Книги

Centennial Perspective

J.Herris

Siemens-Schuckert Aircraft of World War I

327

J.Herris - Siemens-Schuckert Aircraft of World War I /Centennial Perspective/ (12)

An Albatros C.IIIc(SSW) in front of the SSW factory (logo near peak of roof) at Nurnberg in 1917. When production of the SSW D.I was cancelled, SSW was left with unused production capacity and in late 1917 was assigned to produce the Albatros C.IIIc under license as the Albatros C.IIIc(SSW). One hundred aircaft, 14000-14099/17 were ordered and 93 had been delivered by December 1918 when production stopped. Similarly, a contract for 100 LVG B.III (SSW) trainers, 2300-2399/18, was awarded to SSW in August 1918, and two were under construction at the Armistice.

An Albatros D.III and a 500 kg SSW torpedo glider beneath Zeppelin L.35 on Jan. 26, 1918. This was the first time an airplane was launched from an airship.

Details of the restored Albatros H.1, a SSW D.IV rebuilt with extended-span wings for high-altitude flight tests postwar, in the museum at Krakow.

Details of the restored Albatros H.1, a SSW D.IV rebuilt postwar for high-altitude flight tests, in the museum at Krakow.

Erstes Hohenflugzeug (First High-Altitude Aircraft) was painted on both sides of the aircraft as shown here prior to restoration.

The Albatros H.1, a SSW D.IV that was rebuilt postwar for high-altitude flight tests with larger wing and revised tail surfaces.

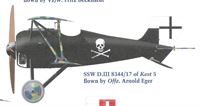

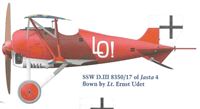

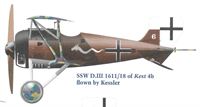

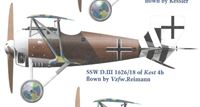

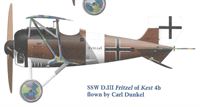

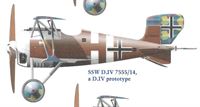

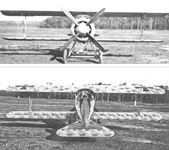

The SSW D.III was powered by the same 205 hp Siemens-Halske Sh.III used in the Pfalz D.VIII; the SSW D.III had similar performance but was more maneuverable than the Pfalz D.VIII. These photos show early production SSW D.III 8346/17 from the first production batch assigned to Lt. Walter Goettsch, then Staffel fuhrer of Jasta 19. It has the large spinner, full cowling, and inset aerodynamic balances of the first D.III production batch. Fokker Triplanes are lined up in the background.

SSW D.III 8346/17. Jasta 19 at Balatre, April 20, 1918. Fokker Triplanes are lined up in the background.

An early-production D.III at Jasta 19. The full image at the top shows a triplane undergoing maintenance. The enlargement below shows another SSW D.III in the background.

An early-production D.III at Jasta 19 undergoing engine maintenance with spinner and cowling removed. A Jasta 19 Fokker Dr.I is at left.

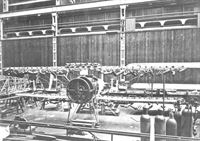

The SSW factory producing D.III fighters and Gotha G.IV(SSW) bombers; 80 Gothas were built under license.

Pre-War & Early War SSW Aircraft

The first SSW airplane was a biplane based on the Wright Flyer. Powered by a 50 hp Argus engine, it was built in 1909 and first flew on December 31, 1909. Damaged on landing after this flight, it was modified and flew again on March 9, 1910 carrying its designer, Bourcart, and one passenger. On March 11 it flew for a kilometer with three people aboard, but crashed when caught in a cross-wind. The next SSW design was a high-wing monoplane first flown in May 1911. A primitive design, it was not successful. A second monoplane to the Bleriot configuration was completed in September 1911, but its failure caused SSW to temporarily abandon aviation.

SSW "Bulldog"

Shortly before the war Swedish designer Villehad Forssman, who had an office in Berlin, designed a monoplane known as the Bulldog for Prince Friedrich Sigismund of Prussia. Soon after the war started, Forssman offered SSW his design. The War Ministry desperately needed warplanes, and with their support SSW hired Forssman to supervise construction of two of his Bulldogs for reconnaissance. SSW began assembly of the aircraft at their Dynamo Works in their community of Siemensstadt.

The first Bulldog, built in late 1914, was powered by a 100 hp Mercedes D.I in-line, six-cylinder engine. The second Bulldog, powered by one of the first 110 hp Siemens-Halske Sh.I counter-rotary engines, first flew on April 18, 1915. Both featured side-by-side seating for two crewmen. Both Bulldogs were rejected by the Army for mediocre flying qualities and poor performance. After modification, the rotary-powered Bulldog was used for air-launching trials for models of the missiles SSW was developing.

The first SSW airplane was a biplane based on the Wright Flyer. Powered by a 50 hp Argus engine, it was built in 1909 and first flew on December 31, 1909. Damaged on landing after this flight, it was modified and flew again on March 9, 1910 carrying its designer, Bourcart, and one passenger. On March 11 it flew for a kilometer with three people aboard, but crashed when caught in a cross-wind. The next SSW design was a high-wing monoplane first flown in May 1911. A primitive design, it was not successful. A second monoplane to the Bleriot configuration was completed in September 1911, but its failure caused SSW to temporarily abandon aviation.

SSW "Bulldog"

Shortly before the war Swedish designer Villehad Forssman, who had an office in Berlin, designed a monoplane known as the Bulldog for Prince Friedrich Sigismund of Prussia. Soon after the war started, Forssman offered SSW his design. The War Ministry desperately needed warplanes, and with their support SSW hired Forssman to supervise construction of two of his Bulldogs for reconnaissance. SSW began assembly of the aircraft at their Dynamo Works in their community of Siemensstadt.

The first Bulldog, built in late 1914, was powered by a 100 hp Mercedes D.I in-line, six-cylinder engine. The second Bulldog, powered by one of the first 110 hp Siemens-Halske Sh.I counter-rotary engines, first flew on April 18, 1915. Both featured side-by-side seating for two crewmen. Both Bulldogs were rejected by the Army for mediocre flying qualities and poor performance. After modification, the rotary-powered Bulldog was used for air-launching trials for models of the missiles SSW was developing.

The Siemens Schuckert Bulldogge. The caption on the photo give it as 'Bulldogg-Eindecker des Prinzen Friedrich Sigismund'

View of the "Bulldog" monoplane Forssman designed and built for Prince Friedrich Sigismund of Prussia. The royal crest was applied to the rudder. Engine was a Mercedes. At the underside of the wing is written 80 PFS (Pferde Starke = Horsepower).

Forssman's 100 hp Mercedes D.I-powered "Bulldog" with Forssman standing in front of it; the vertical tail has been enlarged from the aircraft for Prince Sigismund. This aircraft and the other "Bulldog" powered by a 110 hp Siemens-Halske Sh.I counter-rotary engine were both rejected by the Army for poor performance and mediocre flying qualities.

Another view of a test glider mounted under the modified, rotary-powered SSW Bulldog before a test launch.

After being modified to eliminate its protruding belly, the SSW Bulldog, powered by one of the first 110 hp Siemens-Halske Sh.I counter-rotary engines, was used to launch scale gliders to develop shapes for the SSW guided missile program.

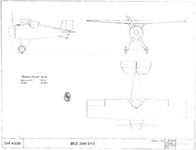

SSW B.I

In the summer of 1915 brothers Bruno and Franz Steffen, both famous pre-war pilots and aircraft builders who joined SSW in December 1914, began designing single-engine military aircraft. The B.I was a two-seat reconnaissance aircraft powered by a 110 hp Siemens-Halske Sh.I and was the only one of these designs that was not a fighter. The B.I two- bay biplane achieved 95 mph, a good speed for the time, and was sent to BAO (Brieftauben Abteilung Ostende - Carrier Pigeon Section Ostend), a code name for one of Germany's original bombing units, at the request of its commander, Freiherr von Thuna. The only B.I built, it crashed in November 1915 and was not repaired.

