Книги

Centennial Perspective

J.Herris

AEG Aircraft of WWI

344

J.Herris - AEG Aircraft of WWI /Centennial Perspective/ (16)

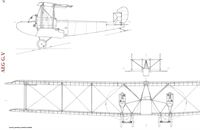

AEG-Wagner Monoplane

In late 1914 the AEG-Wagner monoplane was built by the AEG Flugtechnische Abteilung in Hennigsdorf to evaluate the wing shape designed by Ingenieur Wagner. The purpose of the design may have had something to do with using the propeller wash to develop additional lift. The first model and five other aircraft were destroyed in a hangar fire in September 1914, although the steel-tube fuselage and rotary engine survived. A second AEG-Wagner monoplane appeared in early 1915. Flight trials demonstrated little advantage of the Wagner wing and the second AEG-Wagner monoplane was hung from the rafters in the AEG factory for storage. The fuselage and vertical tail surfaces are presently in the Polish aircraft collection at Krakow.

In late 1914 the AEG-Wagner monoplane was built by the AEG Flugtechnische Abteilung in Hennigsdorf to evaluate the wing shape designed by Ingenieur Wagner. The purpose of the design may have had something to do with using the propeller wash to develop additional lift. The first model and five other aircraft were destroyed in a hangar fire in September 1914, although the steel-tube fuselage and rotary engine survived. A second AEG-Wagner monoplane appeared in early 1915. Flight trials demonstrated little advantage of the Wagner wing and the second AEG-Wagner monoplane was hung from the rafters in the AEG factory for storage. The fuselage and vertical tail surfaces are presently in the Polish aircraft collection at Krakow.

AEG B-Types

After some unspecified problems were overcome the air service ordered six B-type (unarmed, two-seat biplanes) of the Z6 type for training and operations that were delivered in early 1914.

AEG B.I

The AEG Z6 gave satisfactory service and the air service ordered 20 improved aircraft (Z6a) in April 1914. These were powered by a variety of 100-120 hp NAG, Mercedes, or Benz six-cylinder engines. A small number of these aircraft served at the front between August 1914 and December 1915, their steel-tube structures proving their reliability and durability. When Idflieg published the new aircraft designations in August 1915 the AEG Z6a biplanes were retroactively designated AEG B.I even though they were no longer in production.

After some unspecified problems were overcome the air service ordered six B-type (unarmed, two-seat biplanes) of the Z6 type for training and operations that were delivered in early 1914.

AEG B.I

The AEG Z6 gave satisfactory service and the air service ordered 20 improved aircraft (Z6a) in April 1914. These were powered by a variety of 100-120 hp NAG, Mercedes, or Benz six-cylinder engines. A small number of these aircraft served at the front between August 1914 and December 1915, their steel-tube structures proving their reliability and durability. When Idflieg published the new aircraft designations in August 1915 the AEG Z6a biplanes were retroactively designated AEG B.I even though they were no longer in production.

AEG B.I, the retroactive designation for the AEG Z6a. (The Peter M. Bowers Collection/The Museum of Flight)

AEG 1914 Flying Boat

AEG completed a monoplane flying boat with side-by-side seating and powered by a 150 hp Benz Bz.III pusher engine in July 1914, just before the war started. Intended for the Ostseeflug Warnemunde competition, the AEG flying boat was impressed by the Navy when Germany mobilized on 1 August 1914. There is no record of tests in the naval war diary, but it is possible some flights were performed by AEG personnel who had come to Warnemunde for the Ostseeflug and were required to remain until released by the Navy. The Navy judged the AEG flying boat as unsuitable for military duties and it was returned to the factory August 26, 1914.

AEG 1914 Flying Boat Specifications

Engine: 150 hp Benz Bz.III

Wing: Span 16.00 m

General: Length 10.00 m

Height 3.65 m

AEG completed a monoplane flying boat with side-by-side seating and powered by a 150 hp Benz Bz.III pusher engine in July 1914, just before the war started. Intended for the Ostseeflug Warnemunde competition, the AEG flying boat was impressed by the Navy when Germany mobilized on 1 August 1914. There is no record of tests in the naval war diary, but it is possible some flights were performed by AEG personnel who had come to Warnemunde for the Ostseeflug and were required to remain until released by the Navy. The Navy judged the AEG flying boat as unsuitable for military duties and it was returned to the factory August 26, 1914.

AEG 1914 Flying Boat Specifications

Engine: 150 hp Benz Bz.III

Wing: Span 16.00 m

General: Length 10.00 m

Height 3.65 m

The AEG monoplane flying boat completed in July 1914. Only one was built; the Navy evaluated the aircraft and judged that it was unsuitable for naval service. The rod mounted above the engine was for lifting the boat out of the water.

AEG S1

In early 1914 AEG built a floatplane variant of the Z6 landplane for the German Navy. The AEG S1 had folding wings for shipboard use. Completed in May, the S1 (work number 42, Marine Number 45) was powered by a 150 hp Benz Bz.III. It was delivered to the naval seaplane command at Holtenau in June for testing. The S1 was returned to AEG for repair after several flights and was returned to Warnemunde on August 21, 1914. Tests flown in September reveals that the S1 was not acceptable for service,- carrying only the pilot and 20 liters of fuel, the S1 lost speed in a turn to such an extent that it became dangerously unstable. On October 27 the S1 was again returned to AEG, this time for conversion to a landplane. Navy landplane number LF35 had been reserved for the converted S1 but this number was re-assigned to the Aviatik WP18 in October.

AEG entered a second AEG S1 (w/n 43) in the Ostseeflug Warnemunde competition supported by the National Flug Spende and German Navy that was scheduled for August 1-10, 1914. With the general mobilization on August 1, the 22 Ostseeflug competitors were impressed and held at Warnemunde for acceptance testing. On August 11, naval pilots reported that the heavy S1 possessed insufficient climb. Fitted with lighter floats, additional trials were conducted by AEG pilots at Warnemunde between August 19 and October 3 but showed no improvement. Consequently, on October 27 the S1 was shipped to Hennigsdorf for conversion to a landplane.

AEG S1 Specifications

Engine: 150 hp Benz Bz.III

Wing: Span, Upper 16.00 m

Chord, Upper 2.00 m

Gap 2.00 m

General: Length 11.80 m

Height 3.80 m

In early 1914 AEG built a floatplane variant of the Z6 landplane for the German Navy. The AEG S1 had folding wings for shipboard use. Completed in May, the S1 (work number 42, Marine Number 45) was powered by a 150 hp Benz Bz.III. It was delivered to the naval seaplane command at Holtenau in June for testing. The S1 was returned to AEG for repair after several flights and was returned to Warnemunde on August 21, 1914. Tests flown in September reveals that the S1 was not acceptable for service,- carrying only the pilot and 20 liters of fuel, the S1 lost speed in a turn to such an extent that it became dangerously unstable. On October 27 the S1 was again returned to AEG, this time for conversion to a landplane. Navy landplane number LF35 had been reserved for the converted S1 but this number was re-assigned to the Aviatik WP18 in October.

AEG entered a second AEG S1 (w/n 43) in the Ostseeflug Warnemunde competition supported by the National Flug Spende and German Navy that was scheduled for August 1-10, 1914. With the general mobilization on August 1, the 22 Ostseeflug competitors were impressed and held at Warnemunde for acceptance testing. On August 11, naval pilots reported that the heavy S1 possessed insufficient climb. Fitted with lighter floats, additional trials were conducted by AEG pilots at Warnemunde between August 19 and October 3 but showed no improvement. Consequently, on October 27 the S1 was shipped to Hennigsdorf for conversion to a landplane.

AEG S1 Specifications

Engine: 150 hp Benz Bz.III

Wing: Span, Upper 16.00 m

Chord, Upper 2.00 m

Gap 2.00 m

General: Length 11.80 m

Height 3.80 m

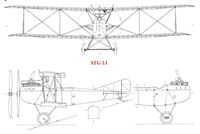

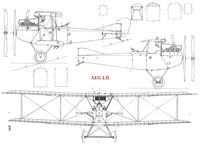

AEG B.II

In late 1914 Idflieg ordered the improved AEG B.II powered by the 150 hp Benz Bz.III. This aircraft, company designation Z9, was a more compact development of the earlier B.I. Nothing is know about designs Z7 and Z8; these were probably unbuilt projects. The first production AEG B.II was rolled out in February 1915 and arrived at the front in April 1915. According to AEG records, ten aircraft were delivered and some served at the front until August-September 1915. Some B.II biplanes were re-engined with a 120 hp Mercedes D.II engine and fitted with dual controls for training purposes.

AEG B.II Specifications

Engine: 150 hp Benz Bz.III 120 hp Mercedes D.II

Wing: Span Upper 13.07 m

Span Lower 11.83 m

Chord Upper 1.60 m

Chord Lower 1.60 m

Gap 1.95 m

Area 36.0 m2

General: Length 7.95 m

Track 2.30 m

Empty Weight 710 kg

Loaded Weight 1,125 kg

Maximum Speed: 130 kmh

Climb: 1000m 4.5 min

AEG B.III

The AEG B.III (company designation Z10) was built in January 1915 as a lightened derivative of the B.II. Visually, the difference was a rounded fin and rudder and use of the 160 hp Mercedes D.III six-cylinder engine. As far as is known, only one B.III was built. Performance testing of the B.III compared to the B.II showed the B.III had a poorer climb despite being 10% lighter and having a slightly more powerful engine. Investigation revealed the bulged center-section gravity tank interfered with airflow from the propeller,- when the tank was removed and the wing gap increased the B.III achieved the expected climb rate. As a result, starting with the AEG C.IV the center-section tank and airfoil radiator were eliminated from AEG designs. This improvement was later confirmed by wind-tunnel tests at Gottingen.

