Книги

Putnam

O.Tapper

Armstrong Whitworth Aircraft since 1913

36

O.Tapper - Armstrong Whitworth Aircraft since 1913 /Putnam/

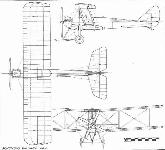

The first Armstrong Whitworth aeroplane to be designed by Koolhoven was a small single-seater. This aeroplane was known, probably correctly, as the F.K.I; the qualification arises because there is considerable uncertainty about the true sequence of the F.K. numbers. Koolhoven himself seems to have applied, in retrospect, F.K. numbers to all the designs with which he had been in any way concerned, and in one Dutch publication the F.K.I appears as the F.K.14. The uncertainty about the F.K. numbers is made worse by the secrecy concerning its experimental types which Armstrong Whitworth maintained even after the war.

The F.K.I, originally planned as a monoplane, was altered in the design stage to a biplane. It was a simple, straightforward, single-seat aircraft with single-bay wings, no stagger and a large gap. The fuselage terminated in a horizontal knife-edge, and there were divided elevators but no fixed tailplane. When first flown, by Koolhoven himself, the F.K.I proved to be seriously underpowered, having been fitted with a Gnome engine of 50 hp in place of the intended 80 hp version. Later, the aircraft was given larger ailerons and a fixed tailplane and in this form was flown by B. C. Hucks and some naval pilots; but there was clearly no future for the type and its development was abandoned.

The F.K.I, originally planned as a monoplane, was altered in the design stage to a biplane. It was a simple, straightforward, single-seat aircraft with single-bay wings, no stagger and a large gap. The fuselage terminated in a horizontal knife-edge, and there were divided elevators but no fixed tailplane. When first flown, by Koolhoven himself, the F.K.I proved to be seriously underpowered, having been fitted with a Gnome engine of 50 hp in place of the intended 80 hp version. Later, the aircraft was given larger ailerons and a fixed tailplane and in this form was flown by B. C. Hucks and some naval pilots; but there was clearly no future for the type and its development was abandoned.

B.E.2c aircraft on the assembly line at Gosforth during the early months of 1915. On the left is the fuselage of the F.K.I single-seat biplane.

The Wartime Veterans

When Frederick Koolhoven joined Annstrong Whitworth in 1914 the works at Gosforth were being prepared for B.E.2c production and he concluded, after studying the official design, that it was unnecessarily difficult to build. He therefore straightway offered to design an aircraft which, without sacrifice of performance, would be easier to produce. Rather surprisingly, in view of their unshakable faith in the B.E.2c, the authorities agreed and, in August 1915, Koolhoven went ahead with the construction of the Armstrong Whitworth version, the F.K.3.

F.K.3

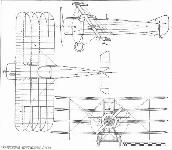

The F.K.3 bore an obvious resemblance to the B.E.2c, and it is evident that Koolhoven's ideas about improving the design were concerned mainly with the structural features; indeed, his aim was, among other things, to eliminate welding and intricate metal fittings. The F.K.3, like the B.E.2c, had a slender fuselage, high aspect ratio wings, and two-bay bracing; unlike the B.E, it had more dihedral on the top plane than on the bottom. The prototype, which was test-flown by Norman Spratt, was fitted with a 70 hp Renault engine, but production aircraft were powered by the RAF 1a of 90 hp. One F.K.3, No.5519, was tested in June 1916 with the more powerful RAF Ib engine, but the tests with this aircraft were plagued by constant engine failures due to faulty pistons.

Seating arrangements in the F.K.3 prototype followed the B.E.2c precedent of placing the observer in the front in a separate cockpit underneath the top wing, but this was later changed so that both crew members were accommodated in one large cockpit, with the observer at the back where he could use his Lewis gun with much greater effect. The rear portion of the long cockpit opening was shielded by side screens extending forward to the rearmost centre-section struts, giving from the side the appearance of two separate cockpits. All the earlier production aircraft with the observer's seat in front, of which there were twelve, were afterwards modified to reverse the crew positions. The undercarriage was of unusual design in that it employed oleo shock-absorbers mounted vertically on the sides of the fuselage from which struts extended down to the ends of a divided axle. A central skid extended forward from the axle to protect the propeller in the event of a tail-high landing.

No provision was made for a forward-firing gun, but the observer was provided with a Lewis gun mounted on a pillar behind his seat. As was the case with the B.E. aeroplanes, pilots used considerable ingenuity in attempts to equip themselves with some form of gun mounted to fire past the propeller, but none of the methods adopted was noticeably successful. External bomb racks fitted under the lower mainplane were capable of carrying bombs up to the weight of 112 lb but, because of weight limitations, it was usual to fly without the observer when bombs were carried.

An F.K.3, No.5552, with a 90 hp RAF la engine, was tested alongside a B.E.2c at the Central Flying School at Upavon in May 1916. The tests showed that the F.K.3 had a slightly better all-round performance and that it was lighter on the controls and more pleasant to handle. The report commented favourably on the crew positions, the roomy rear cockpit, and the ease of communication between the pilot and observer even without the use of a speaking tube; it criticized the positioning of control column and rudder bar and mentioned a draught in the cockpit coming from the fuselage openings at the junction of the undercarriage struts. In general the aircraft was considered to be well designed and easy to manufacture; it was simple to control and the oleo undercarriage was adjudged to be very good, although the long shock-absorber travel allowed the wingtips to touch the ground.

Early in the F.K.3 production run the RAF la engine became temporarily unobtainable and, at one time, according to a contemporary account, there were about a hundred complete aircraft awaiting engines. This may have been something of an exaggeration, but there is no doubt that a crisis had arisen and, in an endeavour to overcome it, some 120 hp Beardmore engines were sent to Newcastle in the hope that they might provide a satisfactory substitute.

The fitting of this engine into the F.K.3 presented many problems: the six-cylinder inline water-cooled Beardmore engine was some twenty inches longer than the RAF la and, even without the radiator, it was at least 90 lb heavier. To make room for the bigger engine, the fuel tank was removed from the fuselage and a larger, streamlined tank was located under the top centre section, together with a small header tank for the radiator. When installed, the engine sat high on its bearers and virtually blocked the forward view. The all-up weight of the aircraft was increased by about 400 lb, of which about 100 lb was accounted for by the additional fuel. To compensate for this extra load, the wing span of the aircraft was increased by two feet.

The first two Beardmore-powered F.K.3s (one of which was numbered 5528) were tested at Upavon in March 1916, and a report issued in May indicated that, although the climb performance was better than that of the RAF la version, the speed showed only a marginal improvement. That the Beardmore installation was not considered satisfactory is evident from the fact that all of the twelve aircraft so adapted were re-converted to standard as soon as RAF la engines again became available.

Precise production figures for the F.K.3 are difficult to ascertain because most of the official records of the time refer indiscriminately to Armstrong Whitworth biplanes without making any distinction between the F.K.3 and the F.K.8 which followed it. It is known that the War Office ordered one hundred and fifty F.K.3s from Armstrong Whitworth in 1915 and that the production rate is said to have reached 35 to 45 aircraft a month. In addition, orders for three hundred and fifty F.K.3s were placed with Hewlett & Blondeau of Luton, in Bedfordshire, a firm formed before the war by Gustav Blondeau, an early French aviator, and Mrs Maurice Hewlett, the wife of the author and herself the first British woman pilot.

In spite of the fact that the F.K.3 was clearly a better proposition than the B.E.2c, if only because it could defend itself more adequately if attacked from the rear, it seems that the type saw no active service on the Western Front, and the only operational unit that used it was No. 47 Squadron which served in Salonika from September 1916 until the end of the war. In that theatre the F.K.3s gave excellent service, performing a variety of duties including ground straffing, artillery spotting and bombing.

At home, the F.K.3 was used extensively for training, for which role its ease of handling and its ability to perform aerobatics made it eminently suitable, and it was probably the best of the British trainers until the arrival of the Avro 504. It was also used for observer training at the observer and air gunnery schools at Dymchurch, Hythe, Stirling and Turnberry. An F.K.3 was used as a personal transport by Major-General Sir Sefton Brancker, later to become the first Director General of Civil Aviation. He was a brave and resourceful man but a notoriously poor pilot, and his choice of the F.K.3 was a tribute to its ease of handling.

