Книги

Журнал

Flight за 1918 г.

479

Журнал - Flight за 1918 г.

Flight, May 23, 1918.

THE AUSTRIAN BERG SINGLE-SEATER FIGHTER.

200 H.P. AUSTRO-DAIMLER ENGINE.

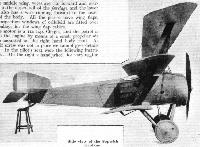

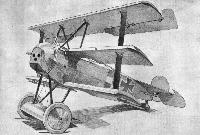

[While the different types of aeroplanes produced in Germany are fairly well known in this country, owing chiefly to the number of them that have been captured from time to time, our knowledge of the Austrian aircraft industry is more limited. This is partly due to the fact that fewer of them are seen on the western front, Austrian activities in the air being more particularly confined to the Italian theatre of war, where the various types of Austrian machines are probably as well known as are the German on the battle front in France. Also it should be remembered that to a large extent, so far as our knowledge goes, the Austrian industry has been conducted more along the lines of constructing German-designed machines under licence, thus tending to increase output, rather than with an aim to encouraging original design. That home designing has not been altogether stopped in Austria is evident, however, since from time to time one hears of Austrian machines, of makes known not to be German licence productions, being seen by Allied pilots. Among these is the Austrian Berg single-seater fighter. Reports have been received occasionally of this machine, but up to the present nothing definite has been generally known concerning it. Now, however, one of these has been added to the collection in the Enemy Aircraft View Rooms, and by the courtesy of the authorities we are able this week to publish a brief description and an illustration of the Austrian Berg. To the best of our knowledge this is the first description to be published in this country.-ED.]

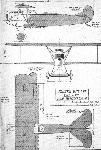

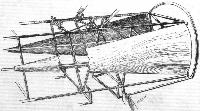

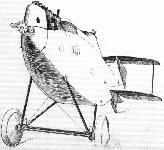

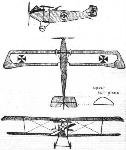

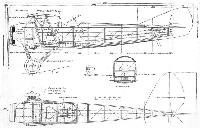

SIMPLICITY would appear to be the keynote of design in the Austrian Berg single-seater fighter, both as regards mass, or aerodynamic, design and structural design. The machine has every appearance of being designed chiefly with a view to rapidity of production, yet this object has been attained by a studied simplicity of detail rather than by any scamping in workmanship. In fact, although the finish is not, perhaps, as good as on some machines, the workmanship appears everywhere to be really quite good, and the materials employed in the construction are, if anything, better than found on a good many German machines. Whether this is due to a more plentiful supply of the right materials in Austria than in Germany, or whether Austrian inspection is stricter than that obtaining in Germany, is difficult to say; and one can only call attention to the fact without venturing an explanation.

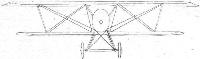

Fundamentally the Austrian Berg is of the single-seater fighter type in which the pilot and top plane are so placed in relation to each other that the wing obstructs the view to a very small extent only. This has been accomplished, not so much by reducing the gap to a smaller proportion of the chord than usual, as by making the body very deep and placing the pilot fairly high inside the body. On closer examination it is found that the extra depth of the body is provided by deepening the turtle back, which forms a much greater proportion of the overall depth than is the case in most machines.

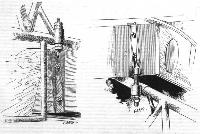

The body proper, which is of the flat-sided variety, is constructed on similar lines to those of the older models of Albatros biplanes, i.e., of longerons and struts of fairly small section, the whole being covered with three-ply wood. As distinct from the Albatros, however, there are only four longerons, the auxiliary rails halfway up the sides of the latter having evidently been deemed unnecessary by the designer of the Berg. The turtle back, which is different from the majority in that it does not, except in front, cover the whole width of the flat top of the body, but comes to a point just in front of the vertical fin, is of a peculiar section. This may, in the absence of a sketch, best be described by saying that it consists of three curvatures, a convex at the top, a concave halfway down, and again a convex at the bottom. The object, evidently, is to provide stream lining of the pilot's head by having the turtle back deep without, however, obstructing the view to too great an extent by having it very wide. Roughly the configuration is that of a man's head and shoulders.

The pilot's cockpit is very comfortable, the deep top efficiently screening his face while at the same time, owing to the peculiar outline, not obstructing the view to as great an extent as one would imagine. By leaning his head slightly the pilot can easily look past the nose of the machine, so that there is really no "blind" spot beyond a few yards ahead of the machine. The fact that the chord line of the upper wing if projected passes through the pilot's line of vision renders the view forward and upward particularly good. Small circular windows are inserted in the turtle back in front of the pilot, but it appears that the view obtainable through these is of very little practical utility, and the inference is that they are placed there to admit light on to the instrument board rather than to provide direct vision.

The pilot's seat is extremely comfortable, and is provided with arm rests, thus enabling the pilot to rest one arm while working the control lever with the other. For a long flight this makes for comfort. It is only a minor point, it is true, but one nevertheless which is worthy of consideration. On the whole the machine gives the impression that it would be a very comfortable machine to fly, regarded purely from the flying point of view, and without knowing anything about its capabilities as used for fighting.

The controls are more or less of the usual type. There is a longitudinal rocking shaft, mounted rather higher above the floor boards than is generally the case. The control lever is forked around this shaft, and is free to oscillate forward and backward for operating the elevator. A short length of cable passes from the lower end of the "joystick" to a point on the floor boards. This limits the extent to which the lower end of the lever can move back, and has the effect of preventing, when on the ground, the elevators from touching and getting damaged. In connection with the lateral controls, the wing flaps are fitted with cranks resting in slots in the planes, and there is a somewhat unusual arrangement whereby the positive cable is taken to the front arm of the crank, so that it is the return cable which pulls the wing flap down. The reason for this may be found in the warped wing flap, which may conceivably have its outer tip tilted upwards to such an extent that the effect of moving the flaps is to put a force acting downward on the flap moved upwards before the flap on the opposite side, which has, of course, been moved down simultaneously, receives an upward force. To bring this peculiar action about the crank on the rocking shaft points downwards instead of, as is more usually the case, pointing upwards.

The foot bar operating the rudder is of the T type. That is to say, the rudder control cables are attached to a crank arm projecting forward at right angles to the foot bar. The cables are then taken around pulleys near the side of the body, and hence to the rudder cranks. The guards on the rudder bar, which prevent the accidental slipping off of the pilot's feet, are in the form of spiral springs, each composed of two layers, an inner spiral of fairly thin wire, and an outer spiral of heavier wire.

The engine, which, we are informed, was a 200 h.p. Austro-Daimler, is not shown in place on the machine, but it would appear to have been totally covered in by a deep engine housing. It is mounted on two spruce bearers, each made up of three laminations, mounted on four transverse partitions. These are made up of a spruce centre with facings of three-ply. The armament appears to have been made up of two machine guns, one on each side of the engine, and fitted with the usual interrupter gear.

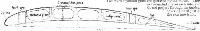

The wings, which are both of equal span, present nothing out of the ordinary as regards their construction, except that some of the fittings for the internal wire bracing and compression tubes are exceptionally neat in conception and well carried out. Aerodynamically, however, the wings present an interesting feature. The upper surface of the wing section has a most decided return sweep, beginning behind the rear spar and being of such a magnitude as to present a considerable area of concave surface.

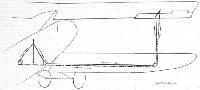

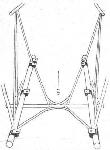

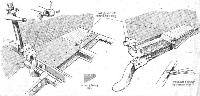

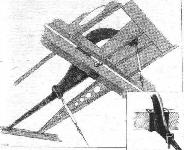

The undercarriage of the Berg is not in place on the machine as exhibited, but from fragments it is judged to have been of the Vee type, and in the accompanying illustration we have endeavoured to reconstruct it approximately as various considerations indicate that it must have been.

The tail planes are built of steel tubing throughout, and the fixed tail plane is chiefly remarkable on account of the fact that, although it is built up of single steel tubes, the section is made cambered by bending the single tubes forming the ribs. Both upper and lower surfaces, therefore, have the same camber. The incidence of the tail plane is adjustable, but not during flight.

Later, as opportunity occurs, we hope to be able to publish some illustrations of the more important constructional details of the Austrian Berg fighter.

Flight, October 24, 1918.

THE AUSTRIAN BERG SINGLE-SEATER

200 H.P. AUSTRO-DAIMLER ENGINE

[In our issue of May 23rd, 1918, we published a brief description and an illustration of the Austrian Berg Single-Seater. We have since been able to carefully examine this machine in detail, and to prepare drawings and sketches of its main constructional features.-ED.]

