Форум Breguet's Aircraft Challenge

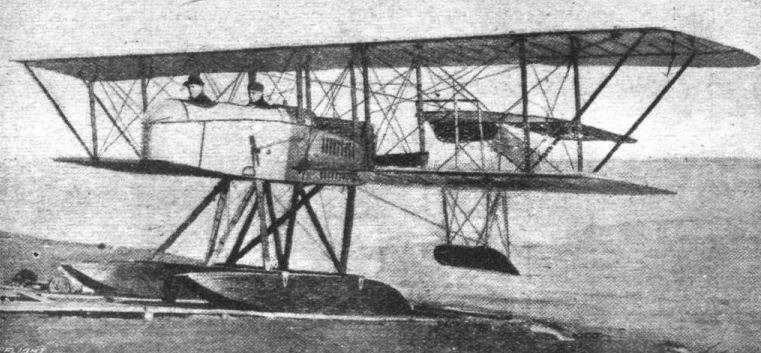

The prototype of the General Aeroplane Co. (GAC) second product, a 2 place pusher intended for military use,designed by Alfred Verville in Nov. 1916. The machine was initially tested on floats on the Detroit River, but the onset of winter made a change to a wheeled undercarriage necessary to continue testing from the ice of Lake St. Clair. Unfortunately on its first flight with the wheels it overshot its landing and crashed in open water being destroyed.

Журнал Flight

Flight, September 20, 1917.

THE G.A.C. "VERVILLE" PUSHER BIPLANE.

THE "Verville" pusher biplane, manufactured by the General Aeroplane Co., of Detroit, Mich., U.S.A., has been designed primarily for bombing and observation work, and, being of the pusher type, is capable of being efficiently armed for defensive or fighting purposes. It can be fitted with either wheels or floats, and a factor of safety of seven is employed throughout. All wiring is double, the factor of safety being taken on one wire. The cable joints are wrapped with 24 gauge soft copper wire, sweated with solder, and all joints are at least 3 ins. long. All metal parts are treated with primer and baked with three coats of non-corroding enamel.

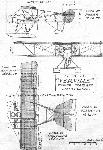

The main planes are 40 ft. and 30 ft. span top and bottom respectively, the top plane being staggered forward 8 ins., and top and bottom planes each set at a dihedral angle of 5.

A highly efficient section permits the use of liberal sized I-beam section spruce spars. The ribs are of I-beam section spruce with web and cap strips. The trailing edge is made of Shelby steel tubing. Strong internal drift wire bracing is carried out with Roebling aviator wire, and the whole of the internal wing structure is treated with shellac. The wings are covered with unbleached Irish linen as specified by the British Government. It has a strength in weft of 91 lbs. per inch width, and in warp of 103 lbs., and is doped with nine coats of Emaillite and surfaced with three coats of Valspar to reduce friction to a minimum and to render the wing impervious to the action of air and water. The linen cloth is stitched with No. 8 Irish linen thread at intervals of 4 ins. along ribs, thus obviating the use of nails, which have a tendency to split the members. This method, which adds to the staying qualities of the wing structure with ease and without injury, also renders the recovering of the wing framework a simple operation. The linen used is 35 ins. wide, and is sewed with the English welt seam.

The interplane struts - of which there are two pairs each side of the nacelle, and two shorter pairs on the latter supporting the central panel of the top plane - are made of Virginia silver spruce, well seasoned, and coated with three rubbed coats of Valspar. The strut ends are copper tipped, and the struts are bound at intervals of 12 ins. with three wraps of 3/4-in. grey silk to relieve shattering of the wood fibre. They are built with a 2 1/2 to 1 streamline fineness ratio, and have a weight to resistance ratio of 6. The strut wing fastenings are of unusual design and obviate the disadvantages of the conventional fastenings by bolts and piercing of the spar. The lower spars extend through a metal box at the body, and are joined internally by a steel casing. The two outer sections of the top plane are attached to a small central panel.

The ailerons, 40 sq. ft. in area, are hinged to the extremities of the top wing at the rear wing spar by five cold rolled steel hinges. Two sets of pylons are mounted near the aileron edge in a steel casing. The equalising aileron control passes through an aluminium pulley box and fair leaders along the front spar of the top wing; 2 1/4-in. Lynite pulleys having brass bushings are used throughout.

