Книги

Schiffer

M.Goodall, A.Tagg

British Aircraft before the Great War

743

M.Goodall, A.Tagg - British Aircraft before the Great War /Schiffer/

Deleted by request of (c)Schiffer Publishing

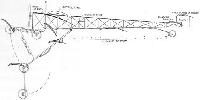

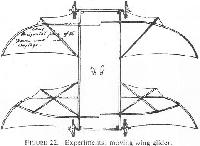

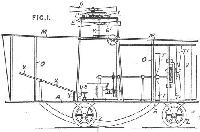

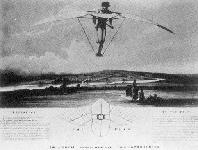

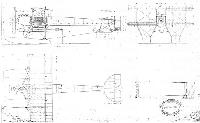

AERIAL MANUFACTURING COMPANY monoplane with subsidiary stabilizers. (Aerial Manufacturing Co. of Great Britain and Ireland, Upper Charles St., Finsbury. Designer W.J. Potter, Elysia, Woodham Ferrers, Essex.)

The machine illustrated was built in 1909 and was flown by Alec Ogilvie at Camber Sands, near Rye in Sussex, at the end of the year for distances up to 250 yards.

The special feature was the undercarriage that folded forward in stages and was designed to provide extra lift at takeoff and to provide a braking effect on landing. This was achieved by mounting two aerofoils on the undercarriage, which presented a change of incidence as the undercarriage was raised or lowered. A fixed aerofoil as wide as the fuselage was also fitted forward of the airscrew together with additional small aerofoils on top of the rudder and below the rear fuselage. Another feature was the fuel tank of aerofoil section.

Power: 50hp believed to be a four-cylinder vee NEC two-stroke as used by Ogilvie in his Short-Wright biplane, driving a four-bladed propeller.

Data

Span 44ft

Length 44ft

In 1910 they were reported to be building a Farman type biplane for Edward Mines.

In January 1910 they were advertising aeroplanes with very imposing names 'The British King', 'The British Queen', 'The Flying Scotsman' and 'The Tradescent'. None of them appear to have been sold and nothing further was heard of them. Potter registered the following patents in 1910: 19198 (monoplane), 20108 (biplane), 21189 and 22475.

The machine illustrated was built in 1909 and was flown by Alec Ogilvie at Camber Sands, near Rye in Sussex, at the end of the year for distances up to 250 yards.

The special feature was the undercarriage that folded forward in stages and was designed to provide extra lift at takeoff and to provide a braking effect on landing. This was achieved by mounting two aerofoils on the undercarriage, which presented a change of incidence as the undercarriage was raised or lowered. A fixed aerofoil as wide as the fuselage was also fitted forward of the airscrew together with additional small aerofoils on top of the rudder and below the rear fuselage. Another feature was the fuel tank of aerofoil section.

Power: 50hp believed to be a four-cylinder vee NEC two-stroke as used by Ogilvie in his Short-Wright biplane, driving a four-bladed propeller.

Data

Span 44ft

Length 44ft

In 1910 they were reported to be building a Farman type biplane for Edward Mines.

In January 1910 they were advertising aeroplanes with very imposing names 'The British King', 'The British Queen', 'The Flying Scotsman' and 'The Tradescent'. None of them appear to have been sold and nothing further was heard of them. Potter registered the following patents in 1910: 19198 (monoplane), 20108 (biplane), 21189 and 22475.

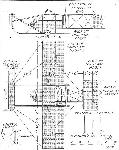

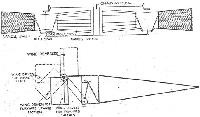

Aerial Manufacturing Company monoplane with folding undercarriage and subsidiary stabilizers covered by Patent No.21 189/1909.

Deleted by request of (c)Schiffer Publishing

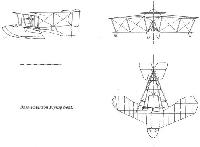

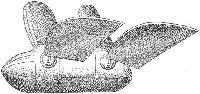

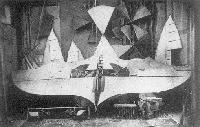

AERIAL WHEEL monoplane. (Aerial Wheel Syndicate Ltd., Ralph Platts and George Sturgess, Mablethorpe, Lincolnshire.)

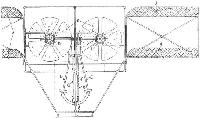

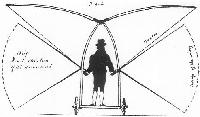

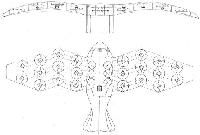

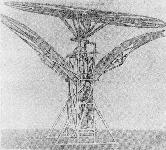

This most unorthodox monoplane arrived incomplete at Larkhill for the Military Trials in September 1912 but although entered as No. 18 it took no part in the trials. The machine, which was built in Birmingham, was a tractor canard with swept wings and was powered by a 50hp NEC four-cylinder, water-cooled, two-stroke engine. A nacelle between the booms that supported the front elevator housed both engine and crew and was surrounded by a circular frame incorporating a revolving tread which, with skids under the wings, constituted the landing gear. Patent No.26 924/1908 was an early version by the Sturgess brothers.

Pilots were reluctant to test the Aerial Wheel and it is believed that the machine was abandoned unflown. It was still in existence in a hangar at the Midland Flying School at Billesley Common, King's Heath, Birmingham when it was wrecked by a gale in the autumn of 1915.

This most unorthodox monoplane arrived incomplete at Larkhill for the Military Trials in September 1912 but although entered as No. 18 it took no part in the trials. The machine, which was built in Birmingham, was a tractor canard with swept wings and was powered by a 50hp NEC four-cylinder, water-cooled, two-stroke engine. A nacelle between the booms that supported the front elevator housed both engine and crew and was surrounded by a circular frame incorporating a revolving tread which, with skids under the wings, constituted the landing gear. Patent No.26 924/1908 was an early version by the Sturgess brothers.

Pilots were reluctant to test the Aerial Wheel and it is believed that the machine was abandoned unflown. It was still in existence in a hangar at the Midland Flying School at Billesley Common, King's Heath, Birmingham when it was wrecked by a gale in the autumn of 1915.

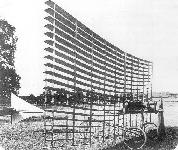

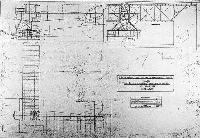

Aerial Wheel monoplane. The design of this 1912 monoplane concentrated on the rough field performance for the Military Trials, but its flying ability was never tested.

Two rough sketches giving an idea of the arrangement and proportions of the monoplane entered by the Aerial Wheel Syndicate.

Deleted by request of (c)Schiffer Publishing

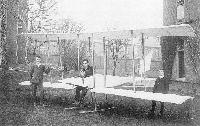

AEROPLANE BUILDING and FLYING SOCIETY gliders. (Sec. W. le Maitre, Workshop Kings Rd., Hammersmith. Shed at Kensal Rise Athletic Ground.)

J.D. North, later chief designer at the Grahame-White Company and Boulton and Paul Aircraft designed a biplane glider with front elevator and tail. This was built in 1910-1911 and donated to the society. Because of the lack of gradient at the ground, a launching apparatus consisting of a trolley on two ropes, giving a gradient of 1 in 6 was prepared. This seems to have been used successfully.

Later it was fitted with a 15hp JAP engine lent by one of the members. It had two propellers, one on each side of the tail. There is no evidence that the machine flew in this form.

A monoplane glider, with a span of 30 ft, designed by AN Myers and donated to the Society was in the shed at the ground in October 1910 and awaiting the fitting of an engine.

Data

Biplane glider

Span 27ft

Length 30ft

Chord 5ft

Weight 130 lb

J.D. North, later chief designer at the Grahame-White Company and Boulton and Paul Aircraft designed a biplane glider with front elevator and tail. This was built in 1910-1911 and donated to the society. Because of the lack of gradient at the ground, a launching apparatus consisting of a trolley on two ropes, giving a gradient of 1 in 6 was prepared. This seems to have been used successfully.

Later it was fitted with a 15hp JAP engine lent by one of the members. It had two propellers, one on each side of the tail. There is no evidence that the machine flew in this form.

A monoplane glider, with a span of 30 ft, designed by AN Myers and donated to the Society was in the shed at the ground in October 1910 and awaiting the fitting of an engine.

Data

Biplane glider

Span 27ft

Length 30ft

Chord 5ft

Weight 130 lb

Deleted by request of (c)Schiffer Publishing

ALDRITT monoplane (Aldritt's Garage, Portlaiose, Ireland)

This Bleriot type monoplane was built by the Aldritts in 1912, but does not seem to have been very successful. The three-cylinder engine was also designed and built by the Aldritts, but was rather heavy. The main wing spars were made of large diameter bamboo poles, possibly from a local market garden.

The monoplane took off and flew several hundred yards, but the excessive weight caused it to make a very heavy landing. The engine was unfortunately sent to a scrap yard by mistake but this very early monoplane still exists, minus engine, as an exhibit at Filching Manor Motor Museum, near Polegate, Sussex.

Data

Span c.40ft

Length c.30ft

This Bleriot type monoplane was built by the Aldritts in 1912, but does not seem to have been very successful. The three-cylinder engine was also designed and built by the Aldritts, but was rather heavy. The main wing spars were made of large diameter bamboo poles, possibly from a local market garden.