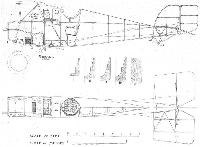

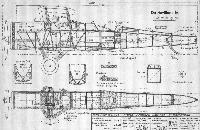

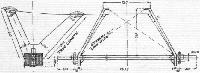

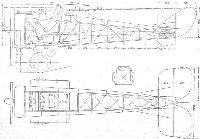

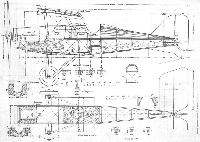

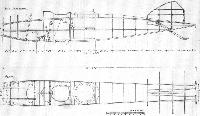

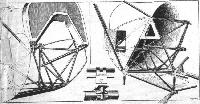

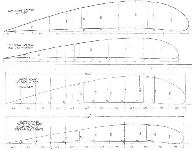

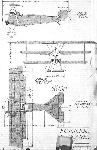

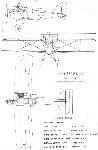

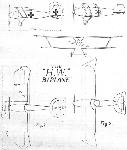

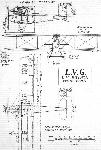

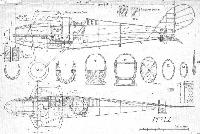

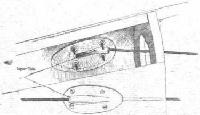

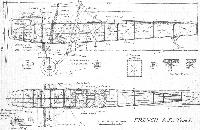

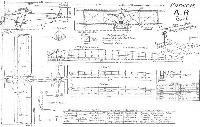

As a type the Austrian Berg belongs to the single-seater fighter class with high-power engine. It follows what has now become almost standard practice for single-seaters in its strut arrangement, which comprises only one pair of interplane struts on each side. As a single-seater it is desirable that the view forward and upward shall be as good as possible, and this has been aimed at, and attained to quite a fair extent, in the Berg by placing the top plane low over the body, where, owing to the angle of incidence, the pilot from where he is placed sees it practically edge on. When we say that the top plane has been placed low over the body we do not mean to infer that the gap between the planes has been reduced beyond normal. Rather has the relative position of top plane and top of body been attained by making the body very deep at this point, and by so seating the pilot - fairly high in the body - that he obtains the view desired. This is accomplished, not so much by making the main body very deep, but by surmounting it with a fairing of turtleback of much greater depth than those usually found on machines of this size. With the object always in view of obstructing the pilot's vision to as small extent as possible, this turtle-back, also that portion of it lying in front of the pilot, has been kept narrow at the top. In section it forms what is roughly the shape of a man's head and shoulders, as will be seen from the front elevation in the general arrangement drawings. In this manner, by leaning his head slightly to one side or other, the pilot can easily see past his engine, the cowling of which, although not in place on the machine examined, has probably conformed to the same contour as the rest of the fuselage top. To the rear of the pilot's seat this turtle-back tapers off until it ends in a point some little distance ahead of the tail planes. The lateral taper of it is somewhat more abrupt than is that of the body rails, so that as the rear portion of the body is approached there is a widening strip of flat horizontal surface on each side of the turtle-back. This will be seen in the plan view of the general arrangement drawings and also in the plan of the body in Fig. 1.

Fuselage.

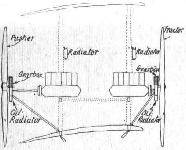

Constructionally the fuselage of the Berg biplane is of the same type as that of the earlier models of Albatros biplanes, i.e., there is a light internal framework of wood, covered on sides as well as top and bottom with three-ply. There are no internal wires for bracing the body, the three-ply covering being relied upon to perform this function. Although not possessing such refinements as rounded sides, the body of the Berg is of fairly good stream-line form, as will be seen from the illustrations. The machine exhibited is in a somewhat incomplete state as regards its front portion, especially the top covering of it and the engine-housing and radiator, which is absent. We have endeavoured, however, to reconstruct it to a certain extent, as shown by the dotted lines in the side elevation of the general arrangement drawings. The top plane shows clearly that no radiator has been mounted in its centre section, and as there are no indications that the radiator has been fitted on the sides of the body, the inference is that it must have been placed in the extreme nose. As to the exact shape the radiator may have had, this is a matter for conjecture, but in view of the shape of the fuselage top it appears probable that the radiator was of somewhat similar shape, as otherwise undesirable lines must have developed where the shape of the radiator was carried into that of the engine-housing.

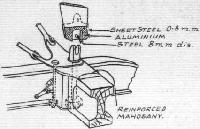

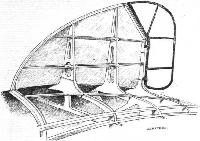

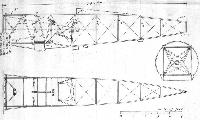

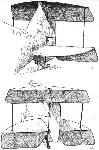

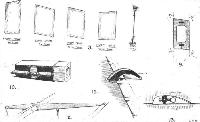

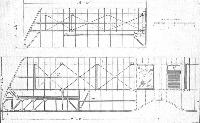

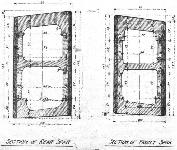

The general shape of the body, and many of the details will be clear from Fig. 1. It will be seen that there are only four main longerons, whereas the early-type Albatros had six, two of which were placed approximately halfway up between upper and lower corner rails. In the front portion of the body the bulkheads are of special form to provide supports for the two engine-bearers. The shape of these bulkheads or engine cradles is shown in the half-sections I to V inset in Fig 1. As none of these cradles had been sectioned up on the machine examined, it has not been possible to do more than give their outward shape. Judging from such external evidence, however, as rows of tacks, it appears that these cradles or bulkheads are built up of an internal framework of spruce, leaving plenty of open spaces, the whole being covered on both sides by thin layers of three-ply wood. This applies to bulkhead V as well as to the others, although in the drawing it gives the impression of a solid piece of wood.

From behind the pilot's cockpit to the stern the main members of the body are of simpler form, simple frames of vertical and horizontal struts alternating with bays in which the rectangular strut frame-is reinforced by diagonal struts crossing from corner to corner of the fuselage. These have not been shown in the drawing as they present no features of special interest.

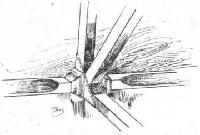

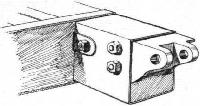

The manner of joining the struts and cross-members to the main longerons of the Berg is of the simplest, there being no wire bracing to provide for with consequent complexity. The struts simply rest, as shown in Fig. 2, on the longerons, and are secured in place by wood blocks. For the quite plain frames the wood blocks are the only supports for the struts, while where the frame is reinforced by diagonal struts - in the manner referred to above - the joint is slightly more complicated as shown in Fig. 2. Here the angles between the vertical and diagonal struts are filled with wood blocks, while a small triangle of three-ply is tacked to the sides, binding the three struts together. In the neighbourhood of the tail skid some slight variations dictated by local considerations are to be found, but the joint shown in Fig. 2 is typical of the fundamental principle

The three-ply covering is in the form of fairly large sheets, the use of these being rendered possible by keeping the sides of the body quite flat. Adjoining sheets are butt-jointed, the joint being covered on the inside with a narrow strip of three-ply, which is riveted to the two sheets, thus holding them together. The whole appears to be done in the simplest possible manner so as to facilitate construction, yet it would appear to work quite well in practice. Altogether the impression an inspection of the Berg leaves is to the effect that everything has been designed to meet the requirements of easy production, everything being kept as simple as possible to this end. This does not mean that the workmanship is inferior. As a matter of fact, the workmanship is very good generally speaking, although the finish may be here and there of a slightly less polished order than is found in some machines. The flat top of the fuselage is covered underneath the turtleback by a thin layer of three-ply wood, extensively fretted, as shown in the plan view, Fig. 1. The turtle-back, itself is also of thin three-ply, mounted on light frames built up of several laminations bent to the curvature of the turtle-back at any point, and glued together. The front faces of these frames are covered with thin sheets of three-ply to prevent bending. Where it joins the flat top of the fuselage the turtle-back is tacked to thin strips of spruce, which are in turn tacked and glued to the flat top of the body. With this brief description of the fundamental construction of the Berg body we will leave this subject, the equipment and accessories that, although being placed in it do not form part of the main structure, being reserved for a further instalment.

(To be continued.)

Flight, October 31, 1918.

THE AUSTRIAN BERG SINGLE-SEATER

200 H.P. AUSTRO-DAIMLER ENGINE

(Continued from page 1198.)

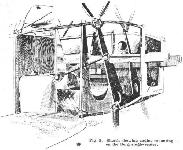

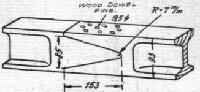

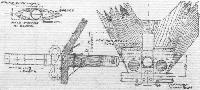

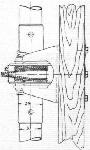

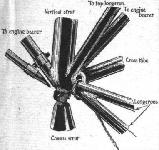

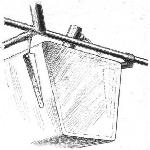

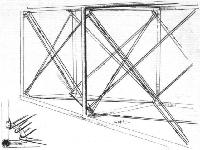

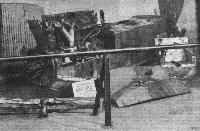

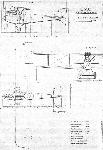

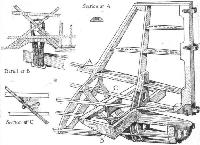

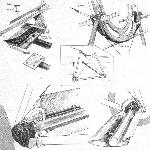

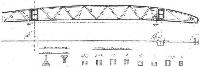

REFERENCE was made, in our last issue to the front bulkheads of the body, which serve the double purpose of body struts and cradles for the engine bearers. In Fig. 1 were shown half-sections of the five front bulkheads showing their general shape and proportions. Fig. 3 shows the general arrangement of the engine bearers and the cradles supporting them. The two engine bearers are built up of three laminations each, all of spruce. As the cradles are not so arranged as to form a series of triangles when seen in side elevation, as is not infrequently done on German machines, the diagonal bracing formed by the 3-ply covering has been reinforced, in the Berg, by two steel tubes on each side. These will be seen in Fig. 3. The front one runs from the point where the engine bearer rests on the front bulkhead to the 3-ply side where this joins former No. 2, the tube being horizontal in side view but sloping out in plan. This was also indicated in Fig. 1 published last week. The second tube, bolted at its front end to the second former, runs through an opening in the third and to the outer edge of the fourth former.

