Книги

Putnam

A.Weyl

Fokker: The Creative Years

113

A.Weyl - Fokker: The Creative Years /Putnam/

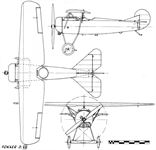

After the Fok. D.IV had been discarded from service on the Western Front, priority for deliveries of the 160-h.p. Mercedes D.IIIa engine was given to the Albatros works and later to the Pfalz concern. This was so, not to discriminate against Fokker, but simply because the Albatros and Pfalz fighters were in great demand for the hard-pressed Western Front, especially in the Somme. Aisne and Flanders areas. Fokker’s complaint about delays in the supply of engines was understandable, but was hardly justified from the Service point of view.

To add to Fokker’s displeasure, he was directed to build, under licence, 400 A.E.G. C.IV two-seaters that were required for instructional purposes. This happened just at the time when he had no-one to design new types for him, but the contract at least had the virtue of keeping the Schwerin factory occupied. Production of the A.E.G. two-seaters was thought to be particularly appropriate to the Fokker works, for the aircraft had welded steel-tube fuselages; the wings had tubular steel spars but wooden ribs. Moreover, it was hoped that Fokker’s organization would profit from the experience of producing a carefully designed aircraft.

Fokker complained bitterly that the A.E.G. C.IV was so immensely complicated that he could not make a penny of profit from the order, large though it was. Hauptmann Dr. Hoff, whom he approached in the matter, advised him to study the soundness of the A.E.G.’s design.

The licence-production at Schwerin was supervised by Dr. Koner, the new expert on production control and materials. The first Fokker-built A.E.G. C.IV (Fok) No. 255/17, was accepted after a flight test at Schwerin on August 1, 1917, and was submitted for a type test on August 25, 1917.

To add to Fokker’s displeasure, he was directed to build, under licence, 400 A.E.G. C.IV two-seaters that were required for instructional purposes. This happened just at the time when he had no-one to design new types for him, but the contract at least had the virtue of keeping the Schwerin factory occupied. Production of the A.E.G. two-seaters was thought to be particularly appropriate to the Fokker works, for the aircraft had welded steel-tube fuselages; the wings had tubular steel spars but wooden ribs. Moreover, it was hoped that Fokker’s organization would profit from the experience of producing a carefully designed aircraft.

Fokker complained bitterly that the A.E.G. C.IV was so immensely complicated that he could not make a penny of profit from the order, large though it was. Hauptmann Dr. Hoff, whom he approached in the matter, advised him to study the soundness of the A.E.G.’s design.

The licence-production at Schwerin was supervised by Dr. Koner, the new expert on production control and materials. The first Fokker-built A.E.G. C.IV (Fok) No. 255/17, was accepted after a flight test at Schwerin on August 1, 1917, and was submitted for a type test on August 25, 1917.

UNWILLINGLY TO SCHOOL

One day early in 1910, among the passengers aboard a Rhine steamer was a disconsolate young Dutchman. His name was Anthony Herman Gerard Fokker; his destination was Bingen; and his immediate future lay in Bingen’s Technical College. If young Fokker seemed preoccupied and oblivious to the splendours of the scenery it was because he viewed with extreme distaste the prospect of a return to the atmosphere and discipline of the classroom. He had had what he regarded as his fill of academic education in the elementary and secondary schools at Haarlem; now his interests lay in new and more practical fields.

Fokker was never happier than when tinkering with motor-cars and their engines. His was the enthusiasm of the mechanic, for he affected a strong dislike of all paperwork and theoretical engineering, largely because he lacked the ability to understand it. He had seen an aeroplane at an exhibition in Brussels in 1908, and had followed developments from the time of Wilbur Wright’s visit to France. Aviation beckoned young Fokker alluringly: here was a fresh world in which he would - for he had supreme confidence in himself - achieve practical success.

Fokker’s first aeronautical experiments were with model gliders cut from paper and celluloid, and he later designed a man-lifting kite. Perhaps fortunately, this was never built, for he was called upon to perform his year’s conscription just after buying the materials. Fokker regarded his military service as an intolerable interference with his aeronautical experiments; he malingered without scruple and ultimately succeeded in bribing a doctor to declare him unfit for military duty.

Fokker’s father, a well-to-do retired coffee planter, became increasingly insistent that the young man should lay the foundations of a career. Although appalled at his son’s desire to fly, Fokker senior did not try to deflect Tony from his technical interests; he insisted, however, that if Tony wanted to be an engineer he must learn engineering thoroughly and obtain a diploma. Herman Fokker may also have entertained the hope that the training might turn the unruly spirit that was his son into a respectable citizen. He was wrong. Tony was perfectly certain that his father would have done better to buy him a flying machine; that was all he needed in order to become world-famous-not classrooms and examinations. As it turned out, the young man was right.

Thus it was that Tony Fokker came to be aboard a Rhine steamer early in 1910, bound for Bingen. Little did he know that, only eight years later, he would flee from Germany a multi-millionaire, owner of an engineering empire, a world-famous personality - and a criminal; that his name would be one of the most familiar in aviation and be bandied about in politics the world over; that honours would be heaped upon him; that the world’s press would describe - and vilify - him as a most patriotic German. And all because he went the way of his own, not his father’s, choosing.

The Bingen Technical School did not have the status of a university, but it had an excellent reputation for producing practical engineers. Ordinarily students were expected to have served an apprenticeship before entering the school, but it seems that in the case of Tony Fokker an exception was made, perhaps on the strength of his experiments with unpuncturable tyres and other practical work.

Despite this concession the Bingen school was not to enjoy the privilege of enrolling Mynheer A. H. G. Fokker. Before he reported to the school he learned that, some twenty miles away at Zalbach, near Mainz, there was a training establishment for automobile engineers that was advertising a course in aviation with prospects of flying tuition. A carefully worded letter that avoided any mention of the aviation course secured the ready agreement of Fokker pere to his son’s transfer from Bingen to Zalbach.

When Tony Fokker arrived at the Erste deutsche Automobil-Fachschule, Mainz, he discovered - so he alleged in his autobiography - that no-one at the school knew much more about aeroplanes than he did. That statement needs to be taken with a pinch of salt. At that time Tony Fokker could not have known much about aircraft or flying: the one and only aeroplane he had seen had been on static display in an exhibition; he had never seen anyone flying, nor had he met anyone who was working in aeronautics. The Zalbach establishment actually possessed a small laboratory with engines, airscrews and aircraft components, and at the time of Fokker’s arrival an aeroplane was under construction. Someone on the staff must, therefore, have known something about the subject.

In point of fact the Erste deutsche Automobil-Fachschule had opened its aviation department on October 15, 1909. The school’s advertisements had begun to appear in German technical journals as early as June 1909; they included illustrations of a workshop with wing structures and control surfaces for a biplane under construction. Also illustrated was an engine test-bed with a 30-h.p. water-cooled engine driving a two-bladed airscrew by a chain; equipment for the measurement of thrust and torque was available. None of this looked like ignorance or incompetence, nor did it suggest false pretences.

Modesty was never one of Tony Fokker’s failings, and he habitually disparaged contemporary people and institutions. In the light of fact his later attempts to belittle the Mainz school and the grave doubts he cast upon the honesty of its management were absurd. Fokker was probably more deeply indebted than he cared to admit to the Fachschule for his rapid advance in German aviation; indeed it is not impossible that the school may have provided the spiritual and material origin of the first Fokker aircraft, which Fokker claimed to be his own work.

The aviation course provided by the Fachschule was not intended to provide ab initio instruction: according to the prospectus it was intended to help men with engineering experience or apprenticeships to enter aviation. Fokker, of course, did not qualify, but the school welcomed his guilders and a place was found for him; he was promised that he would be considered for flying tuition if and when it became possible to do so.

The Automobil-Fachschule did not possess an aeroplane at the time of Fokker’s enrolment: the students themselves had to design and build the aeroplanes on which they would learn to fly. In 1910 the school erected an aeroplane shed on the military training ground at Dotzheim near Wiesbaden. Flying pupils were invited to join; the tuition fee was modest but, as was customary at that time, a deposit was required as a cover against crash damage caused by the pupil.

Work proceeded on the construction of the school’s first aeroplane, work in which Fokker participated eagerly. As he had neither served an apprenticeship nor had any craft training, his contribution can hardly have amounted to more than that of any interested, enthusiastic beginner. He spent little or no time in attending classes or drawing exercises: such activities he regarded as mere theory; and theory, in his opinion, never led to anything.