In the summer of 1915 brothers Bruno and Franz Steffen, both famous pre-war pilots and aircraft builders who joined SSW in December 1914, began designing single-engine military aircraft. The B.I was a two-seat reconnaissance aircraft powered by a 110 hp Siemens-Halske Sh.I and was the only one of these designs that was not a fighter. The B.I two- bay biplane achieved 95 mph, a good speed for the time, and was sent to BAO (Brieftauben Abteilung Ostende - Carrier Pigeon Section Ostend), a code name for one of Germany's original bombing units, at the request of its commander, Freiherr von Thuna. The only B.I built, it crashed in November 1915 and was not repaired.

The SSW B.I reconnaissance biplane. It was a neat, two-bay design for two crewmen. Engine was a 110 hp Sh.I counter-rotary. No armament was fitted.

View of the SSW B.I. The 110 hp Sh.I counter-rotary required a front bearing support. The Siemens-Schuckert company logo is on the hangar doors below.

This view of the SSW B.I reconnaissance biplane reveal that the fuselage and tail were closely related to those of the SSW E.I monoplane fighter. The only B.I built was sent to BAO at the request of its commander, where it crashed in November 1915.

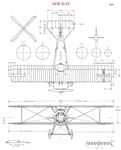

SSW DD 5

Designed by Franz Steffen, the SSW DD 5 was basically an E.I airframe with a biplane wing cellule, and was SSW's first biplane fighter. Power remained a 110 hp Siemens-Halske Sh.I counter-rotary engine, and a single synchronized machine gun was fitted. Tubular steel was used for the wing spars and I-struts. Tested in August 1916, it was rejected because of poor field of view for the pilot and poor handling qualities. Development then focused on the SSW D.I.

Unusually for a WWI aircraft, the DD 5's wing planform tapered from the fuselage to the wing tips,- most WWI featured wings of rectangular planform as seen in the SSW E-types. Tapered wings are more efficient because they generate less induced drag (drag induced by creating lift, which generates vortices at the wing tips) and also reduce weight, which is likely why the designer used taper.

However, tapered wings aggravate the tendency of the wing to stall first at the tips. Since the ailerons are normally fitted at the tips of the wings for greatest effectiveness, the tendency of the wing to stall first at the tips is very dangerous because it robs the pilot of roll control in a critical situation, increasing the likelihood of the aircraft entering an unintended spin. Most designers of the time 'washed out' the angle of incidence at the wing tips to prevent the wing from stalling at the tip first, and more sophisticated means were developed later to prevent tip stall. However, a look at the DD 5 shows no evidence of any aerodynamic measures designed into the wing to alleviate the tip stall problem, undoubtedly resulting in poor handling near stalling speed.

Designed by Franz Steffen, the SSW DD 5 was basically an E.I airframe with a biplane wing cellule, and was SSW's first biplane fighter. Power remained a 110 hp Siemens-Halske Sh.I counter-rotary engine, and a single synchronized machine gun was fitted. Tubular steel was used for the wing spars and I-struts. Tested in August 1916, it was rejected because of poor field of view for the pilot and poor handling qualities. Development then focused on the SSW D.I.

Unusually for a WWI aircraft, the DD 5's wing planform tapered from the fuselage to the wing tips,- most WWI featured wings of rectangular planform as seen in the SSW E-types. Tapered wings are more efficient because they generate less induced drag (drag induced by creating lift, which generates vortices at the wing tips) and also reduce weight, which is likely why the designer used taper.

However, tapered wings aggravate the tendency of the wing to stall first at the tips. Since the ailerons are normally fitted at the tips of the wings for greatest effectiveness, the tendency of the wing to stall first at the tips is very dangerous because it robs the pilot of roll control in a critical situation, increasing the likelihood of the aircraft entering an unintended spin. Most designers of the time 'washed out' the angle of incidence at the wing tips to prevent the wing from stalling at the tip first, and more sophisticated means were developed later to prevent tip stall. However, a look at the DD 5 shows no evidence of any aerodynamic measures designed into the wing to alleviate the tip stall problem, undoubtedly resulting in poor handling near stalling speed.

SSW E.I

The SSW E.I was completed in October 1915 and finished its tests on March 17, 1916. Of conventional wire-braced wood construction with fabric-covered wings and ply-covered fuselage, it was recommended for production and an order for 20 aircraft, 550-569/15, was placed by Idflieg. Production was undertaken by the SSW Transformer Works in Nurnberg. The E.I was fitted with one synchronized machine gun. Eight E.Is were powered by the 90 hp Sh.O and the remainder by the 110 hp Sh.I. An additional airframe was powered by a 120 hp Argus As.II, becoming the sole SSW E.II. Like the Fokker designs, it used wing-warping instead of conventional ailerons for roll control. Unfortunately, the SSW monoplanes arrived after the D.H.2 and Nieuport 11 had established technical superiority over the early monoplane designs and were too late to make an impact.

SSW E.I Specifications

Engine: 110 hp Siemens-Halske Sh.I

Wing: Span 10.00 m

Area 16.0 m2

General: Length 7.10 m

Height 2.80 m

Empty Weight 473 kg

Loaded Weight 673 kg

Maximum Speed: 140 km/h

SSW E.II

The SSW E.II was essentially an E.I airframe powered by an in-line 120 hp Argus As.II engine; like the E.I it carried a single machine gun. The one prototype built first flew in early 1916. Its designer, Franz Steffen, suffered a fatal crash in the E.II while demonstrating it at Doberitz on June 26, 1916.

SSW E.III & E.IV

Ordered in April 1916, the SSW E.III was an E.I airframe with a 100 hp Oberursel; again one synchronized gun was carried. Six aircraft, 620-625/16, were built. A derivative of the E.III was proposed with a circular fuselage; known as the E.IV, it remained a project.

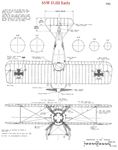

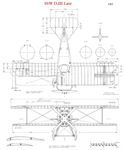

Siemens-Schuckert Monoplane Fighter Specifications

E.I E.II E.III D.VI

Engine 110 hp Sh.I 120 hp As.II 100 hp Oberursel U.I 205 hp Sh.IIIa

Armament One MG One MG One MG Two MG *

Span 10.00 m — 7.10 m 9.37 m

Length 7.10 m — 7.10 m 6.50 m

Height 2.80 m — 2.80 m 2.72 m

Wing Area 16.0 m2 — 16.0 m2 12.46 m2

Empty Weight 473 kg — 478 kg 540 kg

Loaded Weight 673 kg — 678 kg 710 kg

Maximum Speed: 140 km/h — — 220 km/h (@ 2,000m)

Climb: 6,000m NA — — 16 minutes

7,000m NA — — 22 minutes

Ceiling: — — — 8,000m

Notes: 1. E.II dimensions similar to E.I except length.

2. SSW D.VI armament is that projected for production; the two prototypes were unarmed.

The SSW E.I was completed in October 1915 and finished its tests on March 17, 1916. Of conventional wire-braced wood construction with fabric-covered wings and ply-covered fuselage, it was recommended for production and an order for 20 aircraft, 550-569/15, was placed by Idflieg. Production was undertaken by the SSW Transformer Works in Nurnberg. The E.I was fitted with one synchronized machine gun. Eight E.Is were powered by the 90 hp Sh.O and the remainder by the 110 hp Sh.I. An additional airframe was powered by a 120 hp Argus As.II, becoming the sole SSW E.II. Like the Fokker designs, it used wing-warping instead of conventional ailerons for roll control. Unfortunately, the SSW monoplanes arrived after the D.H.2 and Nieuport 11 had established technical superiority over the early monoplane designs and were too late to make an impact.

SSW E.I Specifications

Engine: 110 hp Siemens-Halske Sh.I

Wing: Span 10.00 m

Area 16.0 m2

General: Length 7.10 m

Height 2.80 m

Empty Weight 473 kg

Loaded Weight 673 kg

Maximum Speed: 140 km/h

SSW E.II

The SSW E.II was essentially an E.I airframe powered by an in-line 120 hp Argus As.II engine; like the E.I it carried a single machine gun. The one prototype built first flew in early 1916. Its designer, Franz Steffen, suffered a fatal crash in the E.II while demonstrating it at Doberitz on June 26, 1916.

SSW E.III & E.IV

Ordered in April 1916, the SSW E.III was an E.I airframe with a 100 hp Oberursel; again one synchronized gun was carried. Six aircraft, 620-625/16, were built. A derivative of the E.III was proposed with a circular fuselage; known as the E.IV, it remained a project.