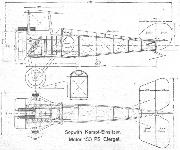

Engine.

The engine with which the Berg was fitted is a 200 h.p. Austro-Daimler [particulars of which are published elsewhere in this issue, ED.], but as it was not in place on the machine when our representatives examined it we have not been able to obtain any details.

Tanks.

The main petrol tank is placed in the bottom of the fuselage, and has, according to a stamp on it, a capacity of 82 litres (about 18 gallons). A small service tank is mounted inside the top cowling of the body, supported on four small steel tubes from the top longerons. This tank has a capacity of 16 litres (about 3.5 gallons). As the various connections are not intact on the machine it has been difficult to follow in detail the petrol feed system, but it appears probable that the main petrol tank is under pressure, the fuel being forced from it up into the small service tank by a hand pump mounted on the port side in the pilot's cockpit.

Instruments.

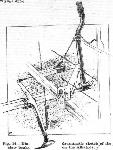

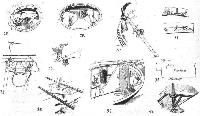

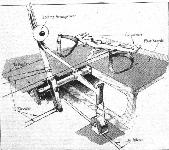

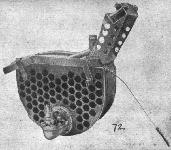

Fig. 4 shows, in perspective, the whole front portion of the Berg. Underneath the turtle-back, which has been shown broken, will be seen, in front of the wind screen, the instrument board. Few of the instruments were in place when we examined the machine, and there were no indications that the set of instruments fitted contained any of unusual interest. The sides of the turtle-back are fitted at this point with circular windows in order to provide better lighting of the instrument board.

The pilot's cockpit is of fairly roomy proportions, and the seat itself is of the "bucket" type, fitted with comfortable arm rests, which would appear to be a considerable advantage on a long flight. The seat is mounted, as indicated in Fig 4, partly on the built-up transverse framework at this point and partly on a tubular structure which supports the front of the seat. A safety belt is provided, the springs of which are in the form of rings made up of two sets of coil springs, one inside the other.

Controls.

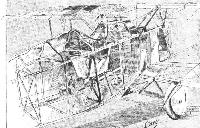

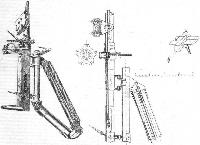

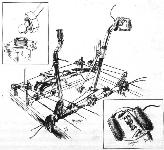

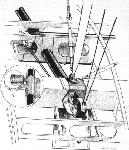

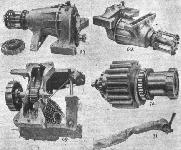

The controls of the Berg are shown in Fig. 5. The control lever itself is somewhat incomplete on the machine, the handle in which it terminates at the top being absent so that it has not been possible to ascertain the shape of the grip, otherwise the controls are intact. The control column, it will be seen, is a steel tube, forked at its lower end, the arms of the fork passing on each side of the longitudinal tubular rocking shaft. From upper and lower ends respectively of this fork pass the top and bottom cables of the elevator controls. A transverse bolt forms the pivot around which the control lever oscillates in a fore-and-aft direction. The longitudinal rocking shaft is carried in two bearings, the front one mounted on the bulkhead in front of the pilot, and the rear one carried on two short tubes sloping up from the floor of the cockpit. The aileron control cables, are attached to a crank passing down from the fore end of the rocking shaft. The effect of this arrangement is that the positive cable - that is to say, the cable that passes from the controls to the aileron - raises an aileron, while the return cable lowers an aileron. Why this arrangement has been adopted is not clear, unless it is assumed that the upturned tip of the ailerons has the effect of putting one aileron under a negative load before the corresponding aileron on the other side begins to exert a positive lift.

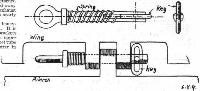

The rudder bar of the Berg is welded up of sheet steel. It is of T shape, as shown in the sketch, the control cables passing from the base of the T instead of from the ends of the main cross bar. The foot bar is mounted on a cone of sheet steel, and is prevented from oscillating by a guide on each side, mounted on two short lengths of steel tubing. The base plate of the rudder bar cone has at its rear a lug, to which is attached a short length of cable that is bolted at its other end to the lower end of the control column. This cable has the effect of limiting the amount the control lever can be pushed forward, and has probably been incorporated in order to prevent the elevators from hanging down too low when the machine is on the ground. The rudder cables, after leaving the foot bar, pass over pulleys near the floor, on the sides of the body. These pulleys are indicated in Fig. 5, and one of them is shown in detail in Fig. 6. The pulleys are carried on simple sheet steel brackets bolted to a wood base. The pulley is surrounded with a guard to prevent the cable getting wedged between the pulley and the brackets.

Where the elevator and rudder cables pass through the 3-ply sides of the body, they are provided with guides of the form shown in Fig. 7. On the inside of the body the guides are in the form of wood blocks shaped to the angle of the cable as shown in the bottom sketch, while on the outside the guides are made of thin sheet steel, screwed at each end to the 3-ply. The top sketch of Fig. 7 shows one of these.

Undercarriage.

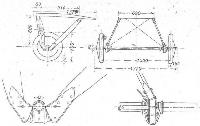

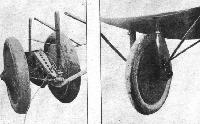

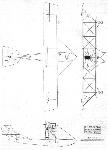

Although in the machine on view at the Enemy Aircraft View Rooms the undercarriage is not in place, there are sufficient of its component parts available to show that it is of the Vee type with struts of stream-line steel tubes. These tubes have been welded at their upper ends to base plates on the lower longerons, and in all four struts this welded joint has given way in the rough landing. The manner in which the struts were joined at the lower end is not apparent from the fragments available, and all it has been possible to do by way of reconstruction is to indicate, as was done in dotted lines in the general arrangement drawings and in the side elevation of Fig. 1, published last week, approximately the proportions and position of the undercarriage. The track, as nearly as it has been possible to judge, has been about 6 ft., and the tyres are marked 760 by 100.

The tail skid is of the simplest possible form, and does not in itself present any unusual features. The manner of mounting it is, however, rather different from the majority of machines. As shown in Fig. 8, the swivelling skid is pivoted on a short forked member, which is in turn carried at the truncated end of a structure of light wooden strips covered with 3-ply. This structure is of good stream-line form, and although appearing very light, seems to stand up to its work quite satisfactorily. The details of the arrangement will be obvious from the illustration. Springing of the tail skid is provided by coil springs of similar type to those employed for the pilot's safety belt and for the foot guards on the rudder bar, i.e., a smaller spring is placed inside a larger one, and the whole is made up into the form of a ring, one loop of which passes over the free end of the tail skid, while the other is resting on a stub having a bell mouth, and which is mounted on the lower corner of the fuselage.

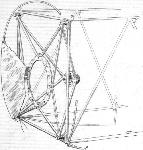

Tail Planes.

The tail planes of the Berg are built up throughout of steel tubes. As distinct from the majority of German machines in which steel tubing is employed for tail planes, those of the Berg are of fairly large diameter, but are everywhere single, whereas in many German machines .the diameter of the tubes is very much smaller, but two, used to form a rib. The Berg tail plane is slightly cambered, but owing to its construction of single tubes the upper and lower cambers are parallel. Provision has been made for varying the angle of incidence of the tail plane to a small extent, but not during flight. The divided elevator is similarly built up, but is, of course, perfectly fiat. The tail plane is brazed to the vertical tube forming the stern post and to the bottom longerons of the fuselage. On top there is a stream-line strut joining the rear tube of the tail plane to the vertical stern post, and a cable bracing the tubular leading edge to the vertical fin, as shown in Fig. 9, while underneath the strut is in front and a cable at the rear. Thus on the tail plane a strut on top is balanced by a cable underneath, and vice versa. The lower bracing members of the tail plane come to a point on the fuselage. This was indicated in the general arrangement drawings and also in Fig. 1, published last week.

The vertical fin is formed by a light structure of steel tubes, and to its rear edge is hinged the rudder, which is constructed on lines similar to those of the tail plane and elevator. Wood blocks spanning the hinges are provided for the attachment of the fabric covering.

(To be continued.)

Flight, November 14, 1918.

THE AUSTRIAN BERG SINGLE-SEATER

200 H.P. AUSTRO-DAIMLER ENGINE

(Concluded from page 1227.)

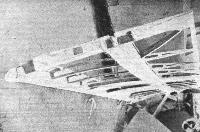

THE wings of the Berg single-seater are characterised by the same simplicity - as regards their construction - as that found in the other parts of this machine, a simplicity, be it said, which does not result in scamped workmanship and hurried finish, but which bears evidence of careful design, with ease of production always kept in mind. The timber employed for the wings is of excellent quality, better than that found in the average German machine. The fittings, while apparently combining good strength with light weight, are as simple as possible, and welding is resorted to to a much smaller extent than is the case with the majority of fittings in German aeroplanes. Of the merits of the Berg as a fighting machine we have no information, but from a constructional point of view it shows many features that might with advantage be studied for cheap and rapid production of commercial aeroplanes after the war.

