Книги

Putnam

A.Brew

Boulton Paul Aircraft since 1915

57

A.Brew - Boulton Paul Aircraft since 1915 /Putnam/

P.3 Bobolink

With Boulton & Paul producing large numbers of Sopwith Camels, it was logical that John North should take an immediate interest in producing a Camel replacement, for which the Air Ministry had issued the official Specification A.1A. North began to urgently consider several layouts. The engine designated by the Air Ministry for use in the A.1A contenders was the 230 hp Bentley B.R.2 rotary, which was only 93 lb heavier than the 150 hp B.R.1. A second clutch of designs was built around the compact 170 hp ABC Wasp radial, the Sopwith 8F.l Snail, the Westland Wagtail and the BAT FK.22/2 Bantam.

Sopwith's entry in the design competition was the Snipe, which was some way ahead of its competitors, first flying late in 1917, powered by a B.R.l, as the larger engine was not yet available. It began life as a single-bay design, with a slab-sided fuselage, with two prototypes of slightly differing layouts being evaluated in December 1917. The third prototype was converted to a two-bay layout with a rounded fuselage, being delivered to Martlesham Heath fitted with one of the first B.R.2s in February 1918.

Although the Snipe represented the main competition, there were also two other important contenders for the Camel-replacement order, the Austin A.F.T.3 Osprey triplane, designed by North's successor at Austin, John Kenworthy, along with C H Brooks; and the Nieuport BN.1, Henry Folland's first design for the British Nieuport company, and owing much to his earlier design, the S.E.5A.

Boulton & Paul were awarded orders on 1 December, 1918, for two of their layouts, the P.3 and the P.5. Three prototypes were ordered for each design, the earlier set of serials, C8652-C8654, going to the P.5, and the later ones, C8655-C8657, to the P.3. The company bestowed the name Hawk on the P.5, though it may well have also been used for the P.3, but were forced to change it because of an Air Ministry nomenclature system which came into effect in 1918.

The names of birds of prey were reserved for aero-engines, (the Hawk being a Rolls-Royce engine), and single-seat single-engined landplanes were to be named after land-birds, other than birds of prey, or reptiles. In addition Boulton & Paul were awarded the initial letters BO. (Sopwith were awarded the initial letters SO, SA and SN-hence the name Snipe, and Austin were awarded AU, AS or OS - hence Osprey.) Boulton & Paul chose to rename their entry Boblink, later to be changed to Bobolink, which is a North American bird.

The P.5 was abandoned at an early stage and the serial numbers were re-allocated to other aircraft, but construction of the first P.3 went ahead with some urgency, to ready it for trials against the other three contenders at Martlesham Heath. Availability of the B.R.2 was as much a constraining factor as construction of the aircraft, and the first P.3 Bobolink, C8655, was eventually fitted with only the fourth B.R.2 built.

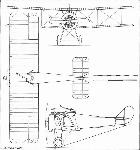

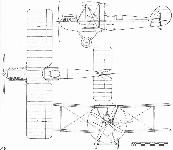

Like the revised Snipe it was a two-bay design with equal-span wings with 2 ft 31/2 in stagger. They featured N struts, which were still an unusual feature, though they had been used by North before the War on the Grahame-White Type 13. Their advantage was that they simplified rigging. The structure was a conventional wooden one, with fabric covering. The wings were very light, the lower ones, without their fabric covering weighed only 29 lb, a tribute to North's design, and Boulton & Paul craftsmanship. To begin with ailerons were only fitted on the upper wings, but a lack of manoeuvrability shown in early trials at Mousehold caused strut-linked ailerons to be fitted to the lower wings. There was a large rectangular cut-out in the upper wing to give the pilot excellent upper hemisphere vision.

Of necessity the front fuselage was of circular section to accommodate the rotary engine, but the aft fuselage was flat-sided, made up of a simple wire-braced box-girder, with a curved upper section behind the pilot's head. One feature displayed the clever thinking and careful design which were to become associated with North. These were the two fuel tanks, of 34 and 6 gal, placed behind the pilot, with an armour plate between them, so that one bullet would have little chance of damaging both. In case they caught fire, both tanks could be jettisoned in flight so that the pilot could glide safely to a landing, saving the rest of his aircraft. In the days when pilots were still not being allowed to wear parachutes in highly inflammable wood and fabric aircraft, this was a very clever idea.

The tail had a sharply-swept leading edge running to a curved fin. Overall length of the aircraft was 20 ft, span was 29 ft, and the height was 8 ft 4 in. In comparison the third prototype Snipe had 2 ft 1 in greater span, 1 ft 2 in more height, but was 9 in shorter.

Two Vickers machine-guns were fitted on the forward fuselage, firing through the 9 ft diameter arc of the two-blade propeller, and provision was made for a Lewis gun on a rail on the upper wing. When C8655 was rolled out of Riverside Works in December 1917, complete except for the front fuselage covering, this rail and Lewis gun were actually fitted, as well as the twin Vickers guns. Before delivery for evaluation the Lewis mounting was removed however. As might be expected the engine mounts and Vickers installation were very similar to those of the Camel.

Capt Frank Courtney undertook the company's initial flight trials at Mousehold. He had been transferred from training to RFC experimental flying and was engaged in the programme to fit 150 hp Monosoupape engines to Sopwith Camels for the Americans. Flight testing for this programme was undertaken at Mousehold on Boulton & Paul-built Camels, so it was natural that, as an experienced test pilot, he should give the Bobolink its first flights.

As well as finding fault with its manoeuvrability, which caused the ailerons to be fitted to the lower wings, Courtney also criticised the Bobolink for the narrow track of its undercarriage, which made taxi-ing difficult, though he felt it was not so serious a fault as to warrant any immediate change. The propeller fitted when the aircraft was first rolled out at Riverside had markedly square-cut tips, but all later pictures of it show conventionally rounded tips, probably the Snipe propeller with which it was fitted at Martlesham.

Delivery of C8655 to Martlesham Heath was made in the week ending 9 March, 1918, where it joined the Snipe. The Nieuport BN.1 and Austin Osprey were delivered in the same week, and flying evaluations were undertaken as a matter of urgency. As a final test a number of Service pilots, including Capt James McCudden were invited to evaluate the four aircraft in a day's trials at Sutton's Farm.

Each of the machines was tested with a Snipe propeller and a full specification load ie 40 gal of fuel, 8 gal of oil, 150 lb of Vickers guns and ammunition, 50 lb of Lewis gun and ammunition and 25 lb of electrical clothing and oxygen. Because of a breakage of its cowling no reliable performance trials could be made on the Nieuport.

The Osprey with its 23 ft wingspan was easily the most manoeuvrable, followed by the Nieuport, with the Bobolink the least favoured because of heavy handling and slow lateral reaction. The Osprey was clearly the slowest of the four; the short era of the triplane was really over. It had not in fact been granted an official order, but was built as a private venture, with special permission from the Air Ministry under Licence No.17, and awarded the serial X.15 in a special series reserved for such private-venture aircraft. The BN.l was a two-bay design like the Bobolink and Snipe, but featured revolutionary I struts, which were looked on with suspicion. It was the fastest of the four aircraft, with a very promising all-round performance, but on 10 March it suffered an unfortunate accident, catching fire in the air, and was completely destroyed, ruling it out of the contest, as a second prototype was not immediately available.

The view from the pilot's seat was best in the Snipe, followed by the Nieuport and the Bobolink, though with small alterations all three would be very similar in this respect. The Osprey was very much poorer, and there was no easy way to improve the pilot s view. As far as accessibility to engines and accessories were concerned, the Osprey was clearly the best, followed by the Snipe and the Bobolink, which were much on a par. The Nieuport was much the worst of the four, though alterations could improve to the standard of the other two biplanes.

The Vickers guns were equally well sited on the biplanes, but the crank handles were difficult to reach on the Osprey. The Lewis gun was difficult to use on the Bobolink and Snipe, as the pilot sat too near the rear spar, the Nieuport being much better in this respect. The Lewis gun was impossible to fit on the Osprey, except in a fixed vertical mounting.

The Applied Design Branch submitted a report on the ease of production and maintenance of the four aircraft. The Osprey and Nieuport were considered the best, though the design of the Nieuport's wings was criticised. The Bobolink was described as very bad from the production and maintenance point of view. This view does seem strange as the Bobolink had such a simple rectangular box-girder fuselage, whereas the Snipe for instance had a complicated rounded fuselage made up of formers and stringers.

There was little to choose between the four aircraft, though the greater experience of the Sopwith company, and the fact that the Snipe had been flying for some time, and had already had fundamental changes to its design, weighed heavily in its favour. Although its top speed was disappointing, (121 mph at 10,000 ft, 4 mph slower than the Bobolink), its rate of climb was magnificent, and its handling at altitude was excellent, feeling like a well-behaved Camel in the air.