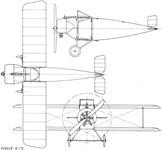

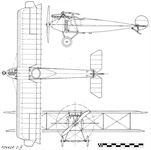

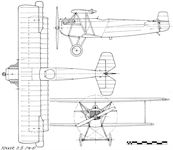

The Automobil-Fachschule aeroplane was a pusher of the then-familiar Farman configuration. Some thirty problematic horse-power were provided by a converted motor-car engine, with which the aircraft was considerably underpowered. It was abandoned in favour of a tractor biplane which, although of lighter construction than the first, yet retained the tail booms. This second aircraft was fitted with a 50-h.p. Argus aero-engine, the property of one of the students at the Fachschule.

As test pilot and flying instructor the school engaged Bruno Buechner, a burly, jovial Bavarian whose seventeen stone promised to tax the little Argus engine severely. Buechner’s weight was not his only handicap, however: he himself had not yet learned to fly. He was a racing driver of great repute, but his flying experience was confined to a few tentative hops in a monoplane that he acquired and all too quickly wrecked.

<...>

One day early in 1910, among the passengers aboard a Rhine steamer was a disconsolate young Dutchman. His name was Anthony Herman Gerard Fokker; his destination was Bingen; and his immediate future lay in Bingen’s Technical College. If young Fokker seemed preoccupied and oblivious to the splendours of the scenery it was because he viewed with extreme distaste the prospect of a return to the atmosphere and discipline of the classroom. He had had what he regarded as his fill of academic education in the elementary and secondary schools at Haarlem; now his interests lay in new and more practical fields.

Fokker was never happier than when tinkering with motor-cars and their engines. His was the enthusiasm of the mechanic, for he affected a strong dislike of all paperwork and theoretical engineering, largely because he lacked the ability to understand it. He had seen an aeroplane at an exhibition in Brussels in 1908, and had followed developments from the time of Wilbur Wright’s visit to France. Aviation beckoned young Fokker alluringly: here was a fresh world in which he would - for he had supreme confidence in himself - achieve practical success.

Fokker’s first aeronautical experiments were with model gliders cut from paper and celluloid, and he later designed a man-lifting kite. Perhaps fortunately, this was never built, for he was called upon to perform his year’s conscription just after buying the materials. Fokker regarded his military service as an intolerable interference with his aeronautical experiments; he malingered without scruple and ultimately succeeded in bribing a doctor to declare him unfit for military duty.

Fokker’s father, a well-to-do retired coffee planter, became increasingly insistent that the young man should lay the foundations of a career. Although appalled at his son’s desire to fly, Fokker senior did not try to deflect Tony from his technical interests; he insisted, however, that if Tony wanted to be an engineer he must learn engineering thoroughly and obtain a diploma. Herman Fokker may also have entertained the hope that the training might turn the unruly spirit that was his son into a respectable citizen. He was wrong. Tony was perfectly certain that his father would have done better to buy him a flying machine; that was all he needed in order to become world-famous-not classrooms and examinations. As it turned out, the young man was right.

Thus it was that Tony Fokker came to be aboard a Rhine steamer early in 1910, bound for Bingen. Little did he know that, only eight years later, he would flee from Germany a multi-millionaire, owner of an engineering empire, a world-famous personality - and a criminal; that his name would be one of the most familiar in aviation and be bandied about in politics the world over; that honours would be heaped upon him; that the world’s press would describe - and vilify - him as a most patriotic German. And all because he went the way of his own, not his father’s, choosing.

The Bingen Technical School did not have the status of a university, but it had an excellent reputation for producing practical engineers. Ordinarily students were expected to have served an apprenticeship before entering the school, but it seems that in the case of Tony Fokker an exception was made, perhaps on the strength of his experiments with unpuncturable tyres and other practical work.

Despite this concession the Bingen school was not to enjoy the privilege of enrolling Mynheer A. H. G. Fokker. Before he reported to the school he learned that, some twenty miles away at Zalbach, near Mainz, there was a training establishment for automobile engineers that was advertising a course in aviation with prospects of flying tuition. A carefully worded letter that avoided any mention of the aviation course secured the ready agreement of Fokker pere to his son’s transfer from Bingen to Zalbach.

When Tony Fokker arrived at the Erste deutsche Automobil-Fachschule, Mainz, he discovered - so he alleged in his autobiography - that no-one at the school knew much more about aeroplanes than he did. That statement needs to be taken with a pinch of salt. At that time Tony Fokker could not have known much about aircraft or flying: the one and only aeroplane he had seen had been on static display in an exhibition; he had never seen anyone flying, nor had he met anyone who was working in aeronautics. The Zalbach establishment actually possessed a small laboratory with engines, airscrews and aircraft components, and at the time of Fokker’s arrival an aeroplane was under construction. Someone on the staff must, therefore, have known something about the subject.

In point of fact the Erste deutsche Automobil-Fachschule had opened its aviation department on October 15, 1909. The school’s advertisements had begun to appear in German technical journals as early as June 1909; they included illustrations of a workshop with wing structures and control surfaces for a biplane under construction. Also illustrated was an engine test-bed with a 30-h.p. water-cooled engine driving a two-bladed airscrew by a chain; equipment for the measurement of thrust and torque was available. None of this looked like ignorance or incompetence, nor did it suggest false pretences.

Modesty was never one of Tony Fokker’s failings, and he habitually disparaged contemporary people and institutions. In the light of fact his later attempts to belittle the Mainz school and the grave doubts he cast upon the honesty of its management were absurd. Fokker was probably more deeply indebted than he cared to admit to the Fachschule for his rapid advance in German aviation; indeed it is not impossible that the school may have provided the spiritual and material origin of the first Fokker aircraft, which Fokker claimed to be his own work.

The aviation course provided by the Fachschule was not intended to provide ab initio instruction: according to the prospectus it was intended to help men with engineering experience or apprenticeships to enter aviation. Fokker, of course, did not qualify, but the school welcomed his guilders and a place was found for him; he was promised that he would be considered for flying tuition if and when it became possible to do so.

The Automobil-Fachschule did not possess an aeroplane at the time of Fokker’s enrolment: the students themselves had to design and build the aeroplanes on which they would learn to fly. In 1910 the school erected an aeroplane shed on the military training ground at Dotzheim near Wiesbaden. Flying pupils were invited to join; the tuition fee was modest but, as was customary at that time, a deposit was required as a cover against crash damage caused by the pupil.

Work proceeded on the construction of the school’s first aeroplane, work in which Fokker participated eagerly. As he had neither served an apprenticeship nor had any craft training, his contribution can hardly have amounted to more than that of any interested, enthusiastic beginner. He spent little or no time in attending classes or drawing exercises: such activities he regarded as mere theory; and theory, in his opinion, never led to anything.

The Automobil-Fachschule aeroplane was a pusher of the then-familiar Farman configuration. Some thirty problematic horse-power were provided by a converted motor-car engine, with which the aircraft was considerably underpowered. It was abandoned in favour of a tractor biplane which, although of lighter construction than the first, yet retained the tail booms. This second aircraft was fitted with a 50-h.p. Argus aero-engine, the property of one of the students at the Fachschule.

As test pilot and flying instructor the school engaged Bruno Buechner, a burly, jovial Bavarian whose seventeen stone promised to tax the little Argus engine severely. Buechner’s weight was not his only handicap, however: he himself had not yet learned to fly. He was a racing driver of great repute, but his flying experience was confined to a few tentative hops in a monoplane that he acquired and all too quickly wrecked.

<...>

UNWILLINGLY TO SCHOOL

<...>

Among the other would-be pilots whose hopes were shattered by Buechner’s crash was Franz von Daum, an ex-officer of the German army, about fifty years of age and of independent means. He was so keenly interested in aviation that he was willing to help finance the construction of an aeroplane. This was Fokker’s opportunity, and he and von Daum entered into an informal partnership: Fokker would construct an aeroplane to their ideas; von Daum would put up most of the money and provide the engine; both would learn to fly on the completed aircraft. Such seems to have been the general nature of their agreement. Von Daum apparently gave up his interest in aviation after the abrupt ending of his collaboration with Fokker; we therefore have only Fokker’s account of the whole affair, and this, of course, is somewhat one-sided.