Siemens-Schuckert Monoplane Fighter Specifications

E.I E.II E.III D.VI

Engine 110 hp Sh.I 120 hp As.II 100 hp Oberursel U.I 205 hp Sh.IIIa

Armament One MG One MG One MG Two MG *

Span 10.00 m — 7.10 m 9.37 m

Length 7.10 m — 7.10 m 6.50 m

Height 2.80 m — 2.80 m 2.72 m

Wing Area 16.0 m2 — 16.0 m2 12.46 m2

Empty Weight 473 kg — 478 kg 540 kg

Loaded Weight 673 kg — 678 kg 710 kg

Maximum Speed: 140 km/h — — 220 km/h (@ 2,000m)

Climb: 6,000m NA — — 16 minutes

7,000m NA — — 22 minutes

Ceiling: — — — 8,000m

Notes: 1. E.II dimensions similar to E.I except length.

2. SSW D.VI armament is that projected for production; the two prototypes were unarmed.

The SSW E.I prototype designed by Franz Steffen featured a small spinner that was omitted from production aircraft. Like most Eindeckers one synchronized gun was carried and it was powered by a rotary engine, in this case either a 90 hp Sh.O (eight aircraft) or a 110 hp Siemens-Halske Sh.I counter-rotary engine (a dozen aircraft).

The SSW E.I prototype, identified by the small spinner, photographed at the SSW factory. By the time the SSW Eindeckers appeared the basic configuration and wing-warping instead of ailerons, was outdated. (The Peter M. Bowers Collection/The Museum of Flight)

The fuselage of the SSW E.I in front of the pilot was painted a dark color, probably to reduce glare.

The SSW E.I production aircraft dispensed with the small spinner fitted to the prototype. The E I achieved operational service in small numbers in the summer of 1916.

Another view of an SSW E.I production aircraft. The support structure for the front bearing needed by the Sh.I counter-rotary engine is clearly shown. (The Peter M. Bowers Collection/The Museum of Flight)

An SSW E.I production aircraft in flight. Although using the same configuration as the Fokker and Pfalz Eindeckers, the SSW E.I was much different in detail, and in particular the tail surfaces were distinctly different. Most of these airplanes were delivered directly to flying schools.

This close-up view of an SSW E.I fighter shows the gun installation in greater detail together with a closer view of the dark-painted anti-glare panel in front of the pilot.

SSW E.I fighters in production at the modern SSW factory. The SSW design was cleaner than the Fokker and Pfalz Eindeckers but was simply too late for important operational use at the front and most were delivered to single-seat flying schools.

A few SSW E.I fighters reached the front. These two are shown during construction in the factory, but by the time these reached the Front the Eindecker era was drawing to a close as higher-performance biplane fighters were appearing.

A few SSW E.I fighters reached the front. These two are shown during construction in the factory, but by the time these reached the Front the Eindecker era was drawing to a close as higher-performance biplane fighters were appearing.

SSW E.I fighter airframe undergoing static load testing at the SSW factory. The load had to be distributed along the wing to simulate flight loads. The sandbag method was used widely throughout the aviation industry for many years.

The sole SSW E.II prototype is shown in side view. The large exhaust for its in-line Argus engine is prominent. The SSW E.II was one of two Eindeckers to feature an in-line engine, the other being the Pfalz E.V.

The SSW E.II prototype designed by Franz Steffen was powered by a 120 hp Argus As.II engine. Like most Eindeckers, one synchronized gun was carried. (The Peter M. Bowers Collection/The Museum of Flight)

Rearview of the SSW E.II fighter prototype at the SSW factory. For an Eindecker the E.II was quite streamlined.

The SSW E.II prototype under construction. This view clearly shows the well-streamlined installation of the in-line 120 hp Argus As.II engine. (The Peter M. Bowers Collection/The Museum of Flight)

The fatal crash of Franz Steffen in the SSW E.II prototype he designed. Steffen was demonstrating the E.II at Doberitz on June 26, 1916 when he crashed.

SSW Forssman "R"

Construction of the Forssman "R", SSW's first experience with R-plane building, began in October 1914. Its design was clearly inspired by the Sikorsky Il'ya Muromets and construction was completed in the first half of 1915. The initial configuration had four uncowled, 110 hp Mercedes D.I engines independently mounted on the lower wing, each driving its own propeller. The cabin was fully glazed for an excellent field of view and, like its Sikorsky inspiration, projected just a small distance in front of the wings.

Early test hops quickly revealed the design was seriously tail heavy, and an observer's/gunner's pulpit was added in front of the pilot to add weight to the nose. The biplane wing cellule had three bays, but the aft strut was omitted from the middle bay, probably in an attempt to save weight. This weakened the cellule and the 'missing' strut had to be installed. To improve directional control and stability a second rudder had to be added. Although the wing struts and landing gear were too strong and heavy, overall the structure was weak. In addition to poor handling qualities and a weak structure, the Forssman R was also under-powered. The design was a failure and SSW and Forssman parted ways.

This should have been the end of the story. Unfortunately, SSW was reluctant to accept failure and tried to salvage the design, resulting in a painful, protracted development process that was foredoomed to failure. To improve performance the inboard engines were replaced with 220 hp Mercedes D.IV engines and the outboard engines were cowled and moved to a higher position thought to improve propeller efficiency. In addition, the nose was rebuilt to a more streamlined form. In its modified form the machine was tested by Lt. Walter Hohndorf (later to become a fighter ace awarded the Pour le Merite), but the Forssman over-turned on landing.

Despite the resulting damage, SSW again rebuilt the aircraft, adding a more rounded nose. By now the Forssman had acquired the reputation of being a white elephant and no pilot wanted to fly it. Anxious to sell the aircraft to the Army, SSW offered the Steffen brothers 10% of the delivery price if they would perform the acceptance flight. Idflieg agreed to reduced specifications in return for a lower price. The Steffen brothers examined the aircraft and determined it was flyable.

In October 1915 Bruno Steffen flew the aircraft on its acceptance flight. He flew alone,- all of the people he invited to accompany him declined, including members of Idflieg’s acceptance commission! The flight was an adventure. The aircraft was very tail heavy and Bruno struggled to control it. After exceeding the required 2,000 meter height in 28 minutes, Bruno was descending when one of the outboard engines failed due to inadequate fuel pressure. While trying to restart the engine by manually pumping fuel, all the other engines stopped! Despite total engine failure, Bruno was able to land the aircraft safely and it was accepted by Idflieg in April 1916 for training. However, further development was cancelled.

While running the engines on the ground shortly after acceptance, the fuselage broke in two just aft of the wings due to excessive vibration and the aircraft was scrapped. A relieved Bruno Steffen was glad no one had been killed in the aircraft. Despite extensive development, being modified at least four times, the Forssman was a complete failure.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

Construction of the Forssman "R", SSW's first experience with R-plane building, began in October 1914. Its design was clearly inspired by the Sikorsky Il'ya Muromets and construction was completed in the first half of 1915. The initial configuration had four uncowled, 110 hp Mercedes D.I engines independently mounted on the lower wing, each driving its own propeller. The cabin was fully glazed for an excellent field of view and, like its Sikorsky inspiration, projected just a small distance in front of the wings.

Early test hops quickly revealed the design was seriously tail heavy, and an observer's/gunner's pulpit was added in front of the pilot to add weight to the nose. The biplane wing cellule had three bays, but the aft strut was omitted from the middle bay, probably in an attempt to save weight. This weakened the cellule and the 'missing' strut had to be installed. To improve directional control and stability a second rudder had to be added. Although the wing struts and landing gear were too strong and heavy, overall the structure was weak. In addition to poor handling qualities and a weak structure, the Forssman R was also under-powered. The design was a failure and SSW and Forssman parted ways.

This should have been the end of the story. Unfortunately, SSW was reluctant to accept failure and tried to salvage the design, resulting in a painful, protracted development process that was foredoomed to failure. To improve performance the inboard engines were replaced with 220 hp Mercedes D.IV engines and the outboard engines were cowled and moved to a higher position thought to improve propeller efficiency. In addition, the nose was rebuilt to a more streamlined form. In its modified form the machine was tested by Lt. Walter Hohndorf (later to become a fighter ace awarded the Pour le Merite), but the Forssman over-turned on landing.