In late 1914 Idflieg ordered the improved AEG B.II powered by the 150 hp Benz Bz.III. This aircraft, company designation Z9, was a more compact development of the earlier B.I. Nothing is know about designs Z7 and Z8; these were probably unbuilt projects. The first production AEG B.II was rolled out in February 1915 and arrived at the front in April 1915. According to AEG records, ten aircraft were delivered and some served at the front until August-September 1915. Some B.II biplanes were re-engined with a 120 hp Mercedes D.II engine and fitted with dual controls for training purposes.

AEG B.II Specifications

Engine: 150 hp Benz Bz.III 120 hp Mercedes D.II

Wing: Span Upper 13.07 m

Span Lower 11.83 m

Chord Upper 1.60 m

Chord Lower 1.60 m

Gap 1.95 m

Area 36.0 m2

General: Length 7.95 m

Track 2.30 m

Empty Weight 710 kg

Loaded Weight 1,125 kg

Maximum Speed: 130 kmh

Climb: 1000m 4.5 min

AEG B.III

The AEG B.III (company designation Z10) was built in January 1915 as a lightened derivative of the B.II. Visually, the difference was a rounded fin and rudder and use of the 160 hp Mercedes D.III six-cylinder engine. As far as is known, only one B.III was built. Performance testing of the B.III compared to the B.II showed the B.III had a poorer climb despite being 10% lighter and having a slightly more powerful engine. Investigation revealed the bulged center-section gravity tank interfered with airflow from the propeller,- when the tank was removed and the wing gap increased the B.III achieved the expected climb rate. As a result, starting with the AEG C.IV the center-section tank and airfoil radiator were eliminated from AEG designs. This improvement was later confirmed by wind-tunnel tests at Gottingen.

This view of AEG B.II B.283 shows the overall shape and many national insignia on the wings, but none on the fuselage. (The Peter M. Bowers Collection/The Museum of Flight)

AEG B-type trainers at AEG Flugplatz Nieder-Neuendorf. These aircraft were owned by the flying school and the numbers were their school numbers, not military serial numbers.

AEG B.II B.283 shows its engine and radiator details and the ability to fold its wings for storage. (The Peter M. Bowers Collection/The Museum of Flight)

AEG B.II B.244 in flight. The wings carry a surplus of national insignia but there are none on the fuselage.

AEG C.I

The AEG C.I (company designation KZ9 for Kampf-Zweidecker 9, or battle biplane 9) was derived from the earlier, unarmed B.II by adding a machine-gun turret; there was no fixed gun for the pilot. Although structurally the same as the B.II, with steel-tube construction except for wooden wing ribs, the C.I had a different wing planform than the B.II; however, the wing-folding mechanism was retained. Idflieg ordered six C.I aircraft in early 1915 and the C.I prototype was completed in March. Additional C.I aircraft were ordered, a total of about 70 being delivered.

The AEG C.I was among the first C-type aircraft to reach the front, serving from June 1915 to April 1916. Climb rate was mediocre despite the C.I being lighter than most contemporary C-types. Due to its sturdy metal airframe the C.I was used well into 1917 as a trainer after being removed from the front.

AEG C.II & C.IIa - C.IIe

The AEG C.II was basically a lightened C.I with a modified wing planform. Like the C.I it was powered by the 150 hp Benz Bz.III engine. It was 122 kg lighter than the C.I, giving it better performance, but airframe strength was compromised, resulting in a number of failures during load tests. Modifications to strengthen the airframe took time and the first six C.II aircraft were not delivered until April 1916. One C.II was sent to the front that month, but was soon removed from the front and sent to join the other C.II aircraft for training use.

From early 1915 through the spring of 1916, AEG modified C.II biplanes with different airfoil sections, chord, span, and gap, with the different configurations given factory (not Idflieg] designations C.IIa through C.IIe. Data was collected that led to aerodynamic improvements to wing and radiator design, some of which were key in the design of the AEG C.IV.

The AEG C.IIe tested an armored, annular radiator (Patent 299,725) in which the cooling air was forced through the radiator by a fan attached to the propeller. This particular development was driven by combat experience with the armored AEG J.I, which demonstrated that the radiator was the most vulnerable part of the armored aircraft during low-level ground attacks.

AEG C-Type Production Orders

Serial Numbers Qty Order Date & Notes

AEG C.I (70 Total)

C.74-79/15 6 Unknown

C.82-93/15 12 April 1915

C.130-153/15 24 May 1915

C.324-348/15 25 May 1915

C.1366-1368/17 3 Unknown

AEG C.II (37 Total)

C.869-888/15 20 September 1915

C.1887-1902/15 16 October 1915

C.9421/16 1 C.II prototype?

AEG C-Type Specifications

C.I C.II C.III C.IV C.IV(Fok)

Engine 150 hp Benz Bz.III 150 hp Benz Bz.III 150 hp Benz Bz.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.07 m 11.95 m 12.00 m 13.00 m 12.99 m

Span Lower 11.83 m 11.45 m 11.30 m 12.50 m 12.36 m

Chord Upper 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Chord Lower 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Gap 1.95 m 1.80 m 1.40 m 1.95 m 1.95 m

Wing Area 36.0 m2 39.0 m2 33.90 m2 39.0 m2 -

Length 7.95 m 7.09 m 6.50 m 7.20 m 7.22 m

Track 2.30 m 2.15 m 2.15 m 2.15 m 2.16 m

Empty Weight 710 kg 680 kg 687 kg 800 kg 901 kg

Loaded Weight 1,125 kg 1,200 kg 1,232 kg 1,320 kg 1,414 kg

Maximum Speed 130 kmh 138 kmh 145 kmh 158 kmh -

Climb, 1000m 11 min. 8 min. - 6 min. 4.8 min.

Climb, 2000m 25 min. 18 min. - 12.5 min. 12.1 min.

Climb, 3000m 55 min. 41 min. - 23 min. 21.9 min.

Climb, 4000m - - - 38 min. 35.4 min.

Armament 1 flexible machine gun, small bombs 1 flexible machine gun, 4x10 kg bombs 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 flexible machine gun

The AEG C.I (company designation KZ9 for Kampf-Zweidecker 9, or battle biplane 9) was derived from the earlier, unarmed B.II by adding a machine-gun turret; there was no fixed gun for the pilot. Although structurally the same as the B.II, with steel-tube construction except for wooden wing ribs, the C.I had a different wing planform than the B.II; however, the wing-folding mechanism was retained. Idflieg ordered six C.I aircraft in early 1915 and the C.I prototype was completed in March. Additional C.I aircraft were ordered, a total of about 70 being delivered.

The AEG C.I was among the first C-type aircraft to reach the front, serving from June 1915 to April 1916. Climb rate was mediocre despite the C.I being lighter than most contemporary C-types. Due to its sturdy metal airframe the C.I was used well into 1917 as a trainer after being removed from the front.

AEG C.II & C.IIa - C.IIe

The AEG C.II was basically a lightened C.I with a modified wing planform. Like the C.I it was powered by the 150 hp Benz Bz.III engine. It was 122 kg lighter than the C.I, giving it better performance, but airframe strength was compromised, resulting in a number of failures during load tests. Modifications to strengthen the airframe took time and the first six C.II aircraft were not delivered until April 1916. One C.II was sent to the front that month, but was soon removed from the front and sent to join the other C.II aircraft for training use.

From early 1915 through the spring of 1916, AEG modified C.II biplanes with different airfoil sections, chord, span, and gap, with the different configurations given factory (not Idflieg] designations C.IIa through C.IIe. Data was collected that led to aerodynamic improvements to wing and radiator design, some of which were key in the design of the AEG C.IV.

The AEG C.IIe tested an armored, annular radiator (Patent 299,725) in which the cooling air was forced through the radiator by a fan attached to the propeller. This particular development was driven by combat experience with the armored AEG J.I, which demonstrated that the radiator was the most vulnerable part of the armored aircraft during low-level ground attacks.

AEG C-Type Production Orders

Serial Numbers Qty Order Date & Notes

AEG C.I (70 Total)

C.74-79/15 6 Unknown

C.82-93/15 12 April 1915

C.130-153/15 24 May 1915

C.324-348/15 25 May 1915

C.1366-1368/17 3 Unknown

AEG C.II (37 Total)

C.869-888/15 20 September 1915

C.1887-1902/15 16 October 1915

C.9421/16 1 C.II prototype?

AEG C-Type Specifications

C.I C.II C.III C.IV C.IV(Fok)

Engine 150 hp Benz Bz.III 150 hp Benz Bz.III 150 hp Benz Bz.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.07 m 11.95 m 12.00 m 13.00 m 12.99 m

Span Lower 11.83 m 11.45 m 11.30 m 12.50 m 12.36 m

Chord Upper 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Chord Lower 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Gap 1.95 m 1.80 m 1.40 m 1.95 m 1.95 m

Wing Area 36.0 m2 39.0 m2 33.90 m2 39.0 m2 -

Length 7.95 m 7.09 m 6.50 m 7.20 m 7.22 m

Track 2.30 m 2.15 m 2.15 m 2.15 m 2.16 m

Empty Weight 710 kg 680 kg 687 kg 800 kg 901 kg

Loaded Weight 1,125 kg 1,200 kg 1,232 kg 1,320 kg 1,414 kg

Maximum Speed 130 kmh 138 kmh 145 kmh 158 kmh -

Climb, 1000m 11 min. 8 min. - 6 min. 4.8 min.