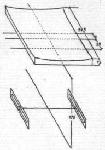

The wing section of the Berg is somewhat unusual in that it has a pronounced reflex curvature of its trailing edge (upper camber), while the maximum camber of both upper and lower surface is much farther back than is usually the case in modern wing sections. This is clearly shown in Fig. 10. One result of the reflex curvature of the top camber is to provide a very flexible trailing edge, as the ribs become very thin towards the rear. It is probable that in this way a fair amount of lateral stability is provided, since a gust striking a wing will deflect the trailing portion, thus virtually reducing the lift, and the equilibrium of the whole machine may not, as a consequence, be disturbed to the same extent as would be the case in a machine having a rigid section. It is also possible that the reflex curvature may reduce to some extent the travel of the centre of pressure, and so improve the longitudinal stability. As regards the efficiency of this section we have no data available.

Constructionally, the wings are built up of spruce spars of the box type, with ribs having spruce flanges and poplar webs. The webs are fret-sawed for lightness, and the solid portions between lightening holes are reinforced by vertical pieces of wood, riveted through the webs. The leading edge is also of spruce, hollowed out to a U section. The trailing edge is in the form of a wire. Between the spars there is a zig-zag formation of tape, passing over one rib and under the next and so on.

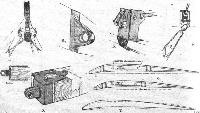

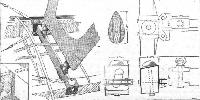

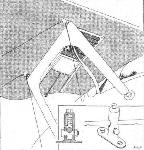

The top plane, which is in one piece and has no dihedral angle, is supported from the body by N struts sloping outward slightly, as shown in the scale drawings published in our issue of October 24th. These struts are stream-line steel tubes, and are pin jointed so as to allow of adjustment when rigging. The fore-and-aft adjustment - which also serves to bring the wings at right angles to the centre line of the body - is carried out by having portions of the diagonal struts provided with a thread-and-locknut arrangement. The lateral adjustment is carried out in a, similar manner. The centre section struts form a letter W, as seen in front view, and the inner legs are provided with the same form of adjustment as are the diagonal side struts. In the rear bay the lateral bracing is in the form of cables, crossing above the body, since these are out of the way of the engine. By using struts in the front bay and placing them in a W formation the difficulty of clearing the engine is overcome, and adjustment still rendered possible. Fig. 11 shows the attachment of the front and diagonal side-struts to the top longeron. The struts have forked ends, which fit over the vertical lugs of the base plate that rests on and is bolted to the longeron. Directly bolted to the inner part of this base plate is the foot of the strut that provides lateral bracing for the front bay. This strut is rigidly attached to the longeron, but has the thread-and-locknut adjustment at its upper end. The attachment of the rear side-strut is shown in Fig. 12. This is similar to the attachment of the front struts, but there is the difference caused by the fact that in this bay the lateral bracing is in the form of cables. The manner in which this cable is attached to the base plate is shown in the sketch.

The attachment of the lower planes to the fuselage is shown in the sketches, Figs. 13 and 14. The rear spar attachment is shown in Fig. 13. To the outer base plate is welded the lug to which the spar is attached by a forked spar box and a quick-release bolt. The rear strut of the undercarriage is also welded to this base plate, but to the lower horizontal part of it.

Fig. 14 shows the attachment of the lower front spar and of the lift cables. The spar attachment is, it will be seen, very similar to that of the rear spar. There is, however, a horizontal tube running across the fuselage, thus resisting any tension there may be on the spars, while the lift cable attachment is also extended some distance in the manner shown, so as to spread the load to other of the members of which the bulkhead is composed.

The fittings for the internal bracing of the planes are of a very neat and simple type. The compression struts are in the form of steel tubes, and the drift bracing is stranded cables, while the anti-drift wires are of the solid type. The inter-plane struts are streamline steel tubes, forked at their ends and fitting over eyebolts passing vertically through the spars. The general arrangement of these attachments and of the internal bracing system are indicated in Fig. 15. An analytical sketch of the fitting is given in Fig. 16. It consists of two forgings, one placed on top of the spar and one on the lower side of the spar, the two being held together by vertical bolts passing on the outside of the spar. In addition there is an eyebolt going through the-spar, and to this is anchored the forked end of the inter-plane strut. The lift cable is attached by means of a shackle to a lug formed on the top forging. The incidence cable is attached to the horizontal bolt passing through the fork end of the strut and through the eyebolt, by two very long chain links as shown. The compression tube between the wing spars also occurs at this point, and is attached to one of the vertical bolts on the side of the spars. This is done by welding to the end of the compression tube a strip of sheet steel forming the lugs of the internal bracing, and through the solid part of metal thus formed bore a hole for the vertical bolt. The whole joint is very neat when in place, and is shown from the outside in Fig. 17. This sketch also shows the mounting, on the lower spar, of the aileron cable pulleys.

In last week s issue we referred to the aileron control system, in which the direct cable from the controls passes to the forward arm of the aileron crank lever, thus pulling the aileron up, while the pulling down of the opposite aileron is left to the return cable. It was pointed out that this system, which is rather the reverse of what is usual practice, has probably been adopted because of the warped ailerons, which may possibly owing to their upward turned tips come under a negative load before the opposite aileron begins to give a positive lift. The aileron and a portion of the upper plane are shown in Fig. 18. The aileron, which is of tubular construction, is hinged to a false spar as in nearly all machines of enemy origin. It will be noticed that this portion of the top plane is generously provided with three-ply reinforcement. The horizontal aileron crank lever works in a slot formed by triangles of ply-wood, and the control cables pass from the cranks over pulleys as shown in Fig. 17, and hence to the controls, passing through the bottom plane.

Camouflage.

The Berg single-seater is somewhat different from German machines in its camouflage, possibly because it has been used on the Italian front, where the ground is of different colouring. The whole of the tail and the under surface of both main planes are painted a pale sandy yellowish brown, while the body and top surfaces of the planes are painted in addition with irregular streaks of a darker brown.

THE AUSTRIAN BERG SINGLE-SEATER FIGHTER.

200 H.P. AUSTRO-DAIMLER ENGINE.

[While the different types of aeroplanes produced in Germany are fairly well known in this country, owing chiefly to the number of them that have been captured from time to time, our knowledge of the Austrian aircraft industry is more limited. This is partly due to the fact that fewer of them are seen on the western front, Austrian activities in the air being more particularly confined to the Italian theatre of war, where the various types of Austrian machines are probably as well known as are the German on the battle front in France. Also it should be remembered that to a large extent, so far as our knowledge goes, the Austrian industry has been conducted more along the lines of constructing German-designed machines under licence, thus tending to increase output, rather than with an aim to encouraging original design. That home designing has not been altogether stopped in Austria is evident, however, since from time to time one hears of Austrian machines, of makes known not to be German licence productions, being seen by Allied pilots. Among these is the Austrian Berg single-seater fighter. Reports have been received occasionally of this machine, but up to the present nothing definite has been generally known concerning it. Now, however, one of these has been added to the collection in the Enemy Aircraft View Rooms, and by the courtesy of the authorities we are able this week to publish a brief description and an illustration of the Austrian Berg. To the best of our knowledge this is the first description to be published in this country.-ED.]

SIMPLICITY would appear to be the keynote of design in the Austrian Berg single-seater fighter, both as regards mass, or aerodynamic, design and structural design. The machine has every appearance of being designed chiefly with a view to rapidity of production, yet this object has been attained by a studied simplicity of detail rather than by any scamping in workmanship. In fact, although the finish is not, perhaps, as good as on some machines, the workmanship appears everywhere to be really quite good, and the materials employed in the construction are, if anything, better than found on a good many German machines. Whether this is due to a more plentiful supply of the right materials in Austria than in Germany, or whether Austrian inspection is stricter than that obtaining in Germany, is difficult to say; and one can only call attention to the fact without venturing an explanation.

Fundamentally the Austrian Berg is of the single-seater fighter type in which the pilot and top plane are so placed in relation to each other that the wing obstructs the view to a very small extent only. This has been accomplished, not so much by reducing the gap to a smaller proportion of the chord than usual, as by making the body very deep and placing the pilot fairly high inside the body. On closer examination it is found that the extra depth of the body is provided by deepening the turtle back, which forms a much greater proportion of the overall depth than is the case in most machines.

The body proper, which is of the flat-sided variety, is constructed on similar lines to those of the older models of Albatros biplanes, i.e., of longerons and struts of fairly small section, the whole being covered with three-ply wood. As distinct from the Albatros, however, there are only four longerons, the auxiliary rails halfway up the sides of the latter having evidently been deemed unnecessary by the designer of the Berg. The turtle back, which is different from the majority in that it does not, except in front, cover the whole width of the flat top of the body, but comes to a point just in front of the vertical fin, is of a peculiar section. This may, in the absence of a sketch, best be described by saying that it consists of three curvatures, a convex at the top, a concave halfway down, and again a convex at the bottom. The object, evidently, is to provide stream lining of the pilot's head by having the turtle back deep without, however, obstructing the view to too great an extent by having it very wide. Roughly the configuration is that of a man's head and shoulders.