At the end of the war, in November J918, there were sixty-two F.K.3s still serving with the RAF, fifty-three at home, mostly based at flying schools, and nine in the Middle East. After the war only four found their way on to the civil register: G-EABY (ex B9629) and G-EABZ (ex B9518) which operated from Porthcawl, in South Wales, flown by E. D. C. Heme. Another, G-EAEU (ex B9612), was owned by the Kingsbury Aviation Co Ltd, but was crashed after a few months of civilian life. Finally, there was G-EALK (ex B9603) which was registered in the name of L. G. Lowe and held a certificate of airworthiness until September 1920.

A noticeable feature of the F.K.3 was an engine cowling panel carrying the initials 'AW'. These were not merely painted on but heavily embossed into the metal. As a result, perhaps not surprisingly, the aircraft soon became known, in the vernacular of the day, as the 'Ack·W' and, when its successor, the F.K.8, appeared with similar embellishment, it inevitably became another 'Ack-W': from then on the two aircraft were invariably referred to as the 'Little Ack' and the 'Big Ack'.

F.K.3

Dimensions: Span 40 ft (12.19 m); length 29 ft (8.84 m); height 11 ft 11 in (3.63 m); wing area 457 sq ft (42.46 sq m)

90hp RAF 1A 120 hp Beardmore

Max weight: 2,056 lb (933 kg) 2,447 lb (1,110 kg)

Empty weight: 1,386 lb (629 kg) 1,682 lb (763 kg)

Max speed

Sea level: 89 mph (143 km/hr) 91 mph (146 km/hr)

6,500 ft (1,981 m) 81 mph (130 km/hr) 84 mph (135 km/hr)

Stalling speed: 48 mph (77 km/hr) 56 mph (90 km/hr)

Climb

to 6,500 ft(1,981 m): 26.5 min 19 min

to 10,000 ft(3.048 m): 48.9 min 35 min

Service ceiling: 12,000 ft(3,658 m) 12,000 ft(3.658 m)

Endurance: 3 hr 3 hr

When Frederick Koolhoven joined Annstrong Whitworth in 1914 the works at Gosforth were being prepared for B.E.2c production and he concluded, after studying the official design, that it was unnecessarily difficult to build. He therefore straightway offered to design an aircraft which, without sacrifice of performance, would be easier to produce. Rather surprisingly, in view of their unshakable faith in the B.E.2c, the authorities agreed and, in August 1915, Koolhoven went ahead with the construction of the Armstrong Whitworth version, the F.K.3.

F.K.3

The F.K.3 bore an obvious resemblance to the B.E.2c, and it is evident that Koolhoven's ideas about improving the design were concerned mainly with the structural features; indeed, his aim was, among other things, to eliminate welding and intricate metal fittings. The F.K.3, like the B.E.2c, had a slender fuselage, high aspect ratio wings, and two-bay bracing; unlike the B.E, it had more dihedral on the top plane than on the bottom. The prototype, which was test-flown by Norman Spratt, was fitted with a 70 hp Renault engine, but production aircraft were powered by the RAF 1a of 90 hp. One F.K.3, No.5519, was tested in June 1916 with the more powerful RAF Ib engine, but the tests with this aircraft were plagued by constant engine failures due to faulty pistons.

Seating arrangements in the F.K.3 prototype followed the B.E.2c precedent of placing the observer in the front in a separate cockpit underneath the top wing, but this was later changed so that both crew members were accommodated in one large cockpit, with the observer at the back where he could use his Lewis gun with much greater effect. The rear portion of the long cockpit opening was shielded by side screens extending forward to the rearmost centre-section struts, giving from the side the appearance of two separate cockpits. All the earlier production aircraft with the observer's seat in front, of which there were twelve, were afterwards modified to reverse the crew positions. The undercarriage was of unusual design in that it employed oleo shock-absorbers mounted vertically on the sides of the fuselage from which struts extended down to the ends of a divided axle. A central skid extended forward from the axle to protect the propeller in the event of a tail-high landing.

No provision was made for a forward-firing gun, but the observer was provided with a Lewis gun mounted on a pillar behind his seat. As was the case with the B.E. aeroplanes, pilots used considerable ingenuity in attempts to equip themselves with some form of gun mounted to fire past the propeller, but none of the methods adopted was noticeably successful. External bomb racks fitted under the lower mainplane were capable of carrying bombs up to the weight of 112 lb but, because of weight limitations, it was usual to fly without the observer when bombs were carried.

An F.K.3, No.5552, with a 90 hp RAF la engine, was tested alongside a B.E.2c at the Central Flying School at Upavon in May 1916. The tests showed that the F.K.3 had a slightly better all-round performance and that it was lighter on the controls and more pleasant to handle. The report commented favourably on the crew positions, the roomy rear cockpit, and the ease of communication between the pilot and observer even without the use of a speaking tube; it criticized the positioning of control column and rudder bar and mentioned a draught in the cockpit coming from the fuselage openings at the junction of the undercarriage struts. In general the aircraft was considered to be well designed and easy to manufacture; it was simple to control and the oleo undercarriage was adjudged to be very good, although the long shock-absorber travel allowed the wingtips to touch the ground.

Early in the F.K.3 production run the RAF la engine became temporarily unobtainable and, at one time, according to a contemporary account, there were about a hundred complete aircraft awaiting engines. This may have been something of an exaggeration, but there is no doubt that a crisis had arisen and, in an endeavour to overcome it, some 120 hp Beardmore engines were sent to Newcastle in the hope that they might provide a satisfactory substitute.

The fitting of this engine into the F.K.3 presented many problems: the six-cylinder inline water-cooled Beardmore engine was some twenty inches longer than the RAF la and, even without the radiator, it was at least 90 lb heavier. To make room for the bigger engine, the fuel tank was removed from the fuselage and a larger, streamlined tank was located under the top centre section, together with a small header tank for the radiator. When installed, the engine sat high on its bearers and virtually blocked the forward view. The all-up weight of the aircraft was increased by about 400 lb, of which about 100 lb was accounted for by the additional fuel. To compensate for this extra load, the wing span of the aircraft was increased by two feet.

The first two Beardmore-powered F.K.3s (one of which was numbered 5528) were tested at Upavon in March 1916, and a report issued in May indicated that, although the climb performance was better than that of the RAF la version, the speed showed only a marginal improvement. That the Beardmore installation was not considered satisfactory is evident from the fact that all of the twelve aircraft so adapted were re-converted to standard as soon as RAF la engines again became available.

Precise production figures for the F.K.3 are difficult to ascertain because most of the official records of the time refer indiscriminately to Armstrong Whitworth biplanes without making any distinction between the F.K.3 and the F.K.8 which followed it. It is known that the War Office ordered one hundred and fifty F.K.3s from Armstrong Whitworth in 1915 and that the production rate is said to have reached 35 to 45 aircraft a month. In addition, orders for three hundred and fifty F.K.3s were placed with Hewlett & Blondeau of Luton, in Bedfordshire, a firm formed before the war by Gustav Blondeau, an early French aviator, and Mrs Maurice Hewlett, the wife of the author and herself the first British woman pilot.

In spite of the fact that the F.K.3 was clearly a better proposition than the B.E.2c, if only because it could defend itself more adequately if attacked from the rear, it seems that the type saw no active service on the Western Front, and the only operational unit that used it was No. 47 Squadron which served in Salonika from September 1916 until the end of the war. In that theatre the F.K.3s gave excellent service, performing a variety of duties including ground straffing, artillery spotting and bombing.

At home, the F.K.3 was used extensively for training, for which role its ease of handling and its ability to perform aerobatics made it eminently suitable, and it was probably the best of the British trainers until the arrival of the Avro 504. It was also used for observer training at the observer and air gunnery schools at Dymchurch, Hythe, Stirling and Turnberry. An F.K.3 was used as a personal transport by Major-General Sir Sefton Brancker, later to become the first Director General of Civil Aviation. He was a brave and resourceful man but a notoriously poor pilot, and his choice of the F.K.3 was a tribute to its ease of handling.

At the end of the war, in November J918, there were sixty-two F.K.3s still serving with the RAF, fifty-three at home, mostly based at flying schools, and nine in the Middle East. After the war only four found their way on to the civil register: G-EABY (ex B9629) and G-EABZ (ex B9518) which operated from Porthcawl, in South Wales, flown by E. D. C. Heme. Another, G-EAEU (ex B9612), was owned by the Kingsbury Aviation Co Ltd, but was crashed after a few months of civilian life. Finally, there was G-EALK (ex B9603) which was registered in the name of L. G. Lowe and held a certificate of airworthiness until September 1920.

