Книги

Putnam

H.King

Sopwith Aircraft 1912-1920

159

H.King - Sopwith Aircraft 1912-1920 /Putnam/

The 'Sopwith Mouse'

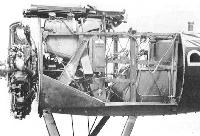

The above name was conferred by John ('Jack' later Sir John) Alcock himself upon the single-seat 'fighting scout' built at his instigation in mid-1917. Alcock had flown the Triplane and the Camel, and in his own little two-bay machine used major Sopwith components. The front fuselage and bottom wings, for instance, were adapted from the Triplane, while the top wings were in essence those of the Pup (though with longer ailerons, and these on the top wings only the bottom ones, of course, being much smaller). From the Camel came the horizontal tail-surfaces.

Alcock's delightful little creation had a 110 hp Clerget engine. Apparently it performed well, and was flown at Mudros after Alcock himself had been taken prisoner, the recognised designations, apart from 'Sopwith Mouse', being 'Alcock Scout’ or A.I.

Later (June 1919) Capt John Alcock and Lieut Arthur Whitten Brown, in a Vickers Vimy, made the first nonstop air crossing of the Atlantic. Earlier before the 1914 war Alcock had helped in developing the 150 hp Sunbeam engine, using a Farman pusher biplane, and thus presaging the installation in the Robey-built Sopwith Gun Bus. He had, in fact, been engaged by Louis Coatalen, the Sunbeam engine-designer himself.

The above name was conferred by John ('Jack' later Sir John) Alcock himself upon the single-seat 'fighting scout' built at his instigation in mid-1917. Alcock had flown the Triplane and the Camel, and in his own little two-bay machine used major Sopwith components. The front fuselage and bottom wings, for instance, were adapted from the Triplane, while the top wings were in essence those of the Pup (though with longer ailerons, and these on the top wings only the bottom ones, of course, being much smaller). From the Camel came the horizontal tail-surfaces.

Alcock's delightful little creation had a 110 hp Clerget engine. Apparently it performed well, and was flown at Mudros after Alcock himself had been taken prisoner, the recognised designations, apart from 'Sopwith Mouse', being 'Alcock Scout’ or A.I.

Later (June 1919) Capt John Alcock and Lieut Arthur Whitten Brown, in a Vickers Vimy, made the first nonstop air crossing of the Atlantic. Earlier before the 1914 war Alcock had helped in developing the 150 hp Sunbeam engine, using a Farman pusher biplane, and thus presaging the installation in the Robey-built Sopwith Gun Bus. He had, in fact, been engaged by Louis Coatalen, the Sunbeam engine-designer himself.

The award to Beardmore of the first large Pup contract for the Admiralty and the special armament provisions connected with this early association having been recorded, it remains to note that the Sopwith Pup aeroplanes ordered as such from William Beardmore & Co Ltd., Dalmuir, Dunbartonshire, Scotland, were Nos. 9901-9950 and Nos. N6430-N6459. From these aeroplanes 9950 was selected for a metamorphosis - a transformation, at least, which represents one of the most imaginative (if one of the less successful) Naval-air undertakings on the British technical record, spattered though this record is with 'make-dos', ‘mods' and 'variants'.

Stowage-space for Pups in the smaller classes of vessel involved in Naval operations generally and anti-Zeppelin work in particular being clearly at a premium, Beardmore undertook a complete redesign of the Pup accordingly. Not only were the wings (now without stagger, and with less dihedral) adapted to be folded 'Folding Pup' being a popular name for the aircraft but the landing gear likewise was largely 'retractable' into the fuselage. Later the gear was fixed, but could be jettisoned for emergency alighting at sea. Flotation gear, jury struts and wingtip skids were added in the early stages, the control system was redesigned and the fuselage slightly lengthened all these features being connoted by the new designation W.B.III. Though some of the novelties were abandoned or mitigated, one hundred W.B.IIIs were ordered; and though not all reached Service units, at one time the carrier Furious had fourteen of her own.

Stowage-space for Pups in the smaller classes of vessel involved in Naval operations generally and anti-Zeppelin work in particular being clearly at a premium, Beardmore undertook a complete redesign of the Pup accordingly. Not only were the wings (now without stagger, and with less dihedral) adapted to be folded 'Folding Pup' being a popular name for the aircraft but the landing gear likewise was largely 'retractable' into the fuselage. Later the gear was fixed, but could be jettisoned for emergency alighting at sea. Flotation gear, jury struts and wingtip skids were added in the early stages, the control system was redesigned and the fuselage slightly lengthened all these features being connoted by the new designation W.B.III. Though some of the novelties were abandoned or mitigated, one hundred W.B.IIIs were ordered; and though not all reached Service units, at one time the carrier Furious had fourteen of her own.

From steam-cooling, direct fuel-injection and supercharging we must now pursue our essentially chronological narration; and in a technical context this is conveniently achieved by recalling that, in the present writer's earlier Putnam volume Armament of British Aircraft 1909-1939 it was shown that the Coventry Ordnance Works Ltd was best-known in the development of military aeronautics for its 37 mm guns. Yet this same company had an even earlier association with the design and construction of airframes - an association which had its beginnings in 1911, when the 'C.O.W.' absorbed the Warwick Wright concern, acquiring also the services of Howard T. Wright and W.O. Manning. The talents of these two men Manning in particular were evident in two biplanes that were built (under the Battersea railway-arches) for the Military Trials of August 1912; and in this Sopwith story these aeroplanes have a special place because T.O.M. Sopwith was the test-pilot for them both.

Though entered in the Military Trials as No.10, the first of the pair was otherwise known as the Wombus, the first three letters connoting Manning's involvement. This involvement was, in fact, more than a purely technical one, for it was Manning who occupied one of the side-by-side seats when Sopwith made the first ground tests and short flights; but the technical feature calling for special attention here (and certainly for study on Sopwith's part) was the 14-cylinder 100 hp Gnome rotary engine which - after steam-cooling and direct fuel-injection - afforded him experience with a geared powerplant. True, the Gnome itself lacked any built-in gearing; but a 2:1 reduction ratio was afforded by a chain drive. The high thrust line thus resulting allowed a propeller diameter of no less than 11 ft 6 in - a figure appreciably greater than the 10-ft diameter that characterised the Sopwith B.1 bomber of 1917. On one occasion the big chain-driven propeller of 1912 enabled Sopwith to carry not one, but two passengers though these had to sit on the bottom wing.

Sopwith's second C.O.W. responsibility was the testing and demonstration of another biplane - No.11 which had tandem seating and a Chenu water-cooled engine. There were frequent troubles with this aeroplane, as with its predecessor, and during August 1912 Sopwith set out for America on a second visit, to race not aeroplanes but motor-boats. He returned triumphantly in September.

Though entered in the Military Trials as No.10, the first of the pair was otherwise known as the Wombus, the first three letters connoting Manning's involvement. This involvement was, in fact, more than a purely technical one, for it was Manning who occupied one of the side-by-side seats when Sopwith made the first ground tests and short flights; but the technical feature calling for special attention here (and certainly for study on Sopwith's part) was the 14-cylinder 100 hp Gnome rotary engine which - after steam-cooling and direct fuel-injection - afforded him experience with a geared powerplant. True, the Gnome itself lacked any built-in gearing; but a 2:1 reduction ratio was afforded by a chain drive. The high thrust line thus resulting allowed a propeller diameter of no less than 11 ft 6 in - a figure appreciably greater than the 10-ft diameter that characterised the Sopwith B.1 bomber of 1917. On one occasion the big chain-driven propeller of 1912 enabled Sopwith to carry not one, but two passengers though these had to sit on the bottom wing.

Sopwith's second C.O.W. responsibility was the testing and demonstration of another biplane - No.11 which had tandem seating and a Chenu water-cooled engine. There were frequent troubles with this aeroplane, as with its predecessor, and during August 1912 Sopwith set out for America on a second visit, to race not aeroplanes but motor-boats. He returned triumphantly in September.

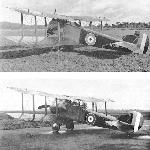

For the Military Trials of 1912 Tom Sopwith acted as test pilot for the Coventry Ordnance Works respecting No.10 (the Wombus) shown in these two views, and No.11, later depicted. Note the names on the hangars in the lower of this pair of pictures, showing No.10 in rebuilt form.

The second of the two C.O.W. Military Trials biplanes which had Sopwith associations No.11, with Chenu engine and distinctive tail.