The pilot's cockpit is very comfortable, the deep top efficiently screening his face while at the same time, owing to the peculiar outline, not obstructing the view to as great an extent as one would imagine. By leaning his head slightly the pilot can easily look past the nose of the machine, so that there is really no "blind" spot beyond a few yards ahead of the machine. The fact that the chord line of the upper wing if projected passes through the pilot's line of vision renders the view forward and upward particularly good. Small circular windows are inserted in the turtle back in front of the pilot, but it appears that the view obtainable through these is of very little practical utility, and the inference is that they are placed there to admit light on to the instrument board rather than to provide direct vision.

The pilot's seat is extremely comfortable, and is provided with arm rests, thus enabling the pilot to rest one arm while working the control lever with the other. For a long flight this makes for comfort. It is only a minor point, it is true, but one nevertheless which is worthy of consideration. On the whole the machine gives the impression that it would be a very comfortable machine to fly, regarded purely from the flying point of view, and without knowing anything about its capabilities as used for fighting.

The controls are more or less of the usual type. There is a longitudinal rocking shaft, mounted rather higher above the floor boards than is generally the case. The control lever is forked around this shaft, and is free to oscillate forward and backward for operating the elevator. A short length of cable passes from the lower end of the "joystick" to a point on the floor boards. This limits the extent to which the lower end of the lever can move back, and has the effect of preventing, when on the ground, the elevators from touching and getting damaged. In connection with the lateral controls, the wing flaps are fitted with cranks resting in slots in the planes, and there is a somewhat unusual arrangement whereby the positive cable is taken to the front arm of the crank, so that it is the return cable which pulls the wing flap down. The reason for this may be found in the warped wing flap, which may conceivably have its outer tip tilted upwards to such an extent that the effect of moving the flaps is to put a force acting downward on the flap moved upwards before the flap on the opposite side, which has, of course, been moved down simultaneously, receives an upward force. To bring this peculiar action about the crank on the rocking shaft points downwards instead of, as is more usually the case, pointing upwards.

The foot bar operating the rudder is of the T type. That is to say, the rudder control cables are attached to a crank arm projecting forward at right angles to the foot bar. The cables are then taken around pulleys near the side of the body, and hence to the rudder cranks. The guards on the rudder bar, which prevent the accidental slipping off of the pilot's feet, are in the form of spiral springs, each composed of two layers, an inner spiral of fairly thin wire, and an outer spiral of heavier wire.

The engine, which, we are informed, was a 200 h.p. Austro-Daimler, is not shown in place on the machine, but it would appear to have been totally covered in by a deep engine housing. It is mounted on two spruce bearers, each made up of three laminations, mounted on four transverse partitions. These are made up of a spruce centre with facings of three-ply. The armament appears to have been made up of two machine guns, one on each side of the engine, and fitted with the usual interrupter gear.

The wings, which are both of equal span, present nothing out of the ordinary as regards their construction, except that some of the fittings for the internal wire bracing and compression tubes are exceptionally neat in conception and well carried out. Aerodynamically, however, the wings present an interesting feature. The upper surface of the wing section has a most decided return sweep, beginning behind the rear spar and being of such a magnitude as to present a considerable area of concave surface.

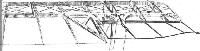

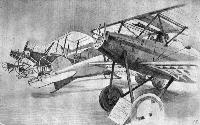

The undercarriage of the Berg is not in place on the machine as exhibited, but from fragments it is judged to have been of the Vee type, and in the accompanying illustration we have endeavoured to reconstruct it approximately as various considerations indicate that it must have been.

The tail planes are built of steel tubing throughout, and the fixed tail plane is chiefly remarkable on account of the fact that, although it is built up of single steel tubes, the section is made cambered by bending the single tubes forming the ribs. Both upper and lower surfaces, therefore, have the same camber. The incidence of the tail plane is adjustable, but not during flight.

Later, as opportunity occurs, we hope to be able to publish some illustrations of the more important constructional details of the Austrian Berg fighter.

Flight, October 24, 1918.

THE AUSTRIAN BERG SINGLE-SEATER

200 H.P. AUSTRO-DAIMLER ENGINE

[In our issue of May 23rd, 1918, we published a brief description and an illustration of the Austrian Berg Single-Seater. We have since been able to carefully examine this machine in detail, and to prepare drawings and sketches of its main constructional features.-ED.]

As a type the Austrian Berg belongs to the single-seater fighter class with high-power engine. It follows what has now become almost standard practice for single-seaters in its strut arrangement, which comprises only one pair of interplane struts on each side. As a single-seater it is desirable that the view forward and upward shall be as good as possible, and this has been aimed at, and attained to quite a fair extent, in the Berg by placing the top plane low over the body, where, owing to the angle of incidence, the pilot from where he is placed sees it practically edge on. When we say that the top plane has been placed low over the body we do not mean to infer that the gap between the planes has been reduced beyond normal. Rather has the relative position of top plane and top of body been attained by making the body very deep at this point, and by so seating the pilot - fairly high in the body - that he obtains the view desired. This is accomplished, not so much by making the main body very deep, but by surmounting it with a fairing of turtleback of much greater depth than those usually found on machines of this size. With the object always in view of obstructing the pilot's vision to as small extent as possible, this turtle-back, also that portion of it lying in front of the pilot, has been kept narrow at the top. In section it forms what is roughly the shape of a man's head and shoulders, as will be seen from the front elevation in the general arrangement drawings. In this manner, by leaning his head slightly to one side or other, the pilot can easily see past his engine, the cowling of which, although not in place on the machine examined, has probably conformed to the same contour as the rest of the fuselage top. To the rear of the pilot's seat this turtle-back tapers off until it ends in a point some little distance ahead of the tail planes. The lateral taper of it is somewhat more abrupt than is that of the body rails, so that as the rear portion of the body is approached there is a widening strip of flat horizontal surface on each side of the turtle-back. This will be seen in the plan view of the general arrangement drawings and also in the plan of the body in Fig. 1.

Fuselage.

Constructionally the fuselage of the Berg biplane is of the same type as that of the earlier models of Albatros biplanes, i.e., there is a light internal framework of wood, covered on sides as well as top and bottom with three-ply. There are no internal wires for bracing the body, the three-ply covering being relied upon to perform this function. Although not possessing such refinements as rounded sides, the body of the Berg is of fairly good stream-line form, as will be seen from the illustrations. The machine exhibited is in a somewhat incomplete state as regards its front portion, especially the top covering of it and the engine-housing and radiator, which is absent. We have endeavoured, however, to reconstruct it to a certain extent, as shown by the dotted lines in the side elevation of the general arrangement drawings. The top plane shows clearly that no radiator has been mounted in its centre section, and as there are no indications that the radiator has been fitted on the sides of the body, the inference is that it must have been placed in the extreme nose. As to the exact shape the radiator may have had, this is a matter for conjecture, but in view of the shape of the fuselage top it appears probable that the radiator was of somewhat similar shape, as otherwise undesirable lines must have developed where the shape of the radiator was carried into that of the engine-housing.

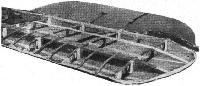

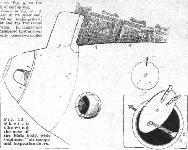

The general shape of the body, and many of the details will be clear from Fig. 1. It will be seen that there are only four main longerons, whereas the early-type Albatros had six, two of which were placed approximately halfway up between upper and lower corner rails. In the front portion of the body the bulkheads are of special form to provide supports for the two engine-bearers. The shape of these bulkheads or engine cradles is shown in the half-sections I to V inset in Fig 1. As none of these cradles had been sectioned up on the machine examined, it has not been possible to do more than give their outward shape. Judging from such external evidence, however, as rows of tacks, it appears that these cradles or bulkheads are built up of an internal framework of spruce, leaving plenty of open spaces, the whole being covered on both sides by thin layers of three-ply wood. This applies to bulkhead V as well as to the others, although in the drawing it gives the impression of a solid piece of wood.

From behind the pilot's cockpit to the stern the main members of the body are of simpler form, simple frames of vertical and horizontal struts alternating with bays in which the rectangular strut frame-is reinforced by diagonal struts crossing from corner to corner of the fuselage. These have not been shown in the drawing as they present no features of special interest.

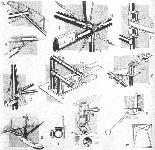

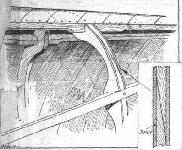

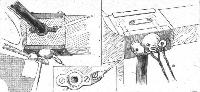

The manner of joining the struts and cross-members to the main longerons of the Berg is of the simplest, there being no wire bracing to provide for with consequent complexity. The struts simply rest, as shown in Fig. 2, on the longerons, and are secured in place by wood blocks. For the quite plain frames the wood blocks are the only supports for the struts, while where the frame is reinforced by diagonal struts - in the manner referred to above - the joint is slightly more complicated as shown in Fig. 2. Here the angles between the vertical and diagonal struts are filled with wood blocks, while a small triangle of three-ply is tacked to the sides, binding the three struts together. In the neighbourhood of the tail skid some slight variations dictated by local considerations are to be found, but the joint shown in Fig. 2 is typical of the fundamental principle

The three-ply covering is in the form of fairly large sheets, the use of these being rendered possible by keeping the sides of the body quite flat. Adjoining sheets are butt-jointed, the joint being covered on the inside with a narrow strip of three-ply, which is riveted to the two sheets, thus holding them together. The whole appears to be done in the simplest possible manner so as to facilitate construction, yet it would appear to work quite well in practice. Altogether the impression an inspection of the Berg leaves is to the effect that everything has been designed to meet the requirements of easy production, everything being kept as simple as possible to this end. This does not mean that the workmanship is inferior. As a matter of fact, the workmanship is very good generally speaking, although the finish may be here and there of a slightly less polished order than is found in some machines. The flat top of the fuselage is covered underneath the turtleback by a thin layer of three-ply wood, extensively fretted, as shown in the plan view, Fig. 1. The turtle-back, itself is also of thin three-ply, mounted on light frames built up of several laminations bent to the curvature of the turtle-back at any point, and glued together. The front faces of these frames are covered with thin sheets of three-ply to prevent bending. Where it joins the flat top of the fuselage the turtle-back is tacked to thin strips of spruce, which are in turn tacked and glued to the flat top of the body. With this brief description of the fundamental construction of the Berg body we will leave this subject, the equipment and accessories that, although being placed in it do not form part of the main structure, being reserved for a further instalment.

