay led to a reduction in output. As a stop-gap, the Wolseley concern were asked to make 400 Hispano-Suiza engines of the original 150 h.p. direct-drive version, an order which was later increased to 1,100. However, it was apparently not made clear to the contractors that they were required to produce the existing type, for they set about developing from the 150 h.p. Hispano-Suiza a high-compression engine of the same nominal power. The new engine became known as the Wolseley Viper, but the time spent on its design seriously retarded production by the company and did nothing to alleviate the immediate shortage of Hispano- Suiza engines: whereas it had been expected that 140 of these engines would have been delivered by the end of August, 1917, only ten had been completed.

This serious situation was further aggravated by the unreliability of the first 200 h.p. Hispano-Suiza engines delivered from the French firm of Brasier. Failures were frequent, and the engines had to be sent to the Clement Talbot works for overhaul. One of the most serious defects lay in the faulty hardening of the gearwheels and airscrew shaft; these had to be replaced by British-made spares. By October, 1917, however, the shortage of engines had become so acute that some of the French Hispanos were passed into service with the original unevenly hardened gears. The engines were accepted by the Aeronautical Inspection Directorate only on direct written instructions; and cautionary entries in the engine log-books warned that the faulty gearwheels had been fitted for lack of others, and that the running of the engine should be carefully watched. In extenuation of this indefensible action it was pleaded that defective engines were better than none at all.

These failures hit the S.E.5a particularly hard, and by January, 1918, no fewer than 400 new S.E.5 were held up in stores because no engines were available for them. The set-back could hardly have occurred at a more unfortunate time, for airframe production had expanded greatly during the last quarter of 1917: during the period 604 S.E.s were produced, whereas only 157 had been built during the preceding three months.

When in service, the machines with the defective engines were bad for morale: no pilot could be reasonably expected to have confidence in a machine of known unreliability.

Fortunately, the Admiralty’s foresight in 1916 saved the situation, which had become ugly indeed; for in the early months of 1918 the first deliveries of Mayen-built Hispano-Suizas were made against the order for 8,000 engines.

In action, the S.E.5a was an excellent fighting aircraft, and its finest testimonial lies in the fact that it was the mount of the leading British fighter pilots of the war. Major Edward (“Mick”) Mannock, V.C., S.O., M.C., scored more than 50 of his 73 confirmed victories while flying an S.E.5a, and the type was also flown with signal success by such pilots as Bishop, McCudden, Beauchamp-Proctor, McElroy and Rhys-Davids. The S.E., though it had none of the hair-trigger sensitivity of its great contemporary, the Sopwith Camel, was usefully manoeuvrable and yet stable enough to facilitate accurate shooting. Its reputation for strength was an enormous asset in combat, for if it lacked anything in manoeuvrability that small deficiency was more than outweighed by the liberties which could be taken without fear of structural failure.

S.E.5a’s became available in increasing numbers throughout the summer of 1917, and were issued to several squadrons. Despite trouble with the engines and Constantinesco gun-gear the aircraft gave a good account of itself. On September 28th, 1917, Captain J. T. B. McCudden of No. 56 Squadron led his patrol of S.E.5a’s to attack a group of Albatros scouts over Boesinghe, and destroyed five of the enemy without loss to the British machines.

McCudden had several S.E.5a’s while he was with No. 56 Squadron. The first was B.519, and was followed by A.4863 which gave him a great deal of trouble, particularly with its Constantinesco gear. In October, 1917, he took over the Martinsyde-built S.E.5a B.35, after another pilot had discovered the strength of the S.E.’s construction by flying McCudden’s previous machine through the side of a house: the pilot concerned was unhurt. On December 3rd McCudden received B.4891, an S.E.5a built by the Royal Aircraft Factory.

This machine had a smaller fin than was standard, and narrow-chord elevators were fitted. It was one of the first S.E.5a’s to have the improved undercarriage with the strengthened forward leg in each vee. For a time B.4891 wore the spinner of an L.V.G. C.V. that McCudden had shot down on November 30th, 1917: this spinner was painted red, and added 3 m.p.h. to the speed of the S.E.5a.