A noticeable feature of the F.K.3 was an engine cowling panel carrying the initials 'AW'. These were not merely painted on but heavily embossed into the metal. As a result, perhaps not surprisingly, the aircraft soon became known, in the vernacular of the day, as the 'Ack·W' and, when its successor, the F.K.8, appeared with similar embellishment, it inevitably became another 'Ack-W': from then on the two aircraft were invariably referred to as the 'Little Ack' and the 'Big Ack'.

F.K.3

Dimensions: Span 40 ft (12.19 m); length 29 ft (8.84 m); height 11 ft 11 in (3.63 m); wing area 457 sq ft (42.46 sq m)

90hp RAF 1A 120 hp Beardmore

Max weight: 2,056 lb (933 kg) 2,447 lb (1,110 kg)

Empty weight: 1,386 lb (629 kg) 1,682 lb (763 kg)

Max speed

Sea level: 89 mph (143 km/hr) 91 mph (146 km/hr)

6,500 ft (1,981 m) 81 mph (130 km/hr) 84 mph (135 km/hr)

Stalling speed: 48 mph (77 km/hr) 56 mph (90 km/hr)

Climb

to 6,500 ft(1,981 m): 26.5 min 19 min

to 10,000 ft(3.048 m): 48.9 min 35 min

Service ceiling: 12,000 ft(3,658 m) 12,000 ft(3.658 m)

Endurance: 3 hr 3 hr

The crew positions were reversed in the second F.K.3 production batch so that the observer could use his gun to better effect.

The standard F.K.3 was similar in appearance to the B.E.2c but had a rather better performance. This picture was taken at Doncaster in 1916.

An F.K.3 with an interesting example of dazzle painting; or was it just a light-hearted decorative scheme?

The F.K.3 was notable for its elaborate oleo undercarriage; on the right, an ingenious, but not altogether successful, attempt to provide a forward-firing gun.

One of a small number of F.K.3 aircraft that were fitted temporarily with the 120 hp Beardmore engine.

The Koolhoven Multiplanes

In the early stages of the 1914--18 war, before the pattern of aerial warfare had developed, there was a school of thought in Great Britain which argued the merits of the 'flying battleship' or 'aerial destroyer'. This concept, which envisaged a large aeroplane with a multiplicity of guns having a wide field of fire, arose perhaps from the nation's deep-seated naval traditions. The proponents of the theory gave little regard to the virtues of speed or manoeuvrability, the idea apparently being that the aircraft would proceed in a dignified fashion, possibly in line ahead, firing broadsides at the enemy, who, it might be supposed, would adopt similar tactics. This may be extending the analogy too far, but the fact remains that considerable effort was expended in devising large fighter aeroplanes in which performance took second place to armament. Needless to say, the concept proved unsound, and it was the more adaptable fixed-gun fighter which dominated the scene where the battles were actually fought.

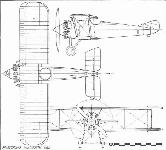

The large multi-seat-fighter notion certainly produced some odd-looking aircraft, with both Sopwith and Vickers trying their hand at the idea, but perhaps the strangest of all were the two Armstrong Whitworth triplanes produced to the designs of Frederick Koolhoven. The first of these featured two machine-gun nacelles mounted on the top surface of the middle wing, which was considerably longer than the other two. In order to provide the best possible field of fire for the two gunners, the nacelles projected well forward of the tractor propeller, which was situated but a few inches ahead of the wing leading edge. The pilot was placed behind the wings where his view in any direction, except upwards and backwards, must have been minimal. The engine was the new 250 hp Rolls-Royce twelve-cylinder unit which later became known as the Eagle. The undercarriage, which, like the rest of the aircraft, was highly unconventional, consisted of a single centrally placed shock-absorber strut terminating in two closely-spaced wheels, lateral stability being provided by a small single wheel under each wingtip. The tail was supported by a skid carried on long struts emanating from the underside of the fuselage at a point just aft of the wings. The whole aircraft seemed ill-balanced and gave the impression of frailty, and it is, perhaps, not surprising that Fairbairn-Crawford, the works manager, is on record as saying that he refused permission for it to be flown.

Subsequently, the design was re-vamped to conform to a requirement initiated by the War Office for a multi-seat escort fighter and Zeppelin destroyer. Using the same type of Rolls-Royce engine, the new triplane was larger than its predecessor and the span of all three wings was greater than before, with the overhang of the centre wing being less pronounced. A second bay was added to the wing structure, and the bracing appeared to be more substantial. The engine and propeller projected ahead of the wing in the conventional tractor position, and the pilot, again seated behind the wings, had a marginally better view but still not one calculated to arouse much enthusiasm. The undercarriage was short and carried a cross-axle with two pairs of wheels; the track was narrow and ground clearance for the lower wing was small. The two gun nacelles, this time attached to the underside of the middle wing, may have been designed to take the Davis gun. In April 1916 Armstrong Whitworth were supplied with two wooden mock-ups of the 6-pounder and the 2-pounder models for fitment to ‘... a large aeroplane now under construction for the War Office’, which can only have been the triplane. Four prototypes of the second triplane had been ordered in March 1916, but only No.7838 was built, it having by then become obvious that the large, ponderous fighting aeroplane was a mistake. Little is known about the test flights carried out by Peter Legh, but it seems they were somewhat perfunctory, with the performance failing to come up to expectations; in any case, interest in the project had already evaporated and the type was soon abandoned.

The place occupied by the triplanes in the F.K. series remains a mystery: both have been referred to as the F.K.12, but all the evidence points to the conclusion that this number is wrong. The comparative immaturity of the triplane designs would seem to indicate that they pre-dated the more workmanlike and more modem looking F.K.8 biplane and the subsequent quadruplanes which, for all their eccentricity, were more in accord with the designs of the later war years. More conclusive, perhaps, is the fact that both triplanes were designed before the adoption of the machine-gun interrupter gear, whereas the quadruplanes were clearly laid out with this type of armament in view. The true sequence of the F.K. numbers may never now be discovered, but the best guess is that the airship car, previously mentioned, which was an adaptation of the F.K.3 fuselage, was the F.K.4, with the two versions of the triplane following as the F.K.5 and the F.K.6.

In the early stages of the 1914--18 war, before the pattern of aerial warfare had developed, there was a school of thought in Great Britain which argued the merits of the 'flying battleship' or 'aerial destroyer'. This concept, which envisaged a large aeroplane with a multiplicity of guns having a wide field of fire, arose perhaps from the nation's deep-seated naval traditions. The proponents of the theory gave little regard to the virtues of speed or manoeuvrability, the idea apparently being that the aircraft would proceed in a dignified fashion, possibly in line ahead, firing broadsides at the enemy, who, it might be supposed, would adopt similar tactics. This may be extending the analogy too far, but the fact remains that considerable effort was expended in devising large fighter aeroplanes in which performance took second place to armament. Needless to say, the concept proved unsound, and it was the more adaptable fixed-gun fighter which dominated the scene where the battles were actually fought.

The large multi-seat-fighter notion certainly produced some odd-looking aircraft, with both Sopwith and Vickers trying their hand at the idea, but perhaps the strangest of all were the two Armstrong Whitworth triplanes produced to the designs of Frederick Koolhoven. The first of these featured two machine-gun nacelles mounted on the top surface of the middle wing, which was considerably longer than the other two. In order to provide the best possible field of fire for the two gunners, the nacelles projected well forward of the tractor propeller, which was situated but a few inches ahead of the wing leading edge. The pilot was placed behind the wings where his view in any direction, except upwards and backwards, must have been minimal. The engine was the new 250 hp Rolls-Royce twelve-cylinder unit which later became known as the Eagle. The undercarriage, which, like the rest of the aircraft, was highly unconventional, consisted of a single centrally placed shock-absorber strut terminating in two closely-spaced wheels, lateral stability being provided by a small single wheel under each wingtip. The tail was supported by a skid carried on long struts emanating from the underside of the fuselage at a point just aft of the wings. The whole aircraft seemed ill-balanced and gave the impression of frailty, and it is, perhaps, not surprising that Fairbairn-Crawford, the works manager, is on record as saying that he refused permission for it to be flown.