The monoplane took off and flew several hundred yards, but the excessive weight caused it to make a very heavy landing. The engine was unfortunately sent to a scrap yard by mistake but this very early monoplane still exists, minus engine, as an exhibit at Filching Manor Motor Museum, near Polegate, Sussex.

Data

Span c.40ft

Length c.30ft

Deleted by request of (c)Schiffer Publishing

ALLEN Flying Bicycle ornithopter (Richard 'Bobby'Allen, Bradford, Yorkshire)

Designed by a policeman, the 'Bobby' Allen Flying Bicycle was exhibited at Stoney Bridge and Peel Park Gala in June 1908. It was built as a bamboo structure on a bicycle and had a wingspan of 33ft.

The machine had three pairs of narrow chord, beating wings driven by a belt passing over the rims of the cycle wheels. Further pulleys at the top of the structure, with cranks converted the drive into reciprocating motion, which actuated the wings. A tall rectangular fin and rudder were mounted at the front, the latter controlled by the cycle handlebars.

The machine refused to fly or even to move along the ground.

Designed by a policeman, the 'Bobby' Allen Flying Bicycle was exhibited at Stoney Bridge and Peel Park Gala in June 1908. It was built as a bamboo structure on a bicycle and had a wingspan of 33ft.

The machine had three pairs of narrow chord, beating wings driven by a belt passing over the rims of the cycle wheels. Further pulleys at the top of the structure, with cranks converted the drive into reciprocating motion, which actuated the wings. A tall rectangular fin and rudder were mounted at the front, the latter controlled by the cycle handlebars.

The machine refused to fly or even to move along the ground.

Deleted by request of (c)Schiffer Publishing

ALVAREZ monoplane (C.G. Spencer and Co. of Highbury, tested at the Welsh Harp at Hendon)

This machine was taken aloft by a 23,000 cubic ft balloon. A larger machine was reported to be under construction in December 1906.

Power: 2hp

Data

Span 40ft

Wing area 400 sq ft

Weight 150 lb

This machine was taken aloft by a 23,000 cubic ft balloon. A larger machine was reported to be under construction in December 1906.

Power: 2hp

Data

Span 40ft

Wing area 400 sq ft

Weight 150 lb

Deleted by request of (c)Schiffer Publishing

AMOORE monoplane (Frank Amoore, Dover, Kent and 4 City Rd., London EC)

This machine was under construction late in 1913 and early 1914, but appears not to have been completed. It incorporated a lateral pendulum arrangement, to maintain the occupant in a perpendicular attitude, by controlling the seat, which swung below the mainplane. This movement, relative to the airframe, automatically operated the ailerons to correct the attitude of the aircraft. The construction was mainly of light steel tubing. British patent No.29252 of 1912 refers.

The system was similar to that patented in France and Britain by Mons J.A. Moreau No.9445/1911, except that the Moreau Aerostable system operated in the longitudinal sense.

Power: 80hp Dutheil-Chalmers either four- or six-cylinder water-cooled.

Data

Span 36ft

Length 24ft 3in

Weight 1,000lb

This machine was under construction late in 1913 and early 1914, but appears not to have been completed. It incorporated a lateral pendulum arrangement, to maintain the occupant in a perpendicular attitude, by controlling the seat, which swung below the mainplane. This movement, relative to the airframe, automatically operated the ailerons to correct the attitude of the aircraft. The construction was mainly of light steel tubing. British patent No.29252 of 1912 refers.

The system was similar to that patented in France and Britain by Mons J.A. Moreau No.9445/1911, except that the Moreau Aerostable system operated in the longitudinal sense.

Power: 80hp Dutheil-Chalmers either four- or six-cylinder water-cooled.

Data

Span 36ft

Length 24ft 3in

Weight 1,000lb

Deleted by request of (c)Schiffer Publishing

ANDERSON and SINGER glider

This Chanute type biplane glider was built at Aberdeen in 1911 and was flown successfully. Glides up to 30 yards were reported after September 1911.

Data

Span 24ft

Wing area 288 sq ft

This Chanute type biplane glider was built at Aberdeen in 1911 and was flown successfully. Glides up to 30 yards were reported after September 1911.

Data

Span 24ft

Wing area 288 sq ft

Deleted by request of (c)Schiffer Publishing

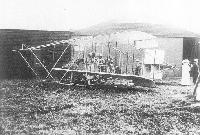

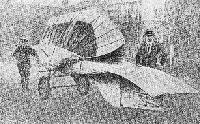

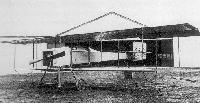

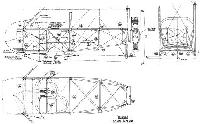

ARMSTRONG monoplane (Gordon Armstrong, Beverley, near Hull, Yorkshire)

No doubt inspired by Bleriot's Channel flight, the monoplane built by Gordon Armstrong, resembled a Bleriot XI in general layout and its use of the 35hp Anzani fan type radial. The levered type suspension and the tip elevators were similar features but the rest of the aircraft appeared to be of original conception.

The fuselage was a triangular section open girder structure with a single bottom longeron, the three longerons curving to a point at the extreme rear. There was no fin and the rectangular shaped rudder was hinged on a vertical post, braced by a diagonal strut. The tail was supported by a flexible strip, clamped to the bottom longeron.

The monoplane was housed at the East Riding Garage and tested at Beverley Westwood on 26 August 1910 and 2 September 1910, damage occurring on both occasions. The machine complete with engine was offered for sale in February 1912.

From small beginnings at Beverley, Armstrong shock absorbers were developed for cars, together with other engineering products, forming the basis of a large engineering company with several factories in Britain and overseas.

No doubt inspired by Bleriot's Channel flight, the monoplane built by Gordon Armstrong, resembled a Bleriot XI in general layout and its use of the 35hp Anzani fan type radial. The levered type suspension and the tip elevators were similar features but the rest of the aircraft appeared to be of original conception.

The fuselage was a triangular section open girder structure with a single bottom longeron, the three longerons curving to a point at the extreme rear. There was no fin and the rectangular shaped rudder was hinged on a vertical post, braced by a diagonal strut. The tail was supported by a flexible strip, clamped to the bottom longeron.

The monoplane was housed at the East Riding Garage and tested at Beverley Westwood on 26 August 1910 and 2 September 1910, damage occurring on both occasions. The machine complete with engine was offered for sale in February 1912.

From small beginnings at Beverley, Armstrong shock absorbers were developed for cars, together with other engineering products, forming the basis of a large engineering company with several factories in Britain and overseas.

The Armstrong monoplane as modified after crashing on its first flight. The tailwheel has been replaced by a Bleriot-type bamboo tail-skid.

Deleted by request of (c)Schiffer Publishing

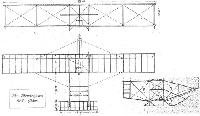

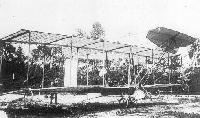

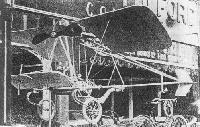

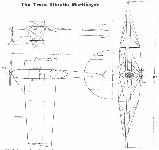

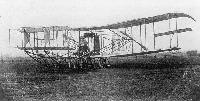

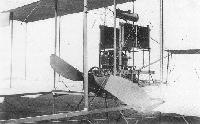

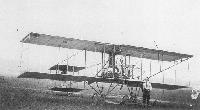

ARMSTRONG WHITWORTH FK.1 (Sir W.G. Armstrong Whitworth Co., Gosforth, Newcastle on Tyne)

This two-seater tractor scout biplane, designed by Dutchman Frederick Koolhoven, was the first type built by the Aircraft Dept of this large company. It was a typical biplane design of the period and flew for the first time in September 1914.

The fuselage was a wooden girder which tapered to a horizontal knife-edge. The single bay wings were not staggered and the top wings were connected at the aircraft centerline, where two inverted vee struts supported them. Parallel chord ailerons were replaced with tapered surfaces with a large rear overhang. No tailplane was originally provided but one was added during the early trials.

The machine was under-powered, having been planned for an 80hp engine, which was not available at the time. The performance was not as good as contemporary types and no production resulted.

Power: 50hp Gnome seven-cylinder air-cooled rotary.

Data

Speed range 30-75 mph

This two-seater tractor scout biplane, designed by Dutchman Frederick Koolhoven, was the first type built by the Aircraft Dept of this large company. It was a typical biplane design of the period and flew for the first time in September 1914.

The fuselage was a wooden girder which tapered to a horizontal knife-edge. The single bay wings were not staggered and the top wings were connected at the aircraft centerline, where two inverted vee struts supported them. Parallel chord ailerons were replaced with tapered surfaces with a large rear overhang. No tailplane was originally provided but one was added during the early trials.

The machine was under-powered, having been planned for an 80hp engine, which was not available at the time. The performance was not as good as contemporary types and no production resulted.

Power: 50hp Gnome seven-cylinder air-cooled rotary.

Data

Speed range 30-75 mph

Armstrong Whitworth FK1. Koolhoven's first design for this large armament company.

The completed F.K.l, also known as the Sissit, was originally designed as a monoplane. It was first flown by Koolhoven himself, probably in 1914.

The completed F.K.l, also known as the Sissit, was originally designed as a monoplane. It was first flown by Koolhoven himself, probably in 1914.