Climb, 2000m 25 min. 18 min. - 12.5 min. 12.1 min.

Climb, 3000m 55 min. 41 min. - 23 min. 21.9 min.

Climb, 4000m - - - 38 min. 35.4 min.

Armament 1 flexible machine gun, small bombs 1 flexible machine gun, 4x10 kg bombs 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 flexible machine gun

AEG C.I 90/15 wears black and white bands on its fuselage and carries white identification pennants. Powered by a 150 hp Benz Bz.III like the AEG B.II, the AEG C.I still retained the side radiators normally associated with B-types. About 70 AEG C.I reconnaissance two-seaters were built.

AEG C.I 139/15 has broken its back in a hard landing. It wears national insignia on its fuselage as well as its rudder.

AEG C.II with an additional gun mounted over the wing.The C.II did not have a synchronized gun for the pilot.

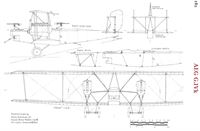

AEG C.III

The AEG C.III was designed to give the observer the maximum field of fire, achieved by placing the top wing at the lever of the top of the fuselage and the observer in the front cockpit. The Roland C.II to similar format, although with pilot in front, first flew in October 1915 and the AEG C.III, clearly inspired by the Roland, flew two months later.

The C.III was developed from the C.II and used the same 150 hp Benz Bz.III engine. One or two prototypes were built but the insufficient wing gap caused interference in the airflow between the upper and lower wings, limiting performance and flying qualities, and further development was abandoned in favor of more conventional configurations.

AEG C-Type Specifications

C.I C.II C.III C.IV C.IV(Fok)

Engine 150 hp Benz Bz.III 150 hp Benz Bz.III 150 hp Benz Bz.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.07 m 11.95 m 12.00 m 13.00 m 12.99 m

Span Lower 11.83 m 11.45 m 11.30 m 12.50 m 12.36 m

Chord Upper 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Chord Lower 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Gap 1.95 m 1.80 m 1.40 m 1.95 m 1.95 m

Wing Area 36.0 m2 39.0 m2 33.90 m2 39.0 m2 -

Length 7.95 m 7.09 m 6.50 m 7.20 m 7.22 m

Track 2.30 m 2.15 m 2.15 m 2.15 m 2.16 m

Empty Weight 710 kg 680 kg 687 kg 800 kg 901 kg

Loaded Weight 1,125 kg 1,200 kg 1,232 kg 1,320 kg 1,414 kg

Maximum Speed 130 kmh 138 kmh 145 kmh 158 kmh -

Climb, 1000m 11 min. 8 min. - 6 min. 4.8 min.

Climb, 2000m 25 min. 18 min. - 12.5 min. 12.1 min.

Climb, 3000m 55 min. 41 min. - 23 min. 21.9 min.

Climb, 4000m - - - 38 min. 35.4 min.

Armament 1 flexible machine gun, small bombs 1 flexible machine gun, 4x10 kg bombs 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 flexible machine gun

The AEG C.III was designed to give the observer the maximum field of fire, achieved by placing the top wing at the lever of the top of the fuselage and the observer in the front cockpit. The Roland C.II to similar format, although with pilot in front, first flew in October 1915 and the AEG C.III, clearly inspired by the Roland, flew two months later.

The C.III was developed from the C.II and used the same 150 hp Benz Bz.III engine. One or two prototypes were built but the insufficient wing gap caused interference in the airflow between the upper and lower wings, limiting performance and flying qualities, and further development was abandoned in favor of more conventional configurations.

AEG C-Type Specifications

C.I C.II C.III C.IV C.IV(Fok)

Engine 150 hp Benz Bz.III 150 hp Benz Bz.III 150 hp Benz Bz.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.07 m 11.95 m 12.00 m 13.00 m 12.99 m

Span Lower 11.83 m 11.45 m 11.30 m 12.50 m 12.36 m

Chord Upper 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Chord Lower 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Gap 1.95 m 1.80 m 1.40 m 1.95 m 1.95 m

Wing Area 36.0 m2 39.0 m2 33.90 m2 39.0 m2 -

Length 7.95 m 7.09 m 6.50 m 7.20 m 7.22 m

Track 2.30 m 2.15 m 2.15 m 2.15 m 2.16 m

Empty Weight 710 kg 680 kg 687 kg 800 kg 901 kg

Loaded Weight 1,125 kg 1,200 kg 1,232 kg 1,320 kg 1,414 kg

Maximum Speed 130 kmh 138 kmh 145 kmh 158 kmh -

Climb, 1000m 11 min. 8 min. - 6 min. 4.8 min.

Climb, 2000m 25 min. 18 min. - 12.5 min. 12.1 min.

Climb, 3000m 55 min. 41 min. - 23 min. 21.9 min.

Climb, 4000m - - - 38 min. 35.4 min.

Armament 1 flexible machine gun, small bombs 1 flexible machine gun, 4x10 kg bombs 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 flexible machine gun

Like the earlier C.I and C.II, the AEG C.III was powered by a 150 hp Benz Bz.III. (The Peter M. Bowers Collection/The Museum of Flight)

The C.III was designed for a more offensive role than the C.I or C.II and the observer with his flexible gun was in the front cockpit, giving him a good field of fire, but it was not synchronized so could not safely fire through the propeller arc.

The AEG C.III was a prototype powered by a 150 hp Benz Bz.III. It was probably inspired by the Roland C.II, which appeared two months earlier. The AEG C.III had a somewhat similar side profile but a rectangular cross section. The observer/gunner sat in the front cockpit with a flexible machine gun; the gun was not synchronized so the propeller obscured a wide arc of fire. Similar in design to the Germania DB, it may have been intended as a two-seat fighter the the Germania prototype. The wing cellule was a typical 2-bay design. It remained a prototype.

The AEG C.III was a prototype powered by a 150 hp Benz Bz.III. It was probably inspired by the Roland C.II, which appeared two months earlier. The AEG C.III had a somewhat similar side profile but a rectangular cross section. The observer/gunner sat in the front cockpit with a flexible machine gun; the gun was not synchronized so the propeller obscured a wide arc of fire. Similar in design to the Germania DB, it may have been intended as a two-seat fighter the the Germania prototype. The wing cellule was a typical 2-bay design. It remained a prototype.

AEG Bombers

Despite the wide variety of AEG aircraft that served operationally, AEG is perhaps best known for its twin-engine bombers. These originated from development of a 'battle plane' that was essentially an aerial cruiser armed with flexible machine guns and bombs. This aircraft lead to a series of designs that became twin-engine bombers based on operational experience.

In addition to these G-type bombers, AEG also built the successful N.I single-engine night bomber and a giant bomber, the R.I, that suffered a fatal crash during flight testing.

AEG K.I

In March 1914 the German general staff sanctioned the development of the Kampfflugzeug (battle plane), and in July 1914 Idflieg issued specifications for the type in preparation for a competition planned for spring 1915. The Kampfflugzeug idea was basically an 'aerial cruiser' armed with machine guns and bombs. The aircraft was to have 200 hp, carry a crew of three, and have an endurance of six hours.

AEG responded to the requirement with a biplane powered by two 100 hp Mercedes D.I engines; the factory designation was GZ1 and the military designation was AEG K.I. The K-type designation was soon changed to G-type, the 'G' standing for 'Grossflugzeug' or large aircraft, later to become synonymous with twin-engine bombing aircraft. The K.I had side-by-side seating for two crewmen and a single flexible machine gun was mounted in a nose turret because the aircraft was intended to chase and destroy enemy airplanes. The airframe was constructed of self-fused (autogenous) welded steel tubes. The nose was covered with light armored plate and the rest of the aircraft was fabric covered.

In January 1915 the AEG K.I prototype was first flown by test pilot Willy Kanitz and gave promising results during flight tests in January-February. This convinced Idflieg to order a second prototype as the AEG G.I for combat evaluation.

AEG G.I

The second AEG Kampfflugzeug prototype, now designated AEG G.I but internally retaining the company designation GZ1, was completed in March 1915 and may have incorporated components from the K.I. The G.I differed from the K.I primarily in its crew and armament; the G.I had three crewmen and flexible machine guns in fore and aft turrets. Power remained two 100 hp Mercedes D.I engines.

The AEG G.I was shipped from the factory on April 24, 1915 for the 4.Armee for combat assessment without first being tested at Adlershof. Only one G.I was built.

AEG G.II

Prior to the operational trials of the AEG G.I, Idflieg ordered six aircraft of an improved type, the AEG G.II (factory designation GZ2). Idflieg’s requirements for the AEG G.II included two 150 hp Benz Bz.III engines, a crew of two with three seats, a single machine gun, a 200 kg bomb load, and 150 kg of armor plate (front and side 2.3 mm and floor 1.5 mm). Controlling a multi-engine aircraft after the failure of one engine was dependent on both pilot technique and design of the aircraft; accordingly Idflieg urged AEG "to make every effort to assure that the aircraft would maintain a straight flight path with only one engine running at full power." With the more powerful engines in the G.II a larger fin and rudder were needed to main control with asymmetric thrust.

As expected the more powerful engines gave the AEG G.II better performance and greater load-carrying capability, and Idflieg ordered a second batch of 12 G.II aircraft on May 6, 1915 before the results of the combat trials of the AEG G.I were known. The first two G.II aircraft were completed in May and reached the front in June, with a maximum of 13 at the front in December.