Subsequently, the design was re-vamped to conform to a requirement initiated by the War Office for a multi-seat escort fighter and Zeppelin destroyer. Using the same type of Rolls-Royce engine, the new triplane was larger than its predecessor and the span of all three wings was greater than before, with the overhang of the centre wing being less pronounced. A second bay was added to the wing structure, and the bracing appeared to be more substantial. The engine and propeller projected ahead of the wing in the conventional tractor position, and the pilot, again seated behind the wings, had a marginally better view but still not one calculated to arouse much enthusiasm. The undercarriage was short and carried a cross-axle with two pairs of wheels; the track was narrow and ground clearance for the lower wing was small. The two gun nacelles, this time attached to the underside of the middle wing, may have been designed to take the Davis gun. In April 1916 Armstrong Whitworth were supplied with two wooden mock-ups of the 6-pounder and the 2-pounder models for fitment to ‘... a large aeroplane now under construction for the War Office’, which can only have been the triplane. Four prototypes of the second triplane had been ordered in March 1916, but only No.7838 was built, it having by then become obvious that the large, ponderous fighting aeroplane was a mistake. Little is known about the test flights carried out by Peter Legh, but it seems they were somewhat perfunctory, with the performance failing to come up to expectations; in any case, interest in the project had already evaporated and the type was soon abandoned.

The place occupied by the triplanes in the F.K. series remains a mystery: both have been referred to as the F.K.12, but all the evidence points to the conclusion that this number is wrong. The comparative immaturity of the triplane designs would seem to indicate that they pre-dated the more workmanlike and more modem looking F.K.8 biplane and the subsequent quadruplanes which, for all their eccentricity, were more in accord with the designs of the later war years. More conclusive, perhaps, is the fact that both triplanes were designed before the adoption of the machine-gun interrupter gear, whereas the quadruplanes were clearly laid out with this type of armament in view. The true sequence of the F.K. numbers may never now be discovered, but the best guess is that the airship car, previously mentioned, which was an adaptation of the F.K.3 fuselage, was the F.K.4, with the two versions of the triplane following as the F.K.5 and the F.K.6.

F.K.10

In spite of the disappointing performance of the first aircraft, a second, much modified, version was built. This was, indisputably, designated the F.K.10 and it had a more powerful Clerget engine rated at 130 hp. It had a similar wing arrangement but with the span increased by six inches, and, in order to give more room for the crew, the fuselage was both deeper and wider. The tail surfaces were also modified; instead of the fixed tailplane and no upper vertical fin, the second aeroplane had balanced elevators without fixed surfaces and vertical fins above and below the fuselage supporting a conventional, if rather small, rudder. In an attempt to overcome the undercarriage weakness of the previous aircraft, the longerons, from the undercarriage struts forward, were strengthened with plywood, but the structure was still not strong enough and it was reported that the diagonal struts within the fuselage, designed to take the compression loads from the undercarriage, were bent when the aircraft was delivered for official trials.

These trials were undertaken in March 1917, and the performance seems to have been slightly inferior to that of the lower-powered version. This may have been due to the fatter fuselage, but it is equally possible that the difference between the two aircraft arose because of variations in piloting skill and because of the somewhat imprecise methods of performance measurement then in use. The test pilot reported that the machine handled well, with good controllability and with very little tendency to spin. The take-off and landing distance was measured as 80 yards. As might be expected with an all-moving tailplane, the aircraft was somewhat unstable longitudinally, and the pilot noted that the controls could not, therefore, be left alone. In other respects the aircraft was considered easy to fly. Minor criticisms were that the windscreen was inefficient and that it was necessary to remove the engine cowling in order to replenish the oil tank. Like its predecessor, the second aircraft was reported as having a performance below that specified.

In view of the poor performance, an order for fifty F.K.10s which had been placed with Angus Sanderson and Co was cancelled in March 1917, and the serial numbers A8950 to A8999 set aside for this batch were reallocated. However, small batches of the F.K.10 were produced by Armstrong Whitworth, Angus Sanderson and the Phoenix Dynamo Manufacturing Co. Most of the production aircraft had the 130 hp Clerget engine, but at least one of those built by Armstrong Whitworth was powered by a Le Rhone engine of 110 hp. There is some uncertainty about the numbers of quadruplanes actually built: two, with the serial numbers A5212 and A5213, were ordered from Armstrong Whitworth, one of which may have been the original F.K.9, and a further five, numbered 83996 to 84000, were ordered from Angus Sanderson, but it is not known whether all were delivered. Three more, N511, N512 and N514, were built for the Royal Naval Air Service, the first two by Phoenix Dynamo and the third by Armstrong Whitworth. The missing number, N513, was originally allotted to an Angus Sanderson F.K.10 which was cancelled, and there is some evidence that this number was subsequently re-allocated to an Armstrong Whitworth biplane, presumably an F.K.8, with a Sunbeam engine: this aircraft is said to have force-landed near Beverley on 7 April, 1917, while en route from Newcastle to Martlesham Heath.

In spite of the official test reports, which indicated that the aircraft at least handled reasonably well, pilots seem to have been suspicious of the F.K.10 from the start. It certainly had a rather daunting appearance, and no doubt this, coupled with the maintenance problems, seems to have resulted in the few available aircraft being little used. The two RNAS machines, N511 and N514, were reported to be at Manston aerodrome in April and May 1917, but they were apparently considered to be unsafe and by the late summer had been grounded. The RFC aircraft may have lasted rather longer, but they, too, were never taken seriously and eventually, in July 1917, were handed over to the technical department for use as ground targets. Thus, the F.K.10 faded from the scene with, apparently, few regrets.

That Koolhoven's interest in the multiplane arrangement was not altogether damped by the failure of his three- and four-winged prodigies is evident from drawings that exist showing a design, known perhaps as the F.K.11, which had no less than fifteen narrow wings, each about 18-inches wide, attached to an F.K.10 fuselage. This project was never built, but the 'Venetian blind' arrangement of aerofoils had been tried before. One of the first to toy with the idea was Horatio Phillips, who tried out an apparatus with forty slats (if contemporary drawings are to be believed) on a circular track at Harrow in 1893. After the 1914--18 war the idea was revived by H. G. Leigh who, in collaboration with Bert Hinkler of the Avro company, fitted a modified form of the slatted-wing arrangement to the fuselage of an Avro Baby.

F.K.10

Dimensions: Span 28 ft 3 in (8.61 m); length 25 ft 6 in (7.77 m); height 11 ft 6 in (3.50 m); wing area 361 sq ft(33.54 sq m).

F.K.10

130 hp Clerget

Max weight: 2,019lb (916kg)

Empty weight: 1,236lb (561kg)

Max speed

Sea level: -

3,000ft (914 m): 95 mph (153km/hr)

6,500ft (1,981 m): 84 mph (135km/hr)

10,000 ft (3,048 m): 74 mph (119km/hr)

Climb to

6,000ft (1,829 m): -

6,500ft (1,981 m): 15.8min

10,000ft (3,048 m): 37.2min

Service ceiling: 10,000ft (3.048 m)

Endurance: 2 1/2 hr

In spite of the disappointing performance of the first aircraft, a second, much modified, version was built. This was, indisputably, designated the F.K.10 and it had a more powerful Clerget engine rated at 130 hp. It had a similar wing arrangement but with the span increased by six inches, and, in order to give more room for the crew, the fuselage was both deeper and wider. The tail surfaces were also modified; instead of the fixed tailplane and no upper vertical fin, the second aeroplane had balanced elevators without fixed surfaces and vertical fins above and below the fuselage supporting a conventional, if rather small, rudder. In an attempt to overcome the undercarriage weakness of the previous aircraft, the longerons, from the undercarriage struts forward, were strengthened with plywood, but the structure was still not strong enough and it was reported that the diagonal struts within the fuselage, designed to take the compression loads from the undercarriage, were bent when the aircraft was delivered for official trials.

These trials were undertaken in March 1917, and the performance seems to have been slightly inferior to that of the lower-powered version. This may have been due to the fatter fuselage, but it is equally possible that the difference between the two aircraft arose because of variations in piloting skill and because of the somewhat imprecise methods of performance measurement then in use. The test pilot reported that the machine handled well, with good controllability and with very little tendency to spin. The take-off and landing distance was measured as 80 yards. As might be expected with an all-moving tailplane, the aircraft was somewhat unstable longitudinally, and the pilot noted that the controls could not, therefore, be left alone. In other respects the aircraft was considered easy to fly. Minor criticisms were that the windscreen was inefficient and that it was necessary to remove the engine cowling in order to replenish the oil tank. Like its predecessor, the second aircraft was reported as having a performance below that specified.