Deleted by request of (c)Schiffer Publishing

ASL. The Aeronautical Syndicate Ltd. (Horatio C. Barber, Hendon Aerodrome, Sheds 5, 6 and 7. Testing at Larkhill discontinued in September 1910. Head Office at 30 Moorgate St., London EC.l)

ASL monoplane No.2

This second machine for Horatio Barber was built by Howard Wright at Battersea in January and February 1910 and was tested at Larkhill, when it flew in the hands of B. Woodrow on the 6 March. (For first machine see Barber Monoplane)

The ASL No.2 was a pusher monoplane of wooden construction with divided four wheel undercarriage and double nose wheels, together with wheels at the wing tips. The tapered wings had considerable camber and control by warping was aided by hinging the rear spar at the fuselage joint.

The monoplane flew for short distances on several occasions and sustained damage but flew successfully again after repair. The ASL No.2 was succeeded by the Valkyrie also of pusher type.

Power: 60hp Green four-cylinder inline water-cooled with 8ft 2in diameter propeller.

Data

Mainplane Span 42ft

Foreplane Span 12ft

Chord 1 Oft tapering to 6ft

Foreplane Chord 3ft

Area 310sqft

Foreplane Area 36sq ft inc. elevators

Length 31ft

Cruising speed 35mph

Weight 8021b

ASL monoplane No.2

This second machine for Horatio Barber was built by Howard Wright at Battersea in January and February 1910 and was tested at Larkhill, when it flew in the hands of B. Woodrow on the 6 March. (For first machine see Barber Monoplane)

The ASL No.2 was a pusher monoplane of wooden construction with divided four wheel undercarriage and double nose wheels, together with wheels at the wing tips. The tapered wings had considerable camber and control by warping was aided by hinging the rear spar at the fuselage joint.

The monoplane flew for short distances on several occasions and sustained damage but flew successfully again after repair. The ASL No.2 was succeeded by the Valkyrie also of pusher type.

Power: 60hp Green four-cylinder inline water-cooled with 8ft 2in diameter propeller.

Data

Mainplane Span 42ft

Foreplane Span 12ft

Chord 1 Oft tapering to 6ft

Foreplane Chord 3ft

Area 310sqft

Foreplane Area 36sq ft inc. elevators

Length 31ft

Cruising speed 35mph

Weight 8021b

Deleted by request of (c)Schiffer Publishing

ASL VALKYRIE monoplanes, Types A, B and C

The first Valkyrie Type A was flown during September 1910 at Larkhill on Salisbury Plain, but was moved soon after to Hendon, where new works had been established in three sheds. It is uncertain whether No. 1 was built at Larkhill or by Howard Wright, but all later machines were certainly made there. Flight of 24 September 1910 (p.774) illustrated No.1 in the air and stated that it was the fifth of a series of experimental models tested on Salisbury Plain over a period of seventeen months. This suggestion of two additional types to those identified may refer to major variations of the Barber and ASL2 monoplanes.

Production of Valkyrie aircraft continued until it was announced in April 1912 that the company was to be closed down, by which time it was reported that nearly 30 machines had been built. Valkyrie No. 11 was the highest number referred to in reports of the time. Most machines were used by ASL for pilot training, some experimental mail flights and the carriage of light freight. On 25 May 1911 pupil Benson was killed in the crash of Type A No.7.

Barber had been discouraged when refused permission to demonstrate any of his five available aircraft, when the Parliamentary Defense Committee visited Hendon on 12 May 1911. Despite this, he presented four machines to the Government in July, three of which had Green engines and one with a Gnome. Two of these were supplied to the Army and two to the Navy at Eastchurch, later moved to Shomcliffe, but it seems that they were never flown.

Various versions of these pusher canard monoplanes were built and flown at Hendon, the original being a single-seater, but other types able to carry one or two passengers, including some referred to as "military" types followed. All were of similar basic type and construction with wooden open fuselages with fabric covered wings and flying surfaces, all extensively wire braced.

The pilot was seated in an exposed position on the level of the top longerons, just in front of the engine; on the three-seater the passengers were positioned on either side of the engine. The radiator on the Green-engined machines was positioned horizontally below the wing center section. A gravity fuel tank above the engine was supplied from a tank by a plunger pump added to the magneto drive of the Green. On the Gnome engined Type B the combined fuel and oil tank was horseshoe shaped and carried on the front of the engine mounting.

No.1 flew originally with rudders close to the structure and no "blinker" fins at the front. Extensions to mount the rudders further aft and the "blinkers" were added to improve control and became standard for all subsequent machines.

Valkyrie Type A monoplane

This was a single-seater for solo practice flying. First flight was on 13 September 1910.

Power: 35hp Green four-cylinder inline driving a 7ft 3in diameter propeller.

Data

Mainplane span 34ft Single surfaced

(The Aero 31ft 6in)

Foreplane span 14ft Single surfaced

Mainplane chord 6ft

Foreplane chord 3ft

Mainplane area 190 sq ft

Foreplane area 42 sq ft

Elevators area 20 sq ft

Length 22ft increased to 28ft

Width between skids 8ft

Weight 520 lb

Valkyrie Type B monoplane

A single-seater for racing or cross-country work. A passenger could be accommodated behind the pilot. First flight was on 12 November 1910.

Power: 50hp Gnome seven-cylinder air-cooled rotary driving a 8ft diameter propeller.

Data

Mainplane span 31ft Single surfaced

Foreplane span 12ft Single surfaced

Mainplane chord 6ft

Foreplane chord 3 ft

Mainplane area 168 sq ft

Foreplane area 42 sq ft

Elevators area 20 sq ft

Length 26ft

Width between skids 8ft 4in

Weight 550 lb

Max speed 70mph

Price ?920

Valkyrie Type C monoplane

Three-seater with passengers seated either side of the engine. First flight was on 13 September 1913.

Power: 60hp Green four-cylinder inline water-cooled.

Data

Mainplane span 39ft double-surfaced

Foreplane span 14ft

Length 29 ft 9in

Mainplane chord 7ft 6in

Foreplane chord 3ft

Mainplane area 302 sq ft

Foreplane area 42 sq ft

Width between skids 9 ft

Weight 800 lb

Max speed 70mph

Price ?1000

The first Valkyrie Type A was flown during September 1910 at Larkhill on Salisbury Plain, but was moved soon after to Hendon, where new works had been established in three sheds. It is uncertain whether No. 1 was built at Larkhill or by Howard Wright, but all later machines were certainly made there. Flight of 24 September 1910 (p.774) illustrated No.1 in the air and stated that it was the fifth of a series of experimental models tested on Salisbury Plain over a period of seventeen months. This suggestion of two additional types to those identified may refer to major variations of the Barber and ASL2 monoplanes.

Production of Valkyrie aircraft continued until it was announced in April 1912 that the company was to be closed down, by which time it was reported that nearly 30 machines had been built. Valkyrie No. 11 was the highest number referred to in reports of the time. Most machines were used by ASL for pilot training, some experimental mail flights and the carriage of light freight. On 25 May 1911 pupil Benson was killed in the crash of Type A No.7.

Barber had been discouraged when refused permission to demonstrate any of his five available aircraft, when the Parliamentary Defense Committee visited Hendon on 12 May 1911. Despite this, he presented four machines to the Government in July, three of which had Green engines and one with a Gnome. Two of these were supplied to the Army and two to the Navy at Eastchurch, later moved to Shomcliffe, but it seems that they were never flown.

Various versions of these pusher canard monoplanes were built and flown at Hendon, the original being a single-seater, but other types able to carry one or two passengers, including some referred to as "military" types followed. All were of similar basic type and construction with wooden open fuselages with fabric covered wings and flying surfaces, all extensively wire braced.

The pilot was seated in an exposed position on the level of the top longerons, just in front of the engine; on the three-seater the passengers were positioned on either side of the engine. The radiator on the Green-engined machines was positioned horizontally below the wing center section. A gravity fuel tank above the engine was supplied from a tank by a plunger pump added to the magneto drive of the Green. On the Gnome engined Type B the combined fuel and oil tank was horseshoe shaped and carried on the front of the engine mounting.

No.1 flew originally with rudders close to the structure and no "blinker" fins at the front. Extensions to mount the rudders further aft and the "blinkers" were added to improve control and became standard for all subsequent machines.

Valkyrie Type A monoplane

This was a single-seater for solo practice flying. First flight was on 13 September 1910.

Power: 35hp Green four-cylinder inline driving a 7ft 3in diameter propeller.

Data

Mainplane span 34ft Single surfaced

(The Aero 31ft 6in)

Foreplane span 14ft Single surfaced

Mainplane chord 6ft

Foreplane chord 3ft

Mainplane area 190 sq ft

Foreplane area 42 sq ft

Elevators area 20 sq ft

Length 22ft increased to 28ft

Width between skids 8ft

Weight 520 lb

Valkyrie Type B monoplane

A single-seater for racing or cross-country work. A passenger could be accommodated behind the pilot. First flight was on 12 November 1910.

Power: 50hp Gnome seven-cylinder air-cooled rotary driving a 8ft diameter propeller.

Data

Mainplane span 31ft Single surfaced

Foreplane span 12ft Single surfaced

Mainplane chord 6ft

Foreplane chord 3 ft

Mainplane area 168 sq ft

Foreplane area 42 sq ft

Elevators area 20 sq ft

Length 26ft

Width between skids 8ft 4in

Weight 550 lb

Max speed 70mph

Price ?920

Valkyrie Type C monoplane

Three-seater with passengers seated either side of the engine. First flight was on 13 September 1913.