Taking all factors into account the following order of merit was arrived at 1. Snipe, 2. Nieuport, 3. Osprey, 4. Bobolink.

Perhaps inevitably the Snipe was chosen, even though the Bobolink displayed a fractional edge in overall performance. Some of the other criticisms of the Bobolink were the narrow track of its undercarriage, and, though this could presumably have been cured, the poor access to the cockpit, which was set well within the cut-out of the upper wing.

The Bobolink was later fitted with a larger horn-balanced rudder to try to cure the ground-handling difficulties, the horn balance being unshielded, looking rather incongruous above the unchanged fin. The strut connection of the ailerons was also changed, being replaced by cable links. The Snipe too required a larger rudder, increasing its length to 19 ft 10 in.

Another B.R.2 powered fighter appeared later in the year, the Armstrong Whitworth Armadillo. By the time it flew there was no chance of it being ordered, but its details are included in the following comparison of the various contenders for completeness.

Performance and Dimensional Comparisons

Bobolink Snipe Osprey Nieuport BN.1 Armadillo

Speed at 10,000 ft 125 mph 121 mph 118 1/2 mph 127 mph 113 mph

Climb to 6,500 ft 5 min 20 sec 4 min 55 sec 5 min 30 sec n/a 6 min 30 sec

Climb to 10,000 ft 9 min 20 sec 8 min 50 sec 10 min 20 sec n/a n/a

Climb to 15,000 ft 18 min 17 min 40 sec 21 min 20 sec 16 min n/a

Service Ceiling 19,500ft 19,500ft 19,000 ft 26,000 ft 24,000 ft

Endurance 3 1/4 hr 2 1/4 hr 3 hr 3 hr 2 3/4 hr

Span 29 ft 31 ft 1 in 23 ft 28 ft 27 ft 9 in

Length 20 ft 19 ft 3 in 17 ft 7 in 18 ft 6 in 18 ft 10 in

Height 8 ft 4 in 9 ft 6 in 10 ft 8 in 9 ft 7 ft 10 in

Loaded Weight 1,992 lb 1,964 lb 1,888 lb 2,030 lb 1,860 lb

The Snipe was ordered in large numbers', including an initial 400 from Boulton & Paul, which must have been a bitter pill for John North to swallow. The other two Bobolink prototypes, C8656 and C8657 were cancelled on 9 April, though the fact that the serials were not re-issued may indicate that the construction of these two aircraft was well advanced.

The sole Bobolink was delivered to RNAS Hendon on 18 June for assessment as a shipboard fighter, though it was sent to Norwich the following day, for three days, possibly for modifications. It returned to Hendon on the 21st, and then returned to Norwich on 22 July, where presumably it ended its days.

P.3 Bobolink

230 hp Bentley B.R.2.

Span 29 ft; length 20 ft; height 8 ft 4in; wing area 266 sq ft.

Empty weight 1,226 lb; loaded weight 1,992 lb.

Maximum speed 125 mph at 15,000 ft; climb to 6,500 ft 5min 20 sec, to 10,000 ft 9 min 20 sec, to 15,000 ft 18 min; service ceiling 19,500 ft; endurance 3 1/4 hr at 15,000 ft.

Armament: two forward-firing Vickers machine-guns; provision for Lewis gun on universal joint mounting on upper wing.

With Boulton & Paul producing large numbers of Sopwith Camels, it was logical that John North should take an immediate interest in producing a Camel replacement, for which the Air Ministry had issued the official Specification A.1A. North began to urgently consider several layouts. The engine designated by the Air Ministry for use in the A.1A contenders was the 230 hp Bentley B.R.2 rotary, which was only 93 lb heavier than the 150 hp B.R.1. A second clutch of designs was built around the compact 170 hp ABC Wasp radial, the Sopwith 8F.l Snail, the Westland Wagtail and the BAT FK.22/2 Bantam.

Sopwith's entry in the design competition was the Snipe, which was some way ahead of its competitors, first flying late in 1917, powered by a B.R.l, as the larger engine was not yet available. It began life as a single-bay design, with a slab-sided fuselage, with two prototypes of slightly differing layouts being evaluated in December 1917. The third prototype was converted to a two-bay layout with a rounded fuselage, being delivered to Martlesham Heath fitted with one of the first B.R.2s in February 1918.

Although the Snipe represented the main competition, there were also two other important contenders for the Camel-replacement order, the Austin A.F.T.3 Osprey triplane, designed by North's successor at Austin, John Kenworthy, along with C H Brooks; and the Nieuport BN.1, Henry Folland's first design for the British Nieuport company, and owing much to his earlier design, the S.E.5A.

Boulton & Paul were awarded orders on 1 December, 1918, for two of their layouts, the P.3 and the P.5. Three prototypes were ordered for each design, the earlier set of serials, C8652-C8654, going to the P.5, and the later ones, C8655-C8657, to the P.3. The company bestowed the name Hawk on the P.5, though it may well have also been used for the P.3, but were forced to change it because of an Air Ministry nomenclature system which came into effect in 1918.

The names of birds of prey were reserved for aero-engines, (the Hawk being a Rolls-Royce engine), and single-seat single-engined landplanes were to be named after land-birds, other than birds of prey, or reptiles. In addition Boulton & Paul were awarded the initial letters BO. (Sopwith were awarded the initial letters SO, SA and SN-hence the name Snipe, and Austin were awarded AU, AS or OS - hence Osprey.) Boulton & Paul chose to rename their entry Boblink, later to be changed to Bobolink, which is a North American bird.

The P.5 was abandoned at an early stage and the serial numbers were re-allocated to other aircraft, but construction of the first P.3 went ahead with some urgency, to ready it for trials against the other three contenders at Martlesham Heath. Availability of the B.R.2 was as much a constraining factor as construction of the aircraft, and the first P.3 Bobolink, C8655, was eventually fitted with only the fourth B.R.2 built.

Like the revised Snipe it was a two-bay design with equal-span wings with 2 ft 31/2 in stagger. They featured N struts, which were still an unusual feature, though they had been used by North before the War on the Grahame-White Type 13. Their advantage was that they simplified rigging. The structure was a conventional wooden one, with fabric covering. The wings were very light, the lower ones, without their fabric covering weighed only 29 lb, a tribute to North's design, and Boulton & Paul craftsmanship. To begin with ailerons were only fitted on the upper wings, but a lack of manoeuvrability shown in early trials at Mousehold caused strut-linked ailerons to be fitted to the lower wings. There was a large rectangular cut-out in the upper wing to give the pilot excellent upper hemisphere vision.

Of necessity the front fuselage was of circular section to accommodate the rotary engine, but the aft fuselage was flat-sided, made up of a simple wire-braced box-girder, with a curved upper section behind the pilot's head. One feature displayed the clever thinking and careful design which were to become associated with North. These were the two fuel tanks, of 34 and 6 gal, placed behind the pilot, with an armour plate between them, so that one bullet would have little chance of damaging both. In case they caught fire, both tanks could be jettisoned in flight so that the pilot could glide safely to a landing, saving the rest of his aircraft. In the days when pilots were still not being allowed to wear parachutes in highly inflammable wood and fabric aircraft, this was a very clever idea.

The tail had a sharply-swept leading edge running to a curved fin. Overall length of the aircraft was 20 ft, span was 29 ft, and the height was 8 ft 4 in. In comparison the third prototype Snipe had 2 ft 1 in greater span, 1 ft 2 in more height, but was 9 in shorter.

Two Vickers machine-guns were fitted on the forward fuselage, firing through the 9 ft diameter arc of the two-blade propeller, and provision was made for a Lewis gun on a rail on the upper wing. When C8655 was rolled out of Riverside Works in December 1917, complete except for the front fuselage covering, this rail and Lewis gun were actually fitted, as well as the twin Vickers guns. Before delivery for evaluation the Lewis mounting was removed however. As might be expected the engine mounts and Vickers installation were very similar to those of the Camel.

Capt Frank Courtney undertook the company's initial flight trials at Mousehold. He had been transferred from training to RFC experimental flying and was engaged in the programme to fit 150 hp Monosoupape engines to Sopwith Camels for the Americans. Flight testing for this programme was undertaken at Mousehold on Boulton & Paul-built Camels, so it was natural that, as an experienced test pilot, he should give the Bobolink its first flights.

As well as finding fault with its manoeuvrability, which caused the ailerons to be fitted to the lower wings, Courtney also criticised the Bobolink for the narrow track of its undercarriage, which made taxi-ing difficult, though he felt it was not so serious a fault as to warrant any immediate change. The propeller fitted when the aircraft was first rolled out at Riverside had markedly square-cut tips, but all later pictures of it show conventionally rounded tips, probably the Snipe propeller with which it was fitted at Martlesham.