In a purely technical sense Fairey's effort was altogether more ambitious, and although quite properly known as the Fairey Hamble Baby - being virtually a new type, and thus more justly renamed than was the ‘Blackburn Baby' - must have a brief note in this Sopwith book (and not merely because Tom Sopwith knew Hamble well, and was an ardent yachtsman, as was Dick Fairey).

The salient novelty in the Hamble Baby (50 built) was the use of the Fairey Patent Camber Gear first incorporated on the converted Sopwith Baby No.8134 - and production machines were further distinguished by newly designed floats and a characteristic square-cut Fairey tail, this last feature contrasting strongly with the new, rounded, wingtips. Thus was this Sopwith derivative a true forebear of the Fairey Flycatcher, already named in this chapter.

Parnall-built Hamble Babies and their skid-equipped landplane derivatives the Hamble Baby Converts retained the Sopwith-style tail.

The salient novelty in the Hamble Baby (50 built) was the use of the Fairey Patent Camber Gear first incorporated on the converted Sopwith Baby No.8134 - and production machines were further distinguished by newly designed floats and a characteristic square-cut Fairey tail, this last feature contrasting strongly with the new, rounded, wingtips. Thus was this Sopwith derivative a true forebear of the Fairey Flycatcher, already named in this chapter.

Parnall-built Hamble Babies and their skid-equipped landplane derivatives the Hamble Baby Converts retained the Sopwith-style tail.

Fairey Hamble Baby, with its distinctive tin and rudder and camber-changing flaps clearly in evidence

The Parnall-built Hamble Baby retained Sopwith-designed fin and rudder and floats, but had Fairey-designed wings with camber-changing flaps.

Far more than mere 'dignity and impudence' poses, these picture shows N7120 with standard armament, and a Handley Page V/1500 for company and scale.

The aeroplane which first transmitted the 'aviation bug' (as the recipient himself once described the affliction) to Tom Sopwith was a Bleriot monoplane belonging to the American John B. Moisant, one of whose distinction was that of having known his mechanic, and also his kitten Mademoiselle Paree, from Paris to London in under three weeks. The circumstances of this bug-transmission to Sopwith have already been related, and the occurrence was an indication of just how international the sport and business of flying was becoming; so much so, in fact, that during the following year (1911) Sopwith himself was showing-off his own Bleriot - in America'

Yet this Bleriot of Sopwith's was not the first monoplane he had owned; indeed, his very earliest heavier-than-air craft (apart from his skimming boats) was a monoplane of British design and construction. This machine was a product of Howard T. Wright, an Englishman who had assisted the American-born Hiram Maxim in various experiments and enterprises-notably respecting what Maxim called his 'show apparatus', or 'Captive Flying Machines'. Jointly with his brother Warwick Wright. Howard T. Wright had started a coach-building and aircraft business in 1907, under a railway arch at Battersea.

In the autumn of 1910 Sopwith bought a Howard Wright Monoplane (a development of the same designer's 'Avis' series of 1909-10) on which he taught himself to taxi at Brooklands, new on 22 October - for something like 300 yards, stalled by reason of inexperience, and crashed. This Sopwith-owned-and-flown Howard Wright Monoplane had a 40 hp E.N.V. engine (these initials signifying that this British powerplant had its cylinders arranged 'en V') and a four-wheel landing gear, with a skid between each pair of wheels. Above the fuselage were the petrol tank and a kingpost; below it was the radiator. The 'tailskid' was immense and, as the photograph on the previous page proclaims, had only a remote association with the tail.

Early in November, 1910 Sopwith was continuing to put in time on this aircraft (now repaired) with vastly greater success, until the engine burst a cylinder-head; but, even so, he soon had the monoplane airborne once again, and was clearly making progress as a serious-minded aviator.

One later reference to the Howard Wright Monoplane will be made in the context of an A.B.C. engine; but Sopwith's next aeroplane was a biplane - another product of Howard T. Wright - and it was on this sturdy machine, in which he incorporated some of his own modifications, that he really made his name as an airman. As the matter was put in a report of a lecture by Sir Thomas during 1960 (in the lecture theatre of the Institution of Mechanical Engineers - though his audience was dominantly of the RAeS persuasion): 'Crashing the Avis [sic] and buying the biplane was expensive, so he decided to try and get money back by going for the Baron de Forest ?4,000 prize for the longest flight from England to the Continent.'

The first aeroplane to be owned-and-flown-by T.O.M. Sopwith was this 1910 Howard Wright Monoplane. (Sopwith caption: 'S.355 - Howard Wright Monoplane 40 hp E.N.V. Mr. Sopwith pilot.'). This monoplane was still flying in 1912, with a special A.B.C. engine.

One later reference to the Howard Wright Monoplane will be made in the context of an A.B.C. engine; but Sopwith's next aeroplane was a biplane - another product of Howard T. Wright - and it was on this sturdy machine, in which he incorporated some of his own modifications, that he really made his name as an airman. As the matter was put in a report of a lecture by Sir Thomas during 1960 (in the lecture theatre of the Institution of Mechanical Engineers - though his audience was dominantly of the RAeS persuasion): 'Crashing the Avis [sic] and buying the biplane was expensive, so he decided to try and get money back by going for the Baron de Forest ?4,000 prize for the longest flight from England to the Continent.'

The biplane concerned was built in 1910 and was a typical Farman-type pusher 'box-kite' of its period. with two interconnected elevators - one forward, one aft - the latter on the boom-borne monoplane tail. Four ailerons gave lateral control, and the engine was a more powerful (60 hp) E.N.V., of the F series, instead of the original 50 hp Gnome. On 21 November, 1910 (according to Sopwith's own teslimony), he spent the morning 'rolling', or taxying, this biplane, and in the afternoon made a few circuits. These led to his qualification for the Aero Club's Aviator's Certificate No.31 on the same day; and on this day also he took up his first passenger - identified by him merely as 'some trusting person '.

To mix our metaphors with the bug that had entered Sopwith's bloodstream, he now had the bit between his teeth; he was flat-out for flying, and could even contemplate beating the great Samuel Franklin Cody at his own game. 'I seized every opportunity to get into the air', he once recalled, 'and by the time I had ten hours' flying behind me I began to feel that I was a really experienced pilot. Col. S. F. Cody had just set up British distance and duration records of 94 1/2 mile in 2 hours 24 minutes, and 1 thought that something should be done about it and made all preparation (which were not many!). On the first attempt I was fortunate enough to cover a distance of 107 miles in 3 hours and 12 minute .'

For the sake of historical precision, the 'preparations' (in the way of a good breakfast and extra clothes) appear to have been largely due not to Fred Sigrist or any other of Tom's male counsellors and helpers, but to his sister May, who was not merely proud of her brother, but solicitous for his welfare, and useful in such matters as lap-counting and timekeeping.

This is how Flight recorded the feat at the time (issue of 3 December, 1910): ' To Mr. Sopwith, the aviator, and to Messrs. Howard Wright, the builders, we have to extend our hearty congratulations on having put up on Saturday last a new all-British distance record of 107 miles, and at the same time established a British duration record of 3 hrs. 12 mins. for any type of machine, British or foreign, flown in this country.

"Mr. Sopwith has also by the same flight achieved the best performance to date for the British Empire Michelin Cup. The Howard Wright machine on which these records were made is a biplane fitted with a 60-h.p. E.N.V. engine and Spiral tube radiator. It has a Farman type wheel-base [sic], monoplane tail and elevator with a central rudder above and below the tail plane. Mr. Sopwith first flew a Howard Wright monoplane this was only some few weeks ago and we drew attention in a previous issue to the rapid progress he made. He has only had delivery of the biplane a few days, which speaks well for the ease of control of this make of machine.'

Later in its career Sopwith's Howard Wright 1910 biplane was modified to have upper wing extensions, with extra bracing-wires; but the most interesting alterations were those associated with the flight that gained for Sopwith the Baron de Forest prize a performance that greatly enhanced not only the pilot's personal reputation but the prestige of the nation which later types of aeroplane, then bearing Sopwith's own name, were to defend and even symbolize. Chief among the alterations mentioned were increased petrol tankage, and a windshield (more explicitly a foot-scuttle) which, had it been given three-quarters of a chance, would have grown into a nacelle.