Power: 60hp Green four-cylinder inline water-cooled.

Data

Mainplane span 39ft double-surfaced

Foreplane span 14ft

Length 29 ft 9in

Mainplane chord 7ft 6in

Foreplane chord 3ft

Mainplane area 302 sq ft

Foreplane area 42 sq ft

Width between skids 9 ft

Weight 800 lb

Max speed 70mph

Price ?1000

Deleted by request of (c)Schiffer Publishing

ASL VIKING 1 biplane

This was the last design by Horatio Barber and was constructed at Hendon towards the end of 1911. It flew in January 1912 shortly before the closure of the company in April. The pilot and passenger were seated side-by-side behind the rotary engine, which drove the two tractor propellers through chains. Fuel was supplied from two external tanks alongside the cockpit and one in the rear fuselage. The rubber-sprung main undercarriage was supplemented by sprung nose, tail and wing tip skids. The ailerons were mounted on three rear interplane struts. The rudder was above, and the fin below the fuselage.

The first flight was at Hendon on 18 January 1912. The Viking was sold to the Chanter Aviation School at Shoreham, where it was converted into a seaplane. At the same time the twin propeller system was discarded and replaced by a single conventional tractor propeller.

Power: 50hp Gnome driving two 8ft 6in diameter propellers through chains.

Data

Mainplane span 31 ft

Tailplane span 9 ft

Elevator span 9 ft

Mainplane chord 4 ft 6 in

Tailplane chord 2 ft 9 in

Elevator chord 2 ft

Mainplane area 310 sq ft

Foreplane area 24 sq ft

Elevator area 18 sq ft

Length 29 ft 6 in

Cruising speed 55 mph

Endurance 6 hrs

Weight 800 ib

This was the last design by Horatio Barber and was constructed at Hendon towards the end of 1911. It flew in January 1912 shortly before the closure of the company in April. The pilot and passenger were seated side-by-side behind the rotary engine, which drove the two tractor propellers through chains. Fuel was supplied from two external tanks alongside the cockpit and one in the rear fuselage. The rubber-sprung main undercarriage was supplemented by sprung nose, tail and wing tip skids. The ailerons were mounted on three rear interplane struts. The rudder was above, and the fin below the fuselage.

The first flight was at Hendon on 18 January 1912. The Viking was sold to the Chanter Aviation School at Shoreham, where it was converted into a seaplane. At the same time the twin propeller system was discarded and replaced by a single conventional tractor propeller.

Power: 50hp Gnome driving two 8ft 6in diameter propellers through chains.

Data

Mainplane span 31 ft

Tailplane span 9 ft

Elevator span 9 ft

Mainplane chord 4 ft 6 in

Tailplane chord 2 ft 9 in

Elevator chord 2 ft

Mainplane area 310 sq ft

Foreplane area 24 sq ft

Elevator area 18 sq ft

Length 29 ft 6 in

Cruising speed 55 mph

Endurance 6 hrs

Weight 800 ib

Deleted by request of (c)Schiffer Publishing

ASTLEY monoplanes Nos.1 and 2 (H.J.D. Astley, Chequers Court, Ellesborough, near, Tring, Buckinghamshire)

Astley's first machine was at Brooklands in December 1909, where it was photographed with a damaged undercarriage, an occurrence which took place during trials.

The aircraft had an enclosed rectangular section fuselage mounted on a rather weak-looking Bleriot-style undercarriage. The wing spars passed through the fuselage just below the top longerons, the pilot being seated behind the rear spar. The wing was braced by a tall cabane and to the undercarriage and carried small triangular ailerons, hinged at the trailing edge. The fixed fin and tail surfaces were triangular and extended well forward along the fuselage. The elevator was rectangular and in one piece, with small triangular rudders above and below. Separate wheels were provided for control of the moving surfaces, that for the elevator being mounted outside the fuselage on the top longeron.

Astley built a second monoplane in 1910, using the remains of the first, including the engine, in its construction. The undercarriage and front portion of the fuselage were much as before, but the pilot's seat was repositioned on a structure below the bottom longerons. The full length top longerons of No. 1 were shortened and joined to the bottom longerons, midway along the fuselage, where a small tail wheel was fitted on a vertical post. The lower longerons were presumably increased in strength to deal with the loads from the tail, which was of triangular cruciform shape. No fabric was applied to the fuselage. The ailerons were inset into the trailing edges of the wings, which otherwise resembled those of No.1.

No.2 was probably only capable of taxiing and Astley soon discarded these machines and learnt to fly on a Sommer biplane of the Universal Aviation Co. operating from Shed No. 17 at Brooklands, obtaining RAeC certificate No.48 on 24 January 1911. He subsequently carried out many exhibition flights and flew competitively in the UAC Birdling and Bleriot aircraft, including a cross-Channel flight to France and into Germany. He was regarded as a pilot of considerable ability, but was killed in a Bleriot, while performing aerobatics at low level at Belfast on 21 September 1912.

Power: 30-40hp NEC four-cylinder two-stroke inline watercooled

Data

Span 24ft

Length 24ft

Astley's first machine was at Brooklands in December 1909, where it was photographed with a damaged undercarriage, an occurrence which took place during trials.

The aircraft had an enclosed rectangular section fuselage mounted on a rather weak-looking Bleriot-style undercarriage. The wing spars passed through the fuselage just below the top longerons, the pilot being seated behind the rear spar. The wing was braced by a tall cabane and to the undercarriage and carried small triangular ailerons, hinged at the trailing edge. The fixed fin and tail surfaces were triangular and extended well forward along the fuselage. The elevator was rectangular and in one piece, with small triangular rudders above and below. Separate wheels were provided for control of the moving surfaces, that for the elevator being mounted outside the fuselage on the top longeron.

Astley built a second monoplane in 1910, using the remains of the first, including the engine, in its construction. The undercarriage and front portion of the fuselage were much as before, but the pilot's seat was repositioned on a structure below the bottom longerons. The full length top longerons of No. 1 were shortened and joined to the bottom longerons, midway along the fuselage, where a small tail wheel was fitted on a vertical post. The lower longerons were presumably increased in strength to deal with the loads from the tail, which was of triangular cruciform shape. No fabric was applied to the fuselage. The ailerons were inset into the trailing edges of the wings, which otherwise resembled those of No.1.

No.2 was probably only capable of taxiing and Astley soon discarded these machines and learnt to fly on a Sommer biplane of the Universal Aviation Co. operating from Shed No. 17 at Brooklands, obtaining RAeC certificate No.48 on 24 January 1911. He subsequently carried out many exhibition flights and flew competitively in the UAC Birdling and Bleriot aircraft, including a cross-Channel flight to France and into Germany. He was regarded as a pilot of considerable ability, but was killed in a Bleriot, while performing aerobatics at low level at Belfast on 21 September 1912.

Power: 30-40hp NEC four-cylinder two-stroke inline watercooled

Data

Span 24ft

Length 24ft

Deleted by request of (c)Schiffer Publishing

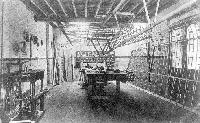

AVRO (ROE) aircraft (Alliott Verdon Roe, later A.V. Roe and Co.)

The early machines built by A. V. Roe were initially identified as Roe types, later the name AVRO was adopted. Manufacture of his first machine was carried out at the home of his brother, Dr. H.V. Roe at 47 West Hill, Putney in 1907, with trials at Brooklands from December until 17 July 1908. The Roe 1 triplanes were also partly made at Putney, but erection and flight trials took place at the Lea Valley, Walthamstow, or at Blackpool.

A.V. Roe and Co. was formed in January 1910 and, from that date, manufacture was carried out at Brownsfield Mills, Great Ancoats St. Manchester with flying at Brooklands. The company became a limited company in January 1913, and moved the factory to Clifton St. Miles Platting, Manchester, in April 1913. The training operations, carried out at Brooklands, had been moved to Shoreham in the previous October, and although some use was made of Brooklands, this ceased by the end of the year. Flying continued from Shoreham and elsewhere until Hamble aerodrome became available much later in wartime.

AVRO aircraft have been extensively researched and are comprehensively dealt with in many publications, to which reference should be made for more complete descriptions and data. The company became a major part of the British aircraft industry and elements of it continue in being to the present day.

ROE I biplane (Avroplane)

The machine was a pusher type canard biplane, mounted on an undercarriage consisting of two pairs of main wheels, spaced well apart, and with small wheels at the wing tips. There was covering on the lower surfaces of the wings and flying controls only, leaving the ribs exposed above.

There was insufficient power to fly with the JAP engine originally used, but towing by car along the Finishing Straight at Brooklands achieved short glides. A later claim to have flown on 8 June 1908 with the Antoinette engine was not accepted officially, through lack of evidence, although hops of a few feet in height were probably accomplished. The Roe I was dismantled in July 1908.

A modern replica of the biplane, and its shed, now exists at the Brooklands Museum.

Power: 6hp JAP vee twin air-cooled driving a four-bladed metal propeller. Replaced by a 24hp Antoinette eight-cylinder vee water-cooled driving a two-bladed metal propeller

Data

Span top 36ft

Additional wing surfaces added to the center section on the fitting of the Antoinette, converting the machine into a semi-triplane.