Von Daum provided a 50-h.p. Argus aero-engine, Fokker 1,500 marks of his father’s money and his services as an aircraft constructor. Fokker implies that he designed the aircraft as well: this is doubtful, and probably only partly true. There are grounds for believing that von Daum had ideas of his own, and that the engineers of the Automobil-Fachschule, and perhaps Jacob Goedecker too, contributed constructive advice and design ideas.

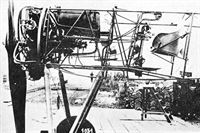

Study of the contemporary aviation journals provides support for the belief that the design of the Fokker-von Daum monoplane was not entirely Fokker’s. Published reports described this monoplane as an aeroplane of the Automobil-Fachschule, Mainz. An illustration depicted the aircraft standing between two biplanes of the Automobil-Fachschule, and the caption stated that all three were the training aeroplanes of the Fachschule. Fokker could be seen in the pilot’s seat of the monoplane but his name was not mentioned, either in the caption or in the accompanying notes. This seems to leave little doubt that the Fachschule had contributed substantially to the aircraft. If such descriptions had been inaccurate Fokker, and probably his partner too, would certainly have protested to the publishers concerned, the more so because Fokker had demanded the return of his 500-mark deposit from the Fachschule and must have regarded his personal connexion with its aviation course as severed.

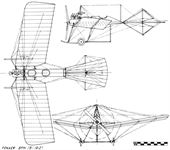

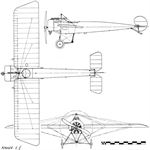

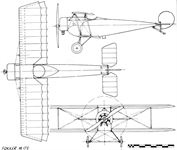

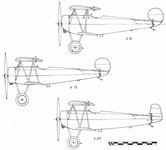

However, there is little doubt that the general arrangement of the aircraft came from Fokker, for it was similar in general configuration to his paper models. It was a tractor monoplane with pronounced dihedral on the mainplanes; the centre of gravity was fairly high above the wing. A small tailplane lay immediately behind the mainplane, but there was neither elevator nor rudder. Control was to be maintained by warping the mainplanes, differentially for lateral and directional control, and in the same sense for control in the looping plane.Construction of the machine began in the autumn of 1910; the work seems to have been done in the Wiesbaden workshop of the Automobil-Fachschule. In his autobiography Fokker states that the steel-tube frames of the mainplanes were made from rough drawings by “a Frankfurt company” ; the wooden components were made in “a neighbouring carpenter’s shop”. Fittings and other metal parts were produced in the Mainz workshops of the Fachschule. There is also the evidence of Jacob Goedecker’s testimony that his workshop contributed, but it seems that the extent and nature of that contribution will never be known.

The “fuselage” consisted of two parallel wooden beams; this idea obviously came from Goedecker, for the contemporary Goedecker monoplanes had the same feature. The influence of Goedecker could also be seen in such details as the tailplane design, seat mounting and engine installation.

For one who had such a high opinion of himself, Fokker was remarkably vague about the part he himself played in the making of this first aircraft. A possible explanation for this vagueness might be that, thanks to his lack of the theoretical knowledge that he so ostentatiously despised, he was incapable of any structural design work.

The Fokker-von Daum monoplane was completed by October 1910. The date is determined by the fact that a photograph of the aircraft in its original form, taken on the Wiesbaden-Dotzheim parade ground, was published in Flugsport for November 2, 1910. The partners seem to have contrived to remove their “training” monoplane from its attachment to the Automobil-Fachschule: before the end of 1910 it was at the airship ground of Baden-Oos, where its testing continued.

Like all experimental aeroplanes of that period, the monoplane was repeatedly modified as its trials proceeded. An essential addition was a conventional rudder: without it the aircraft was virtually uncontrollable on the ground, for no other provision for steering had been made. It was found that warping both wings in the same sense was totally ineffective as a means of control in pitch, consequently the trailing edge of the tailplane had to be made flexible (as on the Goedecker monoplane) to serve as an elevator. This proved effective, but the aircraft’s response when taxied at higher speeds indicated a disconcerting degree of instability. Stability was at that time regarded as perhaps the most desirable attribute an aeroplane could have; that it could be obtained by giving the wings pronounced sweep-back had been conclusively demonstrated in England by J. W. Dunne. Details and drawings of the successful Dunne biplane had appeared in Flugsport for July 6, 1910, and cannot have escaped Fokker’s notice. The Fokker-von Daum monoplane therefore acquired an appreciable degree of sweep-back.

Fokker himself did all the testing of the aircraft; indeed, he virtually prevented von Daum from trying to fly it. Selfish though this action was, it is perhaps well that it was so: Fokker was twenty, slim, wiry and agile, and had exceptionally quick reactions. Although he had no more flying 13 experience than von Daum he was, by virtue of being thirty years younger, more likely to achieve early success in flying their aeroplane, with its new and untried features.

Real success was not achieved until December 1910 when, after all the modifications described above had been made, Fokker succeeded in making a hop of about 100 yards in the monoplane. His labours had been crowned with success, and he was naturally elated and greatly pleased with himself.

As was his wont when immersed in developmental work Fokker had not spared himself. He never indulged himself with personal luxuries; he was a lifelong abstainer from alcohol, and he did not smoke; his sole weakness was sugar in every form. In his endeavours to get the Fokker- von Daum monoplane into the air Fokker had worked long and strenuously in the open. He contracted a severe chill, and went home to spend Christmas at Haarlem, to rest and recuperate.

Not unnaturally, Franz von Daum had come to resent the way in which his younger partner monopolized their jointly-owned aeroplane. Fokker’s absence gave von Daum his first opportunity to try his skill on the aircraft. Unfortunately he taxied into a tree and damaged the machine extensively. Von Daum was honest enough to tell his partner of the mishap at once, and a furious Fokker hurried back from Haarlem - once again his personal flying ambitions had been thwarted by what he regarded as the ineptitude of another.

The monoplane was so extensively damaged that there was little point in trying to repair it. In any case, Fokker had come to realize that it had been too heavy, complicated and unpractical; its destruction brought an opportunity to produce an improved aircraft. This idea Fokker put to von Daum who, chastened by his experience with the original machine, readily agreed. Fokker suggested that this time Jacob Goedecker should build the new monoplane to their ideas. Goedecker was also to help with the detail design.

Goedecker’s name has already been mentioned. He was one of the few qualified engineers who took an early interest in German aviation. He had devoted five years of university study to engineering and naval architecture and had done post-graduate research in the laboratory of Professor Junkers at Aachen University. His scientific work had been of a high standard. Goedecker’s interest in flying started in 1902 with the study of the infant science of aerodynamics. Thence he progressed to practical experiments, and in 1909 he constructed his first monoplane at Gonsenheim, near Mainz.

Fokker had made friends with this approachable, frank and helpful Rhinelander who had neither ambition to become a pilot nor the business acumen to make money out of aviation.

The first Goedecker monoplane had a cantilever wing that could be swivelled about a vertical axis for steering. Fokker and von Daum knew this aircraft well; several of its features influenced their ideas. It proved 14 itself capable of making short hops but was not conspicuously successful; it was therefore abandoned.

Early in 1910 Goedecker designed a Taube-like monoplane powered by a 50-h.p. Argus engine. Taube was the name of a very stable monoplane developed by Etrich and Wels with the guidance of Professor Ahlborn. The Taube wing was shaped like the seed leaf of Zanonia Macrocarpa, which gave perfectly stable glides; and the Etrich-Wels monoplane was remarkably stable. The name Taube was quite widely applied to other aircraft having a wing generally similar to that of the original Etrich-Wels machine.

On April 24, 1910, the Goedecker Taube made a complete circuit of the Grosser Sand parade ground near Gonsenheim. It was flying while Fokker was working on the clumsy pusher biplane of the Automobil-Fachschule; it was, in fact, the first aeroplane he saw flying.

Later in 1910 Goedecker built an improved model of his Taube; it incorporated more steel-tube construction than its predecessors, and probably gave Fokker and von Daum the idea of using steel tubing in their aircraft. Instead of exploiting his talent as an aircraft designer, Goedecker was content to remain in the comparative obscurity of Mainz, where, during 1911, he built three more Taube-type monoplanes and opened a flying school.