Delivery of C8655 to Martlesham Heath was made in the week ending 9 March, 1918, where it joined the Snipe. The Nieuport BN.1 and Austin Osprey were delivered in the same week, and flying evaluations were undertaken as a matter of urgency. As a final test a number of Service pilots, including Capt James McCudden were invited to evaluate the four aircraft in a day's trials at Sutton's Farm.

Each of the machines was tested with a Snipe propeller and a full specification load ie 40 gal of fuel, 8 gal of oil, 150 lb of Vickers guns and ammunition, 50 lb of Lewis gun and ammunition and 25 lb of electrical clothing and oxygen. Because of a breakage of its cowling no reliable performance trials could be made on the Nieuport.

The Osprey with its 23 ft wingspan was easily the most manoeuvrable, followed by the Nieuport, with the Bobolink the least favoured because of heavy handling and slow lateral reaction. The Osprey was clearly the slowest of the four; the short era of the triplane was really over. It had not in fact been granted an official order, but was built as a private venture, with special permission from the Air Ministry under Licence No.17, and awarded the serial X.15 in a special series reserved for such private-venture aircraft. The BN.l was a two-bay design like the Bobolink and Snipe, but featured revolutionary I struts, which were looked on with suspicion. It was the fastest of the four aircraft, with a very promising all-round performance, but on 10 March it suffered an unfortunate accident, catching fire in the air, and was completely destroyed, ruling it out of the contest, as a second prototype was not immediately available.

The view from the pilot's seat was best in the Snipe, followed by the Nieuport and the Bobolink, though with small alterations all three would be very similar in this respect. The Osprey was very much poorer, and there was no easy way to improve the pilot s view. As far as accessibility to engines and accessories were concerned, the Osprey was clearly the best, followed by the Snipe and the Bobolink, which were much on a par. The Nieuport was much the worst of the four, though alterations could improve to the standard of the other two biplanes.

The Vickers guns were equally well sited on the biplanes, but the crank handles were difficult to reach on the Osprey. The Lewis gun was difficult to use on the Bobolink and Snipe, as the pilot sat too near the rear spar, the Nieuport being much better in this respect. The Lewis gun was impossible to fit on the Osprey, except in a fixed vertical mounting.

The Applied Design Branch submitted a report on the ease of production and maintenance of the four aircraft. The Osprey and Nieuport were considered the best, though the design of the Nieuport's wings was criticised. The Bobolink was described as very bad from the production and maintenance point of view. This view does seem strange as the Bobolink had such a simple rectangular box-girder fuselage, whereas the Snipe for instance had a complicated rounded fuselage made up of formers and stringers.

There was little to choose between the four aircraft, though the greater experience of the Sopwith company, and the fact that the Snipe had been flying for some time, and had already had fundamental changes to its design, weighed heavily in its favour. Although its top speed was disappointing, (121 mph at 10,000 ft, 4 mph slower than the Bobolink), its rate of climb was magnificent, and its handling at altitude was excellent, feeling like a well-behaved Camel in the air.

Taking all factors into account the following order of merit was arrived at 1. Snipe, 2. Nieuport, 3. Osprey, 4. Bobolink.

Perhaps inevitably the Snipe was chosen, even though the Bobolink displayed a fractional edge in overall performance. Some of the other criticisms of the Bobolink were the narrow track of its undercarriage, and, though this could presumably have been cured, the poor access to the cockpit, which was set well within the cut-out of the upper wing.

The Bobolink was later fitted with a larger horn-balanced rudder to try to cure the ground-handling difficulties, the horn balance being unshielded, looking rather incongruous above the unchanged fin. The strut connection of the ailerons was also changed, being replaced by cable links. The Snipe too required a larger rudder, increasing its length to 19 ft 10 in.

Another B.R.2 powered fighter appeared later in the year, the Armstrong Whitworth Armadillo. By the time it flew there was no chance of it being ordered, but its details are included in the following comparison of the various contenders for completeness.

Performance and Dimensional Comparisons

Bobolink Snipe Osprey Nieuport BN.1 Armadillo

Speed at 10,000 ft 125 mph 121 mph 118 1/2 mph 127 mph 113 mph

Climb to 6,500 ft 5 min 20 sec 4 min 55 sec 5 min 30 sec n/a 6 min 30 sec

Climb to 10,000 ft 9 min 20 sec 8 min 50 sec 10 min 20 sec n/a n/a

Climb to 15,000 ft 18 min 17 min 40 sec 21 min 20 sec 16 min n/a

Service Ceiling 19,500ft 19,500ft 19,000 ft 26,000 ft 24,000 ft

Endurance 3 1/4 hr 2 1/4 hr 3 hr 3 hr 2 3/4 hr

Span 29 ft 31 ft 1 in 23 ft 28 ft 27 ft 9 in

Length 20 ft 19 ft 3 in 17 ft 7 in 18 ft 6 in 18 ft 10 in

Height 8 ft 4 in 9 ft 6 in 10 ft 8 in 9 ft 7 ft 10 in

Loaded Weight 1,992 lb 1,964 lb 1,888 lb 2,030 lb 1,860 lb

The Snipe was ordered in large numbers', including an initial 400 from Boulton & Paul, which must have been a bitter pill for John North to swallow. The other two Bobolink prototypes, C8656 and C8657 were cancelled on 9 April, though the fact that the serials were not re-issued may indicate that the construction of these two aircraft was well advanced.

The sole Bobolink was delivered to RNAS Hendon on 18 June for assessment as a shipboard fighter, though it was sent to Norwich the following day, for three days, possibly for modifications. It returned to Hendon on the 21st, and then returned to Norwich on 22 July, where presumably it ended its days.

P.3 Bobolink

230 hp Bentley B.R.2.

Span 29 ft; length 20 ft; height 8 ft 4in; wing area 266 sq ft.

Empty weight 1,226 lb; loaded weight 1,992 lb.

Maximum speed 125 mph at 15,000 ft; climb to 6,500 ft 5min 20 sec, to 10,000 ft 9 min 20 sec, to 15,000 ft 18 min; service ceiling 19,500 ft; endurance 3 1/4 hr at 15,000 ft.

Armament: two forward-firing Vickers machine-guns; provision for Lewis gun on universal joint mounting on upper wing.

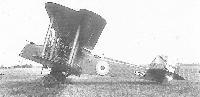

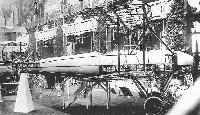

The first Boulton & Paul design to be built, the sole P.3 Bobolink on roll-out at Riverside, with the front fuselage still uncovered.

The P.3 Bobolink when first rolled out at Riverside in December 1917, with Lewis gun fitted to the upper wing

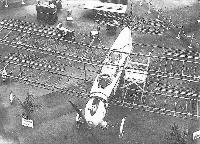

The Bobolink at Mousehold in June 1918. This is the only known picture of it fitted with horn-balanced rudder and cable-connected ailerons.

P.7 Bourges

During 1918 John North began work on a twin-engined day-bomber to the official Specification A.2(b) which called for a twin-engined reconnaissance bomber. The design received the project number P.7. With the formation of the RAF a new list of specifications was issued, and the P.7 was aimed at three of them, No.IV, (Long-distance photographic-reconnaissance fighter), No. VI (Short-distance day bomber), and No.VIII, (Long-distance day bomber). The company referred to it as a Fighter-Bomber, however.

Three prototypes were ordered, each of which was to differ in some details. They were each three-seat, three-bay aircraft with unstaggered wings, and a spruce frame. They were fabric covered with the standard PC10 khaki-green finish on upper and side surfaces, with clear-varnished linen on the underside. The P.7 was in competition with the Avro Type 533 Manchester, a development of the earlier Types 523 Pike and 529, and the Sopwith Cobham triplane.

The Air Ministry had decided that all twin-engined landplanes with an all-up weight of less than 11,000 lb were to be named after inland towns of England and Wales (Seaplanes being named after coastal towns); and Boulton & Paul also still had to use the initial letters BO. For some reason the company chose a French town, Bourges, as the name for the P.7, but this was in keeping with Airco, who chose Amiens for their D.H.10, and Vickers who chose the name Vimy. The name did not find favour with the workforce who tended to call it the 'Burgess' or the 'Boanerges'.

The crew consisted of two gunners in nose and dorsal positions, and a pilot seated in front of the wings. The pilot's position was slightly raised compared with that of the nose gunner, and he was provided with a large windscreen. The nose gunner's Scarff ring was canted forward and fitted with a trunnion device to carry two .303 in Lewis guns. There was transparent panelling in the nose and a sliding panel beneath the nose for bomb aiming. The front gunner acted as bomb-aimer, being equipped with a bombsight, and release gear. The pilot was also able to release the bombs in an emergency. The dorsal gun position was also equipped with twin guns, and the Scarff ring was recessed below the fuselage top-line.