Length 23 ft

Weight 650 lb loaded

The early machines built by A. V. Roe were initially identified as Roe types, later the name AVRO was adopted. Manufacture of his first machine was carried out at the home of his brother, Dr. H.V. Roe at 47 West Hill, Putney in 1907, with trials at Brooklands from December until 17 July 1908. The Roe 1 triplanes were also partly made at Putney, but erection and flight trials took place at the Lea Valley, Walthamstow, or at Blackpool.

A.V. Roe and Co. was formed in January 1910 and, from that date, manufacture was carried out at Brownsfield Mills, Great Ancoats St. Manchester with flying at Brooklands. The company became a limited company in January 1913, and moved the factory to Clifton St. Miles Platting, Manchester, in April 1913. The training operations, carried out at Brooklands, had been moved to Shoreham in the previous October, and although some use was made of Brooklands, this ceased by the end of the year. Flying continued from Shoreham and elsewhere until Hamble aerodrome became available much later in wartime.

AVRO aircraft have been extensively researched and are comprehensively dealt with in many publications, to which reference should be made for more complete descriptions and data. The company became a major part of the British aircraft industry and elements of it continue in being to the present day.

ROE I biplane (Avroplane)

The machine was a pusher type canard biplane, mounted on an undercarriage consisting of two pairs of main wheels, spaced well apart, and with small wheels at the wing tips. There was covering on the lower surfaces of the wings and flying controls only, leaving the ribs exposed above.

There was insufficient power to fly with the JAP engine originally used, but towing by car along the Finishing Straight at Brooklands achieved short glides. A later claim to have flown on 8 June 1908 with the Antoinette engine was not accepted officially, through lack of evidence, although hops of a few feet in height were probably accomplished. The Roe I was dismantled in July 1908.

A modern replica of the biplane, and its shed, now exists at the Brooklands Museum.

Power: 6hp JAP vee twin air-cooled driving a four-bladed metal propeller. Replaced by a 24hp Antoinette eight-cylinder vee water-cooled driving a two-bladed metal propeller

Data

Span top 36ft

Additional wing surfaces added to the center section on the fitting of the Antoinette, converting the machine into a semi-triplane.

Length 23 ft

Weight 650 lb loaded

Deleted by request of (c)Schiffer Publishing

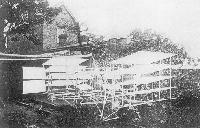

ROE I Triplane (Bulls-Eye Avroplane)

Two of these triplanes were built; No.1 was made at Putney and erected and tested at Lea Valley, Walthamstow. Flight trials of No.2 were carried out at Wembley Park and Brooklands.

A.V. Roe had two triplanes of different types, under construction in the railway arch workshops in the Lea Valley in 1909. The larger one, for car dealer Friswell, was not completed and was auctioned incomplete. The smaller machine was assembled and flown on 23 July 1909, becoming the first all-British machine to fly. It was then taken to Blackpool with second machine of similar type, which was not able to fly at the Meeting. The first triplane was discarded after the Blackpool Meeting and has been on display at the Science Museum since 1925.

The second triplane, with a tail skid instead of a wheel, was taken to the Old Deer Park, Richmond, but since facilities were unsuitable, was moved in November 1909 to Wembley Park, where it flew on 6 December 1909. Brooklands aerodrome was properly established in 1910, and Roe moved the triplane there, housing it in Shed No. 14. It flew in various forms until dismantled in May 1910.

Variations were made in the course of development which included a tapered fuselage to the second aircraft, repositioned fuel tank and a later type undercarriage on this machine known as the 'Two-and-a-Bit Plane'.

On both machines the tailplanes were fixed lifting surfaces and pitch control was by varying the incidence of the mainplanes, which could also be warped to provide roll control. Additional fin area between the outboard struts of the triplane tail was originally fitted to No.1. This system was inadequate for fully controlled flight.

Power: 6hp JAP vee twin air-cooled with four-bladed metal propeller; also a 9-10hp JAP vee twin was fitted to the first machine at a later stage. A 14-20hp JAP vee four-cylinder air-cooled with four-bladed metal propeller was fitted to the second machine.

Data

Mainplane span 20 ft

Mainplane chord 3ft 6in

Mainplane area 210 sq ft

Tailplane span 10ft

Tailplane chord 3ft 6in

Tailplane area 105 sq ft

Length 20 ft

Weight loaded 450 lb

Two upper planes later extended and lower planes reduced on the second machine only, then nicknamed 'Two-and-a-Bit Plane'.

ROE II triplanes (No.1 Mercury)

Two of these machines were built at Brownsfield Mills and flown at Brooklands. They were built of better materials and had improved design features. Most of the fuselage was covered with light wooden sheeting, the rest with fabric. The wings and tail unit were now inter connected, to enable the incidence of both to be controlled.

A triangulated undercarriage, as fitted to the 'Two-and-a-Bit Plane', was used and although wing warping was used initially, this was superseded by ailerons fitted to the center wing from 27 April 1910, and a rudder the full height of the tail unit. A water-cooled Green engine with small vertical radiator behind, provided the power. A second cockpit in front of the pilot could accommodate a passenger.

No. 1 was exhibited at the Manchester Aero Club Exhibition at White City, Manchester, on 4 March 1910, when it was named Mercury; then it appeared at the Olympia Aero Show in London between 11-19 March 1910. The first flight trials followed at Brooklands, with several minor incidents, before the machine was prepared for dispatch by rail to Blackpool for the flying meeting. Roe II No.1, with the successor Roe III, were accidentally burnt on the train on 27 July 1910. No.2 was built for W.G. Windham, being ordered by him at Olympia. It flew for the first time on 26 May 1910. And remained at Brooklands, being used intermittently by the owner.

Power: 35hp Green four-cylinder inline water-cooled driving a 8ft diameter wooden propeller.

Data

Mainplane span 26 ft

Mainplane chord 3 ft 6in

Mainplane area 280 sq ft

Tailplane span 8ft 4in

Tailplane chord 3ft

Tailplane area. 75 sq ft

Length 23 ft

Weight allup 550 lb

Two of these triplanes were built; No.1 was made at Putney and erected and tested at Lea Valley, Walthamstow. Flight trials of No.2 were carried out at Wembley Park and Brooklands.

A.V. Roe had two triplanes of different types, under construction in the railway arch workshops in the Lea Valley in 1909. The larger one, for car dealer Friswell, was not completed and was auctioned incomplete. The smaller machine was assembled and flown on 23 July 1909, becoming the first all-British machine to fly. It was then taken to Blackpool with second machine of similar type, which was not able to fly at the Meeting. The first triplane was discarded after the Blackpool Meeting and has been on display at the Science Museum since 1925.

The second triplane, with a tail skid instead of a wheel, was taken to the Old Deer Park, Richmond, but since facilities were unsuitable, was moved in November 1909 to Wembley Park, where it flew on 6 December 1909. Brooklands aerodrome was properly established in 1910, and Roe moved the triplane there, housing it in Shed No. 14. It flew in various forms until dismantled in May 1910.

Variations were made in the course of development which included a tapered fuselage to the second aircraft, repositioned fuel tank and a later type undercarriage on this machine known as the 'Two-and-a-Bit Plane'.

On both machines the tailplanes were fixed lifting surfaces and pitch control was by varying the incidence of the mainplanes, which could also be warped to provide roll control. Additional fin area between the outboard struts of the triplane tail was originally fitted to No.1. This system was inadequate for fully controlled flight.

Power: 6hp JAP vee twin air-cooled with four-bladed metal propeller; also a 9-10hp JAP vee twin was fitted to the first machine at a later stage. A 14-20hp JAP vee four-cylinder air-cooled with four-bladed metal propeller was fitted to the second machine.

Data

Mainplane span 20 ft

Mainplane chord 3ft 6in

Mainplane area 210 sq ft

Tailplane span 10ft

Tailplane chord 3ft 6in

Tailplane area 105 sq ft

Length 20 ft

Weight loaded 450 lb

Two upper planes later extended and lower planes reduced on the second machine only, then nicknamed 'Two-and-a-Bit Plane'.

ROE II triplanes (No.1 Mercury)

Two of these machines were built at Brownsfield Mills and flown at Brooklands. They were built of better materials and had improved design features. Most of the fuselage was covered with light wooden sheeting, the rest with fabric. The wings and tail unit were now inter connected, to enable the incidence of both to be controlled.

A triangulated undercarriage, as fitted to the 'Two-and-a-Bit Plane', was used and although wing warping was used initially, this was superseded by ailerons fitted to the center wing from 27 April 1910, and a rudder the full height of the tail unit. A water-cooled Green engine with small vertical radiator behind, provided the power. A second cockpit in front of the pilot could accommodate a passenger.

No. 1 was exhibited at the Manchester Aero Club Exhibition at White City, Manchester, on 4 March 1910, when it was named Mercury; then it appeared at the Olympia Aero Show in London between 11-19 March 1910. The first flight trials followed at Brooklands, with several minor incidents, before the machine was prepared for dispatch by rail to Blackpool for the flying meeting. Roe II No.1, with the successor Roe III, were accidentally burnt on the train on 27 July 1910. No.2 was built for W.G. Windham, being ordered by him at Olympia. It flew for the first time on 26 May 1910. And remained at Brooklands, being used intermittently by the owner.