(To be continued.)

Flight, October 31, 1918.

THE AUSTRIAN BERG SINGLE-SEATER

200 H.P. AUSTRO-DAIMLER ENGINE

(Continued from page 1198.)

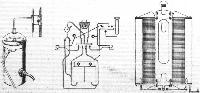

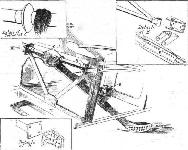

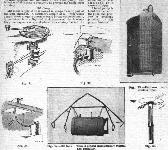

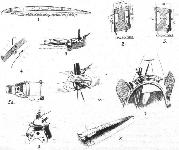

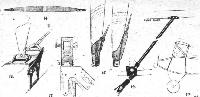

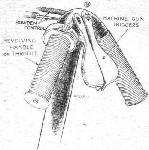

REFERENCE was made, in our last issue to the front bulkheads of the body, which serve the double purpose of body struts and cradles for the engine bearers. In Fig. 1 were shown half-sections of the five front bulkheads showing their general shape and proportions. Fig. 3 shows the general arrangement of the engine bearers and the cradles supporting them. The two engine bearers are built up of three laminations each, all of spruce. As the cradles are not so arranged as to form a series of triangles when seen in side elevation, as is not infrequently done on German machines, the diagonal bracing formed by the 3-ply covering has been reinforced, in the Berg, by two steel tubes on each side. These will be seen in Fig. 3. The front one runs from the point where the engine bearer rests on the front bulkhead to the 3-ply side where this joins former No. 2, the tube being horizontal in side view but sloping out in plan. This was also indicated in Fig. 1 published last week. The second tube, bolted at its front end to the second former, runs through an opening in the third and to the outer edge of the fourth former.

Engine.

The engine with which the Berg was fitted is a 200 h.p. Austro-Daimler [particulars of which are published elsewhere in this issue, ED.], but as it was not in place on the machine when our representatives examined it we have not been able to obtain any details.

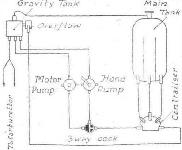

Tanks.

The main petrol tank is placed in the bottom of the fuselage, and has, according to a stamp on it, a capacity of 82 litres (about 18 gallons). A small service tank is mounted inside the top cowling of the body, supported on four small steel tubes from the top longerons. This tank has a capacity of 16 litres (about 3.5 gallons). As the various connections are not intact on the machine it has been difficult to follow in detail the petrol feed system, but it appears probable that the main petrol tank is under pressure, the fuel being forced from it up into the small service tank by a hand pump mounted on the port side in the pilot's cockpit.

Instruments.

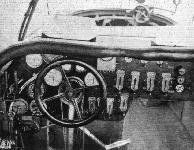

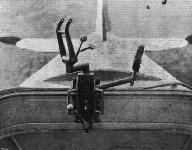

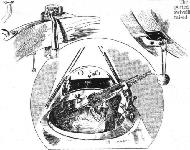

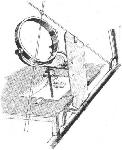

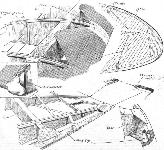

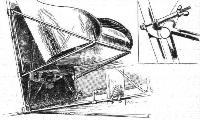

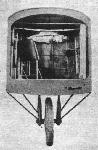

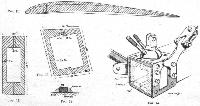

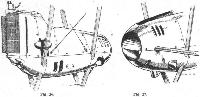

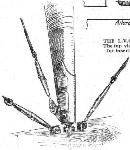

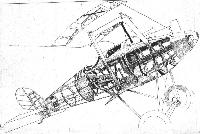

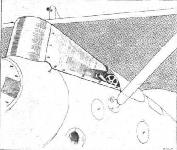

Fig. 4 shows, in perspective, the whole front portion of the Berg. Underneath the turtle-back, which has been shown broken, will be seen, in front of the wind screen, the instrument board. Few of the instruments were in place when we examined the machine, and there were no indications that the set of instruments fitted contained any of unusual interest. The sides of the turtle-back are fitted at this point with circular windows in order to provide better lighting of the instrument board.

The pilot's cockpit is of fairly roomy proportions, and the seat itself is of the "bucket" type, fitted with comfortable arm rests, which would appear to be a considerable advantage on a long flight. The seat is mounted, as indicated in Fig 4, partly on the built-up transverse framework at this point and partly on a tubular structure which supports the front of the seat. A safety belt is provided, the springs of which are in the form of rings made up of two sets of coil springs, one inside the other.

Controls.

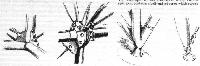

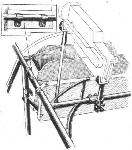

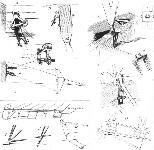

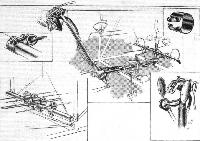

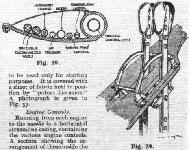

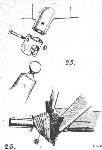

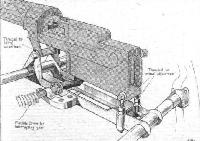

The controls of the Berg are shown in Fig. 5. The control lever itself is somewhat incomplete on the machine, the handle in which it terminates at the top being absent so that it has not been possible to ascertain the shape of the grip, otherwise the controls are intact. The control column, it will be seen, is a steel tube, forked at its lower end, the arms of the fork passing on each side of the longitudinal tubular rocking shaft. From upper and lower ends respectively of this fork pass the top and bottom cables of the elevator controls. A transverse bolt forms the pivot around which the control lever oscillates in a fore-and-aft direction. The longitudinal rocking shaft is carried in two bearings, the front one mounted on the bulkhead in front of the pilot, and the rear one carried on two short tubes sloping up from the floor of the cockpit. The aileron control cables, are attached to a crank passing down from the fore end of the rocking shaft. The effect of this arrangement is that the positive cable - that is to say, the cable that passes from the controls to the aileron - raises an aileron, while the return cable lowers an aileron. Why this arrangement has been adopted is not clear, unless it is assumed that the upturned tip of the ailerons has the effect of putting one aileron under a negative load before the corresponding aileron on the other side begins to exert a positive lift.

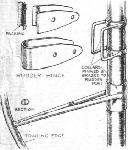

The rudder bar of the Berg is welded up of sheet steel. It is of T shape, as shown in the sketch, the control cables passing from the base of the T instead of from the ends of the main cross bar. The foot bar is mounted on a cone of sheet steel, and is prevented from oscillating by a guide on each side, mounted on two short lengths of steel tubing. The base plate of the rudder bar cone has at its rear a lug, to which is attached a short length of cable that is bolted at its other end to the lower end of the control column. This cable has the effect of limiting the amount the control lever can be pushed forward, and has probably been incorporated in order to prevent the elevators from hanging down too low when the machine is on the ground. The rudder cables, after leaving the foot bar, pass over pulleys near the floor, on the sides of the body. These pulleys are indicated in Fig. 5, and one of them is shown in detail in Fig. 6. The pulleys are carried on simple sheet steel brackets bolted to a wood base. The pulley is surrounded with a guard to prevent the cable getting wedged between the pulley and the brackets.

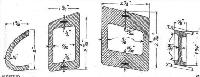

Where the elevator and rudder cables pass through the 3-ply sides of the body, they are provided with guides of the form shown in Fig. 7. On the inside of the body the guides are in the form of wood blocks shaped to the angle of the cable as shown in the bottom sketch, while on the outside the guides are made of thin sheet steel, screwed at each end to the 3-ply. The top sketch of Fig. 7 shows one of these.

Undercarriage.

Although in the machine on view at the Enemy Aircraft View Rooms the undercarriage is not in place, there are sufficient of its component parts available to show that it is of the Vee type with struts of stream-line steel tubes. These tubes have been welded at their upper ends to base plates on the lower longerons, and in all four struts this welded joint has given way in the rough landing. The manner in which the struts were joined at the lower end is not apparent from the fragments available, and all it has been possible to do by way of reconstruction is to indicate, as was done in dotted lines in the general arrangement drawings and in the side elevation of Fig. 1, published last week, approximately the proportions and position of the undercarriage. The track, as nearly as it has been possible to judge, has been about 6 ft., and the tyres are marked 760 by 100.