In view of the poor performance, an order for fifty F.K.10s which had been placed with Angus Sanderson and Co was cancelled in March 1917, and the serial numbers A8950 to A8999 set aside for this batch were reallocated. However, small batches of the F.K.10 were produced by Armstrong Whitworth, Angus Sanderson and the Phoenix Dynamo Manufacturing Co. Most of the production aircraft had the 130 hp Clerget engine, but at least one of those built by Armstrong Whitworth was powered by a Le Rhone engine of 110 hp. There is some uncertainty about the numbers of quadruplanes actually built: two, with the serial numbers A5212 and A5213, were ordered from Armstrong Whitworth, one of which may have been the original F.K.9, and a further five, numbered 83996 to 84000, were ordered from Angus Sanderson, but it is not known whether all were delivered. Three more, N511, N512 and N514, were built for the Royal Naval Air Service, the first two by Phoenix Dynamo and the third by Armstrong Whitworth. The missing number, N513, was originally allotted to an Angus Sanderson F.K.10 which was cancelled, and there is some evidence that this number was subsequently re-allocated to an Armstrong Whitworth biplane, presumably an F.K.8, with a Sunbeam engine: this aircraft is said to have force-landed near Beverley on 7 April, 1917, while en route from Newcastle to Martlesham Heath.

In spite of the official test reports, which indicated that the aircraft at least handled reasonably well, pilots seem to have been suspicious of the F.K.10 from the start. It certainly had a rather daunting appearance, and no doubt this, coupled with the maintenance problems, seems to have resulted in the few available aircraft being little used. The two RNAS machines, N511 and N514, were reported to be at Manston aerodrome in April and May 1917, but they were apparently considered to be unsafe and by the late summer had been grounded. The RFC aircraft may have lasted rather longer, but they, too, were never taken seriously and eventually, in July 1917, were handed over to the technical department for use as ground targets. Thus, the F.K.10 faded from the scene with, apparently, few regrets.

That Koolhoven's interest in the multiplane arrangement was not altogether damped by the failure of his three- and four-winged prodigies is evident from drawings that exist showing a design, known perhaps as the F.K.11, which had no less than fifteen narrow wings, each about 18-inches wide, attached to an F.K.10 fuselage. This project was never built, but the 'Venetian blind' arrangement of aerofoils had been tried before. One of the first to toy with the idea was Horatio Phillips, who tried out an apparatus with forty slats (if contemporary drawings are to be believed) on a circular track at Harrow in 1893. After the 1914--18 war the idea was revived by H. G. Leigh who, in collaboration with Bert Hinkler of the Avro company, fitted a modified form of the slatted-wing arrangement to the fuselage of an Avro Baby.

F.K.10

Dimensions: Span 28 ft 3 in (8.61 m); length 25 ft 6 in (7.77 m); height 11 ft 6 in (3.50 m); wing area 361 sq ft(33.54 sq m).

F.K.10

130 hp Clerget

Max weight: 2,019lb (916kg)

Empty weight: 1,236lb (561kg)

Max speed

Sea level: -

3,000ft (914 m): 95 mph (153km/hr)

6,500ft (1,981 m): 84 mph (135km/hr)

10,000 ft (3,048 m): 74 mph (119km/hr)

Climb to

6,000ft (1,829 m): -

6,500ft (1,981 m): 15.8min

10,000ft (3,048 m): 37.2min

Service ceiling: 10,000ft (3.048 m)

Endurance: 2 1/2 hr

Two F.K.10 quadruplanes and an F.K.8 biplane, with a Lorraine-Dietrich engine, at Duke's Meadow aerodrome at Gosforth.

F.K.8

It was presumably a coincidence that two types of aircraft designed in 1916 for corps-reconnaissance duties should both bear the number 8 as their type designation; certainly, in all other respects they could not have been more dissimilar. The Armstrong Whitworth F.K.8 and the R.E.8, designed by the Royal Aircraft Factory, were both intended as B.E.2c replacements, and it was unfortunate for the long-suffering reconnaissance pilots of the RFC that it was the inferior R.E.8 that was chosen for massive production at the expense of the more popular F.K.8. Nevertheless, the F.K.8 was produced in considerable numbers and played a significant, if unspectacular, part in the war from the beginning of 1917 until the Armistice, including actions which led to the award of two Victoria Crosses.

Although designed for the same duties as its predecessor, the F.K.8 represented a considerable advance over the F.K. 3; it was planned from the start to accommodate internally all the various trappings of army cooperation, such as cameras, which, in previous types had been hung on outside with a noticeable effect on the aircraft's performance. The result, in the F.K.8, was a fuselage of ample proportions with comfortable separate cockpits for pilot and observer.

In construction the F.K.8 was a conventional biplane with two-bay wings of equal span and greater dihedral on the top plane than on the bottom. The upper wing was built in two portions which met on the centre line at the apex of two inverted-V centre-section struts. The controls were conventional; ailerons were fitted to all four wings and the incidence of the tailplane was adjustable by means of a handwheel in the pilot's cockpit. The observer was provided with a rudimentary method of control in the shape of a side-mounted stick to operate the elevators, and hand grips on the rudder control cables where they passed through the observer's cockpit. There was no means of operating the ailerons from this position but, as was shown several times in practice, it was quite possible to fly the aircraft satisfactorily without the aid of the ailerons and there were a number of occasions on which the aircraft was brought back safely by the observer after the pilot had been incapacitated.

The undercarriage was of similar design to that of the F.K.3, with oleo shock-absorbers mounted on the fuselage sides and with a central skid which, in the case of the F.K. 8, was truncated at the forward supporting struts. In April 1917 the RFC headquarters in France reported that the F.K.8's undercarriage was unsatisfactory and suggested that it should be replaced by a plain V-type specimen from a Bristol Fighter. This modification proved a big improvement and No.1 Aircraft Depot proceeded to convert a number of aircraft until, in the following July, the supply of Bristol Fighter undercarriages dried up and B.E.2c undercarriages had to be used instead. The gauge of tube used and the angle of the V was the same in both types, but the rear legs of the B.E. landing gear were shorter. This seems to have been of no great significance. Later, a modified type of undercarriage with a wider V appeared, and this may have been the production version fitted by the makers. The simpler type of landing gear improved the climb performance and raised the top speed by about 5 mph.

There is a widely-held opinion that the first production F.K.8s were powered by the 120 hp Beardmore engine, but in the light of recent research this belief is now thought to have been due to a misunderstanding. As already mentioned, both Armstrong Whitworth and the Service authorities were unusually lax in differentiating between the F.K.3 and the F.K.8, and this seems to have led to some confusion over the powerplants as well as over production figures. The mistake probably arose in the first place because the small batch of F.K. 3s fitted with the 120 hp Beardmore engine, as described earlier, were loosely referred to as 'Armstrong Whitworth 120 hp biplanes' and, because this variant was little known, it was naturally assumed that this description applied to the F.K.8. Apart from a statement in Jane's All the World's Aircraft for 1918 which was repeated in the following year and which may well have been the original source of the misunderstanding, there is a marked absence of direct evidence in favour of the 120 hp engine, and all the indications are that the F.K.8 was powered by the 160 hp Beardmore from the start.

During the course of production, other engines were tried out experimentally in the F.K.8. Two aircraft, B214 and B2l5, were fitted with variants of the twelve-cylinder air-cooled RAF 4 engine, the type which had, by its early unreliability, added to the unpopularity of the R.E.8. Another aircraft, A2696, was fitted with a Lorraine-Dietrich engine of 150 hp, but none of these engines bestowed any significant improvement on the F.K.8's performance and there was no move to adopt them as standard.

As first produced, the F.K.8 had a somewhat angular form of engine cowling, which gave the aircraft a vaguely Germanic appearance, and a crude form of radiator consisting of honeycomb blocks mounted on the sides of the fuselage and extending upwards and inwards to meet at a point in front of the top wing. This radiator proved to be inefficient in service and, as a result of a flood of complaints from the Western Front, a new type was adopted. This new radiator, which consisted of two elements mounted one each side of the fuselage, proved more effective as a radiator as well as improving the view from the cockpit. With the new compact type of radiator, a more rounded form of cowling was introduced, changes which resulted in a marked improvement in the appearance of the machine.

Another complaint voiced by Service pilots concerned the distortion of the view caused by the mirage effect of the fumes from the stub exhaust pipes. To overcome this, some enterprising officers of No. 10 Squadron in France devised and constructed a stack-type exhaust pipe which carried the fumes over the top wing. Permission was granted by RFC HQ in France for tests to be made with this exhaust system, but a warning was given that the large side area of the stack might affect the directional stability of the aircraft, and the advice was added that '... pilot ought to be warned not to do any short turns near the ground with it'. In fact, tests showed that there was no deterioration in directional stability, and the pilots of No. 10 Squadron were favourably impressed with the improvement in visibility and the fact that the after part of the aircraft was no longer smothered in oil: it was, however, noted that the design would have to be strengthened to withstand vibration. In the end this design was not adopted, but a modified system, consisting of a long exhaust pipe extending to a position aft of the observer's seat, was introduced.