The AEG G.II was not only a new aircraft but was exploring a new combat role as a multi-engine Kampfflugzeug, or aerial cruiser. The G.II was used both to escort single-engine reconnaissance and bomber aircraft and to attack enemy aircraft. Based on operational experience the first six G.II aircraft (G.2-7/15) were extensively modified for both technical and operational reasons, with the result that no two aircraft were alike. The square, armor-plated nose was replaced by a streamlined, unarmored one. Two gravity tanks and new oil tanks were installed. Because the small fin and rudder failed to provide adequate directional control with one engine out, some machines were retro-fitted with triple rudders, becoming standard beginning with the second G.II production batch (G.19-30/15).

Despite all the modifications to the G.II, including adding a second and sometimes a third machine gun, operational experience soon made it clear that the multi-engine Kampfflugzeug concept was a failure. The Kampfflugzeug had only modest success as a multi-seat escort and was too slow and cumbersome to catch faster, more maneuverable enemy aircraft - and most enemy single-seaters were faster and more maneuverable.

However, bomb racks were installed in all G.II aircraft and aircrews soon discovered that bombing was the most effective role for the G.II. By mid-1916 Idflieg summarized the operational record of the G.II saying it "had fared poorly in air combat, but had been successfully employed as a bomber in squadron strength." The AEG G.II thus discovered the true role of the G-type as a bomber. It remained at the front through June 1917 and set the standard for future AEG bombers. A total of 27 G.II aircraft were delivered before production was shifted to the improved G.III in May 1916.

AEG G.III

When Idflieg ordered the first six G.II on April 1, 1915, AEG was also requested to build a Kampfflugzeug with two 220/240 hp engines, the type to be decided later. The intention was to provide greater performance and payload, and the resulting aircraft was designated the AEG G.III (factory designation GZ3). A crew of three, 200 kg of armor protection, and a bomb load of 240 kg were specified. Two machine guns or a cannon mounted in the nose and a rear machine gun was the specified armament.

The G.III was very similar to the G.II although the wingspan was 2.24 m longer. Two of the new, 220 hp Mercedes D.IV straight-eight engines were fitted because these were the most powerful engines then in production. A four-bladed propeller was used to absorb all the power of the engine, but the long crankshaft was subject to fractures in service. The AEG specification chart shows December 1915 as the date the first G.III was completed, but the first three production aircraft were not delivered until May 1916. The G.III prototype was tested with a single fin and rudder and an early production aircraft (G.53/15) was delivered with a triple rudder for comparison. All other production G.III bombers had the single fin and rudder and most had external bomb racks.

The G.III reached the front in June 1916 and was first used as an escort aircraft for single-engine bombers, but it quickly became clear that bombing was the appropriate role for the G.III. Kampfgeschwader 1 became "the first formation to be completely equipped with twin-engine aircraft of the G-category for the sole purpose of bombing." Serving with KG1 in Macedonia, the G.III was primarily used as a bomber but at least two strafing attacks were made. The last three G.III bombers were delivered in January 1917, bringing total G.III production to 45 aircraft; the AEG G.IV then followed the AEG G.III in production.

AEG G-Type Specifications

G.I G.II G.III G.IV G.V

Engine 2x100 hp Mercedes D.I 2x150 hp Benz Bz.III 2x220 hp Mercedes D.IV 2x260 hp Mercedes D.IVa 2x260 hp Mercedes D.IVa

Span Upper 16.00 m 16.20 m 18.44 m 18.40 m 27.24 m

Span Lower 15.20 m 15.20 m 17.20 m 17.40 m 26.30 m

Chord Upper 2.20 m 2.20 m 2.50 m 2.40 m 2.80 m

Chord Lower 2.20 m 2.20 m 2.50 m 2.40 m 2.39 m

Gap 2.30 m 2.30 m 2.60 m 2.20 m 3.00 m

Wing Area 61.0 m2 61.0 m2 74.0 m2 ??? 68.7 m2 127.2 m2

Length 8.7 m 9.1 m 9.20 m 9.70 m 10.80 m

Track 3.15 m 3.15 m 2.85 m 5.10m 4.85 m

Empty Weight 1,160 kg 1,450 kg 1,940 kg 2,400 kg 2,700 kg

Loaded Weight 1,610 kg 2,050 kg 2,560 kg 3,635 kg 4,800 kg

Maximum Speed 125 kmh 140 kmh 150 kmh 165 kmh 145 kmh

Climb, 1000m - 11 min. 6 min. 5 min. 16 min.

Climb, 2000m - - - 11 min. 12 min.

Climb, 3000m - - - 21 min. 23 min.

Climb, 4000m - - - 40 min. 34 min.

Armament 2 flexible machine guns, small bombs 2 flexible machine guns, 200 kg bombs 2 flexible machine guns, 240 kg bombs 2 flexible machine guns, 300 kg bombs 2 flexible machine guns, 1,000 kg bombs

Note: The AEG G.IVb wing span was enlarged to 24 m; this enabled a 1,000 kg bomb to be carried. For short missions up to 1,500 kg of bombs could be carried.

AEG G-Type Production Orders

Serial Numbers Qty Order Date & Notes

AEG G.II (27-28 Total)

G.2-7/15 6 April 1, 1915

G.19-30/15 12 May 6, 1915

G.46-51/15 6 September 7, 1915

Unknown (3-4) Sept. 22, 1915 (note 1)

AEG G.III (46 Total)

G.8/15 1 April 1, 1915 (note 2)

G.52-56/15 5 Sep. 7, 1915 (note 3)

G.210-239/15 30 Dec. 1, 1915 (note 4)

G.143-152/16 10 March 1916 (note 4)

Notes:

1. 12 ordered but only 3-4 delivered

2. Prototype, single rudder, serial unconfirmed.

3. G.53/15 had triple rudders

4. Single rudder

6. The AEG G.I serial was G.1/15.

Despite the wide variety of AEG aircraft that served operationally, AEG is perhaps best known for its twin-engine bombers. These originated from development of a 'battle plane' that was essentially an aerial cruiser armed with flexible machine guns and bombs. This aircraft lead to a series of designs that became twin-engine bombers based on operational experience.

In addition to these G-type bombers, AEG also built the successful N.I single-engine night bomber and a giant bomber, the R.I, that suffered a fatal crash during flight testing.

AEG K.I

In March 1914 the German general staff sanctioned the development of the Kampfflugzeug (battle plane), and in July 1914 Idflieg issued specifications for the type in preparation for a competition planned for spring 1915. The Kampfflugzeug idea was basically an 'aerial cruiser' armed with machine guns and bombs. The aircraft was to have 200 hp, carry a crew of three, and have an endurance of six hours.

AEG responded to the requirement with a biplane powered by two 100 hp Mercedes D.I engines; the factory designation was GZ1 and the military designation was AEG K.I. The K-type designation was soon changed to G-type, the 'G' standing for 'Grossflugzeug' or large aircraft, later to become synonymous with twin-engine bombing aircraft. The K.I had side-by-side seating for two crewmen and a single flexible machine gun was mounted in a nose turret because the aircraft was intended to chase and destroy enemy airplanes. The airframe was constructed of self-fused (autogenous) welded steel tubes. The nose was covered with light armored plate and the rest of the aircraft was fabric covered.

In January 1915 the AEG K.I prototype was first flown by test pilot Willy Kanitz and gave promising results during flight tests in January-February. This convinced Idflieg to order a second prototype as the AEG G.I for combat evaluation.

AEG G.I

The second AEG Kampfflugzeug prototype, now designated AEG G.I but internally retaining the company designation GZ1, was completed in March 1915 and may have incorporated components from the K.I. The G.I differed from the K.I primarily in its crew and armament; the G.I had three crewmen and flexible machine guns in fore and aft turrets. Power remained two 100 hp Mercedes D.I engines.

The AEG G.I was shipped from the factory on April 24, 1915 for the 4.Armee for combat assessment without first being tested at Adlershof. Only one G.I was built.

AEG G.II

Prior to the operational trials of the AEG G.I, Idflieg ordered six aircraft of an improved type, the AEG G.II (factory designation GZ2). Idflieg’s requirements for the AEG G.II included two 150 hp Benz Bz.III engines, a crew of two with three seats, a single machine gun, a 200 kg bomb load, and 150 kg of armor plate (front and side 2.3 mm and floor 1.5 mm). Controlling a multi-engine aircraft after the failure of one engine was dependent on both pilot technique and design of the aircraft; accordingly Idflieg urged AEG "to make every effort to assure that the aircraft would maintain a straight flight path with only one engine running at full power." With the more powerful engines in the G.II a larger fin and rudder were needed to main control with asymmetric thrust.

As expected the more powerful engines gave the AEG G.II better performance and greater load-carrying capability, and Idflieg ordered a second batch of 12 G.II aircraft on May 6, 1915 before the results of the combat trials of the AEG G.I were known. The first two G.II aircraft were completed in May and reached the front in June, with a maximum of 13 at the front in December.

The AEG G.II was not only a new aircraft but was exploring a new combat role as a multi-engine Kampfflugzeug, or aerial cruiser. The G.II was used both to escort single-engine reconnaissance and bomber aircraft and to attack enemy aircraft. Based on operational experience the first six G.II aircraft (G.2-7/15) were extensively modified for both technical and operational reasons, with the result that no two aircraft were alike. The square, armor-plated nose was replaced by a streamlined, unarmored one. Two gravity tanks and new oil tanks were installed. Because the small fin and rudder failed to provide adequate directional control with one engine out, some machines were retro-fitted with triple rudders, becoming standard beginning with the second G.II production batch (G.19-30/15).