McCudden took the keenest personal interest in his S.E., and it was largely due to careful tuning that he was able to reach 20,000 feet in it, whereas the average Service S.E. could seldom exceed 17,000 feet.

In January, 1918, he had a specially modified Hispano-Suiza engine installed. It had special high-compression pistons, and greatly improved the S.E.’s rate of climb.

In squadron service the S.E.5a underwent various detail modifications to meet the personal requirements of pilots. Some machines were given extra bracing wires to the fin or mainplanes; some S.E.5a’s of No. 24 Squadron were rigged with reduced dihedral in order to increase manoeuvrability; and, most commonly, many machines had the streamlined headrest removed by pilots who wanted the best possible rearwards view.

The strengthened undercarriage, mentioned above, was introduced late in 1917. The forward leg of each vee, which on earlier S.E.s had been a single steel tube of streamline section, was a built-up component consisting of two steel tubes in the form of a long slender inverted V: the axle lay at the open end of this leg, between the two steel tubes. The double leg was faired over with plywood or sheet metal.

As more powerful Hispano-Suiza engines became available they were installed in S.E5a’s. The 220 h.p. and 240 h.p. geared Hispano-Suiza were fitted to some machines; and finally the Wolseley W.4A Viper was standardised for the type. The Viper was a high-compression development of the Hispano-Suiza engine; it was a direct-drive engine and reverted to having a right-hand airscrew. As has already been stated, a Viper was fitted to an S.E.5 airframe in December, 1917.

The Viper installation in the S.E.5a was of distinctive appearance, for the nose of the aircraft looked bulkier than with the Hispano-Suiza, and was generally less well streamlined. The sides of the radiator housing were quite flat, and short horizontal shutters were fitted to the radiator itself. Most Viper S.E.s dispensed with fairings at the ends of the valve rocker housings of the engine.

A few S.E.5a’s were fitted with the Wolseley W.4B Adder, an engine of the same nominal power as the Viper but with reduction gearing to the airscrew shaft.

During the German offensive of March, 1918, much ground attack work was performed by the scout squadrons of the R.F.C. The S.E.5a’s of Nos. 24 and 84 Squadrons did a considerable amount of this hazardous low-flying duty, and added low-level bombing to their repertoire; each S.E. carried four 25-lb Cooper bombs in racks under the fuselage. In the afternoon of March 22nd, 1918, twelve S.E.5a’s of No. 84 Squadron dropped forty-five bombs on enemy troops and transport near Holnon and scored many direct hits. The work of No. 24 Squadron between February and November, 1918, can be assessed from the facts that their S.E.5a’s dropped 2,229 bombs and fired 92,522 rounds at ground targets.

And so the S.E.5a flew and fought on until victory came in November. Several of the best German fighting pilots fell in combat with S.E.s, among them Werner Voss, Kurt Wusthoff and Erich Loewenhardt. It was an aeroplane whose fighting qualities were recognised and respected by the enemy.

The S.E.5 had an early introduction to Home Defence duties. On June 13th, 1917, the first enemy daylight attack on London was made, with heavy loss of life. So great was public indignation over this attack that the Government instructed Sir Douglas Haig to send one fighting squadron home from France and one to Calais. No. 56 Squadron flew its S.E.5s to Bekesbourne on June 21st and remained there until July 5th, when it returned to France after having seen no enemy aircraft at all.

S.E.5a’s were issued to Home Defence squadrons, but were not regarded as completely suitable for this class of work. They were satisfactory once they were in the air, but the water-cooled engine took much longer to warm up than did contemporary rotary engines, and quick take-offs were not possible. The S.E.5a was also said to be difficult to land on small aerodromes at night. The four Home Defence squadrons which had the type had all been re-equipped with Sopwith Camels by the time of the Armistice.

The S.E. served on other fronts in small numbers, for it was only with reluctance that the War Office permitted the dispatch of up-to-date aircraft to the less spectacular theatres of war. The Germans did not make the same mistake.