The radiators for the E.N.V. engine were mounted fore-and-aft, one on each side between the wings; and as this flight for the de Forest prize was to be an all-British affair a special word must be said for the powerplant. The 'en V’ connotation already mentioned was no mere whim; for contrary to the supposition that all the best aero-engines of those times were French (and. indeed, the E.N.V. concern operated a factory in the Paris suburbs) this engine had very close British associations, though it was used successfully by several eminent French pilots. Thus, when describing a new (100 hp) model early in 1914 Flight saw fit to remind its readers: The E.N.V. Motor is by no means new to the aeronautical world, for as far back as 1908-09 Mr. Moore-Brabazon had one fitted upon his machine, but the E.N.V. Motor Co., of Willesden, N.W.. has now been formed to design and manufacture an entirely new engine...' (The 60 hp E.N.V. presented long ago to the Science Museum was catalogued as having been made in 1910 by the E.N.V. Motor Syndicate Ltd. of London).

True. S. F. Cody once declared publicly: 'I have had a little experience of foreign engines the E.N.V., for instance. I had an E.N.V. engine with which I failed to fly in Manchester. I tried to get the makers to put it right but they did not ... we entered into a law suit. I sent the engine on to them and they kept it for four months. They did get it right themselves after breaking a crank shaft and one or two cylinders ... I then took up the Green.'

Sopwith, too, 'took up the Green', as we shall see; but respecting the sometimes obscure ‘origins' of aero-engines generally it could hardly be improper here to observe that the Rolls-Royce range from Eagle to Merlin had its 'origins' in a German Mercedes racing car stored, during 1914, in a Shaftesbury Avenue showroom, and that the 'origins' of the Rolls-Royce Bristol Siddeley Pegasus vectored-thrust turbofan are traceable to a 1956 submission by the Frenchman Marcel Wibault.

A general account of Sopwith's 'de Forest prize' adventure having already been rendered in the opening chapter it remains here to note that, in the development and application of aircraft of those times, second only to the powerplant were the instruments installed; and thus it came to be recorded in those times: 'Mr. Sopwith had fitted a compass to his machine, but as this persisted in sticking at N.W., in whichever direction the machine was steered. Mr. Sopwith backed his own judgment in preference and steered by the sun."

To continue our perusal of the various aeroplanes that helped Tom Sopwith, in one way or another, to 'originate' his own (and never forgetting the men whose help was ready to his hand nor the powerplants that made their efforts possible) we now transfer attention to the most international of all his early aeronautical ventures - that is, to his American tour of 1911, made within a few months of his having flown the Howard Wright biplane to Windsor for the King's inspection. By the time of this Royal occasion 1 February, 1911 the biplane had acquired not only the wing-extensions already mentioned, but also a new fuel system, of Fred Sigrist's creation.

Although the Howard Wright did not actually accompany its owner to the United States, it was sent on after him; and having been assembled, and thereafter somewhat disarticulated by gale-damage, took part in competitions and displays. Sad to relate further, some time after a package that had been intended by young Sopwith for the deck of the While Star liner Olympic had missed its mark and fallen into the water, the Howard Wright itself came in for a similar ducking.

The biplane concerned was built in 1910 and was a typical Farman-type pusher 'box-kite' of its period. with two interconnected elevators - one forward, one aft - the latter on the boom-borne monoplane tail. Four ailerons gave lateral control, and the engine was a more powerful (60 hp) E.N.V., of the F series, instead of the original 50 hp Gnome. On 21 November, 1910 (according to Sopwith's own teslimony), he spent the morning 'rolling', or taxying, this biplane, and in the afternoon made a few circuits. These led to his qualification for the Aero Club's Aviator's Certificate No.31 on the same day; and on this day also he took up his first passenger - identified by him merely as 'some trusting person '.

To mix our metaphors with the bug that had entered Sopwith's bloodstream, he now had the bit between his teeth; he was flat-out for flying, and could even contemplate beating the great Samuel Franklin Cody at his own game. 'I seized every opportunity to get into the air', he once recalled, 'and by the time I had ten hours' flying behind me I began to feel that I was a really experienced pilot. Col. S. F. Cody had just set up British distance and duration records of 94 1/2 mile in 2 hours 24 minutes, and 1 thought that something should be done about it and made all preparation (which were not many!). On the first attempt I was fortunate enough to cover a distance of 107 miles in 3 hours and 12 minute .'

For the sake of historical precision, the 'preparations' (in the way of a good breakfast and extra clothes) appear to have been largely due not to Fred Sigrist or any other of Tom's male counsellors and helpers, but to his sister May, who was not merely proud of her brother, but solicitous for his welfare, and useful in such matters as lap-counting and timekeeping.

This is how Flight recorded the feat at the time (issue of 3 December, 1910): ' To Mr. Sopwith, the aviator, and to Messrs. Howard Wright, the builders, we have to extend our hearty congratulations on having put up on Saturday last a new all-British distance record of 107 miles, and at the same time established a British duration record of 3 hrs. 12 mins. for any type of machine, British or foreign, flown in this country.

"Mr. Sopwith has also by the same flight achieved the best performance to date for the British Empire Michelin Cup. The Howard Wright machine on which these records were made is a biplane fitted with a 60-h.p. E.N.V. engine and Spiral tube radiator. It has a Farman type wheel-base [sic], monoplane tail and elevator with a central rudder above and below the tail plane. Mr. Sopwith first flew a Howard Wright monoplane this was only some few weeks ago and we drew attention in a previous issue to the rapid progress he made. He has only had delivery of the biplane a few days, which speaks well for the ease of control of this make of machine.'

Later in its career Sopwith's Howard Wright 1910 biplane was modified to have upper wing extensions, with extra bracing-wires; but the most interesting alterations were those associated with the flight that gained for Sopwith the Baron de Forest prize a performance that greatly enhanced not only the pilot's personal reputation but the prestige of the nation which later types of aeroplane, then bearing Sopwith's own name, were to defend and even symbolize. Chief among the alterations mentioned were increased petrol tankage, and a windshield (more explicitly a foot-scuttle) which, had it been given three-quarters of a chance, would have grown into a nacelle.

The radiators for the E.N.V. engine were mounted fore-and-aft, one on each side between the wings; and as this flight for the de Forest prize was to be an all-British affair a special word must be said for the powerplant. The 'en V’ connotation already mentioned was no mere whim; for contrary to the supposition that all the best aero-engines of those times were French (and. indeed, the E.N.V. concern operated a factory in the Paris suburbs) this engine had very close British associations, though it was used successfully by several eminent French pilots. Thus, when describing a new (100 hp) model early in 1914 Flight saw fit to remind its readers: The E.N.V. Motor is by no means new to the aeronautical world, for as far back as 1908-09 Mr. Moore-Brabazon had one fitted upon his machine, but the E.N.V. Motor Co., of Willesden, N.W.. has now been formed to design and manufacture an entirely new engine...' (The 60 hp E.N.V. presented long ago to the Science Museum was catalogued as having been made in 1910 by the E.N.V. Motor Syndicate Ltd. of London).

True. S. F. Cody once declared publicly: 'I have had a little experience of foreign engines the E.N.V., for instance. I had an E.N.V. engine with which I failed to fly in Manchester. I tried to get the makers to put it right but they did not ... we entered into a law suit. I sent the engine on to them and they kept it for four months. They did get it right themselves after breaking a crank shaft and one or two cylinders ... I then took up the Green.'

Sopwith, too, 'took up the Green', as we shall see; but respecting the sometimes obscure ‘origins' of aero-engines generally it could hardly be improper here to observe that the Rolls-Royce range from Eagle to Merlin had its 'origins' in a German Mercedes racing car stored, during 1914, in a Shaftesbury Avenue showroom, and that the 'origins' of the Rolls-Royce Bristol Siddeley Pegasus vectored-thrust turbofan are traceable to a 1956 submission by the Frenchman Marcel Wibault.

A general account of Sopwith's 'de Forest prize' adventure having already been rendered in the opening chapter it remains here to note that, in the development and application of aircraft of those times, second only to the powerplant were the instruments installed; and thus it came to be recorded in those times: 'Mr. Sopwith had fitted a compass to his machine, but as this persisted in sticking at N.W., in whichever direction the machine was steered. Mr. Sopwith backed his own judgment in preference and steered by the sun."

To continue our perusal of the various aeroplanes that helped Tom Sopwith, in one way or another, to 'originate' his own (and never forgetting the men whose help was ready to his hand nor the powerplants that made their efforts possible) we now transfer attention to the most international of all his early aeronautical ventures - that is, to his American tour of 1911, made within a few months of his having flown the Howard Wright biplane to Windsor for the King's inspection. By the time of this Royal occasion 1 February, 1911 the biplane had acquired not only the wing-extensions already mentioned, but also a new fuel system, of Fred Sigrist's creation.