Despite all the modifications to the G.II, including adding a second and sometimes a third machine gun, operational experience soon made it clear that the multi-engine Kampfflugzeug concept was a failure. The Kampfflugzeug had only modest success as a multi-seat escort and was too slow and cumbersome to catch faster, more maneuverable enemy aircraft - and most enemy single-seaters were faster and more maneuverable.

However, bomb racks were installed in all G.II aircraft and aircrews soon discovered that bombing was the most effective role for the G.II. By mid-1916 Idflieg summarized the operational record of the G.II saying it "had fared poorly in air combat, but had been successfully employed as a bomber in squadron strength." The AEG G.II thus discovered the true role of the G-type as a bomber. It remained at the front through June 1917 and set the standard for future AEG bombers. A total of 27 G.II aircraft were delivered before production was shifted to the improved G.III in May 1916.

AEG G.III

When Idflieg ordered the first six G.II on April 1, 1915, AEG was also requested to build a Kampfflugzeug with two 220/240 hp engines, the type to be decided later. The intention was to provide greater performance and payload, and the resulting aircraft was designated the AEG G.III (factory designation GZ3). A crew of three, 200 kg of armor protection, and a bomb load of 240 kg were specified. Two machine guns or a cannon mounted in the nose and a rear machine gun was the specified armament.

The G.III was very similar to the G.II although the wingspan was 2.24 m longer. Two of the new, 220 hp Mercedes D.IV straight-eight engines were fitted because these were the most powerful engines then in production. A four-bladed propeller was used to absorb all the power of the engine, but the long crankshaft was subject to fractures in service. The AEG specification chart shows December 1915 as the date the first G.III was completed, but the first three production aircraft were not delivered until May 1916. The G.III prototype was tested with a single fin and rudder and an early production aircraft (G.53/15) was delivered with a triple rudder for comparison. All other production G.III bombers had the single fin and rudder and most had external bomb racks.

The G.III reached the front in June 1916 and was first used as an escort aircraft for single-engine bombers, but it quickly became clear that bombing was the appropriate role for the G.III. Kampfgeschwader 1 became "the first formation to be completely equipped with twin-engine aircraft of the G-category for the sole purpose of bombing." Serving with KG1 in Macedonia, the G.III was primarily used as a bomber but at least two strafing attacks were made. The last three G.III bombers were delivered in January 1917, bringing total G.III production to 45 aircraft; the AEG G.IV then followed the AEG G.III in production.

AEG G-Type Specifications

G.I G.II G.III G.IV G.V

Engine 2x100 hp Mercedes D.I 2x150 hp Benz Bz.III 2x220 hp Mercedes D.IV 2x260 hp Mercedes D.IVa 2x260 hp Mercedes D.IVa

Span Upper 16.00 m 16.20 m 18.44 m 18.40 m 27.24 m

Span Lower 15.20 m 15.20 m 17.20 m 17.40 m 26.30 m

Chord Upper 2.20 m 2.20 m 2.50 m 2.40 m 2.80 m

Chord Lower 2.20 m 2.20 m 2.50 m 2.40 m 2.39 m

Gap 2.30 m 2.30 m 2.60 m 2.20 m 3.00 m

Wing Area 61.0 m2 61.0 m2 74.0 m2 ??? 68.7 m2 127.2 m2

Length 8.7 m 9.1 m 9.20 m 9.70 m 10.80 m

Track 3.15 m 3.15 m 2.85 m 5.10m 4.85 m

Empty Weight 1,160 kg 1,450 kg 1,940 kg 2,400 kg 2,700 kg

Loaded Weight 1,610 kg 2,050 kg 2,560 kg 3,635 kg 4,800 kg

Maximum Speed 125 kmh 140 kmh 150 kmh 165 kmh 145 kmh

Climb, 1000m - 11 min. 6 min. 5 min. 16 min.

Climb, 2000m - - - 11 min. 12 min.

Climb, 3000m - - - 21 min. 23 min.

Climb, 4000m - - - 40 min. 34 min.

Armament 2 flexible machine guns, small bombs 2 flexible machine guns, 200 kg bombs 2 flexible machine guns, 240 kg bombs 2 flexible machine guns, 300 kg bombs 2 flexible machine guns, 1,000 kg bombs

Note: The AEG G.IVb wing span was enlarged to 24 m; this enabled a 1,000 kg bomb to be carried. For short missions up to 1,500 kg of bombs could be carried.

AEG G-Type Production Orders

Serial Numbers Qty Order Date & Notes

AEG G.II (27-28 Total)

G.2-7/15 6 April 1, 1915

G.19-30/15 12 May 6, 1915

G.46-51/15 6 September 7, 1915

Unknown (3-4) Sept. 22, 1915 (note 1)

AEG G.III (46 Total)

G.8/15 1 April 1, 1915 (note 2)

G.52-56/15 5 Sep. 7, 1915 (note 3)

G.210-239/15 30 Dec. 1, 1915 (note 4)

G.143-152/16 10 March 1916 (note 4)

Notes:

1. 12 ordered but only 3-4 delivered

2. Prototype, single rudder, serial unconfirmed.

3. G.53/15 had triple rudders

4. Single rudder

6. The AEG G.I serial was G.1/15.

AEG G.II G.5/15 of B.A.O. This aircraft was flown by Manfred von Richthofen when he was attached to this unit.

AEG G.II of FA Karlhorst. The text on the fuselage translates as: Training Aircraft 5 of the Aircraft Detachment Karlhorst of the Aerial Photography Command.

G.III G.235/15 seen at the Geschwaderschule at Paderborn. Most of the original plain finish has been recovered with night lozenge; the left wheel is uncovered but the right wheel is covered.

AEG G.III G.143/16 seen at the Geschwaderschule at Paderborn. Most of the original plain finish has been recovered with night lozenge.

The AEG K.I designed to the flawed Kampfflugzeug concept was the first twin-engine AEG design. All subsequent AEG G-types followed the same basic configuration; conventional biplanes with fabric-covered steel-tube structures with two engines mounted as tractors. Almost all other German bombers had engines mounted as pushers.The K.I was a compact design with good handling qualities; only one K.I was built.

The AEG G.I differed from the K.I primarily by having an additional crewman with a flexible gun mounted aft. The G.I may have incorporated some components of the K.I.

This AEG G.II is at the factory and has outsize triple rudders fitted without vertical fins. This was a prototype; as seen above the production aircraft with triple rudders had a central fixed fin.

This photo displays AEG G.II G.6/15.The late A.E. Ferko claimed that this was the plane in which Richthofen and Georg Zeumer often flew together.

AEG G.II with triple rudders and fairly dark single color finish. There is a lot of contrast between the overall finish and the white background of the national insignia, especially on the rudders.

AEG G.II with single rudder. The single color finish is so light there is almost no contrast between the overall finish and the white background of the national insignia.

An aviator poses with his AEG G.II with triple-rudders and two-color sprayed camouflage finish. The AEG G-types all followed the same basic configuration; conventional biplanes with steel-tube structures covered by fabric and two engines mounted as tractors. Nearly all other German bombers had engines mounted as pushers.

AEG G.II G.19/15 serving with Flieger-Abteilung 22 features triple rudders and an unarmored nose. It appears to have a two-color sprayed camouflage.

The AEG G.II used 150 hp Benz Bz.III engines. It had additional rudders compared to other AEG bombers. All AEG aircraft used welded steel tube frames covered by fabric.

The AEG G.II used 150 hp Benz Bz.III engines. It had additional rudders compared to other AEG bombers. All AEG aircraft used welded steel tube frames covered by fabric.

Rudolph Berthold standing in the cockpit AEG G.II G.21/15 during a royal visit by Duke Ernst August of Brunswick and Prince August Wilhelm of Prussia to FFA 23 on Oct. 23, 1915.

Rudolph Berthold sits in the cockpit of AEG G.II G.26/15 that he also flew while serving with FFA 23.

Future ace Rudolf Berthold is in the pilot's cockpit as three gunners demonstrate their flexible machine guns in an AEG G.II. The AEG G.II was designed as a battleplane, but the failure of this concept allowed evolution of the G.II into a family of successful bombers.

Future ace Rudolf Berthold is in the pilot's cockpit as three gunners demonstrate their flexible machine guns in an AEG G.II. The AEG G.II was designed as a battleplane, but the failure of this concept allowed evolution of the G.II into a family of successful bombers.

An AEG G.II in flight. This image has also been identified as a G.IV, but the engines and radiators indicate it is a G.II.

AEG G.II with triple-rudders and single color finish. The color appears darker than some of the earlier monotone finishes used on G.II aircraft like that shown above; on this aircraft there is more contrast between the white background for the national insignia and the overall color. Unfortunately, the serial number is not visible.

AEG G.III G.54/15 serving at the front. The four-blade propellers are a key G.III identification feature.

This portrait of an AEG G.III became Sanke Card 1060. The finish was two camouflage colors sprayed on.

A German Twin-engined Bomber. - It will be seen that at last the enemy has apparently been obliged to employ four-bladed airscrews. Hitherto there has been a marked tendency on the part of German constructors to stick to the two-bladed propeller. Also note in place the wire guards protecting against the propeller tips.

A German Twin-engined Bomber. - It will be seen that at last the enemy has apparently been obliged to employ four-bladed airscrews. Hitherto there has been a marked tendency on the part of German constructors to stick to the two-bladed propeller. Also note in place the wire guards protecting against the propeller tips.

AEG G.III G.213/15 tactical number '3' serving with Kagohl I, Kasta 5 based on the Roman numeral on the rudder. The straight-eight cylinder Mercedes had good power but the long crankshaft was subject to failure, especially in multi-engine aircraft.