Power: 35hp Green four-cylinder inline water-cooled driving a 8ft diameter wooden propeller.

Data

Mainplane span 26 ft

Mainplane chord 3 ft 6in

Mainplane area 280 sq ft

Tailplane span 8ft 4in

Tailplane chord 3ft

Tailplane area. 75 sq ft

Length 23 ft

Weight allup 550 lb

Deleted by request of (c)Schiffer Publishing

AVRO Farman type biplane

In 1910 a machine was constructed for M.F. Edwards of Bolton with a 20hp two-cylinder two-stroke engine, which although identified as an Avro engine, was designed by M.F. and W. Edwards and made by H.W. Cowley and Co. of Daubhill, Bolton. No details of the machine are available, but it was owned by a Manchester group of enthusiasts, including four Edwards brothers, until advertised for sale at the end of 1912.

In 1910 a machine was constructed for M.F. Edwards of Bolton with a 20hp two-cylinder two-stroke engine, which although identified as an Avro engine, was designed by M.F. and W. Edwards and made by H.W. Cowley and Co. of Daubhill, Bolton. No details of the machine are available, but it was owned by a Manchester group of enthusiasts, including four Edwards brothers, until advertised for sale at the end of 1912.

Deleted by request of (c)Schiffer Publishing

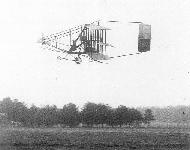

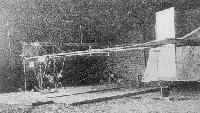

ROE III triplanes

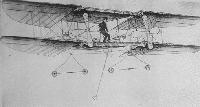

This was a larger machine capable of carrying a passenger in front of the pilot, facing either forward or aft. A major change from Roe II was to fix the wings at the fuselage and rely on the tail unit for control in pitch. Ailerons were fitted to the top wing on the first machine and on the center wing on the three subsequent machines. The substantial undercarriage was of Farman type with four wheels, although it is believed that on the fourth machine, only two were used. A JAP engine was fitted to the first machine and Green engines to the remainder.

This was the first Avro machine capable of fully controlled flight. 'AV' had flown "straights" on it for the first time on 4 July 1910. By 9 July 1910 he was making turns and figures of eight, being airborne for up to twenty-five minutes. He took his tests for the RAeC certificate on the 20 July 1910 and was issued with No. 18 a week later.

Power: 35hp JAP eight-cylinder air-cooled vee. 35hp Green four-cylinder inline water-cooled.

Data

Top and center span 31ft

Bottom span 20ft

Mainplane chord 3 ft 6in

Mainplane area 287 sq ft

Length 23ft

Tailplane span 8ft 4in

Tailplane chord 3ft

Tailplane area 75 sq ft

Weight allup 750 lb

No.1 35hp JAP first flown at Brooklands 24 June 1910. For sale May 1911.

No.2 35hp Green first flown at Brooklands 9 July 1910. Burnt on train on way to the Blackpool Flying Meeting 27 July 1910.

No.3 35hp Green Replacement built urgently after loss of No.2. Assembled at Blackpool. First flown at Blackpool 1 August 1910. Destroyed at Boston on 8 August 1910

No.4 35hp Green supplied to the Harvard Aeronautical Society less engine. First flown at Boston, Massachusetts in the United States using engine from No.3. Crashed but rebuilt.

This was a larger machine capable of carrying a passenger in front of the pilot, facing either forward or aft. A major change from Roe II was to fix the wings at the fuselage and rely on the tail unit for control in pitch. Ailerons were fitted to the top wing on the first machine and on the center wing on the three subsequent machines. The substantial undercarriage was of Farman type with four wheels, although it is believed that on the fourth machine, only two were used. A JAP engine was fitted to the first machine and Green engines to the remainder.

This was the first Avro machine capable of fully controlled flight. 'AV' had flown "straights" on it for the first time on 4 July 1910. By 9 July 1910 he was making turns and figures of eight, being airborne for up to twenty-five minutes. He took his tests for the RAeC certificate on the 20 July 1910 and was issued with No. 18 a week later.

Power: 35hp JAP eight-cylinder air-cooled vee. 35hp Green four-cylinder inline water-cooled.

Data

Top and center span 31ft

Bottom span 20ft

Mainplane chord 3 ft 6in

Mainplane area 287 sq ft

Length 23ft

Tailplane span 8ft 4in

Tailplane chord 3ft

Tailplane area 75 sq ft

Weight allup 750 lb

No.1 35hp JAP first flown at Brooklands 24 June 1910. For sale May 1911.

No.2 35hp Green first flown at Brooklands 9 July 1910. Burnt on train on way to the Blackpool Flying Meeting 27 July 1910.

No.3 35hp Green Replacement built urgently after loss of No.2. Assembled at Blackpool. First flown at Blackpool 1 August 1910. Destroyed at Boston on 8 August 1910

No.4 35hp Green supplied to the Harvard Aeronautical Society less engine. First flown at Boston, Massachusetts in the United States using engine from No.3. Crashed but rebuilt.

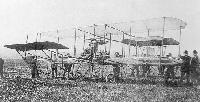

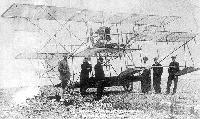

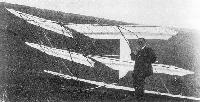

A. V. Roe seated in the 35 h.p. Green engined Roe III triplane at Squantum Point, Boston, U.S.A. in September 1911. This machine was destroyed by fire on the train on the way to the Blackpool Meeting. (Green engine).

Roe III Triplane. Four of these were built, including one exported to the United States. (JAP engine).

Deleted by request of (c)Schiffer Publishing

ROE IV triplane

This single-seater, developed from the earlier machines, was the last of A.V. Roe's triplanes. It incorporated a single tailplane with elevators but reverted to warping wings with the bottom wing of narrow chord. The single machine built was retained at Brooklands for the Avro Flying School. It was crashed on several occasions, including a crash on 14 February 1911, when the opportunity was taken, during the subsequent repair, to insert an extra 4ft length in the fuselage. The Roe IV first flew in September 1910 and was operated until August 1911.

Power: 35hp Green four-cylinder inline water-cooled.

Data

Top and center span 32 ft

Top and center chord 3ft 6in

Bottom span 20 ft

Bottom chord 3 ft

Area 284 sq ft

Weight allup 650 lb

Length 30 ft

(Later extended to 34 ft.)

This single-seater, developed from the earlier machines, was the last of A.V. Roe's triplanes. It incorporated a single tailplane with elevators but reverted to warping wings with the bottom wing of narrow chord. The single machine built was retained at Brooklands for the Avro Flying School. It was crashed on several occasions, including a crash on 14 February 1911, when the opportunity was taken, during the subsequent repair, to insert an extra 4ft length in the fuselage. The Roe IV first flew in September 1910 and was operated until August 1911.

Power: 35hp Green four-cylinder inline water-cooled.

Data

Top and center span 32 ft

Top and center chord 3ft 6in

Bottom span 20 ft

Bottom chord 3 ft

Area 284 sq ft

Weight allup 650 lb

Length 30 ft

(Later extended to 34 ft.)

Deleted by request of (c)Schiffer Publishing

AVRO monoplane

A scheme for a monoplane was advertised in 'The Aviator's Storehouse', the AVRO catalogue, in 1910. The machine was not built. The price less engine was ?200.

Power: 20 or 40hp Avro engine. These were two-stroke engines designed by M.F. and W. Edwards and made by H.W. Cowley of Bolton. The smaller engine was a horizontally opposed two-cylinder air-cooled type, the larger a four-cylinder. 20hp or 35hp JAP or NEC with two or four cylinders were also offered. The JAPs were air-cooled two or four-cylinder vee types. The NECs were water-cooled two-stroke inlines and vee-fours. 35hp Green four-cylinder inline water-cooled could also be used.

Data

Span 36ft

Area 220 sq ft

Price 20hp Avro ?325

with engine 20hp JAP or NEC ?375

AVRO biplane

Also advertised in 'The Aviator's Storehouse' and again, never built, was a biplane with the engine alternatives as for the monoplane. The price less engine was ?225

Data

Span 29ft

Area 350 sq ft

Length 21ft

Height 7ft 6in

Weight 250 lb less engine

Prices 20hp Avro ?350

with engine 20hp JAP or NEC ?400

35hp JAP or NEC ?500

35hp Green ?550

40hp Avro ?450

AVRO Type D biplanes

The first of these biplanes arrived from Manchester in March and was flown for the first time on 1 April 1911 at Brooklands by Howard Pixton. The fuselage and tail surfaces were similar to those of the Roe IV, but with two bay warping biplane wings, plus a partial center section bay. A further six were built in about a year after the first had flown, and these varied in a number of respects. Several types of engine were used, radiator positions were changed, the tailplane shape became rectangular and two machines were converted to sesquiplanes for competition work. Although the basic Type D was a two-seater, provision of an extra fuel tank and other changes converted the machine to a single-seater The prototype was sold for ?700 to Cdr. Schwann RN, for seaplane experiments and was used with seven types of floats, both single and twin type, flown mainly by S.V Sippe at Barrow-in-Furness.

Power:

35hp Green four-cylinder inline water-cooled.

45hp Green with drilled cylinder barrels.

60hp ENV type F eight-cylinder water-cooled vee.