To fulfil the aircraft's role as a reconnaissance bomber, a large camera position was located just in front of the dorsal gunner's position, the gunner operating the camera, with provision for a case of spare plates. Provision was also made for fitting a transmitting/receiving radio.

The first Bourges, F2903, was supposed to be fitted with ABC Dragonfly engines, and as such was designated the Mk 1A. The Dragonfly engines were late in coming, and they suffered horrendous development problems. Designed by Granville Bradshaw they were the first high-power radial engines. Unfortunately they suffered from tremendous vibration and especially cooling problems, the cylinders running a dull red after a few minutes. Their normal power was 320 hp, but this fell away considerably after a little running time. The Bourges was one of many aircraft to suffer from having been designed to take them, another being the rival Avro Manchester.

To enable flight trials to start Bentley B.R.2 rotary engines of 230 hp were fitted to F2903, and it was redesignated Bourges Mk IIA in this form. The letter 'A' denoted the fact that the upper wing was carried straight above the fuselage on conventional struts, the letter 'B' being reserved for a different layout with the upper wing inboard of the engines being of gull configuration, sloping down to join the fuselage, to give all crew members a better all-round view, and the dorsal gunner a better field of fire.

The fuselage was a straightforward wire-braced box-section, with slab sides. The horizontal tail was built into the upper surface of the rear fuselage, and was supported by two struts above each side, connected to the fin, which possessed pleasingly curved lines.

The B.R.2s were set midway between the wings at the inner bay struts, and were eventually replaced by Dragonflies in a closely-cowled arrangement with large spinners and two-blade propellers. The cooling problems of the Dragonfly led to the spinners soon being discarded and the cowlings redesigned with a curved frontal section. Early flight trials had also led to the introduction of large horn balances on the four cable-connected ailerons, which increased the span from 54 ft to 57 ft 4 in.

The undercarriage had a very wide-track, the single mainwheels being carried on V struts directly beneath the engines with a bracing strut running to the underside of the fuselage.

The all-up weight was 6,300 lb, with a fuel capacity of 190 gallons and an internal bombload of 900 lb. The bomb-bay was between the lower spars and the shutter-opening bomb doors were operated by a system of laths and tensioned cords.

Top speed was 124 mph at 10,000 ft, and that height could be reached in only 11 minutes. The landing speed was only 50 mph. The Bourges proved to be capable of being rolled, spun and looped with ease, and in the hands of the usual Boulton & Paul test pilot, Frank Courtney, it astonished the crowds at its first public outing at Hendon in 1919, at the reception for Commander Read and the transatlantic NC-4 flying-boat.

The handling of the Bourges was delightful, and by shutting down one engine, Courtney was able to emulate the gyroscopic effect of the rotary in the Sopwith Camel, making up for the larger dimensions and greater inertia of the Bourges. Charlie Brown, the mechanic on the Bourges was quite happy to lean casually out of the front gunner's cockpit of the aircraft while Courtney was rolling or looping it!

Despite the excellent performance of the Bourges no production orders were forthcoming. They were under discussion at the end of the War, but the Armistice brought an end to them, and the RAF used the D.H.10 which was just coming into service. But for the delays caused by the Dragonfly engines, the Bourges might have secured large contracts before the War's end. After the end of the War Boulton & Paul made strenuous attempts to sell the aircraft around the world, but were not helped by the attitude of the Air Ministry. The company wanted to display the Bourges at the Amsterdam Aviation Exhibition and the Paris Air Show of 1919, but were refused permission to do so by the Air Ministry. The situation must have been very frustrating for John North and the board of directors, though in truth it is unlikely that any sales would have been forthcoming.

The rival Avro Manchester also only flew in prototype form, initially with Siddeley Pumas instead of the Dragonflies, and it was not before December 1919 that the Manchester received its Dragonflies. Because of its larger dimensions the Manchester had a slightly inferior performance to the Bourges, and was not nearly so manoeuvrable.

The other competing aircraft the Sopwith Cobham triplane was unique in being the only Sopwith/Hawker twin-engined aircraft ever built. Like the others it was designed for the ABC engine, but it first flew with Pumas, until the Dragonflies finally arrived. Its development made leisurely progress after the end of the War and it did not even go through its trials until the spring of 1920.

The second prototype Bourges, F2904, was the Mk 1B, and apart from differing because of the sloping inboard upper-wing sections, also had the Dragonflies installed on the lower wing, rather than at mid-gap. Work at Farnborough with a D.H.10 in which the engine positions were varied had shown, against all expectations, that placing the engines in the mid-gap position caused higher drag than if they were placed on the lower wing. Work on the first Bourges had been too advanced to change the engine arrangement, but the opportunity was taken to do so with the second prototype.

The engines were mounted inboard of the inner wing-struts, so that the undercarriage struts had to be slightly lengthened, to give the propellers the necessary clearance. The tail also differed, the rudder being increased in area, and the fin reduced, and a large dihedral angle was given to the tailplane to match the angle of the sloping section of the wing.

A new bomb-release system was also introduced. Stowage for three bomb supporting beams was arranged between vertical guides and supported by quick-pitch screws geared to a common horizontal shaft. When this was free to rotate each bomb came in turn to the discharge position, then left the screws and moved down laterally between oblique guides, and out of the way of the next beam and bomb. There were three bomb cells with shutter doors.

A complete bomb-loading system was also devised for the Bourges. The bomb cell was hoisted into position by gear attached to the upper longerons and could be removed before flight.

The third and last Bourges, F2905, was designated P.7B, and first flew in December 1920. It had the straight upper wing of the Mk 1A, but was fitted with 450 hp water-cooled Napier Lion engines on the lower wing. The mainwheels were moved slightly outboard of the engines. The engines had frontal radiators and drove four-blade propellers, giving the aircraft a top speed of 130 mph at 10,000 ft, up from 124 mph with the Dragonflies. This was a very high speed for a bomber, and coupled with the exceptional manoeuvrability of the aircraft, meant it was sometimes categorised as a fighter/bomber, and was claimed to be the fastest twin-engined aircraft in the world.

On this aircraft revised gun mountings, designed for lightness, were fitted. They could take one or two Lewis guns and had padded stocks to help prevent the gunners receiving bruises as they pressed against them with their shoulders to help traversing.

With a relatively short wing-span and small overall dimensions. the light wing-loading of only 8 lb/sq ft. gave the Bourges almost single-seat fighter-like agility, and yet it had an endurance of 9 1/4 hours, and could carry a significant bomb-load. A projected Mk III version of the Bourges, fitted with 290 hp Siddeley Puma engines was never built.

F2905 was delivered to Martlesham Heath in March 1921 with 3 hr 49 min flying time. A further 5 hr were flown, most of them involving its full range of aerobatic manoeuvres, then serious failures occurred to some of the wing fittings. The top rear centre section strut was badly bent, the fitting plate attaching it to the rear spar with bolts being distorted. The front spar fittings were also deflected, but not as much. Several other fittings in adjoining bays of the top plane also showed signs of deflections. It was considered that the upper wing was moving back during a loop.

As the aircraft was due to fly at the RAF Pageant urgent modifications were made. Oblique struts were fitted from the top longerons to the rear spar of the centre section, and further oblique struts in the bay comprising the gunner's cockpit.

After a further 1 hr and 20 min flying which included aerobatics in practice for the Pageant and the actual display itself, further failures occurred, but not as badly as before. It was considered that the entire wing system was moving relative to the fuselage during violent manoeuvres. These failures show that the impressive aerobatic performance of the Bourges was undertaken right on the edge of the limits of the aircraft's stressing. After the second failures further strengthening was instituted to the plates, and the anti-drag wires were doubled.

As late as 1923 F2905, by then entered on the civil register as G-EAWS, was still thrilling the crowds at the RAF Pageant at Hendon. In the hands of Frank Courtney it undertook a mock dogfight with a pair of Nieuport Nighthawk fighters performing its full repertoire of loops, rolls and spins, completed with speed and accuracy. F2903 had also entered the civil register, as G-EACE, but was scrapped in May 1920. F2904 crashed at Mousehold early in 1919, and ended upside down with severe damage. The remains were obtained from the Air Ministry by the company and were totally rebuilt as the P.8 Atlantic, for an attempt on the nonstop transatlantic flight.

The Armistice had meant the Bourges, outstanding aircraft though it was, never went into production. The Bourges was the first twin-engined combat aircraft which was fully manoeuvrable, an outstanding advertisement for the design skills of John North and the Boulton & Paul company, but it came just too late.