Fokker had much to thank Goedecker for. From him he learned more about technical matters than from anyone else during his long career in aviation. If Fokker had had a real grounding in engineering he might have learned enough from the modest Rhinelander to become an aircraft designer himself. Instead he was compelled throughout his career to depend upon the engineering abilities of others to design the aeroplanes that he falsely claimed to be his brain-children.

Goedecker was willing to build the new Fokker-von Daum monoplane. He agreed to design its structure and have the components made in his workshop; Fokker would work on the assembly of the machine.

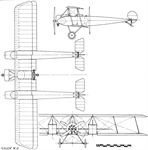

In the new aircraft the ineffective and complicated wing-warping control was abandoned, and conventional elevator and rudder surfaces were fitted. Although Fokker might have found that models with swept-back wings and marked dihedral needed no lateral control, Goedecker knew that even the stable Zanonia plan-form could not do without it. The monoplane therefore had ailerons. The undercarriage, which differed from the type Goedecker had favoured up to that time, was a simpler, cleaner structure than that of the first monoplane. Power was provided by von Daum’s same 50-h.p. Argus engine, which had apparently survived the crash of the earlier machine.

The new monoplane was kept at the Dotzheim parade ground. It was a great improvement over its predecessor: it was lighter and its controls were effective.

Fokker, more than ever resolved to keep his partner from flying this precious monoplane, made progressively longer flights. As his experience increased so did his great natural talent for flying develop. On May 5, 1911, he succeeded in making a shallow turn at a height of about fifty feet. With this proof that “his” monoplane could fly and be controlled in flight, Fokker took and passed the tests for the pilot’s certificate on May 16. He was granted German Licence No. 88, issued on June 7, 1911, by the Deutsche Luftfahrer-Verband. Fokker had achieved his aim.

But if Fokker had attained his goal, von Daum had not; and he insisted that he would now learn to fly on the monoplane. Fokker’s counterarguments were unavailing. Although von Daum made quite a good start, he crashed and damaged the aeroplane beyond repair. He was unhurt physically, but the blistering tirade that the unfeeling Fokker delivered against him killed his enthusiasm for flying. He sold his share in the aircraft to Fokker - which was exactly what the shrewd Dutchman wanted.

<...>

Among the other would-be pilots whose hopes were shattered by Buechner’s crash was Franz von Daum, an ex-officer of the German army, about fifty years of age and of independent means. He was so keenly interested in aviation that he was willing to help finance the construction of an aeroplane. This was Fokker’s opportunity, and he and von Daum entered into an informal partnership: Fokker would construct an aeroplane to their ideas; von Daum would put up most of the money and provide the engine; both would learn to fly on the completed aircraft. Such seems to have been the general nature of their agreement. Von Daum apparently gave up his interest in aviation after the abrupt ending of his collaboration with Fokker; we therefore have only Fokker’s account of the whole affair, and this, of course, is somewhat one-sided.

Von Daum provided a 50-h.p. Argus aero-engine, Fokker 1,500 marks of his father’s money and his services as an aircraft constructor. Fokker implies that he designed the aircraft as well: this is doubtful, and probably only partly true. There are grounds for believing that von Daum had ideas of his own, and that the engineers of the Automobil-Fachschule, and perhaps Jacob Goedecker too, contributed constructive advice and design ideas.

Study of the contemporary aviation journals provides support for the belief that the design of the Fokker-von Daum monoplane was not entirely Fokker’s. Published reports described this monoplane as an aeroplane of the Automobil-Fachschule, Mainz. An illustration depicted the aircraft standing between two biplanes of the Automobil-Fachschule, and the caption stated that all three were the training aeroplanes of the Fachschule. Fokker could be seen in the pilot’s seat of the monoplane but his name was not mentioned, either in the caption or in the accompanying notes. This seems to leave little doubt that the Fachschule had contributed substantially to the aircraft. If such descriptions had been inaccurate Fokker, and probably his partner too, would certainly have protested to the publishers concerned, the more so because Fokker had demanded the return of his 500-mark deposit from the Fachschule and must have regarded his personal connexion with its aviation course as severed.

However, there is little doubt that the general arrangement of the aircraft came from Fokker, for it was similar in general configuration to his paper models. It was a tractor monoplane with pronounced dihedral on the mainplanes; the centre of gravity was fairly high above the wing. A small tailplane lay immediately behind the mainplane, but there was neither elevator nor rudder. Control was to be maintained by warping the mainplanes, differentially for lateral and directional control, and in the same sense for control in the looping plane.Construction of the machine began in the autumn of 1910; the work seems to have been done in the Wiesbaden workshop of the Automobil-Fachschule. In his autobiography Fokker states that the steel-tube frames of the mainplanes were made from rough drawings by “a Frankfurt company” ; the wooden components were made in “a neighbouring carpenter’s shop”. Fittings and other metal parts were produced in the Mainz workshops of the Fachschule. There is also the evidence of Jacob Goedecker’s testimony that his workshop contributed, but it seems that the extent and nature of that contribution will never be known.

The “fuselage” consisted of two parallel wooden beams; this idea obviously came from Goedecker, for the contemporary Goedecker monoplanes had the same feature. The influence of Goedecker could also be seen in such details as the tailplane design, seat mounting and engine installation.

For one who had such a high opinion of himself, Fokker was remarkably vague about the part he himself played in the making of this first aircraft. A possible explanation for this vagueness might be that, thanks to his lack of the theoretical knowledge that he so ostentatiously despised, he was incapable of any structural design work.

The Fokker-von Daum monoplane was completed by October 1910. The date is determined by the fact that a photograph of the aircraft in its original form, taken on the Wiesbaden-Dotzheim parade ground, was published in Flugsport for November 2, 1910. The partners seem to have contrived to remove their “training” monoplane from its attachment to the Automobil-Fachschule: before the end of 1910 it was at the airship ground of Baden-Oos, where its testing continued.

Like all experimental aeroplanes of that period, the monoplane was repeatedly modified as its trials proceeded. An essential addition was a conventional rudder: without it the aircraft was virtually uncontrollable on the ground, for no other provision for steering had been made. It was found that warping both wings in the same sense was totally ineffective as a means of control in pitch, consequently the trailing edge of the tailplane had to be made flexible (as on the Goedecker monoplane) to serve as an elevator. This proved effective, but the aircraft’s response when taxied at higher speeds indicated a disconcerting degree of instability. Stability was at that time regarded as perhaps the most desirable attribute an aeroplane could have; that it could be obtained by giving the wings pronounced sweep-back had been conclusively demonstrated in England by J. W. Dunne. Details and drawings of the successful Dunne biplane had appeared in Flugsport for July 6, 1910, and cannot have escaped Fokker’s notice. The Fokker-von Daum monoplane therefore acquired an appreciable degree of sweep-back.

Fokker himself did all the testing of the aircraft; indeed, he virtually prevented von Daum from trying to fly it. Selfish though this action was, it is perhaps well that it was so: Fokker was twenty, slim, wiry and agile, and had exceptionally quick reactions. Although he had no more flying 13 experience than von Daum he was, by virtue of being thirty years younger, more likely to achieve early success in flying their aeroplane, with its new and untried features.

Real success was not achieved until December 1910 when, after all the modifications described above had been made, Fokker succeeded in making a hop of about 100 yards in the monoplane. His labours had been crowned with success, and he was naturally elated and greatly pleased with himself.

As was his wont when immersed in developmental work Fokker had not spared himself. He never indulged himself with personal luxuries; he was a lifelong abstainer from alcohol, and he did not smoke; his sole weakness was sugar in every form. In his endeavours to get the Fokker- von Daum monoplane into the air Fokker had worked long and strenuously in the open. He contracted a severe chill, and went home to spend Christmas at Haarlem, to rest and recuperate.

Not unnaturally, Franz von Daum had come to resent the way in which his younger partner monopolized their jointly-owned aeroplane. Fokker’s absence gave von Daum his first opportunity to try his skill on the aircraft. Unfortunately he taxied into a tree and damaged the machine extensively. Von Daum was honest enough to tell his partner of the mishap at once, and a furious Fokker hurried back from Haarlem - once again his personal flying ambitions had been thwarted by what he regarded as the ineptitude of another.

The monoplane was so extensively damaged that there was little point in trying to repair it. In any case, Fokker had come to realize that it had been too heavy, complicated and unpractical; its destruction brought an opportunity to produce an improved aircraft. This idea Fokker put to von Daum who, chastened by his experience with the original machine, readily agreed. Fokker suggested that this time Jacob Goedecker should build the new monoplane to their ideas. Goedecker was also to help with the detail design.