The first flight of the F.K.8 took place in May 1916, and in the middle of the following month an F.K.8 numbered A411, which was almost certainly the prototype, was flown by a Service pilot from Newcastle to the Central Flying School at Upavon for official tests. The journey took two days, 16 and 17 June, and the pilot reported favourably on the aircraft's handling qualities. The tests by the CFS pilots were carried out on 18 and 19 June, and the top speed of the aircraft, the average of six runs over a measured course, was recorded as 98·4 mph. In the official report the F.K.8's performance was compared with that called for in the specification; it achieved 93 mph at 8,000 ft, as against the 100 mph called for, and it climbed to that height in 20 min, 4 min longer than the specified time. A criticism was made that the tailskid was not strong enough; later this fault was the cause of numerous complaints from the Western Front and, in 1917, the rudder shape was modified to avoid damage to its base when the skid broke. The test pilot also noted that when the aircraft was trimmed to fly level at 70 mph, it glided fast at 90 mph when the throttle was closed and that it would be an advantage if this tendency could be corrected. To this rather naive comment was added the remark that the aircraft would be good for reconnaissance but poor for bombing. Later, a cut-out between the spars at the root of the lower wing was provided to improve the pilot's view directly downwards. After tests at Upavon the F.K.8, A411, was returned to the makers for experimental work.

For reasons already stated when dealing with the F.K.3, production figures for the F.K. 8 are not now readily obtainable. The first production order for the F.K.8 was apparently that placed at the beginning of August 1916 with Armstrong Whitworth under contract 87/A/508, and such records as are available indicate that this, and two other contracts placed with Armstrong Whitworth, covered a total of 701 aircraft, not including the prototype. The F.K.8 was also built in large numbers by Angus Sanderson & Co, another Newcastle firm which had previously cooperated with Armstrong Whitworth by building bodies for their motorcars. Orders for some 950 F.K.8s were placed with this firm, which brings the total number of F.K.8s ordered to at least 1,652. By the end of 1917 between eighty and one hundred F.K.8s a month were coming off the Armstrong Whitworth line at Gosforth, and the type continued in production there until July 1918, by which time arrangements had been made for Angus Sanderson to continue with F.K.8 production while Armstrong Whitworth turned their attention to building the Bristol Fighter.

The first production F.K.8s were emerging from the Armstrong Whitworth factory at Gosforth at the end of 1916, and there are reports of individual aircraft being with the RFC in France before the year ended. However, the first squadron to be fully equipped with the type was No.35, which received its F.K.8s before proceeding to France in January 1917. Then came a gap until June, when No.2 Squadron, already in France, had its RE.s replaced by F.K.8s, which continued to be the squadron's equipment until the Armistice. Other squadrons in France which used the F.K.8 through to 1918 were Nos. 8, 10 and 82, while in the Near East the type, among others, was used by No.17 Squadron in Salonika and by No.142 in Palestine. The F.K.8 also formed part of the mixed equipment used in 1916 and 1917 for home defence by Nos. 36,47 and 50 Squadrons. It was an F.K.8 of No.50 Squadron, flown by 2nd Lieut F. A. D. Grace and 2nd Lieut G. Murray, that scored one of the few victories against a raiding Gotha, shot down in the North Sea on 7 July, 1917. The F.K.8 was also used quite extensively for training at home, particularly in the specialized arts of army co-operation, photography, map reading and reconnaissance.

In France the F.K.8 undertook a multitude of duties including night and day bombing, reconnaissance, artillery spotting, photography, trench straffing and even the dropping of supplies to forward troops. It was, like the RE.s before it, a maid of all work, but, unlike them, it was capable of putting up a fair degree of resistance when attacked, and had relatively good performance. The observer, with a Scarff mounting for his Lewis gun, had a good field of fire, while the pilot could operate a forward-firing, synchronized Vickers machine-gun. This defensive armament was used to good effect on 29 November, 1917, when Lieuts Pattern and Leicester, after a prolonged fight with five enemy fighters, succeeded in shooting down the German 'Ace' Erwin Bohme.

The battle-worthiness of the F.K.8 was demonstrated on two other occasions which, as already mentioned, resulted in the award of the Victoria Cross to two pilots. On 27 March, 1918, 2nd Lieut A. A. McLeod of No.2 Squadron with Lieut A. W. Hammond as his observer, flying in B5773, were attacked by eight Fokker Triplanes. In spite of being repeatedly wounded, between them the British pair accounted for four of the enemy before their aircraft, already severely damaged, caught fire. Lieut McLeod was forced by the flames to climb out of his cockpit but while standing on the wing managed to control the aircraft by manipulating the control column with one hand, side-slipping away from the flames and directing it towards the Allied lines; meanwhile Hammond, who had been wounded no less than six times, continued to hold the enemy at bay with his machine-gun. In spite of his wounds and the flames, McLeod Succeeded in bringing his aircraft to a comparatively soft crash landing in no-man's land from which both officers were rescued, still under heavy fire, by the infantry. The second F.K.8 pilot to be awarded the Victoria Cross was Captain (later Air Commodore) F. M. F. West of No.8 Squadron who, with his observer Lieut J. A. G. Haslam, was returning from a low-level bombing attack on German gun positions when his aircraft was attacked by six fighters. Although severely wounded in the legs, West managed to fly back to the Allied side of the lines and then refused to allow himself to be taken to hospital until he was able to pass on some important information about enemy troop concentrations.

The sturdy F.K.8 continued to serve on the Western Front until the war ended. At that time there were 182 of them in France, with 320 aircraft in reserve or under repair at home. Outside Europe there were fifty-six F.K.8s in Egypt and Palestine, forty-four in Salonika and two in the North West Province of India. In Great Britain there were sixty-nine aircraft on home airfields, mostly with training units.

After the war's end, the F.K.8 quickly faded from the scene in the RAF, and only eight found their way on to the British civil register; of these, three were sold abroad while the others were all crashed or otherwise written off before the end of 1920. The F.K.8's sole claim to fame in civil aviation is that of flying the first regular airmail service to be operated by a small Australian company, Queensland and Northern Territory Aerial Services Ltd, later to become better known as QANTAS. Formed in 1920 by two ex Australian Flying Corps pilots, W. Hudson Fysh and P. J. M. McGinnis, the company had been operating a successful hire service from their base at Longreach using a mixed fleet consisting of an Avro 504K with a Sunbeam Dyak engine, a D.H.4, an Avro Triplane, and two F.K.8s bearing the registrations G-AUCF and G-AUDE.

In 1922 the company was given a contract to operate a mail service between Charleville and Cloncurry with principal stops at Blackall, Longreach and Winton, railheads all connecting with the coast railway but not directly with each other. The route distance of 577 miles was scheduled to be flown in two days, with a night stop about half way at Longreach. The first service, which left Charieville at 5.30 a.m. on 2 November, 1922, was flown by McGinnis in the F.K.8 G-AUDE and carried a mail package containing 106 letters; it arrived at Longreach at 10.15 a.m., having averaged 82 mph excluding stops. The Longreach Cloncurry sector was scheduled to be flown on the following day by Hudson Fysh using the other F.K.8, G-AUCF, but, due to a slight drop in engine revolutions, this aircraft failed to take-off in the high temperature and G-AUDE was pressed into service again. This time the take-off was successful and the aircraft was soon on its way carrying the mail and one passenger, an 87-year-old settler named Alexander Kennedy.

The F.K.8s gave good service to QANTAS despite the fact that the rate of climb seldom exceeded 500 feet a minute and was often considerably less in the full heat of the day. At first some trouble was experienced with engines overheating, but this was cured by the fitting of larger radiators and a header tank which served to condense the steam if the radiator water did boil.

Thus, both in war and in peace, the F.K.8 carved for itself a positive niche in history for which it has received scant recognition, either in the annals of the time or since: perhaps it was its very qualities of stolid strength and reliability and its consistent but unspectacular performance which made everyone accept it and then forget about it.

F.K.8

Dimensions: Span 43 ft 6 in (13.26 m); length 31 ft 5 in (9.58 m); height 10 ft 11 in (3.33 m); wing area 540sq ft (50.17 sq m).