Frank Courtney later stated that of the many aircraft that he flew in his career, the Bourges was one of his four favourites. The other three were the Camel, the Bristol Fighter and the Siskin; exhalted company indeed!

The Air Ministry and RAF were also impressed, even though they no longer had the money to place production orders, and awarded Boulton & Paul a contract to build a version of the Bourges with an all-steel airframe, the P.15 Bolton.

P.7 Bourges

Mk 1A and 1B: two 320 hp ABC Dragonfly I; Mk IIA: two 230 hp Bentley B.R.2; P.7B: two 450 hp Napier Lion.

Span 54 ft (57 ft 4 in with horn-balanced ailerons); length 37 ft; height 12 ft; wing area 738 sq ft.

Mk 1A and 1B: Empty weight 3,820 lb; Mk 1: loaded weight 6,326 lb; P.7B: loaded weight 6,800 lb.

Mk 1A and 1B: Maximum speed 123.5 mph at 6,500 ft. 121 mph at 10,000 ft. 112.5 mph at 15,000 ft; P. 7B: 130 mph at 10,000 ft. Mk 1A and 1B: Climb to 6,500 ft 7 min 40 sec, to 10,000 ft 13 min 35 sec. to 15,000 ft 25 min 25 sec; service ceiling 20,000 ft; endurance 9 1/4 hr.

Armament: one or two Lewis machine-guns on Scarff rings in nose and dorsal positions. 900 lb bombs.

During 1918 John North began work on a twin-engined day-bomber to the official Specification A.2(b) which called for a twin-engined reconnaissance bomber. The design received the project number P.7. With the formation of the RAF a new list of specifications was issued, and the P.7 was aimed at three of them, No.IV, (Long-distance photographic-reconnaissance fighter), No. VI (Short-distance day bomber), and No.VIII, (Long-distance day bomber). The company referred to it as a Fighter-Bomber, however.

Three prototypes were ordered, each of which was to differ in some details. They were each three-seat, three-bay aircraft with unstaggered wings, and a spruce frame. They were fabric covered with the standard PC10 khaki-green finish on upper and side surfaces, with clear-varnished linen on the underside. The P.7 was in competition with the Avro Type 533 Manchester, a development of the earlier Types 523 Pike and 529, and the Sopwith Cobham triplane.

The Air Ministry had decided that all twin-engined landplanes with an all-up weight of less than 11,000 lb were to be named after inland towns of England and Wales (Seaplanes being named after coastal towns); and Boulton & Paul also still had to use the initial letters BO. For some reason the company chose a French town, Bourges, as the name for the P.7, but this was in keeping with Airco, who chose Amiens for their D.H.10, and Vickers who chose the name Vimy. The name did not find favour with the workforce who tended to call it the 'Burgess' or the 'Boanerges'.

The crew consisted of two gunners in nose and dorsal positions, and a pilot seated in front of the wings. The pilot's position was slightly raised compared with that of the nose gunner, and he was provided with a large windscreen. The nose gunner's Scarff ring was canted forward and fitted with a trunnion device to carry two .303 in Lewis guns. There was transparent panelling in the nose and a sliding panel beneath the nose for bomb aiming. The front gunner acted as bomb-aimer, being equipped with a bombsight, and release gear. The pilot was also able to release the bombs in an emergency. The dorsal gun position was also equipped with twin guns, and the Scarff ring was recessed below the fuselage top-line.

To fulfil the aircraft's role as a reconnaissance bomber, a large camera position was located just in front of the dorsal gunner's position, the gunner operating the camera, with provision for a case of spare plates. Provision was also made for fitting a transmitting/receiving radio.

The first Bourges, F2903, was supposed to be fitted with ABC Dragonfly engines, and as such was designated the Mk 1A. The Dragonfly engines were late in coming, and they suffered horrendous development problems. Designed by Granville Bradshaw they were the first high-power radial engines. Unfortunately they suffered from tremendous vibration and especially cooling problems, the cylinders running a dull red after a few minutes. Their normal power was 320 hp, but this fell away considerably after a little running time. The Bourges was one of many aircraft to suffer from having been designed to take them, another being the rival Avro Manchester.

To enable flight trials to start Bentley B.R.2 rotary engines of 230 hp were fitted to F2903, and it was redesignated Bourges Mk IIA in this form. The letter 'A' denoted the fact that the upper wing was carried straight above the fuselage on conventional struts, the letter 'B' being reserved for a different layout with the upper wing inboard of the engines being of gull configuration, sloping down to join the fuselage, to give all crew members a better all-round view, and the dorsal gunner a better field of fire.

The fuselage was a straightforward wire-braced box-section, with slab sides. The horizontal tail was built into the upper surface of the rear fuselage, and was supported by two struts above each side, connected to the fin, which possessed pleasingly curved lines.

The B.R.2s were set midway between the wings at the inner bay struts, and were eventually replaced by Dragonflies in a closely-cowled arrangement with large spinners and two-blade propellers. The cooling problems of the Dragonfly led to the spinners soon being discarded and the cowlings redesigned with a curved frontal section. Early flight trials had also led to the introduction of large horn balances on the four cable-connected ailerons, which increased the span from 54 ft to 57 ft 4 in.

The undercarriage had a very wide-track, the single mainwheels being carried on V struts directly beneath the engines with a bracing strut running to the underside of the fuselage.

The all-up weight was 6,300 lb, with a fuel capacity of 190 gallons and an internal bombload of 900 lb. The bomb-bay was between the lower spars and the shutter-opening bomb doors were operated by a system of laths and tensioned cords.

Top speed was 124 mph at 10,000 ft, and that height could be reached in only 11 minutes. The landing speed was only 50 mph. The Bourges proved to be capable of being rolled, spun and looped with ease, and in the hands of the usual Boulton & Paul test pilot, Frank Courtney, it astonished the crowds at its first public outing at Hendon in 1919, at the reception for Commander Read and the transatlantic NC-4 flying-boat.

The handling of the Bourges was delightful, and by shutting down one engine, Courtney was able to emulate the gyroscopic effect of the rotary in the Sopwith Camel, making up for the larger dimensions and greater inertia of the Bourges. Charlie Brown, the mechanic on the Bourges was quite happy to lean casually out of the front gunner's cockpit of the aircraft while Courtney was rolling or looping it!

Despite the excellent performance of the Bourges no production orders were forthcoming. They were under discussion at the end of the War, but the Armistice brought an end to them, and the RAF used the D.H.10 which was just coming into service. But for the delays caused by the Dragonfly engines, the Bourges might have secured large contracts before the War's end. After the end of the War Boulton & Paul made strenuous attempts to sell the aircraft around the world, but were not helped by the attitude of the Air Ministry. The company wanted to display the Bourges at the Amsterdam Aviation Exhibition and the Paris Air Show of 1919, but were refused permission to do so by the Air Ministry. The situation must have been very frustrating for John North and the board of directors, though in truth it is unlikely that any sales would have been forthcoming.

The rival Avro Manchester also only flew in prototype form, initially with Siddeley Pumas instead of the Dragonflies, and it was not before December 1919 that the Manchester received its Dragonflies. Because of its larger dimensions the Manchester had a slightly inferior performance to the Bourges, and was not nearly so manoeuvrable.

The other competing aircraft the Sopwith Cobham triplane was unique in being the only Sopwith/Hawker twin-engined aircraft ever built. Like the others it was designed for the ABC engine, but it first flew with Pumas, until the Dragonflies finally arrived. Its development made leisurely progress after the end of the War and it did not even go through its trials until the spring of 1920.

The second prototype Bourges, F2904, was the Mk 1B, and apart from differing because of the sloping inboard upper-wing sections, also had the Dragonflies installed on the lower wing, rather than at mid-gap. Work at Farnborough with a D.H.10 in which the engine positions were varied had shown, against all expectations, that placing the engines in the mid-gap position caused higher drag than if they were placed on the lower wing. Work on the first Bourges had been too advanced to change the engine arrangement, but the opportunity was taken to do so with the second prototype.

The engines were mounted inboard of the inner wing-struts, so that the undercarriage struts had to be slightly lengthened, to give the propellers the necessary clearance. The tail also differed, the rudder being increased in area, and the fin reduced, and a large dihedral angle was given to the tailplane to match the angle of the sloping section of the wing.

A new bomb-release system was also introduced. Stowage for three bomb supporting beams was arranged between vertical guides and supported by quick-pitch screws geared to a common horizontal shaft. When this was free to rotate each bomb came in turn to the discharge position, then left the screws and moved down laterally between oblique guides, and out of the way of the next beam and bomb. There were three bomb cells with shutter doors.

A complete bomb-loading system was also devised for the Bourges. The bomb cell was hoisted into position by gear attached to the upper longerons and could be removed before flight.