Goedecker’s name has already been mentioned. He was one of the few qualified engineers who took an early interest in German aviation. He had devoted five years of university study to engineering and naval architecture and had done post-graduate research in the laboratory of Professor Junkers at Aachen University. His scientific work had been of a high standard. Goedecker’s interest in flying started in 1902 with the study of the infant science of aerodynamics. Thence he progressed to practical experiments, and in 1909 he constructed his first monoplane at Gonsenheim, near Mainz.

Fokker had made friends with this approachable, frank and helpful Rhinelander who had neither ambition to become a pilot nor the business acumen to make money out of aviation.

The first Goedecker monoplane had a cantilever wing that could be swivelled about a vertical axis for steering. Fokker and von Daum knew this aircraft well; several of its features influenced their ideas. It proved 14 itself capable of making short hops but was not conspicuously successful; it was therefore abandoned.

Early in 1910 Goedecker designed a Taube-like monoplane powered by a 50-h.p. Argus engine. Taube was the name of a very stable monoplane developed by Etrich and Wels with the guidance of Professor Ahlborn. The Taube wing was shaped like the seed leaf of Zanonia Macrocarpa, which gave perfectly stable glides; and the Etrich-Wels monoplane was remarkably stable. The name Taube was quite widely applied to other aircraft having a wing generally similar to that of the original Etrich-Wels machine.

On April 24, 1910, the Goedecker Taube made a complete circuit of the Grosser Sand parade ground near Gonsenheim. It was flying while Fokker was working on the clumsy pusher biplane of the Automobil-Fachschule; it was, in fact, the first aeroplane he saw flying.

Later in 1910 Goedecker built an improved model of his Taube; it incorporated more steel-tube construction than its predecessors, and probably gave Fokker and von Daum the idea of using steel tubing in their aircraft. Instead of exploiting his talent as an aircraft designer, Goedecker was content to remain in the comparative obscurity of Mainz, where, during 1911, he built three more Taube-type monoplanes and opened a flying school.

Fokker had much to thank Goedecker for. From him he learned more about technical matters than from anyone else during his long career in aviation. If Fokker had had a real grounding in engineering he might have learned enough from the modest Rhinelander to become an aircraft designer himself. Instead he was compelled throughout his career to depend upon the engineering abilities of others to design the aeroplanes that he falsely claimed to be his brain-children.

Goedecker was willing to build the new Fokker-von Daum monoplane. He agreed to design its structure and have the components made in his workshop; Fokker would work on the assembly of the machine.

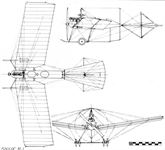

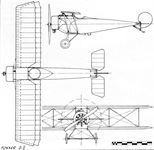

In the new aircraft the ineffective and complicated wing-warping control was abandoned, and conventional elevator and rudder surfaces were fitted. Although Fokker might have found that models with swept-back wings and marked dihedral needed no lateral control, Goedecker knew that even the stable Zanonia plan-form could not do without it. The monoplane therefore had ailerons. The undercarriage, which differed from the type Goedecker had favoured up to that time, was a simpler, cleaner structure than that of the first monoplane. Power was provided by von Daum’s same 50-h.p. Argus engine, which had apparently survived the crash of the earlier machine.

The new monoplane was kept at the Dotzheim parade ground. It was a great improvement over its predecessor: it was lighter and its controls were effective.

Fokker, more than ever resolved to keep his partner from flying this precious monoplane, made progressively longer flights. As his experience increased so did his great natural talent for flying develop. On May 5, 1911, he succeeded in making a shallow turn at a height of about fifty feet. With this proof that “his” monoplane could fly and be controlled in flight, Fokker took and passed the tests for the pilot’s certificate on May 16. He was granted German Licence No. 88, issued on June 7, 1911, by the Deutsche Luftfahrer-Verband. Fokker had achieved his aim.

But if Fokker had attained his goal, von Daum had not; and he insisted that he would now learn to fly on the monoplane. Fokker’s counterarguments were unavailing. Although von Daum made quite a good start, he crashed and damaged the aeroplane beyond repair. He was unhurt physically, but the blistering tirade that the unfeeling Fokker delivered against him killed his enthusiasm for flying. He sold his share in the aircraft to Fokker - which was exactly what the shrewd Dutchman wanted.

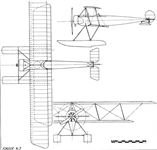

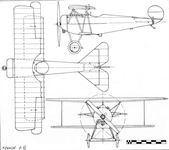

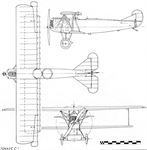

THE SPIDERS

The most important asset Fokker gained from the dissolution of this incongruous partnership was the 50-h.p. Argus engine, which had survived the second crash with little damage. This remarkably durable power unit was installed in another monoplane, which was built by Goedecker. The new aeroplane was a refined development of its predecessor; it was smaller, lighter and simpler. The span was reduced from 43 to 36 ft. and, in accordance with Fokker’s ideas, there were no ailerons.

Fokker took an enthusiastic part in the building of the aircraft. He became competent in the simple structural methods that Goedecker had developed; but he never acquired the skill of a craftsman.

This third monoplane was completed in August 1911. With its lower weight and smaller span it had a better performance than its predecessors: it could carry a passenger and fuel for twenty minutes at full throttle.

By this time Fokker’s father was aware of the nature of Tony’s activities. Apparently he had become resigned to the fact that his son was not going to settle down in a conventional career, for he became a member of the committee that organized a flying demonstration given by Tony Fokker at Haarlem. Thanks to Fokker’s skill as a pilot, the demonstration was a resounding success.

The monoplane had necessarily to travel by rail to Haarlem, and the ease with which it was dismantled and reassembled testified to the soundness of Goedecker’s structural design. Fokker appreciated this advantage; all subsequent Fokker types were designed to be easily transportable.

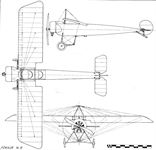

In flight the third monoplane, which became known as the Haarlem Spider, proved to be as stable as Fokker had intended, and no lateral control was required. Although by no means the first two-control aeroplane, the Fokker Spider was the most practical one that had been constructed up to that time.

This did not mean that the Spider was particularly easy to fly, nor was it so completely stable as the Etrich Taube. Later experience showed that the Spider could be difficult in gusty weather, particularly if a take-off or landing were made slightly out of wind.

About twenty-five Spiders in all were made by Goedecker and assembled in the Fokker workshops at Johannisthal. They were flown extensively during 1912 and 1913 and remained in use as primary trainers until late in 1914.

Fokker, who was not a sentimental man, preserved one of the earliest Spiders. After the First World War it was kept at Amsterdam as a museum piece. In 1924 it was fitted with a 70-h.p. Renault (the power unit of a few of the 1912 Spiders) and exhibited at the Paris Aero-Salon; in the following year Fokker demonstrated it in flight. This specimen had the stick control of the 1912 production version. In 1941 it was stolen by the Germans and transferred to the Berlin Air Museum, where it was later destroyed by Allied bombing.

In 1936 a replica of a Spider was built in Holland to celebrate the twenty-fifth anniversary of the date of Fokker’s pilot’s licence. It had a 90-h.p. Argus engine. This replica was flown by Fokker on June 6, 1936, at Schiphol where it is preserved to this day as part of an aeronautical museum.

When Goedecker received Fokker’s order for the third monoplane, Fokker was appointed works pilot and flying instructor of the Goedecker school. In this capacity he flew the Goedecker Taube-type monoplane, which was larger and heavier than his own machine. The Goedecker monoplane was stable and flew well; its rate of climb was poor, however, and it was not very manoeuvrable. It had a hand-wheel control similar to that of the Etrich Taube. This control arrangement became a standard requirement laid down by the German military authorities.

Fokker flew the Goedecker monoplane with skill, and became a good instructor. In the summer of 1911 he flew a new Goedecker on reconnaissance flights during the autumn manoeuvres of the XVIII Army Corps in the Taunus mountains. These flights were highly successful; Goedecker was decorated for the achievement of his aircraft, and the publicity benefited his flying school; Fokker earned high praise and a £25 fee for his part.