Although the Howard Wright did not actually accompany its owner to the United States, it was sent on after him; and having been assembled, and thereafter somewhat disarticulated by gale-damage, took part in competitions and displays. Sad to relate further, some time after a package that had been intended by young Sopwith for the deck of the While Star liner Olympic had missed its mark and fallen into the water, the Howard Wright itself came in for a similar ducking.

T. O. M. Sopwith seated in the 60 hp Howard Wright biplane which was just beaten by the Cody biplane in the 1910 Michelin Cup No.1 event, wherein he began to feel that he was 'a really experienced pilot.'

The 'Sopwith Kitten'

Although Commander Harry Busteed was at one time in charge of the RNAS Experimental Flight at Eastchurch, and - in the course of his work - also had a close relationship with the Sopwith company (being, in any case, one of the three original 'Aussie Harrys' together with Hawker and Kauper) there is scant reason to suppose that the name 'Sopwith Kitten' was justly applicable to the ship's ultra-light armed scout which was otherwise called the Port Victoria P.V.8 Eastchurch Kitten. The ascription might, nevertheless, have been fostered by structural features, the most obvious being the plank-type interplane struts. (The true designer was, it seems, Capt Gilbert Henry Millar, who, after a period as a prisoner of war, escaped. Millar had yachting experience, had joined the RNVR and was transferred successively to the RNAS and the RAF. Although he became a pilot himself, he served also as an observer with the Fleet).

The photograph herewith of the charming little aeroplane just mentioned is reproduced for two reasons - apart from the discredited name 'Sopwith Kitten' and from the fact that this particular picture appears not to have been previously published: (1) The photograph was given to the present writer by Sir Frank Spriggs, who was with Sopwith from 1913 to 1920, and later became managing director of Hawker Siddeley. Though received together with views of indubitable Sopwith types, this Kitten picture had no accompanying text. (2) This same photograph shows a tailplane of seemingly unfamiliar form, though one of another shape was apparently fitted after the aircraft had been initially flown with no horizontal fixed tail-surfaces whatever.

Yet another derivative of the Sopwith Baby was the one-off Port Victoria P.V.1, with wings of higher aspect ratio, heavily cambered and heavily staggered.

Although Commander Harry Busteed was at one time in charge of the RNAS Experimental Flight at Eastchurch, and - in the course of his work - also had a close relationship with the Sopwith company (being, in any case, one of the three original 'Aussie Harrys' together with Hawker and Kauper) there is scant reason to suppose that the name 'Sopwith Kitten' was justly applicable to the ship's ultra-light armed scout which was otherwise called the Port Victoria P.V.8 Eastchurch Kitten. The ascription might, nevertheless, have been fostered by structural features, the most obvious being the plank-type interplane struts. (The true designer was, it seems, Capt Gilbert Henry Millar, who, after a period as a prisoner of war, escaped. Millar had yachting experience, had joined the RNVR and was transferred successively to the RNAS and the RAF. Although he became a pilot himself, he served also as an observer with the Fleet).

The photograph herewith of the charming little aeroplane just mentioned is reproduced for two reasons - apart from the discredited name 'Sopwith Kitten' and from the fact that this particular picture appears not to have been previously published: (1) The photograph was given to the present writer by Sir Frank Spriggs, who was with Sopwith from 1913 to 1920, and later became managing director of Hawker Siddeley. Though received together with views of indubitable Sopwith types, this Kitten picture had no accompanying text. (2) This same photograph shows a tailplane of seemingly unfamiliar form, though one of another shape was apparently fitted after the aircraft had been initially flown with no horizontal fixed tail-surfaces whatever.

Yet another derivative of the Sopwith Baby was the one-off Port Victoria P.V.1, with wings of higher aspect ratio, heavily cambered and heavily staggered.

B.1 and Derivatives

Finally, a brief note on the closely-related two-seat reconnaissance aircraft, the P.V. N50 Grain Griffin, the development of which followed the delivery to Port Victoria of the Sopwith Bomber which had been flown to Dunkirk for assessment in its designated role. After close deliberations in October 1917, folding wings and wireless were installed in a modified example, numbered N50, and the addition of a hydrovane landing gear and a pillar-mounted swivelling bracket for a free Lewis gun behind the rear cockpit further proclaimed the new-found application. Drastic redesign of the whole aircraft was quickly found to be necessary, and the seven aircraft formally named Grain Griffin (N100-N106) were built accordingly. These were somewhat larger aeroplanes, powered by the Sunbeam Arab or Bentley B.R.2 engine; and though they still owed much to the basic Sopwith design, they were not true inmates of the 'zoo'. Certainly they would have done it little credit respecting handling, though during 1919 Griffins, together with Camels, 1 1/2 Strutters and Short 184s were aboard HMS Vindictive (formerly Cavendish) in the Baltic on anti-Bolshevik operations.

Finally, a brief note on the closely-related two-seat reconnaissance aircraft, the P.V. N50 Grain Griffin, the development of which followed the delivery to Port Victoria of the Sopwith Bomber which had been flown to Dunkirk for assessment in its designated role. After close deliberations in October 1917, folding wings and wireless were installed in a modified example, numbered N50, and the addition of a hydrovane landing gear and a pillar-mounted swivelling bracket for a free Lewis gun behind the rear cockpit further proclaimed the new-found application. Drastic redesign of the whole aircraft was quickly found to be necessary, and the seven aircraft formally named Grain Griffin (N100-N106) were built accordingly. These were somewhat larger aeroplanes, powered by the Sunbeam Arab or Bentley B.R.2 engine; and though they still owed much to the basic Sopwith design, they were not true inmates of the 'zoo'. Certainly they would have done it little credit respecting handling, though during 1919 Griffins, together with Camels, 1 1/2 Strutters and Short 184s were aboard HMS Vindictive (formerly Cavendish) in the Baltic on anti-Bolshevik operations.

Commander Samson's Eastchurch Squadron of the RNAS at Dunkirk in 1914. The aeroplanes are (left to right): Henry Farman F.20. Samson's B.E.2a (No.50). Sopwith Tractor Biplane and Short No.42.

Betrayed - or proclaimed by its windows, though distant in this Farman/B.E./ Short Astra-Torres gathering, is a Sopwith tractor biplane of the 'Three-seater' family.

Betrayed - or proclaimed by its windows, though distant in this Farman/B.E./ Short Astra-Torres gathering, is a Sopwith tractor biplane of the 'Three-seater' family.

Commander Samson's Eastchurch Squadron of the RNAS at Dunkirk in 1914. The aeroplanes are (left to right): Henry Farman F.20. Samson's B.E.2a (No.50). Sopwith Tractor Biplane and Short No.42.

Betrayed - or proclaimed by its windows, though distant in this Farman/B.E./ Short Astra-Torres gathering, is a Sopwith tractor biplane of the 'Three-seater' family.

Betrayed - or proclaimed by its windows, though distant in this Farman/B.E./ Short Astra-Torres gathering, is a Sopwith tractor biplane of the 'Three-seater' family.

As was noted a few paragraphs earlier immediately prior to our just-concluded appraisal of the rebuilt Burgess-Wright biplane Sopwith left for some motor-boat racing in America during August 1912 and returned in the following month. Early in the previous July he was making the first flights of a yet more drastically revised machine, in the form of a tractor, though using American Wright-type wings ('Wright planes pure and simple’, as one account stated adding, to make things perfectly clear, that they were 'built roughly on the Wright model')!

For this newly created tractor the name 'Sopwith Three-Seater Tractor Biplane' was used at the time of its introduction, though the description 'Hybrid' (with or without initial capital) has now gained currency, and, apart from being descriptive, serves to differentiate it from the much-improved 'Three-Seater Tractor' shown at Olympia in 1913.

These matters being so, it will be well to consider the 1912 'hybrid' as the true precursor of the Sopwith aeroplanes that form the subject-matter of this book, and to regard it not so much as the ending of the present chapter but as the beginning of the next.

'Three-seaters' and Derivatives

The Sopwith-developed 'hybrid' tractor biplane that T. O. M. Sopwith tested in July 1912 had a wing cellule which closely resembled in plan form, section and bracing that of the Burgess-Wright pusher which he had bought in the USA during 1911, but the span was increased from 38 ft 9 in (11.9 m) to 44 ft (13.4 m). This, at least, seems to have been true of the form in which it was first publicised, though by then it had already been repaired after a crash when Gordon Bell and J. Charteris were setting out, on 12 July, 1912, to fly it down to Cowes, where Sopwith was practising in a Saunders-built craft for the motor-boat racing scheduled for his second American trip. As was so often the case, the Brooklands sewage farm had received the fragmented structure after a sideslip. ‘Reconstruction', it was reported, proceeded 'rapidly'.