Despite the resulting damage, SSW again rebuilt the aircraft, adding a more rounded nose. By now the Forssman had acquired the reputation of being a white elephant and no pilot wanted to fly it. Anxious to sell the aircraft to the Army, SSW offered the Steffen brothers 10% of the delivery price if they would perform the acceptance flight. Idflieg agreed to reduced specifications in return for a lower price. The Steffen brothers examined the aircraft and determined it was flyable.

In October 1915 Bruno Steffen flew the aircraft on its acceptance flight. He flew alone,- all of the people he invited to accompany him declined, including members of Idflieg’s acceptance commission! The flight was an adventure. The aircraft was very tail heavy and Bruno struggled to control it. After exceeding the required 2,000 meter height in 28 minutes, Bruno was descending when one of the outboard engines failed due to inadequate fuel pressure. While trying to restart the engine by manually pumping fuel, all the other engines stopped! Despite total engine failure, Bruno was able to land the aircraft safely and it was accepted by Idflieg in April 1916 for training. However, further development was cancelled.

While running the engines on the ground shortly after acceptance, the fuselage broke in two just aft of the wings due to excessive vibration and the aircraft was scrapped. A relieved Bruno Steffen was glad no one had been killed in the aircraft. Despite extensive development, being modified at least four times, the Forssman was a complete failure.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

The SSW Forssman '"R" in its original form before leaving the workshop clearly shows the influence of the Sikorsky Il'ya Muromets on its design.

Forssman "R" in original configuration under construction in the SSW factory. The blunt nose is essentially in line with the leading edge of the wings.

The Forssman "R" in its second configuration after addition of the observer's/gunner's pulpit to the nose. The engines were four 110 hp Mercedes D.I's with individual propellers. Originally all engines were un-cowled, but the inboard engines now have cowlings. These views show the middle bay of bracing had only a forward strut; the struts that would normally brace the aft wing spars were not fitted. At this stage the aircraft still had a single rudder.

Forssman "R" in its second configuration after an observer's/gunner's 'pulpit' was added to the nose in an attempt to compensate for the extreme tail-heaviness evident during the first attempted flights.

The Forssman "R" in its third configuration after being modified to have two rudders instead of the inadequate single rudder. All engines now have cowlings and the 'missing' rear, middle interplane struts were added.

The Forssman "R" in its fourth configuration after crashing in September 1915 during landing while being tested by Lt. Hohndorf, who later became a fighter ace and was awarded the Pour le Merite. By this time the inner engines had been replaced with 220 hp Mercedes D.IV engines for more power. The Forssman was rebuilt after this accident.

The Forssman "R" in its fifth configuration after being rebuilt from its September 1915 crash. The nose has been extensively rebuilt with large windows and a gunner's position. All the engines are neatly cowled with spinners; the inboard engines are the 220 hp Mercedes D.IV and the outboard engines are the 110 hp Mercedes D.I. Its neat appearance belies the airframe's structural weakness and poor aerodynamics.

The Forssman "R" in its sixth and final configuration. The nose has again been extensively rebuilt. In this configuration Idflieg finally accepted the Forssman based on reduced requirements, but further development was abandoned.

Forssman "R" in final configuration after breaking its back during engine run-up on the ground at Johannisthal. Fortunately, no one was injured and the aircraft was scrapped after this debacle.

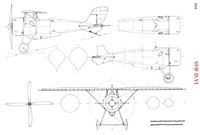

SSW R.I

In 1908 the Steffen brothers, Bruno and Franz, founded the Steffen aircraft works in Neumunster (near Kiel). After first building one airship, they built a series of airplanes, and in one of those, the Falke, Bruno Steffen broke the German endurance record in 1913. Additionally, they also operated a successful flying school. Despite their relative aviation success, they were called to serve in the army upon outbreak of war. Moreover, lack of capital also precluded further independent development, and in December 1914, after release from their regular military duties, the brothers joined SSW. The Steffens immediately started designing the SSW R.I, which made its first flight in May 1915.

The brothers decided that a design with centralized engines offered several important advantages. Concentrating the weight near the center of gravity would make the aircraft more maneuverable and, most importantly, the engines would be accessible to on-board mechanics during flight should repairs be needed. They also expected drag would be reduced, propeller efficiency would be improved, and the ability to shut down an engine in flight would extend range and endurance.

Another critical factor at the time was lack of ability to feather a propeller. To feather a propeller means to turn the propeller blades of an inoperative engine into the wind to stop rotation and reduce the drag as much as possible. This requires a controllable propeller having a pitch-change mechanism to rotate the propeller blades into the wind upon engine failure. However, such a propeller was not available during WWI; the propellers available were all fixed pitch. Upon engine failure, a fixed-pitch propeller continues to rotate as the aircraft's speed pushes the propeller forward, and such a 'wind-milling' propeller creates drag approximating that of a parachute of the same diameter. The result was that twin-engine aircraft and some multi-engine aircraft could not maintain flight after engine failure and a wind-milling propeller. Without a controllable propeller that could be feathered upon engine failure, centralizing the engines and using a clutch to decouple a failed engine from the propellers was one way to avoid a wind-milling propeller in case of engine failure. For this reason many R-planes were designed with central engine arrangements, and the SSW R.I was the first of these.

Originally designated SSW G.31/15, (G for Grossflugzeug [large aircraft]), the designation was changed to SSW G.I 32/15 and finally to SSW R.I 1/15 on November 6, 1915. The SSW R.I was a distinctive biplane with three 150 hp Benz Bz.III engines grouped together in the center fuselage. The engines were connected to a common gearbox via clutches. Two engines were mounted side by side in front of the gearbox on steel engine bearers that were part of the airframe, while the third engine was mounted behind and below it. Unfortunately, the clutch system of the R.I did not enable the mechanic to disengage a failed engine. The gearbox was reliable but there were issues with the clutch and transmission system. Three radiators were fitted around the nose.

The crew included a pilot, an aircraft commander acting as reserve pilot, two gunners, and one mechanic. The fuselage was unique; two triangular tail booms supported the rudder and tailplane. This provided a good field of fire to the rear, but the position was covered with fabric in the R.I. The pilot's cabin was open in front because the pilots insisted on feeling the wind in flight to help them control the airplane. This is not as odd as might be supposed given the limited flight instrumentation of the time; pilots depended on their senses, including the feel of the wind, the sound of the engines and the wind through the wires, etc., for important feedback on aircraft performance.

An upper gun position was located behind the pilots' seats, which were themselves located above the gearbox. This position was an enclosed platform with an access hatch. A ventral gun position was located between the robust landing gear assemblies; the gunner was prone and fired downward toward the rear. In addition to these machine gun positions, the aircraft commander and mechanic were given repeating carbines to help defend against attack. These were not very effective and were most useful as a morale booster.

The three-bay wings were built of wood and the fuselage was built of steel tubing; both were fabric-covered. Some aluminum panels partially covered the nose. Armor plating weighing 200 kg was originally specified but the armor was eliminated by Idflieg. To reduce the pilot's control forces the pilot controlled small auxiliary ailerons that in turn actuated the ailerons mounted on the upper wing. The rudder and elevators were similarly assisted by servo controls.

The R.I was built at the SSW Dynamowerk in Berlin, but the aircraft was disassembled and moved to the Steffens' facility in Neumunster for flight trials for secrecy. Piloted by the Steffen brothers, the R.I first flew on May 24, 1915, only five months after starting the design. The R.I proved to be stable and easily maneuverable, according to one pilot not unlike a typical two-seater.

The first flight was terminated early due to excessive gearbox oil temperature. Installation of forced oil circulation and switching to a lighter grade of oil remedied that problem. Failures of the u-joints in the propeller drive shafts occurred due to vibration; these were remedied by adding stiffener tubes fore and aft.

The R.I had a maximum level speed of 128 km/hr with full load and could maintain level flight on two engines with the third at idle. With only one engine running the R.I could glide 50 km starting from an altitude of 2,000 meters.

In June 1915 the R.I passed its acceptance flight while carrying seven passengers. Before final delivery to the Fliegertruppe on July 26 an additional 24 training and orientation flights were completed. During one of them, with Lt. Walter Hohndorf piloting, an engine problem forced an emergency landing, but the problem was quickly repaired and the flight was continued the same evening.