Fokker’s basic design was protected by his German patent D.R.P. 265,515, which was applied for as late as January 25, 1912, and granted in 1913. It is not clear why Fokker waited so long after his separation from von Damn before applying for the patent: his aeroplane had been publicly exhibited and widely publicized months before the date of application.

The essence of Fokker’s patent was that automatic stability in an aeroplane was produced by the combination of dihedral, sweepback, and a centre-of-gravity position above the centre of pressure: when one of these factors was absent inherent stability could not be obtained.

Fokker had first achieved the combination of these factors in the first Fokker-von Daum monoplane after its wings had been given sweep-back, but the true prototype of the Fokker Spider type was the Haarlem Spider, the third Fokker monoplane. In its essentials this aircraft was similar to the monoplanes built in 1912 and 1913, but had these differences of detail:

(1) The Haarlem Spider had a wheel control; when rotated, the wheel actuated the rudder; fore-and-aft movement of the control column actuated the elevator. From the next monoplane (the A-1912 type) onwards a stick control on a universal pivot was used: sideways movement of the stick operated the rudder; fore-and-aft movement the elevator.

(2) On the Haarlem Spider the two cabane pylons were in line with the wing spars. On production Spiders, beginning with A-1912, the rear pylon was moved aft to the leading edge of the tailplane.

(3) The Haarlem Spider’s ignition switch was on the rim of the control wheel, on the starboard side.

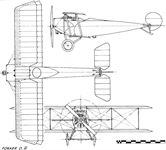

The Haarlem Spider shared with many of its descendants the stark simplicity of its crew accommodation. Pilot and passenger sat in total exposure on exiguous seats between the two longitudinals that did duty as fuselage. Two large flat radiator elements were attached to the longitudinals. A small gravity tank was mounted between the forward cabane struts; a stand-glass on its starboard side indicated its contents.

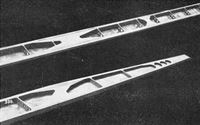

Each wing had two spars of seamless-drawn steel tubes; each spar consisted of three tubes of progressively smaller diameter, bolted together at their ends to produce a tapered spar. The bolts also provided anchorage points for the wing bracing. This method of forming tapered spars was evolved by Goedecker. The ribs were also of his design: each consisted of a short length of steel tube bent to produce the pronounced camber of the wing; into this rib nose a length of bamboo was fitted and formed the remainder of the rib. All ribs were identical and were sheathed in pockets sewn into the strong fabric covering of the wing. The wing was therefore single-surfaced at a time when such contemporary machines as the Etrich-Wels Taube had double-surfaced wings.

The Goedecker-Fokker wing section was too shallow to enclose the spars. The front spar ran under the ribs at the leading edge; the rear spar ran over the ribs and was faired over by a narrow strip of fabric. The ribs were attached to the spars by clamps bolted through the spar tubes. There was no drag bracing between the spars. The wing tips of the early Spiders and those of all training variants were square-cut, but some competition machines had the refinement of slightly rounded tips.

The bracing of the wings was originally effected by wire but, following Goedecker’s example, steel cables were later adopted. The cables were attached to the tall cabane struts above the wings and to the undercarriage skids below, both of which anchorages gave favourable bracing angles.

This Goedecker-designed wing could be easily dismantled, easily assembled, and easily repaired. By the same token it was easy for Fokker’s small workshop to assemble new Spiders from the components supplied by Goedecker. It was also a simple matter to vary the sweepback, dihedral or incidence of the wings: all that was necessary was to fit appropriate sockets to the ends of the central spanwise wing-spar connecting tubes.

This simple wing was so successful at the low air speeds attained by the Spider that Fokker became convinced that there was no need to bother about the aerodynamic refinements that the “theorists” regarded as desirable. The shape of a wing section did not seem to matter; camber was all that was needed. Fokker failed to understand why critics of his Spider wing found fault with it: later, when the Prussian Army took an interest in his products, he was to learn that some of the constructional features that Goedecker had embodied in the Spider did not meet with the approval of structural experts. Fokker remained averse to theory and aerodynamic refinement, and his designers always had to fight whenever a new idea was to be incorporated in a Fokker aeroplane.

Construction of the tailplane was similar to that of the wings, but the ribs were wholly of bamboo. Elevator control was provided by warping the rear portion of the surface. That considerable physical force was required to flex the bamboo rods may be deduced from the substantial size of the stick that replaced the pilot’s wheel control. The advantage of the stick control lay in its greater simplicity and lower weight. The rudder consisted of two triangles of steel tube hinged to the aft bracing pylon, one above and one below the tailplane.

The fuselage had only two longerons, strong ash beams of rectangular cross section, partly spindled out to save weight. They were about 13-2 ft. long and about 34 in. apart. Attached to the longerons were the two inverted-V cabane struts, the undercarriage struts, and the central rear skid.

The undercarriage struts formed an integral part of the wing structure. Not only did they provide anchorage points for the flying wires, but near their upper ends they carried the transverse steel tubes that interconnected the mainplane spars.

The undercarriage proper incorporated two long ash skids that projected forward in order to protect the airscrew. The axle was bound to these skids by rubber shock-absorber cord; it consisted of two steel tubes telescoped one inside the other over their entire length. Two wheels of motor-cycle type were usually fitted, but the 100-h.p. military Spiders had two pairs of such wheels to prevent digging in on soft ground. The whole undercarriage structure was liberally braced with piano wire.

The rear support of the undercarriage was an extraordinary device that gave Spider pilots much trouble. It was rather close to the wheels and made ground handling tricky, for the small rudder was the only means of steering. The unwary pilot might easily find himself travelling in directions he never intended. This troublesome rear support consisted of a long central skid attached to the centre of the axle and having a “scraper” or a claw brake at its rear end. The rear of the skid was sprung via a vertical strut the top of which was connected by rubber cord to the fuselage at a point immediately behind the pilot’s seat. The arrangement was primitive in the extreme, and any competent engineer would have replaced it by a simpler and more practical device. Fokker stuck to it, however: he loved primitive things and disliked tidying up.

No part of the Fokker Spider was welded. Goedecker was opposed to that method of jointing, consequently every tube connexion was made by bolts passed through the tubes; U-bolts threaded on both legs were used as anchoring fitments. The structure was nowhere reinforced to compensate for the loss of strength at the bolt holes. Cast aluminium fittings attached the undercarriage struts to the longerons and formed the sockets for the cabane struts. The flying wires or cables were also attached to cast aluminium fittings bolted to the skids.

Most of these crude joints would be quite unacceptable nowadays, but in their time they were satisfactory and were not considered unsafe.

Fokker held the view that low weight and simplicity mattered more than crew comfort; he therefore set his face against the provision of such refinements as cockpit fairings. His only voluntary concession to luxury in later Spiders was the fitting of bucket seats. Ultimately, however, he had to provide cockpit fairings, to add a faired bottom to the fuselage and finally to fit a complete fuselage shell with windscreens. Army requirements accelerated his change of outlook. Fokker, who hated long flights and could scarcely read a map, did not readily appreciate the importance of providing military crews with enough protection to enable them to handle maps and write messages or sketch enemy positions. The seat fairing fitted to privately owned or competition versions of the 1912 Spider was of the type fitted to the Goedecker monoplane. It was supplied by the Frankfurt car-body manufacturer Georg Kruck. Trainer versions of the Spider had no seat fairing whatever.

One advantage that Fokker could claim for his Spider was that the view from both its seats was as good as could be had from a tractor monoplane. The wide gap between the wings and the fuselage, although inefficient aerodynamically, gave a better field of vision than could be obtained on any other German monoplane of the time.

The power unit of the Haarlem Spider and many of its descendants was an Argus engine, which was bolted directly to the two longerons. During 1912 and 1913 Fokker rejected all suggestions that he should fit other engines to his competition aircraft. This might mean that he had an agreement with the Argus firm to sponsor their products.

The Argus and Daimler-Mercedes companies were then the leading makers of aero-engines in Germany, and Daimler-Mercedes made great efforts to capture the market with their series of water-cooled in-line engines specially designed for use in aeroplanes. Various smaller firms competed, but with little success.

The Argus Motoren G.m.b.H, was one of the oldest aero-engine firms in the world. It had been founded in 1902 by Henri Jeannin, Klingenberg and Rathjen, and had been supplying airship engines since 1906. The 50-h.p. aeroplane engine was developed in 1909, and from 1911 the firm concentrated its efforts on the production of aero-engines. The 50-h.p. version was followed by a 60-h.p. engine that had its cylinders cast in pairs and a camshaft located in the crankcase, actuating the valves by push-rods; the gear drive was at the rear and was not enclosed. In 1912, 70-h.p. and 100-h.p. engines were produced; all were four-cylinder in-line units. These engines had a good reputation but from 1913 the Mercedes engines began to show superiority.