In any case, the engine was a 70 hp Gnome, driving a Chauviere propeller of 9 ft 6 in (2.9 m) diameter, and the fuselage was set between the wings, in the style of the later Bristol Fighter though with a prominent chordwise 'gap-filler' fairing between it and the bottom wing. Here, it might reasonably be suggested, was C.O.W. influence discernible. At first the fuselage was left uncovered aft of the rear (pilot's) cockpit, though later it was completely fabric-covered. The two passengers sat side by side, well forward, in a separate open cockpit. Silver spruce was largely used for the wing structure, and even for the four-wheeled, twin-skid landing gear, which was subsequently exchanged for a twin-wheel type.

A very noticeable feature of this 'hybrid' was the vertically-divided rudder, of which it was observed at the time: "The rudder constitutes an important variation from Wright practice, being situated above and below the elevator, which can be given a warping angle of 6 in (150 mm) in either direction.'

When Sopwith returned from his American motor-boat races he tested the rebuilt machine, and on 8 October, 1912, flew it to Farnborough. There, with one passenger (in the form that "the military' would be likely to use it) the biplane climbed to 3.000 ft (915 m) in just under 3 min, though the maximum speed about 55 mph (88.5 km/h) was poor enough to evoke the comment from a Brooklands observer: 'The Sopwith tractor biplane made its first flight since its repair, piloted by Sopwith. The machine carried a passenger, and left the ground after a very short run, but it is certainly slow.'

Such slowness (it occurs to the present writer) may be a sensation by this time being experienced by any reader who may have had sufficient of 'antediluvian' Sopwith types and is becoming impatient to get along towards the 'real wartime Sopwiths' (as he may well regard the rightfully dominant subjects of this book). In some degree, at least, such readers may now he given satisfaction: for there existed two tractor biplanes of the general form just described. These Nos.27 and 33, with 80 hp Gnome engine - were living early in the war from Eastchurch, and are said to have been used for armament practice. In this regard, clearly, they might have made better targets than 'gun machines', by reason of their low performance. On reflection, indeed, they might have made perfect 'sitting ducks' as ground targets - easier to hit than the airborne feathered duck that the Eastchurch armament pioneer Lieut (later Air Marshal) R. H. Clark-Hall brought down to the Swale Marshes - if not to the cooking-pot - from a Short pusher some time before the war.

Further concerning the two early Naval Sopwith tractors, it seems worth recording that a demi-official drawing once existed showing just such a machine, though with top-plane extensions, revised engine installation and other alterations. This drawing may well have been a mere pastiche; but the tell-tale tail certainly obtruded.

With a tractor aeroplane that was only a little faster than one of his motor-boats and bearing in mind that the contemporary 43.000-ton Titanic was good for over 24 knots (26.5 mph = 42.6 km h) Sopwith could hardly be content: nor was the just-described crude derivation - for 'conception' or 'innovation' would be terms far too enobling - much to the liking of the tiny but talented team now assembling round him.

For this newly created tractor the name 'Sopwith Three-Seater Tractor Biplane' was used at the time of its introduction, though the description 'Hybrid' (with or without initial capital) has now gained currency, and, apart from being descriptive, serves to differentiate it from the much-improved 'Three-Seater Tractor' shown at Olympia in 1913.

These matters being so, it will be well to consider the 1912 'hybrid' as the true precursor of the Sopwith aeroplanes that form the subject-matter of this book, and to regard it not so much as the ending of the present chapter but as the beginning of the next.

'Three-seaters' and Derivatives

The Sopwith-developed 'hybrid' tractor biplane that T. O. M. Sopwith tested in July 1912 had a wing cellule which closely resembled in plan form, section and bracing that of the Burgess-Wright pusher which he had bought in the USA during 1911, but the span was increased from 38 ft 9 in (11.9 m) to 44 ft (13.4 m). This, at least, seems to have been true of the form in which it was first publicised, though by then it had already been repaired after a crash when Gordon Bell and J. Charteris were setting out, on 12 July, 1912, to fly it down to Cowes, where Sopwith was practising in a Saunders-built craft for the motor-boat racing scheduled for his second American trip. As was so often the case, the Brooklands sewage farm had received the fragmented structure after a sideslip. ‘Reconstruction', it was reported, proceeded 'rapidly'.

In any case, the engine was a 70 hp Gnome, driving a Chauviere propeller of 9 ft 6 in (2.9 m) diameter, and the fuselage was set between the wings, in the style of the later Bristol Fighter though with a prominent chordwise 'gap-filler' fairing between it and the bottom wing. Here, it might reasonably be suggested, was C.O.W. influence discernible. At first the fuselage was left uncovered aft of the rear (pilot's) cockpit, though later it was completely fabric-covered. The two passengers sat side by side, well forward, in a separate open cockpit. Silver spruce was largely used for the wing structure, and even for the four-wheeled, twin-skid landing gear, which was subsequently exchanged for a twin-wheel type.

A very noticeable feature of this 'hybrid' was the vertically-divided rudder, of which it was observed at the time: "The rudder constitutes an important variation from Wright practice, being situated above and below the elevator, which can be given a warping angle of 6 in (150 mm) in either direction.'

When Sopwith returned from his American motor-boat races he tested the rebuilt machine, and on 8 October, 1912, flew it to Farnborough. There, with one passenger (in the form that "the military' would be likely to use it) the biplane climbed to 3.000 ft (915 m) in just under 3 min, though the maximum speed about 55 mph (88.5 km/h) was poor enough to evoke the comment from a Brooklands observer: 'The Sopwith tractor biplane made its first flight since its repair, piloted by Sopwith. The machine carried a passenger, and left the ground after a very short run, but it is certainly slow.'

Such slowness (it occurs to the present writer) may be a sensation by this time being experienced by any reader who may have had sufficient of 'antediluvian' Sopwith types and is becoming impatient to get along towards the 'real wartime Sopwiths' (as he may well regard the rightfully dominant subjects of this book). In some degree, at least, such readers may now he given satisfaction: for there existed two tractor biplanes of the general form just described. These Nos.27 and 33, with 80 hp Gnome engine - were living early in the war from Eastchurch, and are said to have been used for armament practice. In this regard, clearly, they might have made better targets than 'gun machines', by reason of their low performance. On reflection, indeed, they might have made perfect 'sitting ducks' as ground targets - easier to hit than the airborne feathered duck that the Eastchurch armament pioneer Lieut (later Air Marshal) R. H. Clark-Hall brought down to the Swale Marshes - if not to the cooking-pot - from a Short pusher some time before the war.

Further concerning the two early Naval Sopwith tractors, it seems worth recording that a demi-official drawing once existed showing just such a machine, though with top-plane extensions, revised engine installation and other alterations. This drawing may well have been a mere pastiche; but the tell-tale tail certainly obtruded.

With a tractor aeroplane that was only a little faster than one of his motor-boats and bearing in mind that the contemporary 43.000-ton Titanic was good for over 24 knots (26.5 mph = 42.6 km h) Sopwith could hardly be content: nor was the just-described crude derivation - for 'conception' or 'innovation' would be terms far too enobling - much to the liking of the tiny but talented team now assembling round him.

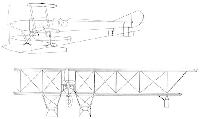

In the Sopwith 'zoo' - for many later members had menagerial names - the tractor biplane shown in these two views, with fuselage both naked and draped, was strictly a mongrel, and has, in fact, come to be known as the 'hybrid'. The rudder was distinctive, but its form was not perpetuated in later Sopwith tractors.

At this point we may reconsider the American-built Burgess-Wright biplane already briefly mentioned, for in 1912 this was quite extensively rebuilt by Sopwith - to such a degree, indeed, that the present writer was at one time led to contemplate a separate study of the machine. Such treatment was, in fact, quite understandably accorded it by Mr Peter Lewis in his Putnam book British Aircraft 1809-1914, under the heading 'Sopwith-Wright Biplane'.

Fred Sigrist, it seems, was largely, if not primarily, responsible for the reconstruction, which was undertaken in the interests of ‘school', or instructional, work, in which Sopwith became quite heavily involved at Brooklands during 1912. (To the credit of the American biplane, in its more-or-less original form, it must be recorded that among its passengers had been a Capt F. H. Sykes, later an eminent figure in the development of British military and civil aeronautics, and better known perhaps to certain readers as Sir Frederick Sykes).