The third and last Bourges, F2905, was designated P.7B, and first flew in December 1920. It had the straight upper wing of the Mk 1A, but was fitted with 450 hp water-cooled Napier Lion engines on the lower wing. The mainwheels were moved slightly outboard of the engines. The engines had frontal radiators and drove four-blade propellers, giving the aircraft a top speed of 130 mph at 10,000 ft, up from 124 mph with the Dragonflies. This was a very high speed for a bomber, and coupled with the exceptional manoeuvrability of the aircraft, meant it was sometimes categorised as a fighter/bomber, and was claimed to be the fastest twin-engined aircraft in the world.

On this aircraft revised gun mountings, designed for lightness, were fitted. They could take one or two Lewis guns and had padded stocks to help prevent the gunners receiving bruises as they pressed against them with their shoulders to help traversing.

With a relatively short wing-span and small overall dimensions. the light wing-loading of only 8 lb/sq ft. gave the Bourges almost single-seat fighter-like agility, and yet it had an endurance of 9 1/4 hours, and could carry a significant bomb-load. A projected Mk III version of the Bourges, fitted with 290 hp Siddeley Puma engines was never built.

F2905 was delivered to Martlesham Heath in March 1921 with 3 hr 49 min flying time. A further 5 hr were flown, most of them involving its full range of aerobatic manoeuvres, then serious failures occurred to some of the wing fittings. The top rear centre section strut was badly bent, the fitting plate attaching it to the rear spar with bolts being distorted. The front spar fittings were also deflected, but not as much. Several other fittings in adjoining bays of the top plane also showed signs of deflections. It was considered that the upper wing was moving back during a loop.

As the aircraft was due to fly at the RAF Pageant urgent modifications were made. Oblique struts were fitted from the top longerons to the rear spar of the centre section, and further oblique struts in the bay comprising the gunner's cockpit.

After a further 1 hr and 20 min flying which included aerobatics in practice for the Pageant and the actual display itself, further failures occurred, but not as badly as before. It was considered that the entire wing system was moving relative to the fuselage during violent manoeuvres. These failures show that the impressive aerobatic performance of the Bourges was undertaken right on the edge of the limits of the aircraft's stressing. After the second failures further strengthening was instituted to the plates, and the anti-drag wires were doubled.

As late as 1923 F2905, by then entered on the civil register as G-EAWS, was still thrilling the crowds at the RAF Pageant at Hendon. In the hands of Frank Courtney it undertook a mock dogfight with a pair of Nieuport Nighthawk fighters performing its full repertoire of loops, rolls and spins, completed with speed and accuracy. F2903 had also entered the civil register, as G-EACE, but was scrapped in May 1920. F2904 crashed at Mousehold early in 1919, and ended upside down with severe damage. The remains were obtained from the Air Ministry by the company and were totally rebuilt as the P.8 Atlantic, for an attempt on the nonstop transatlantic flight.

The Armistice had meant the Bourges, outstanding aircraft though it was, never went into production. The Bourges was the first twin-engined combat aircraft which was fully manoeuvrable, an outstanding advertisement for the design skills of John North and the Boulton & Paul company, but it came just too late.

Frank Courtney later stated that of the many aircraft that he flew in his career, the Bourges was one of his four favourites. The other three were the Camel, the Bristol Fighter and the Siskin; exhalted company indeed!

The Air Ministry and RAF were also impressed, even though they no longer had the money to place production orders, and awarded Boulton & Paul a contract to build a version of the Bourges with an all-steel airframe, the P.15 Bolton.

P.7 Bourges

Mk 1A and 1B: two 320 hp ABC Dragonfly I; Mk IIA: two 230 hp Bentley B.R.2; P.7B: two 450 hp Napier Lion.

Span 54 ft (57 ft 4 in with horn-balanced ailerons); length 37 ft; height 12 ft; wing area 738 sq ft.

Mk 1A and 1B: Empty weight 3,820 lb; Mk 1: loaded weight 6,326 lb; P.7B: loaded weight 6,800 lb.

Mk 1A and 1B: Maximum speed 123.5 mph at 6,500 ft. 121 mph at 10,000 ft. 112.5 mph at 15,000 ft; P. 7B: 130 mph at 10,000 ft. Mk 1A and 1B: Climb to 6,500 ft 7 min 40 sec, to 10,000 ft 13 min 35 sec. to 15,000 ft 25 min 25 sec; service ceiling 20,000 ft; endurance 9 1/4 hr.

Armament: one or two Lewis machine-guns on Scarff rings in nose and dorsal positions. 900 lb bombs.

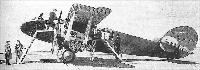

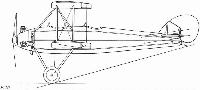

Bourges F2903, as first flown with Bentley B.R.2 rotaries in lieu of ABC Dragonflies, and designated Mk 1B in this form.

This interesting machine was just going into production when the Armistice came. It is a three-seater and can be used for a variety of War purposes, while in a somewhat altered form it has great possibilities as a peace-time aeroplane. In the photograph the machine is fitted with two B.R. 2 rotary engines, but later types are driven by two A.B.C. "Dragonfly" engines. The performance of the Bourges is excellent, and she is particularly easy on the controls, being in fact capable of evolutions which have hitherto been considered chiefly the domain of smaller machines.

This interesting machine was just going into production when the Armistice came. It is a three-seater and can be used for a variety of War purposes, while in a somewhat altered form it has great possibilities as a peace-time aeroplane. In the photograph the machine is fitted with two B.R. 2 rotary engines, but later types are driven by two A.B.C. "Dragonfly" engines. The performance of the Bourges is excellent, and she is particularly easy on the controls, being in fact capable of evolutions which have hitherto been considered chiefly the domain of smaller machines.

The P.6 Bourges Mk IIA F2903 in its original form, with the interim Bentley B.R.2 engines. The suffix 'A' denotes the straight-through upper wing.

Bourges F2903 at Mousehold with newly fitted horn-balanced ailerons. This machine, which is fitted with two A.B.C. "Dragonfly" engines, and the way it was handled by its pilot, Lieut. Courtney, was greatly admired at Hendon.

The short-lived Bourges Mk IB, F2904, with lower wing-mounted Dragonfly engines, gull wing, dihedral tailplane and horn-balanced ailerons.

A Napier Lion under test at Mousehold. The Lion was fitted to both the third Bourges, F2905, and the P.8 Atlantic.

The second P.7 Bourges. after crashing at Mousehold in 1919. The wreckage was used to build the second P.8.

P.6

Immediately after the Bobolink was cancelled Boulton & Paul's design department began work on a full-scale experimental aircraft, drawings for the wings for example being dated 14 April, 1918. Building such an aircraft was quite an unusual step at the time, given that most pioneering aircraft could be considered full-scale experimental machines, as their designers/builders did not really know if they would fly, or how well, until they tried. That John North should consider it, shows the meticulous way he intended to go about improving the company's design potential.

Because the Defence Regulations introduced in 1917 made it illegal to build an aircraft without official sanction, permission had to be obtained for construction of the P.6. It was registered in a special 'X' series reserved for such aircraft, and given the serial X.25, the last of this special series to be awarded.

The P.6 was a conventional wood and fabric two-seat biplane, the main purpose of which was to examine different aerofoil sections, as part of Boulton & Paul's basic systematic research programme. Having a full-size aircraft was useful for eliminating the errors of scale found in wind-tunnel data.

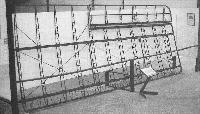

The wings were single-bay, unstaggered, and equal-span with a basic RAF 15 section. The chord was 5 ft and there was a relatively wide gap also of 5 ft compared with the span of only 25 ft, the forward cockpit being beneath the centre section of the upper wing. The wings were built of spruce spars and ribs, with a spruce leading edge, and an ash trailing edge. The 7 1/2 sq ft area ailerons were identical on upper and lower wings.

The fuselage contained a large number of Sopwith Camel parts, and was a similar box-section design, with slightly curved upper surface. The use of Camel parts was only to be expected as the company were still producing an average of 29 Camels a week. The engine cowling was metal, and left unpainted. The very rounded horn-balanced rudder was of 9 sq ft area compared with only 2 1/2 sq ft for the fixed fin.

The P.6 was powered by the RAF 1a air-cooled V-8 of 90 hp driving a four-blade propeller of 9 ft 3 in diameter. This gave it a speed of 103 mph at 1,000 ft and the 20,1 gal fuel tank gave an endurance of 2 hr 20 min.

The date of the P.6's first flight is unknown, but it is likely to have been late in 1918, the use of Camel parts suggesting construction of the P.6 before Camel production gave way to Snipe production in November. It is probable that Frank Courtney made the first flight, he certainly flew the aircraft on several occasions, and gave Mrs Dawson Paul her first flight in it in March 1919.