The original arrangement of the cooling system, in which two large flat radiators were attached to the longerons, was not completely satisfactory. Later Spiders had a single smaller radiator block mounted athwartships behind the engine. Fokker found these radiators something of a nuisance; for this reason he tried the air-cooled Renault engine and liked it.

The Spider’s engine had neither exhaust stubs nor silencers, and pilots willy-nilly inhaled a mixture of exhaust fumes, soot and lubricating oil. The fuel system was generally of the simple gravity type already described. At a later stage a larger tank was fitted: mounted between the longerons just in front of the pilot, it was a pressure tank; a hand pump was fitted to the starboard longeron.

The precise identity of Fokker’s first airscrew is uncertain: it may have been made by Goedecker, or it may have been one of the French Chauviere Integrate airscrews that could be had from Frankfurt. As soon as Fokker had settled at Johannisthal the new A-1912 type Spider was fitted with a Garuda propellor, the blades of which were inclined slightly forward. This unusual airscrew was designed by Bruno Jablonsky, who became a well-known industrialist in Britain.

Ernst Ditzuleit, who was one of the first flying instructors to be employed by Fokker and flew the Spider type extensively, has kindly recorded these impressions of the two-seat versions powered by the 70-h.p. and 100-h.p. Argus engines.

“The Spider was inherently stable. In the air it was perfectly simple to handle. When the engine was throttled down or switched off, the aircraft automatically assumed the correct gliding attitude; for landing one had only to flatten out. Take-off and landing were far from easy, however. The saying among aviators then was that anyone who could take-off and land a Spider could fly anything.”

The difficulties were no doubt largely attributable to the arrangement of the undercarriage already mentioned.

In December 1911 Fokker moved to Johannisthal, at that time the centre of German aviation. Goedecker was sorry to lose him, for he had been a sound pilot and a good if somewhat impatient instructor. Fokker hoped to win some of the substantial prizes offered in the Johannisthal competitions, to teach flying, and possibly to obtain some orders for the Spider.

At Johannisthal the representative of the new aero-engine branch of the Fahrzeugfabrik Eisenach Dixi motor-car firm offered Fokker the use of a shed. Fokker accepted with alacrity. The Dixi company had redesigned their four-cylinder car engine as an aero-engine and had formed a subsidiary company, Dixi Luftfahrt und Bootsmotoren Verkaufs G.m.b.H., to market it. This subsidiary had rented the shed for the use of customers.

Fokker assembled his monoplane in the Dixi shed. He later tried a Dixi engine. Reports in German periodicals stated that the engine had been very successful both in a Goedecker monoplane and in Fokker’s machine, but it seems Fokker found fault with it. He moved out of the Dixi shed after sugar had been put into his monoplane’s petrol tank one Saturday afternoon, preventing him from competing for that part of the gate money shared out among pilots who made flights before the visitors. Fokker rented his own shed and reverted to using the Argus engine.

Fokker and his monoplane were at first looked upon as freaks by the Johannisthal habitues. The aeroplane looked rough and unfinished, and so did its pilot and designer. The absence of any form of lateral control on the monoplane was regarded as final proof that its designer was slightly insane. Fokker was regarded as an aviation maniac who worked hard on a useless and ill-conceived flying machine in preference to entering into the friendly social life of the Johannisthal community.

But Johannisthal changed its opinion of Fokker and his monoplane when he began to fly it: it was obvious that the Spider flew well; it was equally obvious that its pilot knew his trade. The more serious-minded among the mixed crowd of aviators and hangers-on came to realize that the young Dutchman with the deplorable manners was not only the best pilot at Johannisthal but was determined to go into business in aviation. Although he came from a wealthy family and did not need to earn a living, he was no sportsman merely seeking thrills.

When he was not working, Fokker virtually lived in the Cafe Senftleben, for that establishment was an excellent place for making useful connexions and gathering information.

His immediate objective was the establishment of a flying school; for this he needed a business partner with capital. He had the good fortune to find the partner he was seeking in Hans Haller, a man of independent means who owned, and occasionally flew, a biplane at Johannisthal. Haller never took his pilot’s certificate and indeed gave up flying soon after joining forces with Fokker. To the partnership he brought £500 (at pre-1914 value) and undertook to look after the business side of the venture.

Another valuable acquaintance of Fokker’s was Dr. Walther Lissauer,1 a Berlin-born physicist of repute, who had decided to make a career in engineering after studying several subjects. This quiet, cultured man had become a skilled pilot of the Otto Aircraft Works. At Johannisthal he was in charge of the aircraft division of the Berlin motor-body and coachbuilding firm of Kuhlstein. Fokker found that he could gain a great deal of technical information from this older, experienced man.

At a time when most of the aeroplane constructors at Johannisthal were obliged to work on insufficient financial means, young Fokker was particularly fortunate in being able to count on financial help from his family: from them he received a total of over £15,000 at pre-war value. This subsidy enabled him to outlive many of his early contemporaries; without it he could hardly have made the grade in industry.

The shed that Fokker rented after leaving the Dixi shed was one of eight 50 ft. X 50 ft. sections in a long rectangular building. It had formerly been occupied by the Automobil und Aviatik A.G., a Strasbourg firm that built Farman box-kite biplanes and Hanriot monoplanes under licence. The Automobil und Aviatik concern was connected with the Argus engine company. Fokker soon found that for a flying school with facilities for assembly and repair more space was needed, so he rented the adjoining section of the building as well.

Other compartments in the same long building were occupied by the Rumpler company (for housing training aircraft); the Berlin patent agent Haefelin with an interesting but unlucky monoplane of his own design; the A.G.O. firm, then still a branch of the Munich aircraft works of Gustav Otto; and O. Trinks, a Berlin manufacturer of aeronautical components, who had built a twin-fuselage monoplane.

Johannisthal in Fokker’s time was not altogether ideal as an aerodrome. It had been opened by an enterprising syndicate late in 1909. It lay between the boroughs of Johannisthal and Adlershof, beside the Berlin-Goerlitz railway; on the other side of the aerodrome, west of the railway, was the Teltow canal. This canal, although only a narrow waterway, produced unexpected turbulence on occasion, and beginners were not encouraged to fly over it. During the war, certain ex-cavalry officers who had no aviation experience held positions of command at Johannisthal, and one of them achieved a kind of immortality by issuing a strict order that the Teltow canal was to be flown over only where there were bridges: this, he declared, would avoid crashes caused by gusts.

The flying ground proper was large (2,450 yd. in the N.E.-S. W. direction of the prevailing wind and 1,450 yd. across) but not very even. In fact, soon after the First World War a professor described its sandy surface as a most interesting formation of dunes. Care had therefore to be exercised in selecting areas for take-offs and landings - as Fokker discovered at the cost of a dislocated shoulder.

Nor was the flying area reasonably free from obstacles. A few hundred yards west of the building that housed the embryo Fokker company stood two airship sheds. The smaller and older of these was 265 ft. long, 110 ft. wide and 82 ft. high; it housed the non-rigid Parseval airships that regularly flew over Berlin by night bearing illuminated advertisements for toothpaste. The larger shed could accommodate two Zeppelins and was at that time the largest airship shed in Germany. It was four times as large as the Parseval shed, and much higher. To the underpowered aeroplanes of the time with their poor climbing ability, it was a great obstacle; moreover its bulk produced unexpected and unwelcome gusts and eddies.

Other hazards were the narrow belt of tall and scraggy pine trees that lay along the eastern side of the aerodrome between the flying ground proper and the railway line, and an adjoining pine wood in the direction of Johannisthal railway station.

The flying ground was encircled by wooden railings which served the dual purpose of protecting the public from unmanageable aeroplanes and the aeroplanes from the unmanageable public. The precaution was essential, especially when there was a crash, for the souvenir-hungry Berliners were capable of dismantling aircraft and pilot with impressive speed.

A thirteen-foot high fence enclosed the whole aerodrome with all its many sheds, grandstands, offices, refreshment kiosks and other buildings. Its primary function was to keep out gatecrashers, but it was also intended to deny non-paying visitors the pleasure of seeing the flying. It did not succeed completely in doing so, however, for large parts of it were occasionally spirited away by determined aviation enthusiasts.