Closeup of an AEG G.III being serviced. The pilot's headrest is unusual for a twin-engine aircraft. The photo was torn across the bottom.

The touring car, a 30hp Benz 'Runabout', its bonnet marked with Kampfstaffel 7 OHL, about to pull the AEG G.III G.216/15 in overall light finish to the take-off position by means of a wheeled towbar under the tailskid. It also provides transport for the aircrew, already attired in flying kit. The fuel containers and pump previously shown now lie abandoned in the foreground.

AEG G-III на полевом аэродроме.

AEG G.III G.233/15; the enlarged rudder with aerodynamic balance helped the pilot maintain control with an engine out despite its more powerful engines. The aircraft wears a very light overall monotone finish.

The AEG G.III used 220 hp Mercedes D.IV straight-eight engines that drove large, four-bladed propellers. AEG preferred tractor propellers; the other German bomber manufacturers used pusher propellers.

AEG G.III G.233/15; the enlarged rudder with aerodynamic balance helped the pilot maintain control with an engine out despite its more powerful engines. The aircraft wears a very light overall monotone finish.

The AEG G.III used 220 hp Mercedes D.IV straight-eight engines that drove large, four-bladed propellers. AEG preferred tractor propellers; the other German bomber manufacturers used pusher propellers.

The aircrew of an AEG G.III bomber flank damage to their aircraft likely caused by anti-aircraft fire. This photo gives a good view of the complex struts supporting the 220 hp Mercedes D.IV engines.

Twin-engine aircraft were also subject to landing accidents. A gust of wind at the wrong time or poor pilot technique could result in touching down in a sideslip, often with dramatic results.

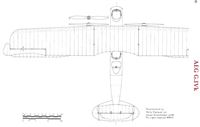

AEG C.IV

The AEG C.II had been insufficiently robust for front-line service and could only be used for training, and the C.III did not have the performance of the Roland C.II. To develop a successful C-type AEG based its C.IV design on the results of the engineering tests done on the C.IIa through C.IIe development prototypes. Attention was also given to speeding production through simplifying the design, rationalizing assembly methods, and building welding jigs to enable production by semi-skilled labor. Outwardly similar to the previous C.I and C.II, the C.IV embodied many detailed structural and aerodynamic improvements and a new wing design that eliminated the unnecessary wing-folding mechanism. Due to the unfortunate experience of the C.II, the C.IV airframe was strengthened and used structural joints machines from solid billets instead of built-up from welded sections. As a result the C.IV had improved strength and durability compared to any of its AEG predecessors.

Powered by a 160 hp Mercedes D.III engine, the C.IV prototype first flew in March 1916. Idflieg awarded AEG a production contract for 100 C.IV aircraft in March 1916 pending successful completion of the static load tests. Unfortunately, a wing spar failed load testing in June and Idflieg refused to accept the AEG C.IV. Idflieg then suggested that AEG build the all-wood Rumpler C.IV under license, but this was clearly not suited for the AEG production methods geared to metal-framed aircraft and the proposal was quickly dropped. In the meantime the AEG C.IV had managed to pass its load tests and was approved for service, the first aircraft reaching the front in October 1916.

At the front the AEG C.IV soon gained a reputation for reliability and speed, but was not an easy aircraft to fly compared to the well-liked Albatros C.III and DFW C.V and some units did not appreciate it. In addition to reconnaissance it also had a useful bombing ability. Never famous like the shapely Roland C.II nor the exceptional Rumpler C.IV, the AEG C.IV was a solid, reliable aircraft that was capable enough to be developed into the production AEG N.I and AEG J.I and J.II.

Its robust metal airframe recommended it for service in the Middle-East where weather and temperature extremes were typical, and C.IV aircraft modified for the heat with larger radiators were delivered to both Turkish units and German units serving in the area. However, the aircraft's structure required welding equipment for even minor repairs, a factor that had been inexplicably overlooked when units using the type quickly found a nearly complete absence of the needed equipment in the area. This small but critical problem seriously reduced C.IV serviceability in the theater.

In January 1918 work was in progress to install a flexible 2cm Becker cannon in a C.IV modified with a larger observer's gun ring. The gun ring operated smoothly but the gunner's position was too cramped for proper loading and aiming of the cannon, and the project was cancelled in April.

AEG C.IV v.R.

AEG lengthened the C.IV fuselage to improve its flying and landing qualities; the modified aircraft was designated the AEG C.IV v.R. (verlangerter Rumpf - lengthened fuselage). This modification is not mentioned in any existing Idflieg records, although the AEG J.II was given a longer fuselage for the same reasons, as were some AEG J.I aircraft. To what extent the long fuselage was incorporated in late production aircraft is unknown.

AEG C.IV(Fok)

By the end of 1916 the Fokker company badly needed a suitable aircraft to manufacture because its own designs had been restricted to training service due to poor design and quality control. To maintain production output and the existing workforce, Idflieg contracted for license production of the AEG C.IV for training service. Fokker was the only other German company with the required welding skills for airframes, and in January 1917 received an order for 200 trainers as the AEG C.IV(Fok). Production deliveries began in July 1917 and the first production aircraft was type-tested in August 1917; deliveries were completed in December 1917.

AEG C.IVa(Fok)

Idflieg ordered 200 AEG C.IVa(Fok) trainers from Fokker in June 1917. The C.IVa(Fok) differed from the C.IV(Fok) in having a 180 hp Argus As.III engine in place of the 160 hp Mercedes D.III; the Mercedes was needed for Albatros and Pfalz fighter production and the Argus was readily available. Fokker delivered 100 of these aircraft between November 1917 and March 1918. However, the remaining 100 aircraft were cancelled to enable Fokker to use the production capacity for its new D.VII fighter.

AEG C.V

When a new engine became available it was common for Idflieg to order new prototypes from several manufacturers; this gave more experience with the new engine and enabled Idflieg to choose the best aircraft for production. When the new 220 hp Mercedes D.IV straight-eight became available Idflieg ordered new C-types powered by this engine from AEG, Albatros, and LVG. The resulting AEG C.V strongly resembled the AEG C.IV that was designed in parallel. Interestingly, the C.V was completed in February 1916, one month before the C.IV. Having a heavier engine, the C.V was slightly larger than the C.IV and was slightly faster. The competing Albatros C.V and LVG C.IV apparently had better performance or flying qualities than the AEG C.V because they were both ordered into production while the AEG C.V was not. Production of the Mercedes D.IV was limited and the engines allocated to AEG were used in the AEG G.III twin-engine bomber.

AEG C.VI

Apparently the AEG C.VI was an un-built project because there is no information about it in existing German records and no photographs exist of an AEG C.VI.

AEG C-Type Production Orders

Serial Numbers Qty Order Date & Notes

AEG C.IV (495 Total)

C.1024-1123/16 100 March 1916

C.6575-6674/16 100 October 1916 (note 1)

C.1700-1799/17 100 April 1917

C.4800-4899/17 100 (May) 1917

C.7052-7126/17 75 July 1917 (note 2)

? 8 December 1917 (note 3)

C.1100-1111/18 12 February 1918 (note 3)

AEG C.IV(Fok) (200 Total)

C.240-439/17 200 January 1917

AEG C.IVa(Fok) ( 100 Total)

C.6500-6699/17 100 January 1917 (note 4)

Notes: 1. Initially order was for 100 Rumpler C.IV(AEG) 2. 25 of these for Turkey, 50 for Germany 3. Special equipment for tropics 4. 200 ordered but only 100 built

AEG C-Type Specifications

C.I C.II C.III C.IV C.IV(Fok)

Engine 150 hp Benz Bz.III 150 hp Benz Bz.III 150 hp Benz Bz.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.07 m 11.95 m 12.00 m 13.00 m 12.99 m

Span Lower 11.83 m 11.45 m 11.30 m 12.50 m 12.36 m

Chord Upper 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Chord Lower 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Gap 1.95 m 1.80 m 1.40 m 1.95 m 1.95 m

Wing Area 36.0 m2 39.0 m2 33.90 m2 39.0 m2 -

Length 7.95 m 7.09 m 6.50 m 7.20 m 7.22 m

Track 2.30 m 2.15 m 2.15 m 2.15 m 2.16 m

Empty Weight 710 kg 680 kg 687 kg 800 kg 901 kg

Loaded Weight 1,125 kg 1,200 kg 1,232 kg 1,320 kg 1,414 kg

Maximum Speed 130 kmh 138 kmh 145 kmh 158 kmh -

Climb, 1000m 11 min. 8 min. - 6 min. 4.8 min.

Climb, 2000m 25 min. 18 min. - 12.5 min. 12.1 min.

Climb, 3000m 55 min. 41 min. - 23 min. 21.9 min.

Climb, 4000m - - - 38 min. 35.4 min.

Armament 1 flexible machine gun, small bombs 1 flexible machine gun, 4x10 kg bombs 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 flexible machine gun

AEG C-Type Specifications

C.V C.VII C.VIII C.VIIIDr

Engine 220 hp Mercedes D.IV 160 hp Mercedes D.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.26 m 11.10m 9.50 m 11.20 m

Span Lower 12.45 m 10.05 m 9.10m 10.40 m

Chord Upper 1.75 m 1.55 m 1.74 m 1.45 m

Chord Lower 1.75 m 1.30 m 1.33 m 0.82 m

Gap 2.07 m 1.85 m 1.60 m 1.00 m

Wing Area 41.5 m2 26.0 m2 22.67 m2 31.0 m2

Length 7.60 m 6.20 m 6.20 m 6.90 m

Track 2.30 m 2.00 m 2.10 m 1.90 m

Empty Weight 900 kg 758 kg 800 kg 800 kg

Loaded Weight 1,432 kg 1,118 kg 1,160 kg 1,160 kg

Maximum Speed 165 kmh 175 kmh 170-190 kmh 158 kmh

Climb, 1000m 7 min. 4 min. 3.8 min. 3.8 min.