Whether interchangeable mainplanes were actually fitted to the aircraft at any time is not recorded, but considerable experimental data was collected from its operation. The P.6 was a handy light aircraft, apart from its experimental usefulness, and after the War was actually offered for sale for ?600, though the company built a slightly larger version, the P.9, as their main offering for the civil flying boom which they hoped would follow.

The P.6 was put to practical use as transport for the company's general sales manager, being registered K-120/G-EACJ on 20 May, 1919; though there is some doubt that the aircraft ever wore these markings, retaining its X.25 serial and RAF roundels in all surviving photographs. It was painted with the large letters Boulton & Paul Ltd, Sales Dept, on the fuselage sides in an early form of aerial advertising, and so became one of the first corporate aircraft, and is credited with making the first business flight, on 1 May, 1919, from Norwich to Bury St Edmunds.

P.6

90 hp RAF 1a.

Span 25 ft; length 19 ft; height 8 ft; wing area 235 sq ft.

Empty weight 1,100 lb; loaded weight 1,725 lb.

Maximum speed 103 mph at 1,000 ft; climb to 5,000 ft 9min; endurance 2 hr 20 min.

Immediately after the Bobolink was cancelled Boulton & Paul's design department began work on a full-scale experimental aircraft, drawings for the wings for example being dated 14 April, 1918. Building such an aircraft was quite an unusual step at the time, given that most pioneering aircraft could be considered full-scale experimental machines, as their designers/builders did not really know if they would fly, or how well, until they tried. That John North should consider it, shows the meticulous way he intended to go about improving the company's design potential.

Because the Defence Regulations introduced in 1917 made it illegal to build an aircraft without official sanction, permission had to be obtained for construction of the P.6. It was registered in a special 'X' series reserved for such aircraft, and given the serial X.25, the last of this special series to be awarded.

The P.6 was a conventional wood and fabric two-seat biplane, the main purpose of which was to examine different aerofoil sections, as part of Boulton & Paul's basic systematic research programme. Having a full-size aircraft was useful for eliminating the errors of scale found in wind-tunnel data.

The wings were single-bay, unstaggered, and equal-span with a basic RAF 15 section. The chord was 5 ft and there was a relatively wide gap also of 5 ft compared with the span of only 25 ft, the forward cockpit being beneath the centre section of the upper wing. The wings were built of spruce spars and ribs, with a spruce leading edge, and an ash trailing edge. The 7 1/2 sq ft area ailerons were identical on upper and lower wings.

The fuselage contained a large number of Sopwith Camel parts, and was a similar box-section design, with slightly curved upper surface. The use of Camel parts was only to be expected as the company were still producing an average of 29 Camels a week. The engine cowling was metal, and left unpainted. The very rounded horn-balanced rudder was of 9 sq ft area compared with only 2 1/2 sq ft for the fixed fin.

The P.6 was powered by the RAF 1a air-cooled V-8 of 90 hp driving a four-blade propeller of 9 ft 3 in diameter. This gave it a speed of 103 mph at 1,000 ft and the 20,1 gal fuel tank gave an endurance of 2 hr 20 min.

The date of the P.6's first flight is unknown, but it is likely to have been late in 1918, the use of Camel parts suggesting construction of the P.6 before Camel production gave way to Snipe production in November. It is probable that Frank Courtney made the first flight, he certainly flew the aircraft on several occasions, and gave Mrs Dawson Paul her first flight in it in March 1919.

Whether interchangeable mainplanes were actually fitted to the aircraft at any time is not recorded, but considerable experimental data was collected from its operation. The P.6 was a handy light aircraft, apart from its experimental usefulness, and after the War was actually offered for sale for ?600, though the company built a slightly larger version, the P.9, as their main offering for the civil flying boom which they hoped would follow.

The P.6 was put to practical use as transport for the company's general sales manager, being registered K-120/G-EACJ on 20 May, 1919; though there is some doubt that the aircraft ever wore these markings, retaining its X.25 serial and RAF roundels in all surviving photographs. It was painted with the large letters Boulton & Paul Ltd, Sales Dept, on the fuselage sides in an early form of aerial advertising, and so became one of the first corporate aircraft, and is credited with making the first business flight, on 1 May, 1919, from Norwich to Bury St Edmunds.

P.6

90 hp RAF 1a.

Span 25 ft; length 19 ft; height 8 ft; wing area 235 sq ft.

Empty weight 1,100 lb; loaded weight 1,725 lb.

Maximum speed 103 mph at 1,000 ft; climb to 5,000 ft 9min; endurance 2 hr 20 min.

The P.6 with Boulton & Paul Ltd painted on the fuselage, as used to make the first busmess flight in the United Kingdom, 1 May, 1919.

The sole P.6 in postwar guise, but still retaining its wartime special serial X 25. It was used as a company transport after its experimental flying.

P.8 Atlantic

At the end of the War there were two dozen aircraft manufacturers in the United Kingdom with their own design departments. All of them were faced with the fact that their only products were no longer wanted. The RAF had thousands of surplus aircraft on strength, and hundreds more were being built each week until contracts were cancelled. There was no prospect of military orders in the immediate future, but most companies hoped for a boom in civil flying, and set about converting whatever designs they had for their most suitable civil use, or drawing new purpose-built machines.

Although they had only built three aircraft of their own design at the end of the War, a Bobolink, a P.6, and the first Bourges, with two more Bourges nearly completed, Boulton & Paul had some advantages over many manufacturers. The P.6, though basically experimental, was really just a two-seat light aircraft, ready for promotion as a private aeroplane with very little modification, and the Bourges was an outstanding twin-engined bomber, once the Dragonflies were abandoned in favour of Napier Lions, and offered a very advanced basis for the design of an airliner.

The company suffered from one grave disadvantage, however. Although they had built over 2,000 aircraft during the War, because so few were of their own design, their name was not in the forefront of aviation circles. There was, however, one very good chance to place their name in the limelight and to promote a new airliner based on the Bourges at the same time. The Daily Mail ?10,000 prize for the first nonstop flight across the Atlantic had been held in abeyance since before the War.

Of course many of the other manufacturers joined the immediate race to win this prize, and to promote their own products. Each attempted to maintain the utmost secrecy so as to try and steal a march on their rivals. Quickest off the mark were Sopwith with their single-engine Atlantic, based largely on their wartime B.1 with many Cuckoo components for speed of construction, and Martinsyde with a much enlarged version of the F.4 Buzzard renamed The Raymor. Frederick Handley Page saw his four-engined V/1500 as the ideal aircraft for the job, and Vickers entered with their twin-engined Vimy. Shorts saw the excellent range of the Shirl torpedo bomber as a basis for a machine capable of flying the Atlantic east to west, unlike all the others who preferred to fly in the other direction with the prevailing winds. Fairey made preparations to convert their Fairey III seaplane for an attempt and the Alliance Aircraft Company built a special aircraft for the task, their P.2 Seabird, powered by a single Napier Lion. Finally Boulton & Paul began the preparation of what would be one of the most thoughtfully conceived designs to be prepared to contest the Daily Mail prize, the P.8 Atlantic.

Two prototypes were to be built, and from the outset the first was designed and built purely for the Atlantic attempt. The second Bourges prototype, F2904, having been heavily damaged in a crash at Mousehold, was obtained from the Air Ministry and dismantled. The remains of its structure formed the basis for the first prototype, the sloping upper wing centre section, and the Dragonfly engines being dispensed with entirely.

The wings of the P.8 were of increased span, to 60 ft 4 in, but were the same basic Bourges three-bay unstaggered units with the straight-through centre section on the upper wing which had 8 ft chord and the lower 6 ft 6 in. There were horn-balanced ailerons on all four wings. Standard wooden construction was used but the spar fittings were very substantial, with all the struts pin-jointed and backed by metal fish-plates at every junction.

Though John North had already decided that the future of aircraft construction lay in metal structures the use of wood was continued in the P.8 for convenience, and above all for speed of construction. That did not prevent him introducing certain improved techniques. For the securing of metal fittings to the wooden fuselage longerons, tubular rivets were introduced instead of bolts. The rivet was inserted through metal fishplates on each side and the ends flattened with rivetting tools which were developed especially for the job, resulting in just a splayed mouth on each side instead of a projecting bolt. This resulted in a joint which was much lighter and compact and they were much quicker to fit, though they took longer to replace than conventional bolts.

Although the major visual change in the P.8 from its predecessor was the fact that the fuselage filled the 6 ft 6 in gap between the wings, the fuselage actually retained the basic Bourges structure. The upper part was merely a fairing of bridges and runners, this, too, was to speed completion, to prepare the aircraft for the Atlantic attempt before its rivals. The fuselage had four longerons braced and cross-strutted with tie-rods. The upper longerons being dead straight when the aircraft was in the flying position, and therefore very useful for bracing purposes. The gunner's position in the nose was replaced by a rounded construction covered with plywood and fabric.