Aloof, and apart from the bustle of that part of Johannisthal where Fokker worked, stood the sheds of the Flugmaschine Wright company. The Wright school was a branch of the first aeronautical enterprise in Germany, sponsored by His Majesty the Kaiser and his powerful friend Dr. Walther Rathenau (later Foreign Minister and an early victim of the Nazis). Although the Wright biplanes were obsolescent the school throve on its own exclusiveness: distinguished visitors paid their respects first to the Wright establishment; and its pupils and staff did not mix with the rest of the Johannisthal fraternity.

Not far from the aerodrome, work was proceeding on a building that was to house the new Deutsche Versuchs-Anstalt fur Luftfahrt (German Aeronautical Research Establishment), better known as the D.V.L. Its chief was Dr.-Ing. Bendemann, a good-looking, kindly man of great ability.

In charge of the aeroplane department was Dr.-Ing. Wilhelm Hoff, who had worked with Professor Dr. Hans Reissner at Aachen Technical University, and with Major Professor Dr. von Parseval in the construction of the Parseval seaplane. Hoff was himself a pilot and one of the very few people who had done full-scale research work at that early date.

The engine expert of the D.V.L. was E. Seppeler, a fair-haired man with a lively personality, a quick temper, and many good ideas. He was never without his notebook, in which he jotted down notes of events and ideas as they occurred.

Little did Fokker guess, in that December of 1911, how many bitter hours he would have to spend in this home of theorists and (as he chose to call them) “slide-rule pushers”.

During January 1912 Fokker flew a great deal, trying to earn gate money and to improve his monoplane. The Spider, still Argus powered, had been improved by the addition of the seat fairing; the original primitive radiator had been replaced by one of the block type mounted just behind the engine.

Fokker’s flying skill increased daily. His turns became neater and were executed so close to the ground that disaster seemed inevitable. His flying won him much admiration and he soon came to be regarded as one of the most daring and skilful pilots at Johannisthal.

Fokker was not the only daredevil at Johannisthal at that time. He had two rivals: the Stuttgart engineer Kurt Rosenstein, who was Rumpler’s chief pilot, and the Russian Abramowitch, chief pilot of the Wright company. Fokker never liked competition, and he heartily disliked Rosenstein and Abramowitch. The more sophisticated mid-century may find it amusing to learn that Rosenstein's stunt flying consisted of shallow dives and zooms, and flying low with both hands off the controls-the Etrich Taube’s stability permitted the latter exercise and made it impossible to do anything more spectacular than the dives and zooms. Abramowitch flew a Wright biplane-large, heavy, somewhat underpowered with 55 h.p., and fitted with a peculiar system of control. But the Wright controls were powerful and effective, and Abramowitch could throw it about low down, near the spectators, and in winds that grounded other pilots.

Photographic evidence proves that Fokker’s steep turns on the Spider, often described as “over the vertical”, never exceeded an angle of about 45 degrees; nevertheless they were steep enough to make Rosenstein give Fokker best, and his admission of defeat gave Fokker immense satisfaction.

Early in February 1912 Fokker made one of his few cross-country flights. He landed on the frozen Mueggelsee about five miles from the aerodrome; on the return journey he climbed to 7,000 ft., a good performance for that time. By that time the Spider had acquired the 60-h.p. version of the Argus engine; later, the 70-h.p. Argus was fitted.

As soon as all the formalities of the Fokker-Haller partnership were settled, two more Spiders were ordered from Goedecker. By this time a modest workshop had been established in Fokker’s sheds, and two mechanics were employed. The two new machines arrived as parts and components; on arrival they were assembled, and the flying school began to function.

In those days, opening a flying school was just as simple as that: there were no licences, no regulations, no applications, approvals nor refusals, no examinations, no inspections. Anyone could open a flying school and teach people to fly.

Fees were high, and profits could be large. The comprehensive fee was between £60 and £100 (at pre-1914 value), and the pupil had to put down the crash-indemnity deposit mentioned earlier. Most schools took good care to see that no part of this deposit was ever returned. In many cases the instructional facilities were of questionable quality: obsolete aircraft of doubtful airworthiness and inexperienced instructors were by no means uncommon, and techniques of instruction seemed to be designed to extract as much money as possible from the students.

A sorely-needed corrective was applied by the German Army’s insistence that its pupils - until 1913, exclusively commissioned officers - must receive adequate flying training from competent pilots and on safe aeroplanes. The tuition fee granted to flying schools was generous: the Prussian Army always paid the industry well. Even Fokker had to admit that.

Fokker hoped to get pupils from the Army. This meant he had to provide good training and adequate facilities. It also meant that he had to operate his school successfully for some time before he could approach the Doeberitz flying centre with a request to be considered.

His training technique was simple but effective. He gave the would-be pupil a few flights in a two-seater. At an early stage Fokker would do several steep turns and then ask the pupil to climb out of his seat and on to the wing. If the pupil showed fear or hesitation Fokker rejected him. After these familiarization flights the pupil was given a low-powered single-seat aircraft. In this he practised taxying, progressed to making short hops, thence to longer straight flights. Further dual instruction was then given, the pupil was taught to turn, and he was then on his own. Solo training was not uncommon in those days, and it produced good pilots at little cost to the school.

While two further Spiders were being assembled a group of Army officers visited Fokker’s shed and examined his monoplane. They liked its simplicity and were impressed by the fact that it was inherently stable: at that time inherent stability was regarded as a desirable characteristic of a military aeroplane, which almost universally was looked on as a reconnaissance vehicle.

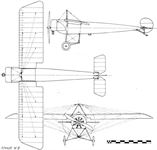

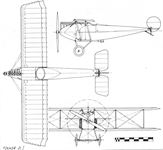

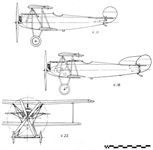

The army wanted 100-h.p. two-seaters capable of carrying enough fuel for several hours’ flying. The seats had to have adequate protection against wind and weather, and - magnificent requirement - there had to be accommodation for an officer’s hat. In view of the Army’s demands, Fokker installed a 100-h.p. Argus in one of the next Spiders and added a shallow fairing underneath the seat bearers. The structure was not strengthened to take the more powerful engine, but the span was increased slightly and a large supplementary fuel tank was fitted. The aircraft was known as the type B-1912 and was successful. It could lift a greater load, had a better rate of climb, and was appreciably faster than its predecessors.

It seems probable that Fokker engaged a design draughtsman to deal with these modifications, for it was at about this time a man named Palm became associated with Fokker. Palm remains one of the unknown men of aviation: the annals of the industry contain no mention of his name; where he came from, where he went to, his Christian name - all are unknown. Yet exist he undoubtedly did: his activities were well-known among Fokker employees, with whom he appears to have been popular. He was probably a draughtsman with a flair for aircraft design. Whatever or whoever he was, he was an indispensable member of Fokker’s organization until their ways parted, late in 1914.

In May 1912 the existence of the newly-formed Fokker Aeroplanbau G.m.b.H, seemed to be placed in jeopardy by an official warning against the formation of new aircraft firms. The Prussian War Ministry pointed out that the money devoted to military flying was insufficient to keep the existing firms going.

Fokker was already working hard to impress the military visitors who dropped in at his shed with increasing frequency. On May 14, 1912, when the Bavarian prince-regent was a spectator, he flew the 100-h.p. monoplane with three passengers and 265 lb. deadweight aboard, a total of 880 lb. But this impressive performance was to have tragic consequences: Fokker had flown with this overload in severely gusty weather, and the structure of the Spider had been strained. Ten days later, again in gusty weather, Fokker was climbing to 2,000 ft. with Leutnant von Schlichting as a passenger, when a lift wire snapped. Deprived of its bracing, the front spar tube bowed upwards. Fokker throttled back and glided down carefully; von Schlichting tried gallantly to comply with Fokker’s request to climb out on to the good wing; but near the ground the wing failed and von Schlichting was killed in the crash.

Fokker was shaken but uninjured. He fainted, and on coming round bewailed his personal misfortune without saying a word about von Schlichting.

This accident made Fokker realize that his Spider would have to be improved before it could be acceptable to the military authorities. As an immediate consequence, the wire bracing of all Spiders was replaced by steel cables.