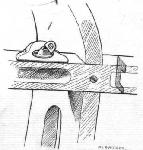

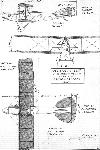

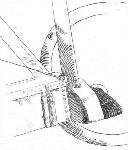

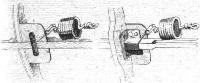

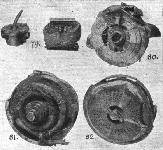

The tail skid is of the simplest possible form, and does not in itself present any unusual features. The manner of mounting it is, however, rather different from the majority of machines. As shown in Fig. 8, the swivelling skid is pivoted on a short forked member, which is in turn carried at the truncated end of a structure of light wooden strips covered with 3-ply. This structure is of good stream-line form, and although appearing very light, seems to stand up to its work quite satisfactorily. The details of the arrangement will be obvious from the illustration. Springing of the tail skid is provided by coil springs of similar type to those employed for the pilot's safety belt and for the foot guards on the rudder bar, i.e., a smaller spring is placed inside a larger one, and the whole is made up into the form of a ring, one loop of which passes over the free end of the tail skid, while the other is resting on a stub having a bell mouth, and which is mounted on the lower corner of the fuselage.

Tail Planes.

The tail planes of the Berg are built up throughout of steel tubes. As distinct from the majority of German machines in which steel tubing is employed for tail planes, those of the Berg are of fairly large diameter, but are everywhere single, whereas in many German machines .the diameter of the tubes is very much smaller, but two, used to form a rib. The Berg tail plane is slightly cambered, but owing to its construction of single tubes the upper and lower cambers are parallel. Provision has been made for varying the angle of incidence of the tail plane to a small extent, but not during flight. The divided elevator is similarly built up, but is, of course, perfectly fiat. The tail plane is brazed to the vertical tube forming the stern post and to the bottom longerons of the fuselage. On top there is a stream-line strut joining the rear tube of the tail plane to the vertical stern post, and a cable bracing the tubular leading edge to the vertical fin, as shown in Fig. 9, while underneath the strut is in front and a cable at the rear. Thus on the tail plane a strut on top is balanced by a cable underneath, and vice versa. The lower bracing members of the tail plane come to a point on the fuselage. This was indicated in the general arrangement drawings and also in Fig. 1, published last week.

The vertical fin is formed by a light structure of steel tubes, and to its rear edge is hinged the rudder, which is constructed on lines similar to those of the tail plane and elevator. Wood blocks spanning the hinges are provided for the attachment of the fabric covering.

(To be continued.)

Flight, November 14, 1918.

THE AUSTRIAN BERG SINGLE-SEATER

200 H.P. AUSTRO-DAIMLER ENGINE

(Concluded from page 1227.)

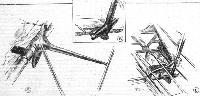

THE wings of the Berg single-seater are characterised by the same simplicity - as regards their construction - as that found in the other parts of this machine, a simplicity, be it said, which does not result in scamped workmanship and hurried finish, but which bears evidence of careful design, with ease of production always kept in mind. The timber employed for the wings is of excellent quality, better than that found in the average German machine. The fittings, while apparently combining good strength with light weight, are as simple as possible, and welding is resorted to to a much smaller extent than is the case with the majority of fittings in German aeroplanes. Of the merits of the Berg as a fighting machine we have no information, but from a constructional point of view it shows many features that might with advantage be studied for cheap and rapid production of commercial aeroplanes after the war.

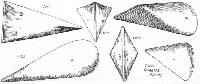

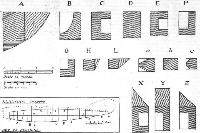

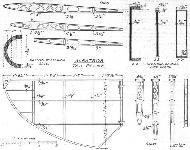

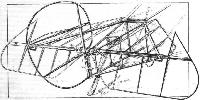

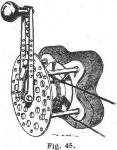

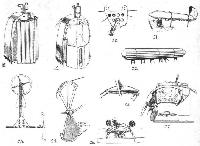

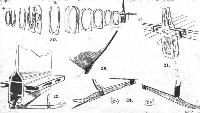

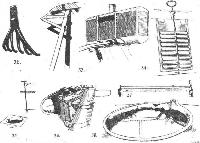

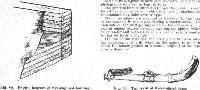

The wing section of the Berg is somewhat unusual in that it has a pronounced reflex curvature of its trailing edge (upper camber), while the maximum camber of both upper and lower surface is much farther back than is usually the case in modern wing sections. This is clearly shown in Fig. 10. One result of the reflex curvature of the top camber is to provide a very flexible trailing edge, as the ribs become very thin towards the rear. It is probable that in this way a fair amount of lateral stability is provided, since a gust striking a wing will deflect the trailing portion, thus virtually reducing the lift, and the equilibrium of the whole machine may not, as a consequence, be disturbed to the same extent as would be the case in a machine having a rigid section. It is also possible that the reflex curvature may reduce to some extent the travel of the centre of pressure, and so improve the longitudinal stability. As regards the efficiency of this section we have no data available.

Constructionally, the wings are built up of spruce spars of the box type, with ribs having spruce flanges and poplar webs. The webs are fret-sawed for lightness, and the solid portions between lightening holes are reinforced by vertical pieces of wood, riveted through the webs. The leading edge is also of spruce, hollowed out to a U section. The trailing edge is in the form of a wire. Between the spars there is a zig-zag formation of tape, passing over one rib and under the next and so on.

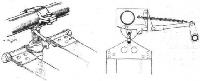

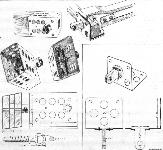

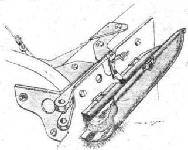

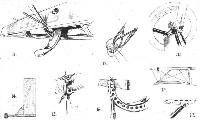

The top plane, which is in one piece and has no dihedral angle, is supported from the body by N struts sloping outward slightly, as shown in the scale drawings published in our issue of October 24th. These struts are stream-line steel tubes, and are pin jointed so as to allow of adjustment when rigging. The fore-and-aft adjustment - which also serves to bring the wings at right angles to the centre line of the body - is carried out by having portions of the diagonal struts provided with a thread-and-locknut arrangement. The lateral adjustment is carried out in a, similar manner. The centre section struts form a letter W, as seen in front view, and the inner legs are provided with the same form of adjustment as are the diagonal side struts. In the rear bay the lateral bracing is in the form of cables, crossing above the body, since these are out of the way of the engine. By using struts in the front bay and placing them in a W formation the difficulty of clearing the engine is overcome, and adjustment still rendered possible. Fig. 11 shows the attachment of the front and diagonal side-struts to the top longeron. The struts have forked ends, which fit over the vertical lugs of the base plate that rests on and is bolted to the longeron. Directly bolted to the inner part of this base plate is the foot of the strut that provides lateral bracing for the front bay. This strut is rigidly attached to the longeron, but has the thread-and-locknut adjustment at its upper end. The attachment of the rear side-strut is shown in Fig. 12. This is similar to the attachment of the front struts, but there is the difference caused by the fact that in this bay the lateral bracing is in the form of cables. The manner in which this cable is attached to the base plate is shown in the sketch.

The attachment of the lower planes to the fuselage is shown in the sketches, Figs. 13 and 14. The rear spar attachment is shown in Fig. 13. To the outer base plate is welded the lug to which the spar is attached by a forked spar box and a quick-release bolt. The rear strut of the undercarriage is also welded to this base plate, but to the lower horizontal part of it.

Fig. 14 shows the attachment of the lower front spar and of the lift cables. The spar attachment is, it will be seen, very similar to that of the rear spar. There is, however, a horizontal tube running across the fuselage, thus resisting any tension there may be on the spars, while the lift cable attachment is also extended some distance in the manner shown, so as to spread the load to other of the members of which the bulkhead is composed.

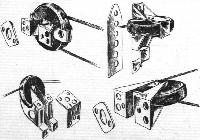

The fittings for the internal bracing of the planes are of a very neat and simple type. The compression struts are in the form of steel tubes, and the drift bracing is stranded cables, while the anti-drift wires are of the solid type. The inter-plane struts are streamline steel tubes, forked at their ends and fitting over eyebolts passing vertically through the spars. The general arrangement of these attachments and of the internal bracing system are indicated in Fig. 15. An analytical sketch of the fitting is given in Fig. 16. It consists of two forgings, one placed on top of the spar and one on the lower side of the spar, the two being held together by vertical bolts passing on the outside of the spar. In addition there is an eyebolt going through the-spar, and to this is anchored the forked end of the inter-plane strut. The lift cable is attached by means of a shackle to a lug formed on the top forging. The incidence cable is attached to the horizontal bolt passing through the fork end of the strut and through the eyebolt, by two very long chain links as shown. The compression tube between the wing spars also occurs at this point, and is attached to one of the vertical bolts on the side of the spars. This is done by welding to the end of the compression tube a strip of sheet steel forming the lugs of the internal bracing, and through the solid part of metal thus formed bore a hole for the vertical bolt. The whole joint is very neat when in place, and is shown from the outside in Fig. 17. This sketch also shows the mounting, on the lower spar, of the aileron cable pulleys.