During a training flight in early August all three engines failed one after the other on take-off at only 8 meters altitude, resulting in a crash landing and severe damage to the R.I. Fortunately, the crewmen escaped injury. The cause was determined to be foreign matter in the fuel tanks that blocked fuel flow to the engines. The factory repaired the R.I and it flew again in late September, at which time it was sent to the Eastern Front for operational evaluation. At Warsaw the R.I had to be parked in the open in heavy rain. The wings absorbed gallons of rainwater and the R.I would not take off the next morning until the water was drained. Continuing on, the starboard transmission coupling broke and the R.I had to be sent back to Doberitz for repair on October 15. The R.I was returned to the Eastern Front but no bombing raids were undertaken due to continuing unreliability. It was feared the aircraft would be forced down in enemy territory. In March 1916 the R.I was dismantled and shipped back to the SSW factory in Berlin. Unfortunately, due to clearance problems it was damaged during transport.

In June 1916 SSW completed repairs to the R.I, after which it was assigned to train R-plane crews at Doberitz. A year-end report of 1917 by the REA (Riesenflugzeug Ersatz Abteilung - giant aircraft replacement unit) described the R.I as larger and heavier than before, possibly due to modifications during its factory repairs.

During 1917 the R.I performed 97 training flights and 26 orientation flights, an excellent record for this complex, early R-plane that was still in training service in late February 1918.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

In 1908 the Steffen brothers, Bruno and Franz, founded the Steffen aircraft works in Neumunster (near Kiel). After first building one airship, they built a series of airplanes, and in one of those, the Falke, Bruno Steffen broke the German endurance record in 1913. Additionally, they also operated a successful flying school. Despite their relative aviation success, they were called to serve in the army upon outbreak of war. Moreover, lack of capital also precluded further independent development, and in December 1914, after release from their regular military duties, the brothers joined SSW. The Steffens immediately started designing the SSW R.I, which made its first flight in May 1915.

The brothers decided that a design with centralized engines offered several important advantages. Concentrating the weight near the center of gravity would make the aircraft more maneuverable and, most importantly, the engines would be accessible to on-board mechanics during flight should repairs be needed. They also expected drag would be reduced, propeller efficiency would be improved, and the ability to shut down an engine in flight would extend range and endurance.

Another critical factor at the time was lack of ability to feather a propeller. To feather a propeller means to turn the propeller blades of an inoperative engine into the wind to stop rotation and reduce the drag as much as possible. This requires a controllable propeller having a pitch-change mechanism to rotate the propeller blades into the wind upon engine failure. However, such a propeller was not available during WWI; the propellers available were all fixed pitch. Upon engine failure, a fixed-pitch propeller continues to rotate as the aircraft's speed pushes the propeller forward, and such a 'wind-milling' propeller creates drag approximating that of a parachute of the same diameter. The result was that twin-engine aircraft and some multi-engine aircraft could not maintain flight after engine failure and a wind-milling propeller. Without a controllable propeller that could be feathered upon engine failure, centralizing the engines and using a clutch to decouple a failed engine from the propellers was one way to avoid a wind-milling propeller in case of engine failure. For this reason many R-planes were designed with central engine arrangements, and the SSW R.I was the first of these.

Originally designated SSW G.31/15, (G for Grossflugzeug [large aircraft]), the designation was changed to SSW G.I 32/15 and finally to SSW R.I 1/15 on November 6, 1915. The SSW R.I was a distinctive biplane with three 150 hp Benz Bz.III engines grouped together in the center fuselage. The engines were connected to a common gearbox via clutches. Two engines were mounted side by side in front of the gearbox on steel engine bearers that were part of the airframe, while the third engine was mounted behind and below it. Unfortunately, the clutch system of the R.I did not enable the mechanic to disengage a failed engine. The gearbox was reliable but there were issues with the clutch and transmission system. Three radiators were fitted around the nose.

The crew included a pilot, an aircraft commander acting as reserve pilot, two gunners, and one mechanic. The fuselage was unique; two triangular tail booms supported the rudder and tailplane. This provided a good field of fire to the rear, but the position was covered with fabric in the R.I. The pilot's cabin was open in front because the pilots insisted on feeling the wind in flight to help them control the airplane. This is not as odd as might be supposed given the limited flight instrumentation of the time; pilots depended on their senses, including the feel of the wind, the sound of the engines and the wind through the wires, etc., for important feedback on aircraft performance.

An upper gun position was located behind the pilots' seats, which were themselves located above the gearbox. This position was an enclosed platform with an access hatch. A ventral gun position was located between the robust landing gear assemblies; the gunner was prone and fired downward toward the rear. In addition to these machine gun positions, the aircraft commander and mechanic were given repeating carbines to help defend against attack. These were not very effective and were most useful as a morale booster.

The three-bay wings were built of wood and the fuselage was built of steel tubing; both were fabric-covered. Some aluminum panels partially covered the nose. Armor plating weighing 200 kg was originally specified but the armor was eliminated by Idflieg. To reduce the pilot's control forces the pilot controlled small auxiliary ailerons that in turn actuated the ailerons mounted on the upper wing. The rudder and elevators were similarly assisted by servo controls.

The R.I was built at the SSW Dynamowerk in Berlin, but the aircraft was disassembled and moved to the Steffens' facility in Neumunster for flight trials for secrecy. Piloted by the Steffen brothers, the R.I first flew on May 24, 1915, only five months after starting the design. The R.I proved to be stable and easily maneuverable, according to one pilot not unlike a typical two-seater.

The first flight was terminated early due to excessive gearbox oil temperature. Installation of forced oil circulation and switching to a lighter grade of oil remedied that problem. Failures of the u-joints in the propeller drive shafts occurred due to vibration; these were remedied by adding stiffener tubes fore and aft.

The R.I had a maximum level speed of 128 km/hr with full load and could maintain level flight on two engines with the third at idle. With only one engine running the R.I could glide 50 km starting from an altitude of 2,000 meters.

In June 1915 the R.I passed its acceptance flight while carrying seven passengers. Before final delivery to the Fliegertruppe on July 26 an additional 24 training and orientation flights were completed. During one of them, with Lt. Walter Hohndorf piloting, an engine problem forced an emergency landing, but the problem was quickly repaired and the flight was continued the same evening.

During a training flight in early August all three engines failed one after the other on take-off at only 8 meters altitude, resulting in a crash landing and severe damage to the R.I. Fortunately, the crewmen escaped injury. The cause was determined to be foreign matter in the fuel tanks that blocked fuel flow to the engines. The factory repaired the R.I and it flew again in late September, at which time it was sent to the Eastern Front for operational evaluation. At Warsaw the R.I had to be parked in the open in heavy rain. The wings absorbed gallons of rainwater and the R.I would not take off the next morning until the water was drained. Continuing on, the starboard transmission coupling broke and the R.I had to be sent back to Doberitz for repair on October 15. The R.I was returned to the Eastern Front but no bombing raids were undertaken due to continuing unreliability. It was feared the aircraft would be forced down in enemy territory. In March 1916 the R.I was dismantled and shipped back to the SSW factory in Berlin. Unfortunately, due to clearance problems it was damaged during transport.

In June 1916 SSW completed repairs to the R.I, after which it was assigned to train R-plane crews at Doberitz. A year-end report of 1917 by the REA (Riesenflugzeug Ersatz Abteilung - giant aircraft replacement unit) described the R.I as larger and heavier than before, possibly due to modifications during its factory repairs.

During 1917 the R.I performed 97 training flights and 26 orientation flights, an excellent record for this complex, early R-plane that was still in training service in late February 1918.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

This side view emphasizes the unusual fuselage design of the SSW R.I. This basic design carried through the SSW R.II to R.VII.

The SSW R.I at Neumunster in May 1915. From the left, the people are Karl Friedrich von Siemens, Franz Steffen and his wife, Dr. Walter Reichel, Bruno Steffen, and Dipl. Ing. Dinslage.

The SSW R.I 1/15 was powered by three 150 hp Benz Bz.III engines mounted in the fuselage and all connected to a central transmission and drive system. The two propellers were powered via drive shafts. The aircraft's type designation was SSW R.I and its military serial number was 1/15; only one aircraft was built.