The tail planes consist of a semi-circular stabilizing surface, 18 sq. ft. area, to the trailing edge of which are hinged two elevator flaps, 18 sq. ft. area, and an elliptically-shaped rudder, 12 sq. ft. area. The stabiliser and elevators are mounted on the top pair of the V outriggers, whilst the rudder is mounted - so that it is partly balanced - on the vertical strut connecting the top and bottom pairs of outriggers. The nacelle, which is of good streamline form, is constructed of ash and spruce, heavily wired top and bottom, and is covered and crowned with light gauge aluminium or protected with light chrome steel sandwich armour to suit military requirements. The engine is covered by a hinged cowl. The pilot and passenger are accommodated in tandem seats in roomy, well protected cockpits, situated so as to provide the maximum range of vision. The cockpits are veneered with bass wood and upholstered with green leather. The seats, which are of the aluminium bucket type, are comfortably upholstered, and the seat cushions are filled with sufficient Kapok to float a 250-lb. man for 24 hours. The engine-bearers, built of oak and spruce, are fitted in the steel engine plate at the rear of the body, and careful provision is made for suitably attaching the radiator.

The laminated dashboard is made of polished mahogany, and is equipped with altitude barometer recording to 15,000 ft., Tycos inclinometer, Tycos speed indicator, Tycos tachometer, petrol pressure gauge, eight-day clock, oil pressure gauge, electric light switch, dashboard light, motor cut-out switch, hand throttle and magneto control. Four Ever-Ready cells are provided for lighting dashboard light, wing tip light, and head and tail lights. The hand pump is convenient to the pilot at the side of the body.

The engine is a 100 h.p. Curtiss OXX-2, 8-cylinder, driving direct an 8 ft. diameter, 6 ft. pitch propeller. The radiator is mounted behind the engine, the water capacity being 3 gallons. The service petrol tank, which has a capacity of 35 gallons, is made of 22 gauge terne coated steel, and is equipped with baffle plates, capacity gauge, pressure gauge, auxiliary pressure pump, 5/16-in. carburettor outlet and a 2 1/4-in. airtight brass filler cap. A 3-gallon auxiliary gravity tank is also supplied. The Dep. type of control is employed.

In the seaplane the main floats are of the twin type, braced to the body by stout streamline members and counter wired oak ribs. They are diagonally spruce planked and longitudinally planked with Honduras mahogany, the two layers being interspersed with 4-oz. treated sheeting. The floats are divided into two watertight compartments by an aluminium bulkhead, and are rendered accessible by 24-in. aluminium inspection covers. The floats have the V-type entering edge, which spreads to a flat surface at rear, and are internally treated with boiled oil. Their displacement factor is 2 1/4 to 1. The tail float of mahogany streamline section has a displacement capacity of 350 lbs.

The chassis for land is of the wheel and skid type, the two 26-in. by 5-in. Goodyear wheels being sprung on a tubular Shelby steel split hinged axle at the centre of the chassis, and is stoutly thrust wired. The shock absorbers are made of ?-in. Goodyear cord elastic, wound around twin drums over the axle head. The wheel hub is made of manganese bronze, and the wheels are dished with aluminium.

The principal characteristics of the "Verville" pusher are:-

Span: (top), 40 ft., (bottom), 30 ft.; gap, 5 ft.; chord 5 ft.; length overall, 25 ft. 10 ins.; supporting surface, 350 sq. ft. ; stagger, 8 ins.; dihedral, 5° ; gliding angle 1 in 7; angle of incidence of planes: (normal), 3°, (fast), 2°, (slow), 140, tail plane, 0°; safe range of incidence, 0° to 14°; power plant, Curtiss OXX-2; fuel capacity, 5 hours; speed range (fully loaded), 4 hours (45 to 78 m.p.h.); climbing speed 2,800 ft. in 10 minutes; weight (empty), 1,360 lbs. (land), 1,500 lbs. (sea); useful load, 600 lbs. (land), 450 lbs. (sea).