The pilot's cockpit was situated just in front of the wings, as in the Bourges, but it was given a fully-enclosed canopy, a very advanced feature for the day. It was faired into the fuselage upper surface, so that rear view was restricted, but the view forward, sideways and down was excellent, better than any airliner extant, and not equalled until the D.H. Dragon appeared. For conservative pilots who liked to feel the wind around their ears, an upper skylight was provided, which could be opened. In the first prototype, for the Atlantic attempt, provision was made for a relief pilot and a radio operator who was provided with two sets, one for communications and one for direction finding. In the event of ditching in the Atlantic, a small balloon and hydrogen bottle were provided, to carry the radio aerial aloft for emergency signals. The radio operator and navigator were accommodated in a cabin just behind the cockpit, illuminated by large rectangular windows on each side.

Behind the crew compartment the whole of the cabin space was taken up with six fuel tanks. They were fitted with jettison valves, so that the entire fuel load could be dumped in 1 1/4 minutes, and were so situated that once empty, they would keep the aircraft afloat the right way up. The fuel capacity was sufficient for a flight of 3,850 miles, and the performance of the aircraft was such (its cruising speed of 116 mph was much higher than any potential competitor), that it could maintain height on only one engine after only two hours' fuel had been consumed. More importantly, of course, this meant that the aircraft could maintain height at only half throttle, thus putting little strain on the engines.

The engines were 450 hp Napier Lions, with aluminium cowlings, carried on the lower wings inside the inner interplane struts. The frontal radiators fitted to each engine on the Bourges P.7b were dispensed with, and replaced by one retractable fuselage mounted radiator. This was connected to a header tank above each engine with two cut-off valves each side so that the system could be closed off should a leak develop on either side. The oil tanks, each of 6 gal capacity were fitted behind each engine, alongside self-starting magnetos. The engines drove four-blade propellers of 9 ft 6 in diameter, and were braced by steel tubing to the fuselage longerons, forming a strong triangulation with the bracing wires.

The fin and horn-balanced rudder were circular in profile, but the tailplane was square-cut like the wings, and the elevators had no horn balance. Because the rudder was insufficient to maintain heading on asymmetric power two small fins were fitted, projecting above and below the tailplane. These could be locked at an angle in the airstream in the event of one engine failing.

The P.8 was so stable it could virtually be flown hands off when fully trimmed, and it was possible, by moving a single lever, to lock the elevators and ailerons and transfer rudder control to the wheel. This was unusual in that such a device would normally have operated the ailerons only, since on most aircraft steering on rudder only produces the effect of tightening into a dive. On the P.8 a slight touch of rudder was enough to return it to the required heading with no loss of height. This device was also useful for steering the aircraft on the ground using hands only instead of feet, as long as the pilot remembered to unlock the controls before taking off!

To the left of the pilot was the wheel for lowering and raising the radiator, to his right were two wheels, one to set the angle of the auxiliary fins on the tailplane, to overcome asymmetric thrust, and the other for controlling the angle of tailplane incidence.

The undercarriage was probably the most advanced feature of the aircraft. The units were V-shaped, with the legs attached at the inner interplane struts, giving a very wide track, and the split-axles hinged at the bottom fuselage longerons. One very large Palmer aircraft wheel and tyre was fitted on each side. The technological advance was in the springing, which was not the normal simple rubber bungee, but also contained an oleo-pneumatic leg to take landing shocks. This combination springing was even more advanced in concept that the pure oleo-pneumatic undercarriages which were soon to appear. The early oleo-pneumatic systems could take landing shocks very well, but were less able to absorb the frequent vertical jolts caused by taxi-ing over rough grass aerodromes.

The crew chosen for the Atlantic flight was, Maj K S Savory as first pilot, Capt A L Howarth as second pilot and radio operator, and Capt J H Woolner as navigator. Boulton & Paul's managing director, Maj Guy ffiske went to Newfoundland and chose a suitable take-off field, and the weather conditions over the North Atlantic were studied in great detail for several months.

The race for the prize was developing publicly. After test flights in February 1919 the Sopwith was shipped, and on 19 March the Daily Mail was officially notified of its entry for the prize. The entries of the Short Shamrock as the modified Shirl had been named in honour of its proposed take-off point at the Curragh, the Martinsyde Raymor, and the Fairey III seaplane were to follow in quick succession.

The Sopwith Atlantic arrived in Newfoundland on 29 March, and shortly afterwards the Martinsyde had a 24 hr ground test, followed by its Rolls-Royce Falcon engine being stripped down and examined. At Vickers the modifications to the 13th Vimy off their production lines were nearing completion and both the pilot, John Alcock and the navigator, Arthur Whitten Brown had been chosen.

Preparations by Boulton & Paul were severely delayed when the still unregistered P.8 crashed. In the haste to get the P.8 ready for the Atlantic flight, Frank Courtney ran up each of the engines separately before the first flight in April 1919, thereby failing to discover that there was a fault in the fuel system which did not give an adequate supply to both at once. One of the Lions cut out just after take off, the aircraft yawed into wind and a wingtip struck the ground, virtually writing it off. The entire nose section broke free, with Courtney within it, and he was unhurt.

The second P.8 was being built, and preparations were put in place to use this on the Atlantic flight. On 11 April the Sopwith Atlantic had been test flown in Newfoundland, but was soon grounded because of rain and thick mist. The Martinsyde had just arrived in Newfoundland and four days later the Handley Page V/1500 was shipped.

On 18 April the Vickers Vimy was test flown at Brooklands, and on the same day the Short Shamrock, which was basically a Shirl with the wing extended to three bays and a huge droppable cylindrical fuel tank bringing the total fuel load to 435 gal, took off from Eastchurch for Ireland. Piloted by Maj J C P Wood with Capt C C Wyllie as navigator, it was refuelled at Holyhead, and then took off for the Curragh, which was considered the only place in Ireland with a long enough take-off run for the fully-laden machine. Twelve miles out across the Irish Sea the engine stopped and Wood had to ditch. The Shamrock remained afloat, though upside down, and was towed into Holyhead harbour, and Wood announced his intention of remaining in the contest.

Although not in competition for the Daily Mail prize, the Americans were mounting an official government attempt to be the first across the Atlantic, albeit in stages via the Azores. Three Curtis NC flying-boats would fly in formation via Newfoundland and the Azores to Lisbon, along a route which would be marked by a line of 68 destroyers stationed at intervals of 50 miles, with five battleships stationed at distances of 500 miles. Every fourth destroyer would act as a meteorological station. Just in case the flying-boats failed to make it, despite this massive support, a four-man airship was moved to Newfoundland to make the attempt. On 8 May the three NCs took off from Rockaway, New York, on the first leg to Newfoundland, though it took five days for them all to get there.

The threat of the Americans being first spurred the small private British teams into action. Both the Sopwith and Martinsyde crews made hasty preparations, but the Americans took off first. On 16 May the three NCs lifted off from Trepassey Bay and headed for the Azores, but only one was to arrive, NC-4 at 9.25 am on 17 May.

Though news of the Americans' arrival in the Azores reached Newfoundland, there was still a chance that the British could be first across. On 18 May the Sopwith Atlantic took off from Newfoundland, piloted by Harry Hawker, with Lieut Cdr MacKenzie-Grieve as navigator. It was eight days before anything more was heard from them. They had ditched in the ocean, and were luckily picked up by a ship, though they were over 100 miles off course after flying 800 miles on dead reckoning. Their failure justified safety measures built into the Boulton & Paul P.8, the single-engined performance, and the direction-finding radio in particular.

The Sopwith aircraft actually passed over the heads of the Martinsyde crew as they were making frantic attempts to get the Raymor ready. Attempting to take off 20 min after the Sopwith had disappeared the undercarriage of the overloaded Raymor collapsed, and the aircraft was heavily damaged.

On 27 May the NC-4, commanded by Lieut Commander Read left the Azores and reached Lisbon the same day, the first aircraft to fly the Atlantic. The honour of making the first nonstop flight, and with it the ?10,000 prize still remained to be captured however.

Meanwhile the Handley Page V/1500 and Alcock and Brown's Vickers Vimy had arrived in Newfoundland. The Handley Page was found to be damaged, and repairs were put in hand. It was to have a four-man crew, Maj H G Brackley, pilot, Admiral Mark Kerr, second pilot, Tryggve Gran, navigator and third pilot and F Wyatt, wireless operator. After the repairs had been completed, a trial flight could not be made until 10 June because of bad weather conditions. Trial flights revealed that the engines had an alarming tendency to overheat, and new radiators were sent for from England, but were not to arrive before the 18th.