SSW R.II - R.VII

Based on the successful launch of the SSW R.I, on June 10, 1915, Idflieg gave SSW a contract to build six more R-planes. These were initially designated G.32-37/15, then changed to G.33-38/15, and finally to R.II 2/15 to R.VII 7/15. The specification required a maximum speed of 135 km/hr (a small increase over the R.I's speed), climb to 2,000 meters in 35 minutes and 3,000 meters in 70 minutes carrying a useful load of 2,450 kg, a crew of five like the R.I, and fuel for an endurance of six hours. Specified armament was a cannon in the forward turret and two machine guns, one in the dorsal position and another in the ventral position, plus 600 kg of bombs. However, the cannon was never fitted and a lighter mount for a machine gun was installed. Armor to protect the pilot was initially specified, but Idflieg later dropped this requirement to save weight.

Idflieg required the aircraft to maintain level flight on the power of two engines, and wanted, but did not require, the aircraft to be able to take off on the power of two engines with full crew and armament (less bombs) and one hour of fuel.

Idflieg also specified a strict aircraft delivery schedule. The first was to be delivered by the end of September, 1915, the second by the end of October, and the remaining four aircraft at eight-day intervals thereafter. The deadline for final delivery of all aircraft in the order was April 1, 1916.

These SSW R-planes were designed to use three 240 hp Maybach HS engines, the most powerful aero-engines then available. Originally designed for airship use, the Maybachs proved unable to withstand the more rigorous demands of aircraft use, especially prolonged running at maximum power during take-off and lengthy climbs to altitude. Engine failures were depressingly common and greatly impeded flight testing. In fact, the engine's reliability was marginal even in airships. Finally the aircraft had to be re-designed to use either the 200 hp Benz Bz.IV or the 260 hp Mercedes D.IVa six-cylinder engines. This was a major problem because the central engine location was integral with the structure, and the engine bearers, clutch, and central transmission system all had to be re-designed for the new engines, causing a great deal of additional work. Overall, the Maybach engine debacle delayed delivery of these aircraft by nearly two years.

The lower-power Benz engines were installed in R.III, R.IV, and R.V. Flight tests soon revealed that these aircraft were under-powered and could not meet Idflieg’s climb and useful load requirements. Wing span and area of these aircraft had to be enlarged for more lift to compensate for the lower power of the Benz engines.

The more powerful Mercedes engines were installed in R.II and R.VII. However, the greater weight of the Mercedes engines again meant the wing span and area had to be enlarged, this time to compensate for the weight increase.

These aircraft, originally designed with three bays of struts, had to have wings enlarged to four, five, or even six bays due to the increased span needed for greater wing area. These "supplementary bays" were installed between the wing center section and the outboard wing sections. The variety of engines, wing variations, and other changes during development meant that no two of these aircraft were alike.

To facilitate in-flight engine servicing and repairs, the engine room was enlarged and each engine was fitted with a separate clutch to enable a failed engine to be de-coupled and stopped while the running engines continued to power the propellers. If the mechanic could repair the engine in flight, it could be restarted and re-engaged with the clutch to power the transmission and propellers.

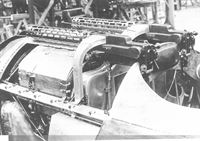

However, despite the enlarged engine room, the space was still very cramped, impeding the mechanic's ability to service the engines in flight. In flight the engine room was hot and often filled with hot, toxic gases from exhaust leaks. The mechanic had to avoid contact with hot exhaust manifolds, which was not easy during flight. The forward engines were so close together that the cylinder head of the left engine had to be removed to provide enough room to replace the exhaust gaskets on the right engine!

Another problem with the complex, centralized power system with internal engines was that any engine or transmission repairs were hardly possible without practically tearing the whole fuselage apart. Additionally, misalignment of assemblies caused frequent drive failures. Lengthy, painstaking development work eventually resolved most of these problems, resulting in reasonable reliability. The SSW R-planes eventually flew a significant number of successful day and night missions. However, the delays meant that, by the time the SSW R-planes arrived at the front, more modern Zeppelin-Staaken R-planes with decentralized power were also in service and gave greater reliability with less development effort. On the positive side, the SSW R-planes had excellent flying characteristics.

R.II 2/15

This was the first aircraft of this batch to be completed and flown, its first flight being on October 26, 1915. However, R.II used the ill-fated Maybach engines, and test-flight experience soon required their replacement. After discussion, Idflieg decided on installation of 260 hp Mercedes D.IVa engines, but by then a shortage of skilled workmen caused SSW to focus on completion of R.V-R.VII and R.II was temporarily stored until the workforce could get to it.

Work finally restarted in early 1917. By then SSW had experience with the Mercedes-powered R.VII and the R.II was completely rebuilt with extended-span wings and enlarged tail surfaces. The R.II was finally delivered to REA on June 29, 1917, but by that time it was not able to compete with the new Staaken R-planes and was relegated to training at the R-plane school at Doberitz. In 1918 it was transferred to REA Cologne and later crashed.

R.III 3/15

R.III was delivered about a month after R.II. However, R.III was also sabotaged by its Maybach engines and crashed in early 1916 due to their failure. At Idflieg’s direction, R.III was stored until SSW had the resources to rebuild it. Later in 1916 R.III was rebuilt with enlarged wing span, 200 hp Benz Bz.IV engines, a reinforced tail, and numerous detail improvements. Idflieg realized the modified R.III was not suitable for combat use and R.III was delivered to REA for training on December 12, 1916. It was still in training service in late February 1918.

R.IV 4/15

R.IV was singled out for extensive development of the Maybach HS engines and related modifications to prove these engines were flight-worthy, and as a result may have been the only airplane powered by these engines to be accepted by Idflieg. The R.IV was delivered on January 29, 1916, and immediately experienced severe engine problems, not performing a useful flight until May. Not being responsible for the engine problems, SSW asked Idflieg to accept R.IV and continue the test program. Idflieg agreed and accepted R.IV on August 27, 1916, after a flight was completed to lowered requirements. By this time the R.IV wing span had been enlarged.

The R.IV was repaired in November, perhaps as a result of a crash. At this time the Maybach engines were replaced by Benz Bz.IV engines and the wing span was again increased. The first flight of the rebuilt aircraft was on March 14, 1917. R.IV joined Rfa 501 at Vilna on the Eastern Front on 27 April and flew several operational missions. The R.IV was then used as a trainer at Vilna and later returned to Berlin and made a safe emergency landing near Spandau in June 1918. By the end of August it was again repaired.

R.V 5/15

R.V was nearly complete when it was decided to replace the Maybach HS engines with 200 hp Benz Bz.IV engines, requiring a complete rebuild. R.V was delivered to REA on August 13, 1916 and then flown to Rfa 501 at Vilna. This delivery flight was a true adventure characterized by clutch and engine failure. Repair required complete disassembly of the gearbox to reach a failed bearing.

R.V flew a number of bombing missions from late 1916 into early 1917. However, in mid-February R.V was severely damaged in a night landing accident. The remains were shipped back to Doberitz for use as spare parts for REA.

R.VI 6/15

R.VI was partially complete when it was decided to replace the Maybach HS engines with 200 hp Benz Bz.IV engines, again requiring a complete rebuild. This included an increased wing span. It was shipped from the factory on April 25, 1916. Several successful test flights were made at the factory, including one that established an unofficial world record of six hours in the air carrying a useful load of 2,400 kg. However, the secrecy required by the war prevented any publicity.

Despite this achievement, the climb and ceiling of the R.VI were marginal and the delivery requirements had to be relaxed to a climb to 3,000 meters in 90 minutes with a reduced useful load of 1,410 kg. R.VI passed these requirements, as R.III and R.V did later, and was delivered to REA on July 20, 1916, from which it was flown to Rfa 501 on August 7. R.VI performed is first operational bombing mission on September 3 but suffered an operational career checkered by mechanical problems and did not complete many operational missions. R.VI was dismantled in November 1917 as being of no further use.

R.VII 7/15

R.VII was the first aircraft of the batch to receive the 260 hp Mercedes D.IVa engines, a change that required extensive rebuilding to strengthen the airframe and power assembly for the larger, more powerful engines. In fact, completely new, larger, stronger wings had to be built and the tailplane had to be enlarged to compensate.