35hp Viale five-cylinder air-cooled radial.

50hp Isaacson seven-cylinder air-cooled radial.

Data

Span top 31ft

Bottom 31ft

Chord 5ft

Area 310 sq ft

Length 28 ft (No. 1 26 ft)

Height 9 ft 2in

Weight allup 500 lb

Sesquiplane

Span top 33ft

Bottom 23ft (No.2 28ft)

Chord 5ft

Area 279 sq ft (No.2 329 sq ft)

Weight allup 550 lb

Speed 45-50 mph

Seaplane 40 mph

No.1 35 and 45hp Green. First flown at Brooklands 1 April 1911. Converted to a seaplane at Barrow-in-Furness from August 1911. Last reported in use April 1912.

No.2 60hp ENV Intended for Circuit of Britain. First flown Brooklands 18 July 1911, but crashed 22 July 1911. Converted to sesquiplane with large triangular tailplane. Extensions fitted to lower wings were unsuccessful.

No.3 35hp Green with slanting radiator. First flown Brooklands 12 October 1911. Used by the Avro School at Brooklands and Shoreham until May 1914.

No.4 45hp Green with fore and aft radiator. Single-seater. First flown at Brooklands 12 October 1911. Abortive attempt at Michelin Prize but used mainly by the Avro School at Brooklands and Shoreham until May 1914.

No.5 35hp Green. Sesquiplane similar to No.2. First flown Brooklands October-November 1911. Reported for sale at Shed No.4 in May 1912 and scrapped in December at Brooklands.

No.6 50hp Viale. School machine. First flown at Brooklands 20 November 1911 and crashed at Abingdon 29 January 1912. The engine was installed by Mons Ducrocq, agent for Viale, and Jack Alcock, later of Atlantic fame.

No.7 50hp Isaacson. School machine. Completed November-December 1911, used at Brooklands and Shoreham until May 1914.

A scheme for a monoplane was advertised in 'The Aviator's Storehouse', the AVRO catalogue, in 1910. The machine was not built. The price less engine was ?200.

Power: 20 or 40hp Avro engine. These were two-stroke engines designed by M.F. and W. Edwards and made by H.W. Cowley of Bolton. The smaller engine was a horizontally opposed two-cylinder air-cooled type, the larger a four-cylinder. 20hp or 35hp JAP or NEC with two or four cylinders were also offered. The JAPs were air-cooled two or four-cylinder vee types. The NECs were water-cooled two-stroke inlines and vee-fours. 35hp Green four-cylinder inline water-cooled could also be used.

Data

Span 36ft

Area 220 sq ft

Price 20hp Avro ?325

with engine 20hp JAP or NEC ?375

AVRO biplane

Also advertised in 'The Aviator's Storehouse' and again, never built, was a biplane with the engine alternatives as for the monoplane. The price less engine was ?225

Data

Span 29ft

Area 350 sq ft

Length 21ft

Height 7ft 6in

Weight 250 lb less engine

Prices 20hp Avro ?350

with engine 20hp JAP or NEC ?400

35hp JAP or NEC ?500

35hp Green ?550

40hp Avro ?450

AVRO Type D biplanes

The first of these biplanes arrived from Manchester in March and was flown for the first time on 1 April 1911 at Brooklands by Howard Pixton. The fuselage and tail surfaces were similar to those of the Roe IV, but with two bay warping biplane wings, plus a partial center section bay. A further six were built in about a year after the first had flown, and these varied in a number of respects. Several types of engine were used, radiator positions were changed, the tailplane shape became rectangular and two machines were converted to sesquiplanes for competition work. Although the basic Type D was a two-seater, provision of an extra fuel tank and other changes converted the machine to a single-seater The prototype was sold for ?700 to Cdr. Schwann RN, for seaplane experiments and was used with seven types of floats, both single and twin type, flown mainly by S.V Sippe at Barrow-in-Furness.

Power:

35hp Green four-cylinder inline water-cooled.

45hp Green with drilled cylinder barrels.

60hp ENV type F eight-cylinder water-cooled vee.

35hp Viale five-cylinder air-cooled radial.

50hp Isaacson seven-cylinder air-cooled radial.

Data

Span top 31ft

Bottom 31ft

Chord 5ft

Area 310 sq ft

Length 28 ft (No. 1 26 ft)

Height 9 ft 2in

Weight allup 500 lb

Sesquiplane

Span top 33ft

Bottom 23ft (No.2 28ft)

Chord 5ft

Area 279 sq ft (No.2 329 sq ft)

Weight allup 550 lb

Speed 45-50 mph

Seaplane 40 mph

No.1 35 and 45hp Green. First flown at Brooklands 1 April 1911. Converted to a seaplane at Barrow-in-Furness from August 1911. Last reported in use April 1912.

No.2 60hp ENV Intended for Circuit of Britain. First flown Brooklands 18 July 1911, but crashed 22 July 1911. Converted to sesquiplane with large triangular tailplane. Extensions fitted to lower wings were unsuccessful.

No.3 35hp Green with slanting radiator. First flown Brooklands 12 October 1911. Used by the Avro School at Brooklands and Shoreham until May 1914.

No.4 45hp Green with fore and aft radiator. Single-seater. First flown at Brooklands 12 October 1911. Abortive attempt at Michelin Prize but used mainly by the Avro School at Brooklands and Shoreham until May 1914.

No.5 35hp Green. Sesquiplane similar to No.2. First flown Brooklands October-November 1911. Reported for sale at Shed No.4 in May 1912 and scrapped in December at Brooklands.

No.6 50hp Viale. School machine. First flown at Brooklands 20 November 1911 and crashed at Abingdon 29 January 1912. The engine was installed by Mons Ducrocq, agent for Viale, and Jack Alcock, later of Atlantic fame.

No.7 50hp Isaacson. School machine. Completed November-December 1911, used at Brooklands and Shoreham until May 1914.

Deleted by request of (c)Schiffer Publishing

AVRO-BURGA monoplane

While the Type E prototype was being built at Manchester, a monoplane to the design of Lt. Burga of the Peruvian Navy was in hand, in which a unique system of lateral control by rudders, above and below the fuselage, was featured. These operated in opposed directions and served instead of ailerons or wing warping. Wings of alternative sections and set at various angles of incidence could be fitted. The narrow fuselage, tail unit and undercarriage owed much to the Avro Type E.

Construction took place throughout 1912 and first flight at Shoreham on 12 November 1912, piloted by H.R. Simms. After severe damage in January 1913 the monoplane was returned to Manchester but was not repaired.

Power: 50hp Gnome seven-cylinder air-cooled rotary.

Data Length 29ft

While the Type E prototype was being built at Manchester, a monoplane to the design of Lt. Burga of the Peruvian Navy was in hand, in which a unique system of lateral control by rudders, above and below the fuselage, was featured. These operated in opposed directions and served instead of ailerons or wing warping. Wings of alternative sections and set at various angles of incidence could be fitted. The narrow fuselage, tail unit and undercarriage owed much to the Avro Type E.

Construction took place throughout 1912 and first flight at Shoreham on 12 November 1912, piloted by H.R. Simms. After severe damage in January 1913 the monoplane was returned to Manchester but was not repaired.

Power: 50hp Gnome seven-cylinder air-cooled rotary.

Data Length 29ft

The monoplane built by A.V. Roe for Lt. R. Burga of the Peruvian Navy, at Shoreham in November 1912.

Deleted by request of (c)Schiffer Publishing

AVRO Duigan biplane

This biplane was made to an order from John R. Duigan, an Australian, who had built his own Wright type glider and Farman-type powered aircraft in 1909-1911, with which he achieved a number of successful flights. He came to England to learn more of current practice and to receive flying instruction.

On arrival he ordered a biplane from Avro, which was built at Manchester and delivered to Huntingdon, when completed in December 1911. The machine was not a great success and Duigan took it back to Brooklands. After some limited straight flights in February, Duigan joined the Avro school. At Brooklands the original Alvaston engine was replaced by an ENV, and together with improvements, the machine was eventually capable of flying for one hour at up to 600ft with the pilot only; flights with a passenger were limited to "straights".

Duigan returned to Australia and his Avro was bought by the Lakes Flying Co. for ?180 and was moved to Windermere on 4 June 1912. At Windermere it was largely rebuilt with a new engine and became the Lakes Sea Bird (q.v.).

This Avro biplane had a deep fuselage with radiators positioned either side of the front cockpit; wing warping was employed. The undercarriage had a leaf spring axle with a central skid. The skid became a feature of many later Avro aircraft. In its final form this machine was the basis of the next type, a much-improved machine, which eventually led to the outstanding Type 504.

Power:

40hp Alvaston two-cylinder horizontally opposed water-cooled

35hp ENV type D eight-cylinder water-cooled vee.

Data

Span 34ft

Chord 4ft 6in

Length 29ft 6in

Area 300 sq ft

Speed 40mph

AVRO Type. E and Es (later known as Types 500 and 502)

This was a slightly larger version of the biplane built for John Duigan, more powerful and able to fly successfully as a two-seater. It was built to meet an official requirement and was often referred to as the 'Military Biplane'. The first flight took place at Brooklands on 14 March 1912 in the hands of Lt. Wilfred Parke RN. Testing proceeded, following which an entry was made for the Mortimer Singer Prize of ?500, offered to an army or navy officer who flew the longest flight with a passenger, in Britain, before the end of March. Parke left Brooklands with W.H. Sayers on 20 March 1912 for Hendon for his bid, but the aircraft suffered engine failure and crashed badly on takeoff. Sayers in the front cockpit was trapped by the radiators and was extricated with difficulty; the radiators were reduced in height in the course of the rebuilding.