Climb, 2000m 13 min. - - -

Climb, 3000m 22 min. - - -

Climb, 4000m 37.5 min. - - -

Armament 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun

The AEG C.II had been insufficiently robust for front-line service and could only be used for training, and the C.III did not have the performance of the Roland C.II. To develop a successful C-type AEG based its C.IV design on the results of the engineering tests done on the C.IIa through C.IIe development prototypes. Attention was also given to speeding production through simplifying the design, rationalizing assembly methods, and building welding jigs to enable production by semi-skilled labor. Outwardly similar to the previous C.I and C.II, the C.IV embodied many detailed structural and aerodynamic improvements and a new wing design that eliminated the unnecessary wing-folding mechanism. Due to the unfortunate experience of the C.II, the C.IV airframe was strengthened and used structural joints machines from solid billets instead of built-up from welded sections. As a result the C.IV had improved strength and durability compared to any of its AEG predecessors.

Powered by a 160 hp Mercedes D.III engine, the C.IV prototype first flew in March 1916. Idflieg awarded AEG a production contract for 100 C.IV aircraft in March 1916 pending successful completion of the static load tests. Unfortunately, a wing spar failed load testing in June and Idflieg refused to accept the AEG C.IV. Idflieg then suggested that AEG build the all-wood Rumpler C.IV under license, but this was clearly not suited for the AEG production methods geared to metal-framed aircraft and the proposal was quickly dropped. In the meantime the AEG C.IV had managed to pass its load tests and was approved for service, the first aircraft reaching the front in October 1916.

At the front the AEG C.IV soon gained a reputation for reliability and speed, but was not an easy aircraft to fly compared to the well-liked Albatros C.III and DFW C.V and some units did not appreciate it. In addition to reconnaissance it also had a useful bombing ability. Never famous like the shapely Roland C.II nor the exceptional Rumpler C.IV, the AEG C.IV was a solid, reliable aircraft that was capable enough to be developed into the production AEG N.I and AEG J.I and J.II.

Its robust metal airframe recommended it for service in the Middle-East where weather and temperature extremes were typical, and C.IV aircraft modified for the heat with larger radiators were delivered to both Turkish units and German units serving in the area. However, the aircraft's structure required welding equipment for even minor repairs, a factor that had been inexplicably overlooked when units using the type quickly found a nearly complete absence of the needed equipment in the area. This small but critical problem seriously reduced C.IV serviceability in the theater.

In January 1918 work was in progress to install a flexible 2cm Becker cannon in a C.IV modified with a larger observer's gun ring. The gun ring operated smoothly but the gunner's position was too cramped for proper loading and aiming of the cannon, and the project was cancelled in April.

AEG C.IV v.R.

AEG lengthened the C.IV fuselage to improve its flying and landing qualities; the modified aircraft was designated the AEG C.IV v.R. (verlangerter Rumpf - lengthened fuselage). This modification is not mentioned in any existing Idflieg records, although the AEG J.II was given a longer fuselage for the same reasons, as were some AEG J.I aircraft. To what extent the long fuselage was incorporated in late production aircraft is unknown.

AEG C.IV(Fok)

By the end of 1916 the Fokker company badly needed a suitable aircraft to manufacture because its own designs had been restricted to training service due to poor design and quality control. To maintain production output and the existing workforce, Idflieg contracted for license production of the AEG C.IV for training service. Fokker was the only other German company with the required welding skills for airframes, and in January 1917 received an order for 200 trainers as the AEG C.IV(Fok). Production deliveries began in July 1917 and the first production aircraft was type-tested in August 1917; deliveries were completed in December 1917.

AEG C.IVa(Fok)

Idflieg ordered 200 AEG C.IVa(Fok) trainers from Fokker in June 1917. The C.IVa(Fok) differed from the C.IV(Fok) in having a 180 hp Argus As.III engine in place of the 160 hp Mercedes D.III; the Mercedes was needed for Albatros and Pfalz fighter production and the Argus was readily available. Fokker delivered 100 of these aircraft between November 1917 and March 1918. However, the remaining 100 aircraft were cancelled to enable Fokker to use the production capacity for its new D.VII fighter.

AEG C.V

When a new engine became available it was common for Idflieg to order new prototypes from several manufacturers; this gave more experience with the new engine and enabled Idflieg to choose the best aircraft for production. When the new 220 hp Mercedes D.IV straight-eight became available Idflieg ordered new C-types powered by this engine from AEG, Albatros, and LVG. The resulting AEG C.V strongly resembled the AEG C.IV that was designed in parallel. Interestingly, the C.V was completed in February 1916, one month before the C.IV. Having a heavier engine, the C.V was slightly larger than the C.IV and was slightly faster. The competing Albatros C.V and LVG C.IV apparently had better performance or flying qualities than the AEG C.V because they were both ordered into production while the AEG C.V was not. Production of the Mercedes D.IV was limited and the engines allocated to AEG were used in the AEG G.III twin-engine bomber.

AEG C.VI

Apparently the AEG C.VI was an un-built project because there is no information about it in existing German records and no photographs exist of an AEG C.VI.

AEG C-Type Production Orders

Serial Numbers Qty Order Date & Notes

AEG C.IV (495 Total)

C.1024-1123/16 100 March 1916

C.6575-6674/16 100 October 1916 (note 1)

C.1700-1799/17 100 April 1917

C.4800-4899/17 100 (May) 1917

C.7052-7126/17 75 July 1917 (note 2)

? 8 December 1917 (note 3)

C.1100-1111/18 12 February 1918 (note 3)

AEG C.IV(Fok) (200 Total)

C.240-439/17 200 January 1917

AEG C.IVa(Fok) ( 100 Total)

C.6500-6699/17 100 January 1917 (note 4)

Notes: 1. Initially order was for 100 Rumpler C.IV(AEG) 2. 25 of these for Turkey, 50 for Germany 3. Special equipment for tropics 4. 200 ordered but only 100 built

AEG C-Type Specifications

C.I C.II C.III C.IV C.IV(Fok)

Engine 150 hp Benz Bz.III 150 hp Benz Bz.III 150 hp Benz Bz.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.07 m 11.95 m 12.00 m 13.00 m 12.99 m

Span Lower 11.83 m 11.45 m 11.30 m 12.50 m 12.36 m

Chord Upper 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Chord Lower 1.60 m 1.85 m 1.60 m 1.65 m 1.65 m

Gap 1.95 m 1.80 m 1.40 m 1.95 m 1.95 m

Wing Area 36.0 m2 39.0 m2 33.90 m2 39.0 m2 -

Length 7.95 m 7.09 m 6.50 m 7.20 m 7.22 m

Track 2.30 m 2.15 m 2.15 m 2.15 m 2.16 m

Empty Weight 710 kg 680 kg 687 kg 800 kg 901 kg

Loaded Weight 1,125 kg 1,200 kg 1,232 kg 1,320 kg 1,414 kg

Maximum Speed 130 kmh 138 kmh 145 kmh 158 kmh -

Climb, 1000m 11 min. 8 min. - 6 min. 4.8 min.

Climb, 2000m 25 min. 18 min. - 12.5 min. 12.1 min.

Climb, 3000m 55 min. 41 min. - 23 min. 21.9 min.

Climb, 4000m - - - 38 min. 35.4 min.

Armament 1 flexible machine gun, small bombs 1 flexible machine gun, 4x10 kg bombs 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 flexible machine gun

AEG C-Type Specifications

C.V C.VII C.VIII C.VIIIDr

Engine 220 hp Mercedes D.IV 160 hp Mercedes D.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.26 m 11.10m 9.50 m 11.20 m

Span Lower 12.45 m 10.05 m 9.10m 10.40 m

Chord Upper 1.75 m 1.55 m 1.74 m 1.45 m

Chord Lower 1.75 m 1.30 m 1.33 m 0.82 m

Gap 2.07 m 1.85 m 1.60 m 1.00 m

Wing Area 41.5 m2 26.0 m2 22.67 m2 31.0 m2

Length 7.60 m 6.20 m 6.20 m 6.90 m

Track 2.30 m 2.00 m 2.10 m 1.90 m

Empty Weight 900 kg 758 kg 800 kg 800 kg

Loaded Weight 1,432 kg 1,118 kg 1,160 kg 1,160 kg

Maximum Speed 165 kmh 175 kmh 170-190 kmh 158 kmh

Climb, 1000m 7 min. 4 min. 3.8 min. 3.8 min.

Climb, 2000m 13 min. - - -

Climb, 3000m 22 min. - - -

Climb, 4000m 37.5 min. - - -

Armament 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun

The AEG C.IV prototype (second version), powered by 160 hp Mercedes D.III, benefited from an improved steel-tube structure compared to the C.II.

AEG C.IV 1103/16 from the first C.IV production batch was captured January 23, 1917 and put on display.

AEG C.IV 1715/17 is run up before its next mission while the aircrew and ground crew pose for a team photograph. The C.IV, powered by the 160 hp Mercedes D.III, was the first AEG C-type to have a synchronized gun for the pilot.

A crewman strikes a jaunty pose by AEG C.IV 1748/17 of the third production batch. The two-color sprayed camouflage typical of AEG practice at the time shows up nicely. Powered by the same 160 hp Mercedes D.III six-cylinder engine used in the Albatros fighters, the AEG C.IV was a competent early C-type whose main claim to fame was its welded steel tube construction. However, undistinguished as it was, it served as the basis for both the AEG J-types and the AEG N.I night bomber.