The R.VII was first test-flown on January 15, 1917. The wings were determined to be too heavy and during its test program new, lighter wings were fitted. R.VII was delivered to REA on February 11 and flown to Rfa 501 at Vilna on the 26th of that month. At Vilna a number of field modifications were made, including painting the wing undersurfaces gray for night operations and adding bomb racks for additional bombs, bringing its total bomb-load to 750 kg. R.VII made its first flight from Vilna on March 12, 1917 and its first operational flight on the 15th. However, failure of the spur gear of the left engine during take-off resulted in an aborted take-off.

After repair R.VII flew bombing missions into the summer of 1917 when Rfa 501 was transferred to the Western Front. R.VII was then used as a trainer at Vilna into January 1918.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

Siemens-Schuckert R-Plane Specifications

R.IV (Orig.) R.IV (Reblt.) R.V R.VI R.VII R.VIII

Engines 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV 3 x 200 hp Benz Bz.IV 3 x 200 hp Benz Bz.IV 3 x 260 hp Mercedes D.IVa 6 x 300 hp B&S BuS.IVa

Span 28.22 m 37.6 m 34.33 m 33.36 m 38.44 m 48 m

Wing Area 140 m2 201 m2 177 m2 171 m2 210 m2 440 m2

Length 17.7 m 18.0 m 17.7 m 17.7 m 18.5 m 21.6 m

Height 4.6 m 4.6 m 4.6 m 4.6 m 4.6 m 7.4 m

Empty Weight - 5,450 kg 5,300 kg 5,250 kg 5,700 kg 10,500 kg

Loaded Weight - 6,900 kg 6,766 kg 6,800 kg 7,960 kg 15,900 kg

Max. Speed: - 130 km/h 132 km/h 132 km/h 130 km/h 125 km/h (est.)

Climb: 2,000m - 36 min. 36 min. 36 min. 27 min. -

3,000m - 104 min. 102 min. - 66 min. -

Ceiling: - 3,050 m 3,000 m 2,950 m 3,200 m 4,000 m (est.)

Duration: - 4 hours 5 1/4 hours 4 hours -

Based on the successful launch of the SSW R.I, on June 10, 1915, Idflieg gave SSW a contract to build six more R-planes. These were initially designated G.32-37/15, then changed to G.33-38/15, and finally to R.II 2/15 to R.VII 7/15. The specification required a maximum speed of 135 km/hr (a small increase over the R.I's speed), climb to 2,000 meters in 35 minutes and 3,000 meters in 70 minutes carrying a useful load of 2,450 kg, a crew of five like the R.I, and fuel for an endurance of six hours. Specified armament was a cannon in the forward turret and two machine guns, one in the dorsal position and another in the ventral position, plus 600 kg of bombs. However, the cannon was never fitted and a lighter mount for a machine gun was installed. Armor to protect the pilot was initially specified, but Idflieg later dropped this requirement to save weight.

Idflieg required the aircraft to maintain level flight on the power of two engines, and wanted, but did not require, the aircraft to be able to take off on the power of two engines with full crew and armament (less bombs) and one hour of fuel.

Idflieg also specified a strict aircraft delivery schedule. The first was to be delivered by the end of September, 1915, the second by the end of October, and the remaining four aircraft at eight-day intervals thereafter. The deadline for final delivery of all aircraft in the order was April 1, 1916.

These SSW R-planes were designed to use three 240 hp Maybach HS engines, the most powerful aero-engines then available. Originally designed for airship use, the Maybachs proved unable to withstand the more rigorous demands of aircraft use, especially prolonged running at maximum power during take-off and lengthy climbs to altitude. Engine failures were depressingly common and greatly impeded flight testing. In fact, the engine's reliability was marginal even in airships. Finally the aircraft had to be re-designed to use either the 200 hp Benz Bz.IV or the 260 hp Mercedes D.IVa six-cylinder engines. This was a major problem because the central engine location was integral with the structure, and the engine bearers, clutch, and central transmission system all had to be re-designed for the new engines, causing a great deal of additional work. Overall, the Maybach engine debacle delayed delivery of these aircraft by nearly two years.

The lower-power Benz engines were installed in R.III, R.IV, and R.V. Flight tests soon revealed that these aircraft were under-powered and could not meet Idflieg’s climb and useful load requirements. Wing span and area of these aircraft had to be enlarged for more lift to compensate for the lower power of the Benz engines.

The more powerful Mercedes engines were installed in R.II and R.VII. However, the greater weight of the Mercedes engines again meant the wing span and area had to be enlarged, this time to compensate for the weight increase.

These aircraft, originally designed with three bays of struts, had to have wings enlarged to four, five, or even six bays due to the increased span needed for greater wing area. These "supplementary bays" were installed between the wing center section and the outboard wing sections. The variety of engines, wing variations, and other changes during development meant that no two of these aircraft were alike.

To facilitate in-flight engine servicing and repairs, the engine room was enlarged and each engine was fitted with a separate clutch to enable a failed engine to be de-coupled and stopped while the running engines continued to power the propellers. If the mechanic could repair the engine in flight, it could be restarted and re-engaged with the clutch to power the transmission and propellers.

However, despite the enlarged engine room, the space was still very cramped, impeding the mechanic's ability to service the engines in flight. In flight the engine room was hot and often filled with hot, toxic gases from exhaust leaks. The mechanic had to avoid contact with hot exhaust manifolds, which was not easy during flight. The forward engines were so close together that the cylinder head of the left engine had to be removed to provide enough room to replace the exhaust gaskets on the right engine!

Another problem with the complex, centralized power system with internal engines was that any engine or transmission repairs were hardly possible without practically tearing the whole fuselage apart. Additionally, misalignment of assemblies caused frequent drive failures. Lengthy, painstaking development work eventually resolved most of these problems, resulting in reasonable reliability. The SSW R-planes eventually flew a significant number of successful day and night missions. However, the delays meant that, by the time the SSW R-planes arrived at the front, more modern Zeppelin-Staaken R-planes with decentralized power were also in service and gave greater reliability with less development effort. On the positive side, the SSW R-planes had excellent flying characteristics.

R.II 2/15

This was the first aircraft of this batch to be completed and flown, its first flight being on October 26, 1915. However, R.II used the ill-fated Maybach engines, and test-flight experience soon required their replacement. After discussion, Idflieg decided on installation of 260 hp Mercedes D.IVa engines, but by then a shortage of skilled workmen caused SSW to focus on completion of R.V-R.VII and R.II was temporarily stored until the workforce could get to it.

Work finally restarted in early 1917. By then SSW had experience with the Mercedes-powered R.VII and the R.II was completely rebuilt with extended-span wings and enlarged tail surfaces. The R.II was finally delivered to REA on June 29, 1917, but by that time it was not able to compete with the new Staaken R-planes and was relegated to training at the R-plane school at Doberitz. In 1918 it was transferred to REA Cologne and later crashed.

R.III 3/15

R.III was delivered about a month after R.II. However, R.III was also sabotaged by its Maybach engines and crashed in early 1916 due to their failure. At Idflieg’s direction, R.III was stored until SSW had the resources to rebuild it. Later in 1916 R.III was rebuilt with enlarged wing span, 200 hp Benz Bz.IV engines, a reinforced tail, and numerous detail improvements. Idflieg realized the modified R.III was not suitable for combat use and R.III was delivered to REA for training on December 12, 1916. It was still in training service in late February 1918.

R.IV 4/15

R.IV was singled out for extensive development of the Maybach HS engines and related modifications to prove these engines were flight-worthy, and as a result may have been the only airplane powered by these engines to be accepted by Idflieg. The R.IV was delivered on January 29, 1916, and immediately experienced severe engine problems, not performing a useful flight until May. Not being responsible for the engine problems, SSW asked Idflieg to accept R.IV and continue the test program. Idflieg agreed and accepted R.IV on August 27, 1916, after a flight was completed to lowered requirements. By this time the R.IV wing span had been enlarged.