Trials at Farnborough were carried out successfully in June 1912, and subsequently the engine was replaced by the new ABC. Testing recommenced in the hands of Raynham and later R.L. Charteris of the engine company until early in 1913, when the ENV was refitted. The machine was then handed over to the Avro school at Shoreham, where it flew until 29 June 1913, when it was crashed by a pupil and burned. The pupil was the first fatality in an Avro aircraft.

Type E prototype

Power:

60hp ENV type F eight-cylinder water-cooled vee.

60hp ABC eight-cylinder water-cooled vee.

Data

Flight

Mainplane span 36 ft

Mainplane chord 4ft 10in The Aeroplane 4ft 9in

Mainplane gap 5 ft

Mainplane area 338 sq ft The Aeroplane 332 sq ft

Tailplane span 8 ft

Area inc. elevators 32 sq ft The Aeroplane 33 sq ft

Length 31 ft The Aeroplane 30ft 6in

Height 9 ft 9in

Weight 1,2001b (Also quoted as 1,100lb)

Weight allup 1,650lb

Speed 60 mph

Production: Eighteen aircraft of various versions.

Type E 1 Prototype. First flight 14 March 1912 at Brooklands. Destroyed at Shoreham 29 June 1913.

This biplane was made to an order from John R. Duigan, an Australian, who had built his own Wright type glider and Farman-type powered aircraft in 1909-1911, with which he achieved a number of successful flights. He came to England to learn more of current practice and to receive flying instruction.

On arrival he ordered a biplane from Avro, which was built at Manchester and delivered to Huntingdon, when completed in December 1911. The machine was not a great success and Duigan took it back to Brooklands. After some limited straight flights in February, Duigan joined the Avro school. At Brooklands the original Alvaston engine was replaced by an ENV, and together with improvements, the machine was eventually capable of flying for one hour at up to 600ft with the pilot only; flights with a passenger were limited to "straights".

Duigan returned to Australia and his Avro was bought by the Lakes Flying Co. for ?180 and was moved to Windermere on 4 June 1912. At Windermere it was largely rebuilt with a new engine and became the Lakes Sea Bird (q.v.).

This Avro biplane had a deep fuselage with radiators positioned either side of the front cockpit; wing warping was employed. The undercarriage had a leaf spring axle with a central skid. The skid became a feature of many later Avro aircraft. In its final form this machine was the basis of the next type, a much-improved machine, which eventually led to the outstanding Type 504.

Power:

40hp Alvaston two-cylinder horizontally opposed water-cooled

35hp ENV type D eight-cylinder water-cooled vee.

Data

Span 34ft

Chord 4ft 6in

Length 29ft 6in

Area 300 sq ft

Speed 40mph

AVRO Type. E and Es (later known as Types 500 and 502)

This was a slightly larger version of the biplane built for John Duigan, more powerful and able to fly successfully as a two-seater. It was built to meet an official requirement and was often referred to as the 'Military Biplane'. The first flight took place at Brooklands on 14 March 1912 in the hands of Lt. Wilfred Parke RN. Testing proceeded, following which an entry was made for the Mortimer Singer Prize of ?500, offered to an army or navy officer who flew the longest flight with a passenger, in Britain, before the end of March. Parke left Brooklands with W.H. Sayers on 20 March 1912 for Hendon for his bid, but the aircraft suffered engine failure and crashed badly on takeoff. Sayers in the front cockpit was trapped by the radiators and was extricated with difficulty; the radiators were reduced in height in the course of the rebuilding.

Trials at Farnborough were carried out successfully in June 1912, and subsequently the engine was replaced by the new ABC. Testing recommenced in the hands of Raynham and later R.L. Charteris of the engine company until early in 1913, when the ENV was refitted. The machine was then handed over to the Avro school at Shoreham, where it flew until 29 June 1913, when it was crashed by a pupil and burned. The pupil was the first fatality in an Avro aircraft.

Type E prototype

Power:

60hp ENV type F eight-cylinder water-cooled vee.

60hp ABC eight-cylinder water-cooled vee.

Data

Flight

Mainplane span 36 ft

Mainplane chord 4ft 10in The Aeroplane 4ft 9in

Mainplane gap 5 ft

Mainplane area 338 sq ft The Aeroplane 332 sq ft

Tailplane span 8 ft

Area inc. elevators 32 sq ft The Aeroplane 33 sq ft

Length 31 ft The Aeroplane 30ft 6in

Height 9 ft 9in

Weight 1,2001b (Also quoted as 1,100lb)

Weight allup 1,650lb

Speed 60 mph

Production: Eighteen aircraft of various versions.

Type E 1 Prototype. First flight 14 March 1912 at Brooklands. Destroyed at Shoreham 29 June 1913.

Deleted by request of (c)Schiffer Publishing

AVRO Type. E and Es (later known as Types 500 and 502)

<...>

A second machine of the type, but with a 50hp Gnome, was built and was flown by Parke at Brooklands on 8 May 1912. This proved to have a better performance and resulted in a early War Office order for three machines. The third of these was given its first flight from Eccles cricket ground near the Manchester factory. It was now also known as the Type 500. Further orders followed from the War Office, Admiralty, the Portuguese Government and civilian sources. It was during the time that these machines were in production that the company moved its Manchester premises in April 1913.

A number of changes were made to the aircraft during its operational life, including fitting ailerons to both top and bottom wings. The sprung rudder was replaced by a separate tail skid also various types of wing tip skids, some with wheels, were fitted. Later the rudder shape was changed to the more familiar comma shape of future Avro aircraft.

The War Office ordered a batch of five of the single-seater version, which were basically the same as the two-seaters and subject to the same modifications. These were identified as Type Es or Type 502.

Flight of 30 March 1912 and The Aeroplane of 11 April 1912 earned drawings and data for the prototype, with dimensions slightly at variance in some respects and neither agreed on the position of the radiators. The risk to the passenger was commented on by The Aeroplane. Flight showed auxiliary radiators just below the top wing, probably fitted later and the cause of Sayers' entrapment.

Type E (Avro Type 500)

Power: 50hp Gnome seven-cylinder air-cooled rotary driving a 9ft diameter propeller.

Data

Span 36ft

Weight 900lb

Weight allup 1,300lb

Length 29ft

Area 335 sq ft

Max speed 62 mph

Production: Eighteen aircraft of various versions.

Type E 1 Prototype. First flight 14 March 1912 at Brooklands. Destroyed at Shoreham 29 June 1913.

Type E (Avro 500) seven machines delivered between May 1912 - April 1913 to the War Office. Serial Nos.404-406, 430, 432-433, 448 used at CFS Upavon.

Two machines delivered May 1913 and February 1914 to Admiralty contract, serial Nos.41 and 150 used at Hendon and Eastchurch.

One machine to Portuguese Government delivered Lisbon October 1912 named Republica.

One machine first flight July 1913 to private owner at Hendon later with RNAS serial No.939.

One machine to Hall School at Hendon January 1914, later with the RFC serial No.491.

Type Es (Avro 502) 5 machines delivered between April-June 1913. to War Office contract. Serial Nos.285, 288-291.

<...>

A second machine of the type, but with a 50hp Gnome, was built and was flown by Parke at Brooklands on 8 May 1912. This proved to have a better performance and resulted in a early War Office order for three machines. The third of these was given its first flight from Eccles cricket ground near the Manchester factory. It was now also known as the Type 500. Further orders followed from the War Office, Admiralty, the Portuguese Government and civilian sources. It was during the time that these machines were in production that the company moved its Manchester premises in April 1913.

A number of changes were made to the aircraft during its operational life, including fitting ailerons to both top and bottom wings. The sprung rudder was replaced by a separate tail skid also various types of wing tip skids, some with wheels, were fitted. Later the rudder shape was changed to the more familiar comma shape of future Avro aircraft.

The War Office ordered a batch of five of the single-seater version, which were basically the same as the two-seaters and subject to the same modifications. These were identified as Type Es or Type 502.

Flight of 30 March 1912 and The Aeroplane of 11 April 1912 earned drawings and data for the prototype, with dimensions slightly at variance in some respects and neither agreed on the position of the radiators. The risk to the passenger was commented on by The Aeroplane. Flight showed auxiliary radiators just below the top wing, probably fitted later and the cause of Sayers' entrapment.

Type E (Avro Type 500)

Power: 50hp Gnome seven-cylinder air-cooled rotary driving a 9ft diameter propeller.

Data

Span 36ft

Weight 900lb

Weight allup 1,300lb

Length 29ft

Area 335 sq ft

Max speed 62 mph

Production: Eighteen aircraft of various versions.

Type E 1 Prototype. First flight 14 March 1912 at Brooklands. Destroyed at Shoreham 29 June 1913.

Type E (Avro 500) seven machines delivered between May 1912 - April 1913 to the War Office. Serial Nos.404-406, 430, 432-433, 448 used at CFS Upavon.

Two machines delivered May 1913 and February 1914 to Admiralty contract, serial Nos.41 and 150 used at Hendon and Eastchurch.

One machine to Portuguese Government delivered Lisbon October 1912 named Republica.