160 hp Beardmore 150 hp Lorraine Dietrich 150 hp RAF 4A

Max weight: 2,811 lb(1,275kg) 2,816 lb(1,277kg) 2,827 lb (1,282 kg)

Empty weight: 1,916 lb(869kg) 1,936 lb(878 kg) 1,980 lb (898kg)

Max speed

Sea level: 95 mph (153km/hr) - -

6,500 ft(1.981 m): - 89 mph (143 km/hr) 94mph(151 km/hr)

8.000 ft(2,438 m): 88 mph (142 km/hr) - -

10,000 ft(3,048 m): - 83 mph (134 km/hr) 89 mph (143 km/hr)

Climb to

6.500 ft(1.981 m): 15.4 min 16.5min 16.4min

8,000 ft(2,438 m): 20 min - -

10,000 ft(3.048 m): 27.8 min 33.2 min 32 min

Service ceiling: 13,000 ft. (3,962 m) 11,000 ft (3.353 m) 12,000 ft. (3.658 m)

Fuel capacity: 50 Imp gal (227 lt) 50 Imp gal (227 lt) 50 Imp gal (227 lt)

Endurance: 3 hr 4 hr 3 hr

It was presumably a coincidence that two types of aircraft designed in 1916 for corps-reconnaissance duties should both bear the number 8 as their type designation; certainly, in all other respects they could not have been more dissimilar. The Armstrong Whitworth F.K.8 and the R.E.8, designed by the Royal Aircraft Factory, were both intended as B.E.2c replacements, and it was unfortunate for the long-suffering reconnaissance pilots of the RFC that it was the inferior R.E.8 that was chosen for massive production at the expense of the more popular F.K.8. Nevertheless, the F.K.8 was produced in considerable numbers and played a significant, if unspectacular, part in the war from the beginning of 1917 until the Armistice, including actions which led to the award of two Victoria Crosses.

Although designed for the same duties as its predecessor, the F.K.8 represented a considerable advance over the F.K. 3; it was planned from the start to accommodate internally all the various trappings of army cooperation, such as cameras, which, in previous types had been hung on outside with a noticeable effect on the aircraft's performance. The result, in the F.K.8, was a fuselage of ample proportions with comfortable separate cockpits for pilot and observer.

In construction the F.K.8 was a conventional biplane with two-bay wings of equal span and greater dihedral on the top plane than on the bottom. The upper wing was built in two portions which met on the centre line at the apex of two inverted-V centre-section struts. The controls were conventional; ailerons were fitted to all four wings and the incidence of the tailplane was adjustable by means of a handwheel in the pilot's cockpit. The observer was provided with a rudimentary method of control in the shape of a side-mounted stick to operate the elevators, and hand grips on the rudder control cables where they passed through the observer's cockpit. There was no means of operating the ailerons from this position but, as was shown several times in practice, it was quite possible to fly the aircraft satisfactorily without the aid of the ailerons and there were a number of occasions on which the aircraft was brought back safely by the observer after the pilot had been incapacitated.

The undercarriage was of similar design to that of the F.K.3, with oleo shock-absorbers mounted on the fuselage sides and with a central skid which, in the case of the F.K. 8, was truncated at the forward supporting struts. In April 1917 the RFC headquarters in France reported that the F.K.8's undercarriage was unsatisfactory and suggested that it should be replaced by a plain V-type specimen from a Bristol Fighter. This modification proved a big improvement and No.1 Aircraft Depot proceeded to convert a number of aircraft until, in the following July, the supply of Bristol Fighter undercarriages dried up and B.E.2c undercarriages had to be used instead. The gauge of tube used and the angle of the V was the same in both types, but the rear legs of the B.E. landing gear were shorter. This seems to have been of no great significance. Later, a modified type of undercarriage with a wider V appeared, and this may have been the production version fitted by the makers. The simpler type of landing gear improved the climb performance and raised the top speed by about 5 mph.

There is a widely-held opinion that the first production F.K.8s were powered by the 120 hp Beardmore engine, but in the light of recent research this belief is now thought to have been due to a misunderstanding. As already mentioned, both Armstrong Whitworth and the Service authorities were unusually lax in differentiating between the F.K.3 and the F.K.8, and this seems to have led to some confusion over the powerplants as well as over production figures. The mistake probably arose in the first place because the small batch of F.K. 3s fitted with the 120 hp Beardmore engine, as described earlier, were loosely referred to as 'Armstrong Whitworth 120 hp biplanes' and, because this variant was little known, it was naturally assumed that this description applied to the F.K.8. Apart from a statement in Jane's All the World's Aircraft for 1918 which was repeated in the following year and which may well have been the original source of the misunderstanding, there is a marked absence of direct evidence in favour of the 120 hp engine, and all the indications are that the F.K.8 was powered by the 160 hp Beardmore from the start.

During the course of production, other engines were tried out experimentally in the F.K.8. Two aircraft, B214 and B2l5, were fitted with variants of the twelve-cylinder air-cooled RAF 4 engine, the type which had, by its early unreliability, added to the unpopularity of the R.E.8. Another aircraft, A2696, was fitted with a Lorraine-Dietrich engine of 150 hp, but none of these engines bestowed any significant improvement on the F.K.8's performance and there was no move to adopt them as standard.

As first produced, the F.K.8 had a somewhat angular form of engine cowling, which gave the aircraft a vaguely Germanic appearance, and a crude form of radiator consisting of honeycomb blocks mounted on the sides of the fuselage and extending upwards and inwards to meet at a point in front of the top wing. This radiator proved to be inefficient in service and, as a result of a flood of complaints from the Western Front, a new type was adopted. This new radiator, which consisted of two elements mounted one each side of the fuselage, proved more effective as a radiator as well as improving the view from the cockpit. With the new compact type of radiator, a more rounded form of cowling was introduced, changes which resulted in a marked improvement in the appearance of the machine.

Another complaint voiced by Service pilots concerned the distortion of the view caused by the mirage effect of the fumes from the stub exhaust pipes. To overcome this, some enterprising officers of No. 10 Squadron in France devised and constructed a stack-type exhaust pipe which carried the fumes over the top wing. Permission was granted by RFC HQ in France for tests to be made with this exhaust system, but a warning was given that the large side area of the stack might affect the directional stability of the aircraft, and the advice was added that '... pilot ought to be warned not to do any short turns near the ground with it'. In fact, tests showed that there was no deterioration in directional stability, and the pilots of No. 10 Squadron were favourably impressed with the improvement in visibility and the fact that the after part of the aircraft was no longer smothered in oil: it was, however, noted that the design would have to be strengthened to withstand vibration. In the end this design was not adopted, but a modified system, consisting of a long exhaust pipe extending to a position aft of the observer's seat, was introduced.

The first flight of the F.K.8 took place in May 1916, and in the middle of the following month an F.K.8 numbered A411, which was almost certainly the prototype, was flown by a Service pilot from Newcastle to the Central Flying School at Upavon for official tests. The journey took two days, 16 and 17 June, and the pilot reported favourably on the aircraft's handling qualities. The tests by the CFS pilots were carried out on 18 and 19 June, and the top speed of the aircraft, the average of six runs over a measured course, was recorded as 98·4 mph. In the official report the F.K.8's performance was compared with that called for in the specification; it achieved 93 mph at 8,000 ft, as against the 100 mph called for, and it climbed to that height in 20 min, 4 min longer than the specified time. A criticism was made that the tailskid was not strong enough; later this fault was the cause of numerous complaints from the Western Front and, in 1917, the rudder shape was modified to avoid damage to its base when the skid broke. The test pilot also noted that when the aircraft was trimmed to fly level at 70 mph, it glided fast at 90 mph when the throttle was closed and that it would be an advantage if this tendency could be corrected. To this rather naive comment was added the remark that the aircraft would be good for reconnaissance but poor for bombing. Later, a cut-out between the spars at the root of the lower wing was provided to improve the pilot's view directly downwards. After tests at Upavon the F.K.8, A411, was returned to the makers for experimental work.

For reasons already stated when dealing with the F.K.3, production figures for the F.K. 8 are not now readily obtainable. The first production order for the F.K.8 was apparently that placed at the beginning of August 1916 with Armstrong Whitworth under contract 87/A/508, and such records as are available indicate that this, and two other contracts placed with Armstrong Whitworth, covered a total of 701 aircraft, not including the prototype. The F.K.8 was also built in large numbers by Angus Sanderson & Co, another Newcastle firm which had previously cooperated with Armstrong Whitworth by building bodies for their motorcars. Orders for some 950 F.K.8s were placed with this firm, which brings the total number of F.K.8s ordered to at least 1,652. By the end of 1917 between eighty and one hundred F.K.8s a month were coming off the Armstrong Whitworth line at Gosforth, and the type continued in production there until July 1918, by which time arrangements had been made for Angus Sanderson to continue with F.K.8 production while Armstrong Whitworth turned their attention to building the Bristol Fighter.