The R.IV was repaired in November, perhaps as a result of a crash. At this time the Maybach engines were replaced by Benz Bz.IV engines and the wing span was again increased. The first flight of the rebuilt aircraft was on March 14, 1917. R.IV joined Rfa 501 at Vilna on the Eastern Front on 27 April and flew several operational missions. The R.IV was then used as a trainer at Vilna and later returned to Berlin and made a safe emergency landing near Spandau in June 1918. By the end of August it was again repaired.

R.V 5/15

R.V was nearly complete when it was decided to replace the Maybach HS engines with 200 hp Benz Bz.IV engines, requiring a complete rebuild. R.V was delivered to REA on August 13, 1916 and then flown to Rfa 501 at Vilna. This delivery flight was a true adventure characterized by clutch and engine failure. Repair required complete disassembly of the gearbox to reach a failed bearing.

R.V flew a number of bombing missions from late 1916 into early 1917. However, in mid-February R.V was severely damaged in a night landing accident. The remains were shipped back to Doberitz for use as spare parts for REA.

R.VI 6/15

R.VI was partially complete when it was decided to replace the Maybach HS engines with 200 hp Benz Bz.IV engines, again requiring a complete rebuild. This included an increased wing span. It was shipped from the factory on April 25, 1916. Several successful test flights were made at the factory, including one that established an unofficial world record of six hours in the air carrying a useful load of 2,400 kg. However, the secrecy required by the war prevented any publicity.

Despite this achievement, the climb and ceiling of the R.VI were marginal and the delivery requirements had to be relaxed to a climb to 3,000 meters in 90 minutes with a reduced useful load of 1,410 kg. R.VI passed these requirements, as R.III and R.V did later, and was delivered to REA on July 20, 1916, from which it was flown to Rfa 501 on August 7. R.VI performed is first operational bombing mission on September 3 but suffered an operational career checkered by mechanical problems and did not complete many operational missions. R.VI was dismantled in November 1917 as being of no further use.

R.VII 7/15

R.VII was the first aircraft of the batch to receive the 260 hp Mercedes D.IVa engines, a change that required extensive rebuilding to strengthen the airframe and power assembly for the larger, more powerful engines. In fact, completely new, larger, stronger wings had to be built and the tailplane had to be enlarged to compensate.

The R.VII was first test-flown on January 15, 1917. The wings were determined to be too heavy and during its test program new, lighter wings were fitted. R.VII was delivered to REA on February 11 and flown to Rfa 501 at Vilna on the 26th of that month. At Vilna a number of field modifications were made, including painting the wing undersurfaces gray for night operations and adding bomb racks for additional bombs, bringing its total bomb-load to 750 kg. R.VII made its first flight from Vilna on March 12, 1917 and its first operational flight on the 15th. However, failure of the spur gear of the left engine during take-off resulted in an aborted take-off.

After repair R.VII flew bombing missions into the summer of 1917 when Rfa 501 was transferred to the Western Front. R.VII was then used as a trainer at Vilna into January 1918.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

Siemens-Schuckert R-Plane Specifications

R.IV (Orig.) R.IV (Reblt.) R.V R.VI R.VII R.VIII

Engines 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV 3 x 200 hp Benz Bz.IV 3 x 200 hp Benz Bz.IV 3 x 260 hp Mercedes D.IVa 6 x 300 hp B&S BuS.IVa

Span 28.22 m 37.6 m 34.33 m 33.36 m 38.44 m 48 m

Wing Area 140 m2 201 m2 177 m2 171 m2 210 m2 440 m2

Length 17.7 m 18.0 m 17.7 m 17.7 m 18.5 m 21.6 m

Height 4.6 m 4.6 m 4.6 m 4.6 m 4.6 m 7.4 m

Empty Weight - 5,450 kg 5,300 kg 5,250 kg 5,700 kg 10,500 kg

Loaded Weight - 6,900 kg 6,766 kg 6,800 kg 7,960 kg 15,900 kg

Max. Speed: - 130 km/h 132 km/h 132 km/h 130 km/h 125 km/h (est.)

Climb: 2,000m - 36 min. 36 min. 36 min. 27 min. -

3,000m - 104 min. 102 min. - 66 min. -

Ceiling: - 3,050 m 3,000 m 2,950 m 3,200 m 4,000 m (est.)

Duration: - 4 hours 5 1/4 hours 4 hours -

SSW R.II with its original wings. The nose radiator installation is much cleaner than on the R.I. Despite the improved cooling, the experimental 240 hp Maybach HS engines continually over-heated and were subject to many other failures. The Maybach engines were the Achilles heel of the SSW R.II-R.VII.

This side view of SSW R.II after being rebuilt with longer wings emphasizes the unusual fuselage design of the SSW R-planes.This basic design carried through the SSW R.II to R.VII.

This front view of the rebuilt SSW R.II emphasizes the long wing-span after addition of the "supplementary bays" required for greater lift.

The SSW R.IV as completed with its original, short-span wings. Originally accepted with the problematic Maybach HS engines, after serious problems the R.IV was re-engined with three 200 hp Benz Bz.IV engines.

The SSW R.IV 4/15 shared the typical SSW R-plane profile. The servo-tabs between the ailerons that reduced the pilot's aileron control forces are clearly shown.

The SSW R.V as completed with its original, short-span wings.

The SSW R.V was one of a series of early R-plane designs. The unusual fuselage design mounted a defensive machine-gun position at the intersection of the split. Three 200 hp Benz engines were mounted in the fuselage and drove the propellers via gears. From late 1916 the R.V 5/15 flew a number of combat missions over the Russian Front from Rfa 501's base at Vilna. It was wrecked in a night landing in mid-February 1917. (PM Grosz Collection/STDB)

The SSW R.V was one of a series of early R-plane designs. The unusual fuselage design mounted a defensive machine-gun position at the intersection of the split. Three 200 hp Benz engines were mounted in the fuselage and drove the propellers via gears. From late 1916 the R.V 5/15 flew a number of combat missions over the Russian Front from Rfa 501's base at Vilna. It was wrecked in a night landing in mid-February 1917. (PM Grosz Collection/STDB)

Result of a bad landing at night of the SSW R.V on January 31, 1917 that severely damaged the aircraft.

The SSW R.VI as modified with extended-span wings. It was powered by three 200 hp Benz Bz.IV engines.

Прототип "Сименс-Шуккерта" D.I в заводском цехе

The prototype SSW D.I, 3503/16, in the factory with an R-plane under construction in the background.

The prototype SSW D.I, 3503/16, in the factory with an R-plane under construction in the background.

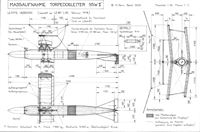

SSW Guided Missiles

Guided missiles are not the kind of 'aircraft' one normally associates with WWI, but SSW built and tested them and they are included here for their interest. In October 1914 Dr. Wilhelm von Siemens proposed remotely-controlled glide bombs, an air to surface missile. Work began that month and by January 1915 small models were under test.

Scale model glide-bombs were launched from towers, balloons, and a track built on the roof of the Siemens airship shed at Biesdorf in addition to launches from airships and airplanes. Initially the gliders' servo-controls were powered by batteries, but these heavy cells were soon replaced by propeller-driven dynamos that generated electricity. Guidance commands were transmitted from airships to the glide bombs by thin wires that unraveled from a spool after the glider was launched. After guidance commands the rudder returned to neutral but the elevator remained in the last position commanded. Many flight tests with gliders from 92 to 265 pounds weight were made from autumn 1915 to spring 1917.

Ships are difficult to hit with conventional bombs due to their ability to maneuver quickly after bombs are released, so they were a natural target for guided missiles. In mid-1916 torpedoes were chosen over bombs for the missile warhead because torpedoes allowed the maximum stand-off distance between the ship and the attacking aircraft. By autumn 1916 a method had been developed and tested to eject the torpedo just before the glider struck the water.

The size of the gliders was then increased significantly since torpedoes were to be carried, and night tests commenced. A flare was added to the glider so it could be seen in the dark and guided to its target. SSW conducted these tests throughout 1917. After more than 75 tests at Biesdorf, Zeppelins were provided to test larger, heavier gliders from higher altitude. From summer 1917 gliders weighing 660 pounds (300 kg) were launched from airship Z.XII in Hannover. In Autumn gliders of 1,100 pounds (500 kg) and 2,200 pounds (1,000 kg) were tested from Zeppelin L.35 at Juterbog and PL 25 at Potsdam.