In September, 1917, Lieutenant-General G. F. Milne, then in command of the British forces in Macedonia, wrote to the War Office and pressed for more aircraft to be placed at his disposal. On October 12th the War Office sanctioned an increase in the establishment of Squadrons Nos. 17 and 47, and stated that nine S.E.5a’s had been allocated. The first S.E. arrived early in November, 1917, and by the following February each squadron had four. These machines had an immediately beneficial effect, and Captain F. G. Saunders and Lieutenant G. E. Gibbs of No. 17 Squadron made excellent use of their new mounts. On April 26th, 1918, the S.E.5a’s of Squadrons Nos. 17 and 47 were handed over to No. 150 Squadron, a new fighting squadron which had been formed on April 1st.

A few S.E.5a’s were used in Mesopotamia by “A” Flight of No. 72 Squadron, which had arrived at Basra on March 2nd, 1918.

For the Palestine campaign, General Sir Edmund Allenby asked for a fighting squadron, composed of one Flight of S.E.5a’s and two of Bristol Fighters, on October 27th, 1917. This request was refused at the time, but in January, 1918, No. 111 Squadron was equipped with S.E.s; and by the time Allenby launched his final offensive on September 19th, No. 145 Squadron was also in the field with six S.E.5a’s. The S.E.s of these two squadrons maintained standing patrols over the enemy aerodrome at Jenin, and kept the German pilots grounded. On September 21st, these S.E5a’s took part in the annihilation of the Turkish Seventh Army in the Wadi el Far‘a; two days later the machines of No. 111 Squadron made similar attacks on the Turkish Fourth Army on the Es Salt-'Amman road.

For training purposes some S.E.5a’s were converted into two-seaters. A second cockpit was cut out in front of the normal one. It has been said, however, that the flying characteristics were badly impaired and that the two-seat S.E.5a would spin at the slightest provocation.

Some S.E.5a’s were used for experimental purposes, both during and after the war. At least one S.E. was fitted with an underslung radiator in place of the usual frontal surface, and the nose was covered in by a blunt cowling. The engine appeared to be a Wolseley Viper, and the radiator apparently consisted of two Viper-type radiator blocks laid on their sides and mounted one above the other to form a single radiator.

At Martlesham Heath the Viper-powered S.E.5a E.5923 was fitted with an experimental tail unit. The fin and rudder were elliptical and somewhat similar to the vertical tail assembly of the German D.F.W. C.V; whilst the tailplane was tapered and sharply swept-back. The tailplane was in two parts: the forward portion was fixed, but the rear portion could be adjusted from the cockpit to provide longitudinal trimming. For spinning experiments another S.E.5a was fitted with a balanced rudder generally similar to that of the Avro 504, and had two small fins on the tailplane.

B.600 was rigged with no dihedral for experiments in manoeuvrability conducted at the R.A.E. just after the war; and C.1091 was fitted with the Royal Aircraft Factory variable-pitch airscrew. Other experiments were conducted to investigate exhaust manifold temperatures, and one S.E.5a was fitted with large finned pipes of cast aluminium for this purpose.

In the field of flight safety, the S.E.5a was used to test automatic landing apparatus and fire-extinguishing equipment. In 1919 one was fitted with a Palethorpe Skid, and in the following year a different type of ground proximity equipment was tested. Major G. H. Norman was responsible for the installation of a French fire-prevention apparatus in an S.E.5a in 1921: this was almost certainly E.5927. To put this equipment to the fullest test, Norman set fire to his machine in the air. The extinguisher put the fire out, but smoke blinded Norman on the approach and he crashed. His injuries later proved to be fatal.

Some S.E5a’s remained in service after the war, but the type was soon withdrawn. Australia and Canada used the type, and one Viper-engined S.E.5a was taken to Japan in 1921 by the British Aviation Mission to the Imperial Japanese Navy.

The S.E. was in service in America in small numbers after the war. It had been intended to mass-produce the type there, and a contract for 1,000 was given to the Curtiss company; the American-built S.E5a’s were to have the 180 h.p. Wright-Martin Hispano-Suiza engine. The Armistice was signed before production was properly under way, and only one all-Curtiss S.E.5a was completed; but fifty-six others were assembled from components sent over from Britain. In Britain itself, the American Expeditionary Force bought thirty-eight S.E5a’s in October, 1918.