The first production F.K.8s were emerging from the Armstrong Whitworth factory at Gosforth at the end of 1916, and there are reports of individual aircraft being with the RFC in France before the year ended. However, the first squadron to be fully equipped with the type was No.35, which received its F.K.8s before proceeding to France in January 1917. Then came a gap until June, when No.2 Squadron, already in France, had its RE.s replaced by F.K.8s, which continued to be the squadron's equipment until the Armistice. Other squadrons in France which used the F.K.8 through to 1918 were Nos. 8, 10 and 82, while in the Near East the type, among others, was used by No.17 Squadron in Salonika and by No.142 in Palestine. The F.K.8 also formed part of the mixed equipment used in 1916 and 1917 for home defence by Nos. 36,47 and 50 Squadrons. It was an F.K.8 of No.50 Squadron, flown by 2nd Lieut F. A. D. Grace and 2nd Lieut G. Murray, that scored one of the few victories against a raiding Gotha, shot down in the North Sea on 7 July, 1917. The F.K.8 was also used quite extensively for training at home, particularly in the specialized arts of army co-operation, photography, map reading and reconnaissance.

In France the F.K.8 undertook a multitude of duties including night and day bombing, reconnaissance, artillery spotting, photography, trench straffing and even the dropping of supplies to forward troops. It was, like the RE.s before it, a maid of all work, but, unlike them, it was capable of putting up a fair degree of resistance when attacked, and had relatively good performance. The observer, with a Scarff mounting for his Lewis gun, had a good field of fire, while the pilot could operate a forward-firing, synchronized Vickers machine-gun. This defensive armament was used to good effect on 29 November, 1917, when Lieuts Pattern and Leicester, after a prolonged fight with five enemy fighters, succeeded in shooting down the German 'Ace' Erwin Bohme.

The battle-worthiness of the F.K.8 was demonstrated on two other occasions which, as already mentioned, resulted in the award of the Victoria Cross to two pilots. On 27 March, 1918, 2nd Lieut A. A. McLeod of No.2 Squadron with Lieut A. W. Hammond as his observer, flying in B5773, were attacked by eight Fokker Triplanes. In spite of being repeatedly wounded, between them the British pair accounted for four of the enemy before their aircraft, already severely damaged, caught fire. Lieut McLeod was forced by the flames to climb out of his cockpit but while standing on the wing managed to control the aircraft by manipulating the control column with one hand, side-slipping away from the flames and directing it towards the Allied lines; meanwhile Hammond, who had been wounded no less than six times, continued to hold the enemy at bay with his machine-gun. In spite of his wounds and the flames, McLeod Succeeded in bringing his aircraft to a comparatively soft crash landing in no-man's land from which both officers were rescued, still under heavy fire, by the infantry. The second F.K.8 pilot to be awarded the Victoria Cross was Captain (later Air Commodore) F. M. F. West of No.8 Squadron who, with his observer Lieut J. A. G. Haslam, was returning from a low-level bombing attack on German gun positions when his aircraft was attacked by six fighters. Although severely wounded in the legs, West managed to fly back to the Allied side of the lines and then refused to allow himself to be taken to hospital until he was able to pass on some important information about enemy troop concentrations.

The sturdy F.K.8 continued to serve on the Western Front until the war ended. At that time there were 182 of them in France, with 320 aircraft in reserve or under repair at home. Outside Europe there were fifty-six F.K.8s in Egypt and Palestine, forty-four in Salonika and two in the North West Province of India. In Great Britain there were sixty-nine aircraft on home airfields, mostly with training units.

After the war's end, the F.K.8 quickly faded from the scene in the RAF, and only eight found their way on to the British civil register; of these, three were sold abroad while the others were all crashed or otherwise written off before the end of 1920. The F.K.8's sole claim to fame in civil aviation is that of flying the first regular airmail service to be operated by a small Australian company, Queensland and Northern Territory Aerial Services Ltd, later to become better known as QANTAS. Formed in 1920 by two ex Australian Flying Corps pilots, W. Hudson Fysh and P. J. M. McGinnis, the company had been operating a successful hire service from their base at Longreach using a mixed fleet consisting of an Avro 504K with a Sunbeam Dyak engine, a D.H.4, an Avro Triplane, and two F.K.8s bearing the registrations G-AUCF and G-AUDE.

In 1922 the company was given a contract to operate a mail service between Charleville and Cloncurry with principal stops at Blackall, Longreach and Winton, railheads all connecting with the coast railway but not directly with each other. The route distance of 577 miles was scheduled to be flown in two days, with a night stop about half way at Longreach. The first service, which left Charieville at 5.30 a.m. on 2 November, 1922, was flown by McGinnis in the F.K.8 G-AUDE and carried a mail package containing 106 letters; it arrived at Longreach at 10.15 a.m., having averaged 82 mph excluding stops. The Longreach Cloncurry sector was scheduled to be flown on the following day by Hudson Fysh using the other F.K.8, G-AUCF, but, due to a slight drop in engine revolutions, this aircraft failed to take-off in the high temperature and G-AUDE was pressed into service again. This time the take-off was successful and the aircraft was soon on its way carrying the mail and one passenger, an 87-year-old settler named Alexander Kennedy.

The F.K.8s gave good service to QANTAS despite the fact that the rate of climb seldom exceeded 500 feet a minute and was often considerably less in the full heat of the day. At first some trouble was experienced with engines overheating, but this was cured by the fitting of larger radiators and a header tank which served to condense the steam if the radiator water did boil.

Thus, both in war and in peace, the F.K.8 carved for itself a positive niche in history for which it has received scant recognition, either in the annals of the time or since: perhaps it was its very qualities of stolid strength and reliability and its consistent but unspectacular performance which made everyone accept it and then forget about it.

F.K.8

Dimensions: Span 43 ft 6 in (13.26 m); length 31 ft 5 in (9.58 m); height 10 ft 11 in (3.33 m); wing area 540sq ft (50.17 sq m).

160 hp Beardmore 150 hp Lorraine Dietrich 150 hp RAF 4A

Max weight: 2,811 lb(1,275kg) 2,816 lb(1,277kg) 2,827 lb (1,282 kg)

Empty weight: 1,916 lb(869kg) 1,936 lb(878 kg) 1,980 lb (898kg)

Max speed

Sea level: 95 mph (153km/hr) - -

6,500 ft(1.981 m): - 89 mph (143 km/hr) 94mph(151 km/hr)

8.000 ft(2,438 m): 88 mph (142 km/hr) - -

10,000 ft(3,048 m): - 83 mph (134 km/hr) 89 mph (143 km/hr)

Climb to

6.500 ft(1.981 m): 15.4 min 16.5min 16.4min

8,000 ft(2,438 m): 20 min - -

10,000 ft(3.048 m): 27.8 min 33.2 min 32 min

Service ceiling: 13,000 ft. (3,962 m) 11,000 ft (3.353 m) 12,000 ft. (3.658 m)

Fuel capacity: 50 Imp gal (227 lt) 50 Imp gal (227 lt) 50 Imp gal (227 lt)

Endurance: 3 hr 4 hr 3 hr

An early production Armstrong, Whitworth-built F.K.8, A2725, displaying the triple V-strut undercarriage, long vertical radiator blocks, angular nose cowling and short engine exhaust manifold.

An F.K.8 with the improved type of engine cowling, and, on the right, an experimental exhaust system devised by No.10 Squadron, RFC, in France to eliminate the distorting mirage effect from lhe open exhaust pipes.

Two F.K.I0 quadruplanes and an F.K.8 biplane, with a Lorraine-Dietrich engine, at Duke's Meadow aerodrome at Gosforth.

The F.K.8 used by Queensland and Northern Territory Aerial Services Ltd, later Qantas Empire Airways Ltd, to fiy Australia's first air mail service. The flight took place on 2 and 3 November, 1922, between Charleville and Cloncurry.

The F.K.8. G-AUDE. arrives with the mail at Winton on 3 November. 1922. The pilot was Wilmot Hudson Fysh, later Sir Wilmot. The date on the photograph is wrong.

F.K.8 biplanes under construction in the Newcastle factory of Angus Sanderson and Co. The site is now occupied by Durham University.

The prototype F.K.8, A411, undergoes a test to destruction at the Royal Aircraft Factory, Farnborough. The load was applied with loose sand heaped on the underside of the mainplanes.

F.K.9