One especially notable modification made to the American aeroplane was to give it side-by-side seating, in a sizable nacelle, with the pilot to starboard. In side elevation the nacelle drooped like a Concorde's nose - though permanently. Of no less interest was the fitting (after a 35 hp Green) of an A.B.C. engine instead of the original 50 hp Gnome. Together with its petrol tank, this A.B.C. engine was offset to port; it was nominally of 40 hp, though was sometimes credited with 45, and it drove two pusher propellers by means of crossed chains, housed in tubes.

Thus, by virtue of this last arrangement, Sopwith could now add contra-rotating propellers to his repertoire of exotic powerplant installations.

On the aeroplane just mentioned (which was described contemporaneously, if somewhat dubiously, as a 'Sopwith British-built biplane' or as a "Sopwith-Wright") Harry Hawker secured the 1912 British Empire Michelin Cup No.1 (and ?500) by staying airborne for 8 hr 23 min. The date of this performance, which constituted a new British record for duration, was 24 October, 1912.

That the foregoing was not Sopwith's first association with A.B.C. engines is affirmed by this report, published as early as March 1912: "The 40-50 h.p. vertical four-cylinder A.B.C. engine, which earlier in the year was put through some severe tests by its makers, has recently been put into one of the earlier Deperdussin monoplanes, and without any tuning up of the machine it flew at the first attempt, Lieutenant Porte. R.N., who piloted the machine, said that he had never flown at such a speed.

‘The same engine has now been refitted into Sopwith's Howard Wright monoplane and is provided with a new water-heated While and Poppe carburetter which has been specially tuned up by the makers, with the result that the engine is giving about twenty per cent, more power than ever.'

Thus here we find yet one more seemingly exotic powerplant - an A.B.C.

Fred Sigrist, it seems, was largely, if not primarily, responsible for the reconstruction, which was undertaken in the interests of ‘school', or instructional, work, in which Sopwith became quite heavily involved at Brooklands during 1912. (To the credit of the American biplane, in its more-or-less original form, it must be recorded that among its passengers had been a Capt F. H. Sykes, later an eminent figure in the development of British military and civil aeronautics, and better known perhaps to certain readers as Sir Frederick Sykes).

One especially notable modification made to the American aeroplane was to give it side-by-side seating, in a sizable nacelle, with the pilot to starboard. In side elevation the nacelle drooped like a Concorde's nose - though permanently. Of no less interest was the fitting (after a 35 hp Green) of an A.B.C. engine instead of the original 50 hp Gnome. Together with its petrol tank, this A.B.C. engine was offset to port; it was nominally of 40 hp, though was sometimes credited with 45, and it drove two pusher propellers by means of crossed chains, housed in tubes.

Thus, by virtue of this last arrangement, Sopwith could now add contra-rotating propellers to his repertoire of exotic powerplant installations.

On the aeroplane just mentioned (which was described contemporaneously, if somewhat dubiously, as a 'Sopwith British-built biplane' or as a "Sopwith-Wright") Harry Hawker secured the 1912 British Empire Michelin Cup No.1 (and ?500) by staying airborne for 8 hr 23 min. The date of this performance, which constituted a new British record for duration, was 24 October, 1912.

That the foregoing was not Sopwith's first association with A.B.C. engines is affirmed by this report, published as early as March 1912: "The 40-50 h.p. vertical four-cylinder A.B.C. engine, which earlier in the year was put through some severe tests by its makers, has recently been put into one of the earlier Deperdussin monoplanes, and without any tuning up of the machine it flew at the first attempt, Lieutenant Porte. R.N., who piloted the machine, said that he had never flown at such a speed.

‘The same engine has now been refitted into Sopwith's Howard Wright monoplane and is provided with a new water-heated While and Poppe carburetter which has been specially tuned up by the makers, with the result that the engine is giving about twenty per cent, more power than ever.'

Thus here we find yet one more seemingly exotic powerplant - an A.B.C.

A particularly fine view of the rebuilt Burgess-Wright (sometimes called Sopwith-Wright) on which Harry Hawker stayed airborne for 8 hr 23 min.

While in the USA during 1911 Sopwith bought a Burgess-Wright biplane which he rebuilt extensively in 1912, and which did service both as a 'school machine' and record-breaker. The close-up picture here shows the offset installation of the A.B.C. engine, while the flying study was said to show the machine at 'extreme angle".

Bat Boats

The principal authors who inspired some of Britain's aircraft pioneers - Tom Sopwith by no means least among these latter were Jules Verne, H. G. Wells and Rudyard Kipling. And here one might add that C. G. Grey, as editor of The Aeroplane continued these writers' work ('For their work continueth", as Kipling declared in Stalky & Co) if only because so many of his compositions were fanciful (or fictitious) as well as being breezy (or blustering). So greatly influenced was Grey himself by Kipling that 'R.K.' was quite often quoted as 'C.G.G.'; but indubitably it was Kipling's story With the Night Mail - published as a separate title in the USA, with special illustrations, though familiar on both sides of the Atlantic as a component of the book Actions and Reactions - which provided the name for Britain's first successful flying-boat and the title for the present chapter of this book.

The true nature of Kipling's fictitious 'Bat-Boats' is conveyed in a page from Actions and Reactions, which calls for no comment here, except to re-emphasise Tom Sopwith's love of motor-boat racing. But, just as the bibliography of Kipling's tale can prove confusing, so is it important at this early point to make it clear that there were two distinct forms of the Sopwith Bat Boat flying-boat, and that, following marine practice, these were called by Sopwith Bat Boat I and II respectively. The Navy (in the manner wherein they styled the 'rig of the day') sometimes referred to them as No.1 and No.2.

Just us the Hawker Hart and Hornet caused a buzzing at the Olympia Aero Show of 1929, so did the joint appearance of the Sopwith Three-seater and Bat Boat (retrospectively called Bat Boat I) at the corresponding show of February 1913.

As first exhibited at Olympia the Bat Boat I (for so we shall call it) was an altogether trimmer craft than its successor, which, nevertheless was a far nearer approach to the big, successful and multi-engined British flying-boats that followed it from other works.

In truth, the Bat Boat I itself was not a wholly Sopwith product, for the hull was built by Saunders of Cowes a name that was to be sustained in the RAF by the sturdy Saunders-Roe London of 1934. As Harald Penrose (a boat-builder himself, as well as a gifted author and eminent test-pilot) remarks in Vol I of his splendid Putnam trilogy British Aviation; The Pioneer Years 1903-1914:

'The sea had long been the passion of Sopwith and Sigrist, and since they had just sold their first aeroplane to the Admiralty, it was natural that they thought in terms of marine aircraft as the opening venture of the new Sopwith aeroplane company, which was rumoured to be backed by the millionaire Barnato Joel, who had married one of Sopwith's sisters. Not only had Tom Sopwith raced speed-boats, but he was a client of the redoubtable boat-builder Sammy Saunders, of the neatly trimmed white beard and powerful personality. Grandson of the founder, he had transferred the family business in 1901 from Goring-on-Thames to Cowes, establishing the "Saunders Patent Launch Building Syndicate", and registered it in 1908 as S. E. Saunders, Ltd., to exploit his patented system of Consuta laminated-strip planking cross-sewn with copper wire to give far greater strength for weight than hitherto available. In developing high-powered racing boats, the new company had experimented with many hull forms, plain and stepped, as well as a sidewall vessel some 35 ft. in length with air-lubricated bottom. Recently Curtiss in the United States had developed his simple single-pontoon biplane into a more capacious hull in which pilot and passenger were seated. The idea attracted Tommy Sopwith, and he discussed it with Sammy Saunders' hull designer Sydney E. Porter, who had started with him in 1903. Already he had evolved for Sopwith the very successful Maple Leaf stepped hydroplane, and he saw no difficulty in designing a similar Consuta-sewn single-stepped cedar hull. 21 ft. long, with V entry, and side-by-side seating immediately above the step.'

Here, then, we have the essence of the Sopwith Bat Boats' history, related with multi-professional authority; and it remains to add the aeronautical appurtenances.

Mounted amidships on two pairs of struts, somewhat above the hull (which, in its bare form, weighed a mere 180 lb) was a two-bay, equal-span unstaggered wing cellule; and set high between the wings was a 90 hp Austro-Daimler six-cylinder inline water-cooled engine driving a pusher propeller. The hull being short - only 21 ft (6.4 m) overall - the tailplane and elevator, together with a deep single rudder, were carried clear of the water on converging tail-booms; but in addition to the rear tailplane and elevator already mentioned there was an auxiliary elevator, strut-mounted over the bow of the hull. Wing-warping was used for lateral control.