Fokker-built AEG C.IV(Fok) 277/17 was assigned to the Flieger Beobachter Schule Coln on Sep. 28, 1917 and landed in Heithuizen, the Netherlands, on Dec. 18,1917. After repair and addition of the Dutch orange circle insignia it was assigned Dutch military serial AEG 403 and served in the Netherlands. The streaked finish of the Fokker-built C.IVs was very distinctive.

AEG C.IV with aircrew, one of whom is distinctly taller than the others, serving with FA304b in Palestine.

An AEG C.IV crew ready for their next mission photographed before takeoff. The large, unprotected radiator was vulnerable to ground fire and created significant drag. If it leaked due to damage the hot water spraying over the crew must have been very uncomfortable.

AEG C.IV 7123/17 v.R. (verlangerter Rumpf = lengthened fuselage) serving postwar with the Polish airforce. Large serial numbers were used with training aircraft.

The AEG C.IV differed from the other German C-types in a number of ways, especially its steel tube construction instead of typical wooden structure which made for a light, yet strong airframe. Access to the engine was through vertically-hinged clamshell cowling panels, removed in this view of an example in Polish postwar service.

The AEG C.IV differed from the other German C-types in a number of ways, especially its steel tube construction instead of typical wooden structure which made for a light, yet strong airframe. Access to the engine was through vertically-hinged clamshell cowling panels, removed in this view of an example in Polish postwar service.

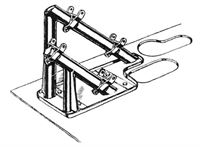

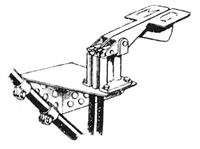

Additional structural details of the AEG C.IV(Fok) at the Fokker factory. Fokker-built AEG C.IVa aircraft were intended for training use; when Fokker received substantial orders for the Fokker D.VII fighter he requested the remaining AEG C.IVa(Fok) aircraft on the order be cancelled to free production capacity for the D.VII and this was granted.

Structural details of the AEG C.IV(Fok) at the Fokker factory. Fokker and AEG were the only two German aircraft manufacturers that used welded steel tube structures. When Fokker's designs fell behind and were not being produced for the front, Fokker was given an order for license-built AEG C.IV aircraft to sustain the factory.

AEG C.IV(Fok) airframes stored at the Fokker factory waiting for engines to be delivered. The streaked finish typical of Fokker F.I and Dr.I triplanes built in parallel with this production order clearly identifies these aircraft as built by Fokker.

On the AEG C.V the unsuccessful Mercedes D.IV was used.

Despite its additional 60 hp, the AEG C.V was only slightly faster than the C.IV designed in parallel.

Despite its additional 60 hp, the AEG C.V was only slightly faster than the C.IV designed in parallel.

AEG C.IV 1724/17 after a landing accident.The serial number painted in large numbers on the fuselage is unusual.

Landing accidents were common during WWI due to the rough fields and sensitivity of the light aircraft to gusts of wind while landing. These two AEG C.IV aircraft demonstrate some of the results. Above is C.IV 6602/16 of the second production batch.

AEG C.IV in Turkish markings after a landing accident. Many AEG C.IV aircraft were sent to the Middle East due to their robust steel-tube airframes, which absorbed the shock of this crash. Apparently no thought was given to the almost total lack of welding equipment in that remote, primitive theater because C.IV serviceability was greatly hampered by its absence. Even minor structural damage was very difficult to repair due to the scarcity of welding equipment.

AEG C.VII

In August 1916 Idflieg issued a requirement for a two-seat escort aircraft. This was to be a lightened C-type, later categorized as a CL-type, powered by a 160-180 hp engine. AEG was one of the companies that responded with a proposal, and in October Idflieg gave AEG a contract for three prototype C.VII aircraft. The C.VII was powered by a 160 hp Mercedes D.III and the first aircraft was completed in December 1916. It was about 20% smaller than the C.IV powered by the same engine. Initial flight testing was apparently done in January 1917 at Nieder-Neuendorf, and the slightly modified C.VII prototype underwent testing in March. The initial Idflieg report (dated April 30, 1917) said the C.VII offered little that was new. The observer's field of fire was considered poor for an escort aircraft and the performance, while superior to the C.IV, was not as good as expected although flying qualities were acceptable. The C.VII was recommended for service on the less-demanding Eastern Front providing the load tests were passed. That recommendation was not compelling and no production was undertaken.

The third C.VII prototype was built with a highly-swept-back wing with minimum gap, intended to improve the gunner's field of fire. However, the competing Halberstadt and Hannover CL-types were superior and were placed in production while the AEG C.VII was not.

AEG C-Type Specifications

C.V C.VII C.VIII C.VIIIDr

Engine 220 hp Mercedes D.IV 160 hp Mercedes D.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.26 m 11.10m 9.50 m 11.20 m

Span Lower 12.45 m 10.05 m 9.10m 10.40 m

Chord Upper 1.75 m 1.55 m 1.74 m 1.45 m

Chord Lower 1.75 m 1.30 m 1.33 m 0.82 m

Gap 2.07 m 1.85 m 1.60 m 1.00 m

Wing Area 41.5 m2 26.0 m2 22.67 m2 31.0 m2

Length 7.60 m 6.20 m 6.20 m 6.90 m

Track 2.30 m 2.00 m 2.10 m 1.90 m

Empty Weight 900 kg 758 kg 800 kg 800 kg

Loaded Weight 1,432 kg 1,118 kg 1,160 kg 1,160 kg

Maximum Speed 165 kmh 175 kmh 170-190 kmh 158 kmh

Climb, 1000m 7 min. 4 min. 3.8 min. 3.8 min.

Climb, 2000m 13 min. - - -

Climb, 3000m 22 min. - - -

Climb, 4000m 37.5 min. - - -

Armament 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun

In August 1916 Idflieg issued a requirement for a two-seat escort aircraft. This was to be a lightened C-type, later categorized as a CL-type, powered by a 160-180 hp engine. AEG was one of the companies that responded with a proposal, and in October Idflieg gave AEG a contract for three prototype C.VII aircraft. The C.VII was powered by a 160 hp Mercedes D.III and the first aircraft was completed in December 1916. It was about 20% smaller than the C.IV powered by the same engine. Initial flight testing was apparently done in January 1917 at Nieder-Neuendorf, and the slightly modified C.VII prototype underwent testing in March. The initial Idflieg report (dated April 30, 1917) said the C.VII offered little that was new. The observer's field of fire was considered poor for an escort aircraft and the performance, while superior to the C.IV, was not as good as expected although flying qualities were acceptable. The C.VII was recommended for service on the less-demanding Eastern Front providing the load tests were passed. That recommendation was not compelling and no production was undertaken.

The third C.VII prototype was built with a highly-swept-back wing with minimum gap, intended to improve the gunner's field of fire. However, the competing Halberstadt and Hannover CL-types were superior and were placed in production while the AEG C.VII was not.

AEG C-Type Specifications

C.V C.VII C.VIII C.VIIIDr

Engine 220 hp Mercedes D.IV 160 hp Mercedes D.III 160 hp Mercedes D.III 160 hp Mercedes D.III

Span Upper 13.26 m 11.10m 9.50 m 11.20 m

Span Lower 12.45 m 10.05 m 9.10m 10.40 m

Chord Upper 1.75 m 1.55 m 1.74 m 1.45 m

Chord Lower 1.75 m 1.30 m 1.33 m 0.82 m

Gap 2.07 m 1.85 m 1.60 m 1.00 m

Wing Area 41.5 m2 26.0 m2 22.67 m2 31.0 m2

Length 7.60 m 6.20 m 6.20 m 6.90 m

Track 2.30 m 2.00 m 2.10 m 1.90 m

Empty Weight 900 kg 758 kg 800 kg 800 kg

Loaded Weight 1,432 kg 1,118 kg 1,160 kg 1,160 kg

Maximum Speed 165 kmh 175 kmh 170-190 kmh 158 kmh

Climb, 1000m 7 min. 4 min. 3.8 min. 3.8 min.

Climb, 2000m 13 min. - - -

Climb, 3000m 22 min. - - -

Climb, 4000m 37.5 min. - - -

Armament 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun 1 fixed & 1 flexible machine gun

Either the first or second AEG C.VII prototype is shown here. Designed as an escort fighter, a category that later became the CL-class, the C.VII was acceptable but not superior, and the excellent Halberstadt CL.II and Hannover CL.II were produced instead.

Either the first or second AEG C.VII prototype is shown here. Designed as an escort fighter, a category that later became the CL-class, the C.VII was acceptable but not superior, and the excellent Halberstadt CL.II and Hannover CL.II were produced instead.

AEG G.IV

The next step in development of the AEG twin-engine bombers was to give the aircraft more powerful and reliable engines, and the G.IV used the new 260 hp Mercedes D.IVa. The new engine not only had more power but was a six-cylinder engine with more robust crankshaft and was notably more reliable than the earlier D.IV straight-eight.

In March 1916 Idflieg placed an initial order for 40 AEG G.IV bombers; the requirements specified a load of 25 x 12 kg or 6 x 50 kg bombs (300 kg total), four machine guns or cannon, a climb to 5,000 meters in 75 minutes, and a top speed of 140 km/h. The G.IV (factory designation GZ4) prototype was completed in September 1916 and exceeded all the requirements except for climb.