A version known as the S.E.5E appeared in America in 1922-23. Fifty were built from spare parts, and the suffix letter indicated the name of the constructor, namely, Eberhardt. The S.E.5E had a plywood-covered fuselage and the 180 h.p. Wright-Hispano E engine.

It was perhaps appropriate that the years of peace should provide no lasting service use for the S.E.5a, for it was essentially a machine of the war and one of the greatest of its day.

SPECIFICATION

Manufacturers: The Royal Aircraft Factory, Farnborough, Hants.

Other Contractors: The Austin Motor Co. (1914), Ltd., Northfield, Birmingham; The Air Navigation Co., Ltd., Addlestone, Surrey; Martinsyde, Ltd., Brooklands, Byfleet;Vickers, Ltd. (Aviation Department), Imperial Court, Basil Street, Knightsbridge, London, S.W. (Factories at Crayford and Weybridge); Wolseley Motors, Ltd., Adderley Park, Birmingham.

Power: S.E.5: Standard, 150 h.p. Hispano-Suiza. Experimental, 150 h.p. Hispano-Suiza engines with compression ratios of 5-3 to 1 and 5-6 to 1, and 200 h.p. Wolseley W.4A Viper. S.E.5a: 200 h.p. Hispano-Suiza; 220 h.p. Hispano-Suiza; 240 h.p. Hispano-Suiza; 200 h.p. Wolseley W.4A Viper; 200 h.p. Wolseley W.4B Adder.

Dimensions: Span: S.E.5 prototypes and early production S.E.5s, 28 ft; S.E.5 and S.E.5a, 26 ft 7 1/2 in. Length: S.E.5, 21 ft 4 in.; S.E.5a, 20 ft 11 in. Height: S.E.5, 9 ft 5 in.; S.E.5a, 9 ft 6 in. Chord: 5 ft. Gap: 4 ft 7 in. Stagger: 1 ft 6 in. Dihedral: 5. Incidence: 5. Span of tail: 11 ft. Wheel track: 5 ft.

Areas: Wings: S.E.5 prototypes and early production, 249 sq ft; S.E.5 and S.E.5a, 244 sq ft. Ailerons: each 7-55 sq ft, total 30-2 sq ft. Tailplane: 15 sq ft. Elevators: 15-5 sq ft. Fin: 6-1 sq ft. Rudder: 5-9 sq ft. (On E.5923, modified at Martlesham, tailplane area was 16 sq ft, elevators 10-2 sq ft, fin 5-4 sq ft and rudder 5-2 sq ft.)

Tankage: Petrol: 35 gallons. Oil: 3 1/2 gallons.

Armament: One fixed Vickers machine-gun mounted on top of fuselage to port of centre, synchronised by Constantinesco gear to fire forward through the revolving airscrew; one Lewis machine-gun on Foster mounting above the upper centre-section, fired by Bowden cable. Four hundred rounds for Vickers gun; four 97-round drums for Lewis. Four 25-lb Cooper bombs could be carried on external racks under the fuselage.

Service Use: Western Front: S.E.5: R.F.C. Squadrons Nos. 24, 40, 56, 60 and 85. S.E.5a: R.F.C. Squadrons Nos. 1, 24, 29, 32, 40, 41, 56, 60, 64, 68 (No. 2 Squadron, Australian Flying Corps), 74, 84, 85, 92 and 94. U.S. Air Service: 25th and 148th Aero Squadrons. Home Defence: Squadrons Nos. 37, 50, 61 and 143. Palestine: Squadrons Nos. 111 and 145. Mesopotamia: “A” Flight of No. 72 Squadron. Macedonia: Squadrons Nos. 17, 47 and 150. Operational Training: Schools of Aerial Fighting at Turnberry, Marske, Sedgeford and Freiston; Australian Flying Corps Depot, Minchinhampton.