'The wing-tip floats' (declared one enthusiast) 'are constructed of copper plate, corrugated in order to give additional strength. A really most original point in their construction is the fact that each is equipped with a bicycle-valve in order that, should they become dented in any way, they can be blown back to their original shape by means of the ordinary pump! This is really worthy of a patent.'

For use by the Naval Wing of the RFC the Admiralty bought a specimen of the type described and used it for experimental work at Calshot, early modifications including the removal of the bow elevator. (No self-respecting sailor would put to sea with such an appendage just where the figurehead should be -or so it was said), and hardly less noticeable was the replacement of the original deep, unbalanced rudder by a larger surface, horn-balanced at each end. Later this gave place to a rudder of roughly oval form.

To render the Bat Boat 'all-British', and thus allow it to compete for the Mortimer Singer ?500 prize for the first such aircraft of amphibious form, the engine-bearers were modified to accept a 100 hp Green water-cooled unit and - of greater technical significance - two wheels were fitted, one on each side of the hull and capable of being raised clear of the water as required. On land, the hull sat tail-down. To absorb the extra power of the Green engine, the propeller diameter was increased to 11 ft (3.3 m) and twin rudders, below a new one-piece elevator, were associated with a modified tail-boom assembly. Instead of the earlier bracing cables, a pair of sturdy struts ran down to the hull from the new engine-mounting, and a further improvement was the fairing-in of the bottom-wing/hull junction round the supporting struts. The wing-warping system now gave place to ailerons, but the original pattern of wing-tip stabilising floats (cylindrical, with pointed ends) remained unchanged.

The demands imposed by the Mortimer Singer prize performance were very stringent and somewhat bewildering; but on 8 July, 1913, carrying Lieut Spenser Grey as official observer, Harry Hawker completed the specified tests in 3 hr 25 min, thus winning the ?500 prize and an important place in British aircraft history. In securing these distinctions Spenser Grey did not lend a hand, as might have been expected of a sailor (even though an official observer) but a foot to kick the wheels down for each landing at Hamble, the reason being that after take-offs from the Solent they had failed to drop into position when released.

Thus, although it bore a general resemblance to the slightly larger Supermarine Walrus of the Second World War, the Bat Boat was far more deserving of the description ‘primitive' that has been too frequently applied to the 'Shagbat', or Walrus - which had, in any case, a full-length hull.

Still, the original Sopwith Bat Boat represented a truly significant accession to the development of British Naval flying. That Naval pilots flew the machine with and without the bow elevator seems certain; and, in his book already referred to, Harald Penrose has shown a photograph of it upside down on land and with the elevator prominent, though much the worse for wear following an incident which Mr Penrose records as follows: 'It was wrecked at the end of August [1913]' - the Austro-Daimler engine having by that time been re-installed, and the wheels removed - 'after it had been moored for the night, because the sea was too rough to beach the machine at Calshot. Next morning heavy seas were breaking over the boat, eventually filling it, aided by the wash from passing steamers. Coastguards attempted to get the craft ashore, but in the process it struck a submerged groyne and was holed and turned over. The Admiralty ordered a replacement.'

This mishap notwithstanding, the Bat Boat which bore the Service number 118, and which was generally regarded as the 'original', though clearly much rebuilt, was sent to Scapa Flow when war broke out for Fleet-patrol work (after being present at the Spithead Naval Review in July 1914) - and though it suffered gale-damage on 21 November, 1914, it was not officially written off until March of the following year.

That this pioneering Bat Boat I was a proud possession of the Royal Navy (if sometimes fractious and fractured) is clear, not only from its presence at the 1914 Spithead Naval Review, but from its use for experiments involving a little searchlight in the bows (searchlights by that time having become as much a part of a warship's equipment as were guns) - and also by some semblance of armament itself. As I recorded in my Armament of British Aircraft 1909-1939: 'The first flying-boat of this type was used for armament experiments with which the names of Lieut A. W. Bigsworth and Sub-Lieut J. L. Travers are particularly associated. The dropping of darts and practice bombs was preceded by the discharge of potatoes, Naval ratings observed the fall of shot. Data on bomb-aiming were thus accumulated.'

Even so, I feel that the Bat Boat's significance in armament development may have been much overplayed by reason of the delightful circumstances attending this episode, for by 1914 - contrary to widely held opinion - a great deal of experimental, as well as theoretical, work had been done in Britain with a variety of weapons and gear bombs and bombsights included.

The second and seemingly separate - example of the Bat Boat supplied for British Naval service was No.38, which, at one stage at least, was distinguished by a triangular fin ahead of a single ellipsoidal rudder. But such was the extent of modification and rebuilding, and so great the perils of confusion that existed in those times (and have since been multiplied) that firm identities are exceedingly difficult to establish. In any case, the Sopwith Bat Boat II - as we shall call it for consideration now - was a very different aircraft, and was used not only by the British, but by the German Naval Air Service.

The fact just stated, though doubtless already known to many readers, has never, in the present writer's view, been accorded due prominence; for if ever the heartcry that has echoed down the years and through the wars - 'Whose side are we on, anyway?' - clamoured for renewed expression it is surely here. Indeed, the instance of the German Bat Boat II must rank almost equally with 'Kestrels for German prototypes' in the 1930s and 'Nenes for Russia' in the later years. True, the aircraft itself probably had little influence on German design or policy; true likewise that such anomalies recurred, as the present writer can attest with warm personal feeling. Yet, whatever the facts of such matters, and the pretexts advanced in extenuation (notably continuance of business contacts until a few weeks before the 1914 war) there is something clammy in any transaction whereby a threatening Power can acquire, on the very eve of conflict, a prime example of a prospective opponent's technical potential.

In essence, the Bal Boat II was not only a larger and more powerful development, but differed quite strongly in appearance from its precursor. This was immediately evident on the first public showing - at Olympia in March 1914, less than five months before Britain declared war on Germany. The differences, moreover, were more than superficial, for the new and stronger hull had been made not by Saunders on their patented system at Cowes, but by Sopwith themselves at Kingston-on-Thames. The entire hull-structure was deeper, and suggestive of the sturdiness that was in fact conferred by a double skinning of mahogany on a framework of ash stringers. As on the earlier boat, there was a single step, though the planing bottom was flatter, and, for better water-clearance, the bottom wing (which was staggered appreciably behind the top one) had quite a sharp dihedral. The outboard stabilising floats were of a new design, with a rectangular instead of a circular section, and similar to those of the Type C torpedo-dropping floatplane.

The uppermost of the three-bay staggered wings had strut-braced extensions (again, as on the Type C) and - unlike the lower wing - carried ailerons. The interplane struts were of spruce, and spruce was also used for the wholly new tail-boom structure, the side-struts of which were raked to conform with the staggering of the wings. Atop the convergence of the upper booms was a tailplane/elevator assembly of very deep chord (far more so than formerly) with raked tips matching those of the mainplanes. There was no fin, and the rudder was ellipsoidal.

One especially remarkable feature of the new, Sopwith-built, hull was the 'vented step', and hardly less remarkable, the means whereby air was led to it. 'The method of leading air to the step", commented one marine-minded observer, 'is very ingenious. Instead of doing this by leading tubes through the interior of the boat, which necessitates piercing of the bottom, the same results have been obtained by sheet brass channels screwed to the sides of the boat."

Much of the interest in the new Sopwith flying-boat was nevertheless concentrated in the powerplant. which resembled the earlier scheme only in driving a pusher propeller and in being associated with forward-running struts between the engine-bearers and the hull. The engine itself was a 200 hp Canton-Unne (Salmson) water-cooled two-row radial - a form somewhat difficult to comprehend these days - with a broad frontal radiator instead of the earlier side-mounted layout. For this impressive engine (concerning which more will be said in connection with the Type C) a compressed-air starter was provided in the side-by-side two-seat cockpit. To deliver power for a wireless transmitter (note how Sopwith were meeting, and even anticipating, Service demands, though there was no provision for armament) a Motosacoche motor-cycle engine could be installed forward of the passenger's seat, and put in gear by hand.

In addition to the German Bat Boat II, which was actually being flown over the Baltic by German Naval pilots before war came, a similar flying-boat (understandably known as the 'Circuit Bat Boat') was constructed for the 1914 Daily Mail “Round Britain" contest, this machine being chiefly distinguished by a 200 hp Sunbeam engine; by the mounting of the bottom wings a little above the hull, instead of being directly attached; and by an increase in petrol tankage to give an endurance of 5 hours. C. Howard Pixton would have been the pilot, but the war caused cancellation of the contest. It was reckoned that the Sunbeam-powered machine was about 5 mph (8 km/h) faster than the Canton-Unne version.