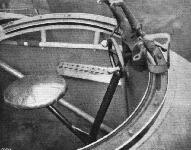

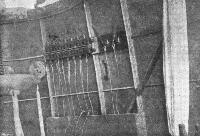

In last week s issue we referred to the aileron control system, in which the direct cable from the controls passes to the forward arm of the aileron crank lever, thus pulling the aileron up, while the pulling down of the opposite aileron is left to the return cable. It was pointed out that this system, which is rather the reverse of what is usual practice, has probably been adopted because of the warped ailerons, which may possibly owing to their upward turned tips come under a negative load before the opposite aileron begins to give a positive lift. The aileron and a portion of the upper plane are shown in Fig. 18. The aileron, which is of tubular construction, is hinged to a false spar as in nearly all machines of enemy origin. It will be noticed that this portion of the top plane is generously provided with three-ply reinforcement. The horizontal aileron crank lever works in a slot formed by triangles of ply-wood, and the control cables pass from the cranks over pulleys as shown in Fig. 17, and hence to the controls, passing through the bottom plane.

Camouflage.

The Berg single-seater is somewhat different from German machines in its camouflage, possibly because it has been used on the Italian front, where the ground is of different colouring. The whole of the tail and the under surface of both main planes are painted a pale sandy yellowish brown, while the body and top surfaces of the planes are painted in addition with irregular streaks of a darker brown.

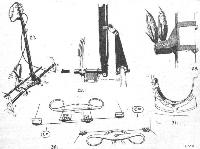

Fig. 4. - Three-quarter rear view of the front portion of the Berg. The covering has been removed to show the internal construction. In the top plane it would appear at first glance that only one spar is fitted. This is not, of course, the case, but is caused by the fact that the front spar is very close to the leading edge, and is therefore, in this particular view, covered by the rear spar.

Fig. 5. - Sketch of the controls of the Berg.

Fig. 6. - Analytical sketch of one of the pulleys over which the rudder cables travel.

Fig. 6. - Analytical sketch of one of the pulleys over which the rudder cables travel.

Fig. 7. - The control cables on the Berg are carried, where passing through the sides of the body, in guides. The top sketch shows the metal guide on the outside of the body, while the lower drawing illustrates the wood guide employed on the inside of the three-ply body covering.

Fig. 8. - The tail skid of the Berg is mounted, as shown in this sketch, on a structure of wood strips, covered with three-ply. The shock absorbers are in the form of coil springs.

Fig. 8. - The tail skid of the Berg is mounted, as shown in this sketch, on a structure of wood strips, covered with three-ply. The shock absorbers are in the form of coil springs.

Fig. 11. - Attachment of front centre-section struts to fuselage of the Berg single-seater.

Fig. 12. - Attachment of rear centre-section struts to top longerons on the Berg single-seater.

Fig. 12. - Attachment of rear centre-section struts to top longerons on the Berg single-seater.

Fig. 13. - Attachment of lower rear spar to fuselage on the Berg single-seater.

Fig. 14. - Attachment of front lower spar and of lift cables to body on the Berg single-seater.

Fig. 14. - Attachment of front lower spar and of lift cables to body on the Berg single-seater.

Fig. 15. - General sketch of internal bracing and of inter-plane strut attachment on lower plane of the Berg single-seater.

Fig. 16. - Analytical sketch of inter-plane strut attachment, lift cable attachment, internal drift bracing and compression tube in lower plane of the Berg single-seater.

Fig. 17. - View from outside of the strut fitting dissected in Fig. 16, also showing mounting of pulleys for aileron control cables.

Flight, January 17, 1918.

FROM OTHER LANDS.

AUSTRIAN AGO AND LOHNER FLYING BOATS.

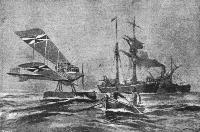

("Aerial Age," U.S.A., from material supplied by the U.S.A. Government.)

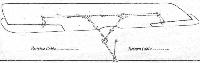

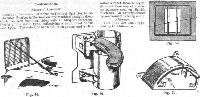

Two types of Austrian seaplanes which have fallen into the hands of the Italians during the present year, and regarded as worthy of special note, are the Ago and Lohner types. The Ago Sea-Pursuit Biplane described here and shown in the accompanying line drawing, bore the number "A-25"; it was captured May 18th, 1917. The Lohner-type flying boat (described later in this article) was brought down on the night of January 12th, 1917, and it was marked "K-301."

<...>

2.- The Lohner Flying Boat.

This is an enlarged machine of the Lohner type, retaining the V which is typical of the Lohner aeroplanes. There are six steel struts on either side and, two by two, are connected in transverse planes with steel tubes of 40 mm. outside diameter. The distance between two struts in the direction of the brace is 1.30 m., and in the direction of the spar 2.17 m.

General Dimensions.

Span, upper plane 9.70 m.

Span, lower plane 7.20 m.

Chord, upper plane 2.70 m.

Chord, lower plane 2.20 m.

Hull, maximum length 12.50m.

Bomb carrying capacity 400 kg.

Motor, Austro-Daimler 300 h.p.

In form the ailerons are trapezoidal, like that of the Italian Lohner machines. Length of ailerons, 3.47 m.; mean width, .90 m.

Dimensions of the empennage or tail group: Length of horizontal stabiliser or tail-plane, 4.74 m.; width, 1.27 m. Length of tail-flaps or elevators, 4.74 m.; width, .87 m. The vertical rudder differs from that of the old Lohner machines in that there is a small balancing area forward of the pivot.

The principal dimensions of the hull are: Maximum width, 1.50 m.; maximum length, 12.50 m.: maximum height, 1.20 m.; step .25 m.

The body has two seats side by side and one in front, upon which is mounted a machine gun arranged to be movable and fired in any direction. Besides the pilot, next to the observer, there is also a machine gun arranged on a movable tube inside the casing. The outside tube is the only additional piece the machine contains.

The turret is armoured. No bomb-dropping devices have been located. There are two vertical pieces of wood, with a circular profile notch fastened to the floats under the wings. It may be that these are used to drop large bombs, but no discovery has been made which would show how they are secured in them. Several hooks for small bombs were found.

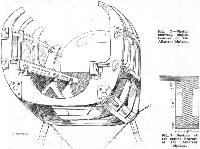

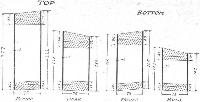

The lateral or wing-floats, instead of being hemispherical in shape, have a bow with good streamlines, which plough on the water surface like the prow of a ship. The accompanying drawing shows their general outlines. Each is 88 cm. wide and 181 cm. long.

The engine, an Austro-Daimler, has 12 cylinders arranged in a V. It is rated at 300 h.p.

FROM OTHER LANDS.

AUSTRIAN AGO AND LOHNER FLYING BOATS.

("Aerial Age," U.S.A., from material supplied by the U.S.A. Government.)

Two types of Austrian seaplanes which have fallen into the hands of the Italians during the present year, and regarded as worthy of special note, are the Ago and Lohner types. The Ago Sea-Pursuit Biplane described here and shown in the accompanying line drawing, bore the number "A-25"; it was captured May 18th, 1917. The Lohner-type flying boat (described later in this article) was brought down on the night of January 12th, 1917, and it was marked "K-301."

<...>

2.- The Lohner Flying Boat.

This is an enlarged machine of the Lohner type, retaining the V which is typical of the Lohner aeroplanes. There are six steel struts on either side and, two by two, are connected in transverse planes with steel tubes of 40 mm. outside diameter. The distance between two struts in the direction of the brace is 1.30 m., and in the direction of the spar 2.17 m.

General Dimensions.

Span, upper plane 9.70 m.

Span, lower plane 7.20 m.

Chord, upper plane 2.70 m.

Chord, lower plane 2.20 m.

Hull, maximum length 12.50m.

Bomb carrying capacity 400 kg.

Motor, Austro-Daimler 300 h.p.

In form the ailerons are trapezoidal, like that of the Italian Lohner machines. Length of ailerons, 3.47 m.; mean width, .90 m.

Dimensions of the empennage or tail group: Length of horizontal stabiliser or tail-plane, 4.74 m.; width, 1.27 m. Length of tail-flaps or elevators, 4.74 m.; width, .87 m. The vertical rudder differs from that of the old Lohner machines in that there is a small balancing area forward of the pivot.

The principal dimensions of the hull are: Maximum width, 1.50 m.; maximum length, 12.50 m.: maximum height, 1.20 m.; step .25 m.

The body has two seats side by side and one in front, upon which is mounted a machine gun arranged to be movable and fired in any direction. Besides the pilot, next to the observer, there is also a machine gun arranged on a movable tube inside the casing. The outside tube is the only additional piece the machine contains.

The turret is armoured. No bomb-dropping devices have been located. There are two vertical pieces of wood, with a circular profile notch fastened to the floats under the wings. It may be that these are used to drop large bombs, but no discovery has been made which would show how they are secured in them. Several hooks for small bombs were found.

The lateral or wing-floats, instead of being hemispherical in shape, have a bow with good streamlines, which plough on the water surface like the prow of a ship. The accompanying drawing shows their general outlines. Each is 88 cm. wide and 181 cm. long.

The engine, an Austro-Daimler, has 12 cylinders arranged in a V. It is rated at 300 h.p.

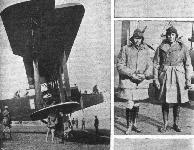

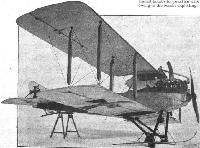

A famous R.A.F. Squadron on the British Western Front in France during the present German offensive. At least three enemy machines have been brought down by every pilot and observer in the above group.

Flight, June 20, 1918.

THE DE HAVILLAND IV BIPLANE.

300 H.P. ROLLS-ROYCE ENGINE.