Bat Boat I

(90 hp Austro-Daimler or 100 hp Green) Span 41 ft (12.5 m); length 32 ft (9.7 m); wing area 422 sq ft (39.2 sq m). Empty weight 1.200 lb (544 kg): maximum weight 1.700 lb (770 kg). Maximum speed 65 mph (104 km/h).

Bat Boat II

(200 hp Canton-Unne) Span 55 ft (16.8 m); length 36 ft (11 m). Empty weight 2,300 lb (1,043 kg); maximum weight 3.180 lb (1.443 kg). Maximum speed 70 mph (112 km/h).

The principal authors who inspired some of Britain's aircraft pioneers - Tom Sopwith by no means least among these latter were Jules Verne, H. G. Wells and Rudyard Kipling. And here one might add that C. G. Grey, as editor of The Aeroplane continued these writers' work ('For their work continueth", as Kipling declared in Stalky & Co) if only because so many of his compositions were fanciful (or fictitious) as well as being breezy (or blustering). So greatly influenced was Grey himself by Kipling that 'R.K.' was quite often quoted as 'C.G.G.'; but indubitably it was Kipling's story With the Night Mail - published as a separate title in the USA, with special illustrations, though familiar on both sides of the Atlantic as a component of the book Actions and Reactions - which provided the name for Britain's first successful flying-boat and the title for the present chapter of this book.

The true nature of Kipling's fictitious 'Bat-Boats' is conveyed in a page from Actions and Reactions, which calls for no comment here, except to re-emphasise Tom Sopwith's love of motor-boat racing. But, just as the bibliography of Kipling's tale can prove confusing, so is it important at this early point to make it clear that there were two distinct forms of the Sopwith Bat Boat flying-boat, and that, following marine practice, these were called by Sopwith Bat Boat I and II respectively. The Navy (in the manner wherein they styled the 'rig of the day') sometimes referred to them as No.1 and No.2.

Just us the Hawker Hart and Hornet caused a buzzing at the Olympia Aero Show of 1929, so did the joint appearance of the Sopwith Three-seater and Bat Boat (retrospectively called Bat Boat I) at the corresponding show of February 1913.

As first exhibited at Olympia the Bat Boat I (for so we shall call it) was an altogether trimmer craft than its successor, which, nevertheless was a far nearer approach to the big, successful and multi-engined British flying-boats that followed it from other works.

In truth, the Bat Boat I itself was not a wholly Sopwith product, for the hull was built by Saunders of Cowes a name that was to be sustained in the RAF by the sturdy Saunders-Roe London of 1934. As Harald Penrose (a boat-builder himself, as well as a gifted author and eminent test-pilot) remarks in Vol I of his splendid Putnam trilogy British Aviation; The Pioneer Years 1903-1914:

'The sea had long been the passion of Sopwith and Sigrist, and since they had just sold their first aeroplane to the Admiralty, it was natural that they thought in terms of marine aircraft as the opening venture of the new Sopwith aeroplane company, which was rumoured to be backed by the millionaire Barnato Joel, who had married one of Sopwith's sisters. Not only had Tom Sopwith raced speed-boats, but he was a client of the redoubtable boat-builder Sammy Saunders, of the neatly trimmed white beard and powerful personality. Grandson of the founder, he had transferred the family business in 1901 from Goring-on-Thames to Cowes, establishing the "Saunders Patent Launch Building Syndicate", and registered it in 1908 as S. E. Saunders, Ltd., to exploit his patented system of Consuta laminated-strip planking cross-sewn with copper wire to give far greater strength for weight than hitherto available. In developing high-powered racing boats, the new company had experimented with many hull forms, plain and stepped, as well as a sidewall vessel some 35 ft. in length with air-lubricated bottom. Recently Curtiss in the United States had developed his simple single-pontoon biplane into a more capacious hull in which pilot and passenger were seated. The idea attracted Tommy Sopwith, and he discussed it with Sammy Saunders' hull designer Sydney E. Porter, who had started with him in 1903. Already he had evolved for Sopwith the very successful Maple Leaf stepped hydroplane, and he saw no difficulty in designing a similar Consuta-sewn single-stepped cedar hull. 21 ft. long, with V entry, and side-by-side seating immediately above the step.'

Here, then, we have the essence of the Sopwith Bat Boats' history, related with multi-professional authority; and it remains to add the aeronautical appurtenances.

Mounted amidships on two pairs of struts, somewhat above the hull (which, in its bare form, weighed a mere 180 lb) was a two-bay, equal-span unstaggered wing cellule; and set high between the wings was a 90 hp Austro-Daimler six-cylinder inline water-cooled engine driving a pusher propeller. The hull being short - only 21 ft (6.4 m) overall - the tailplane and elevator, together with a deep single rudder, were carried clear of the water on converging tail-booms; but in addition to the rear tailplane and elevator already mentioned there was an auxiliary elevator, strut-mounted over the bow of the hull. Wing-warping was used for lateral control.

'The wing-tip floats' (declared one enthusiast) 'are constructed of copper plate, corrugated in order to give additional strength. A really most original point in their construction is the fact that each is equipped with a bicycle-valve in order that, should they become dented in any way, they can be blown back to their original shape by means of the ordinary pump! This is really worthy of a patent.'

For use by the Naval Wing of the RFC the Admiralty bought a specimen of the type described and used it for experimental work at Calshot, early modifications including the removal of the bow elevator. (No self-respecting sailor would put to sea with such an appendage just where the figurehead should be -or so it was said), and hardly less noticeable was the replacement of the original deep, unbalanced rudder by a larger surface, horn-balanced at each end. Later this gave place to a rudder of roughly oval form.

To render the Bat Boat 'all-British', and thus allow it to compete for the Mortimer Singer ?500 prize for the first such aircraft of amphibious form, the engine-bearers were modified to accept a 100 hp Green water-cooled unit and - of greater technical significance - two wheels were fitted, one on each side of the hull and capable of being raised clear of the water as required. On land, the hull sat tail-down. To absorb the extra power of the Green engine, the propeller diameter was increased to 11 ft (3.3 m) and twin rudders, below a new one-piece elevator, were associated with a modified tail-boom assembly. Instead of the earlier bracing cables, a pair of sturdy struts ran down to the hull from the new engine-mounting, and a further improvement was the fairing-in of the bottom-wing/hull junction round the supporting struts. The wing-warping system now gave place to ailerons, but the original pattern of wing-tip stabilising floats (cylindrical, with pointed ends) remained unchanged.

The demands imposed by the Mortimer Singer prize performance were very stringent and somewhat bewildering; but on 8 July, 1913, carrying Lieut Spenser Grey as official observer, Harry Hawker completed the specified tests in 3 hr 25 min, thus winning the ?500 prize and an important place in British aircraft history. In securing these distinctions Spenser Grey did not lend a hand, as might have been expected of a sailor (even though an official observer) but a foot to kick the wheels down for each landing at Hamble, the reason being that after take-offs from the Solent they had failed to drop into position when released.

Thus, although it bore a general resemblance to the slightly larger Supermarine Walrus of the Second World War, the Bat Boat was far more deserving of the description ‘primitive' that has been too frequently applied to the 'Shagbat', or Walrus - which had, in any case, a full-length hull.

Still, the original Sopwith Bat Boat represented a truly significant accession to the development of British Naval flying. That Naval pilots flew the machine with and without the bow elevator seems certain; and, in his book already referred to, Harald Penrose has shown a photograph of it upside down on land and with the elevator prominent, though much the worse for wear following an incident which Mr Penrose records as follows: 'It was wrecked at the end of August [1913]' - the Austro-Daimler engine having by that time been re-installed, and the wheels removed - 'after it had been moored for the night, because the sea was too rough to beach the machine at Calshot. Next morning heavy seas were breaking over the boat, eventually filling it, aided by the wash from passing steamers. Coastguards attempted to get the craft ashore, but in the process it struck a submerged groyne and was holed and turned over. The Admiralty ordered a replacement.'

This mishap notwithstanding, the Bat Boat which bore the Service number 118, and which was generally regarded as the 'original', though clearly much rebuilt, was sent to Scapa Flow when war broke out for Fleet-patrol work (after being present at the Spithead Naval Review in July 1914) - and though it suffered gale-damage on 21 November, 1914, it was not officially written off until March of the following year.