В.Кондратьев Самолеты первой мировой войны

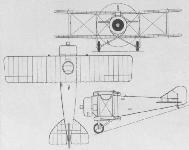

Цельнодеревянный двухстоечный биплан. Фюзеляж типа полумонокок с работающей фанерной обшивкой, крыло и оперение обшиты полотном. "Бэнтэм" - первая разработка известного авиаконструктора голландского происхождения Фредерика Кольховена на фирме "Бритиш Аэриэл Транспорт Компани Лимитед" (British Aerial Transport Co. Ltd - BAT), куда он летом 1917-го перевелся с фирмы "Армстронг-Уитворт".

Прототип под обозначением FK.22 появился осенью того же года. Машина создавалась в инициативном порядке и имела целый ряд важных конструктивных отличий от остальных англо-французских истребителей тех времен. Самолет получился очень легким и аэродинамичным. Но главным отличием стало применение стационарного звездообразного мотора воздушного охлаждения ABC "Уосп". В качестве альтернативной силовой установки рассматривались широко распространенные в странах Антанты ротативные моторы "Рон" и "Гном моносупап".

Для улучшения обзора верхнее крыло истребителя было опущено почти до фюзеляжа, а голова летчика возвышалась над ним. Такое решение, помимо очевидных достоинств, таило в себе угрозу: в случае опрокидывания машины у ее пилота почти не оставалось шансов избежать увечий. Впрочем, подобный недостаток можно было легко компенсировать установкой противокапотажной рамы.

Всего построили шесть предсерийных экземпляров, три из которых оснастили 170-сильными двигателями "Уосп I", а остальные - ротативными моторами мощностью 100 и 110 л.с.

В январе 1918-го первым вышел на испытания образец с ротативным "Гномом моносупапом". Испытания машин со стационарными моторами начались в мае. Самолет с ротативным двигателем ничем не выделялся на фоне иных машин своего класса, зато прототип с "Уоспом" благодаря повышенной энерговооруженности показал гораздо более высокие летные характеристики. Однако это в значительной мере компенсировалось низкой надежностью и частыми отказами еще "сырого" и недоведенного мотора.

Тем не менее военное министерство заказало 12 серийных экземпляров машины с "УОСПОМ". получивших обозначение FK.23 и наименование "Бэнтэм". От FK.22 они отличались слегка увеличенным размахом крыльев, уменьшенным килем и расширенным рулем поворота, а также установкой вооружения - двух синхронных пулеметов "Виккерс", закрепленных внизу передней части фюзеляжа, перед кабиной. Линии огня проходили между двумя нижними цилиндрами двигателя.

Первый серийный экземпляр поднялся в воздух 23 июля 1918 г. Всего было построено 9 "Бэнтэмов", причем последний из них оснастили новым 200-сильным мотором "Уосп II". С такими же двигателями планировалось выпустить и три оставшихся экземпляра военного заказа, но "Уосп II" оказался настолько ненадежным, что от их постройки отказались. Один из "Бэнтэмов" для ознакомления отправили во Францию, еще один - в США.

Дальнейших заказов на FK.23 не последовало, и на фронт эта машина так и не попала. Однако она стала первым в мире серийным истребителем со стационарным радиальным двигателем, получившим в дальнейшем широкое распространение.

ЛЕТНО-ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ ИСТРЕБИТЕЛЯ "БЭНТЭМ"

Размах, м 7,62

Длина, м 5,61

Площадь крыла, кв.м 17,2

Сухой вес, кг 376

Взлетный вес, кг 599

Скорость максимальная, км/ч 206

Время набора высоты

3000 м, мин.,сек. 7,2

Потолок практический, м 6100

Показать полностью

P.Lewis The British Fighter since 1912 (Putnam)

While the Camel, S.E.5 and other production types continued to bear the brunt of the fighting in the air, prototypes of new fighters continued to appear in Britain. Among the companies which made bids to establish themselves as fighter constructors was the paradoxically-named British Aerial Transport Co., the chief designer of which was F. Koolhoven, late of Armstrong Whitworth. Koolhoven’s initial design for his new firm was the F.K.22 Bat, a single-seat fighter biplane drawn up around the 120 h.p. A.B.C. Mosquito radial engine, the airframe consisting of two-bay, equal-span wings fitted to a shapely monocoque fuselage. A particularly unusual feature of the F.K.22 was the location of the cockpit immediately underneath the upper wings so that the pilot’s head projected above the centre-section. Failure of the proposed engine brought about redesign to make use of a later A.B.C. radial unit, the 170 h.p. Wasp, with which the Bat was renamed Bantam. Cancellation of development of the Wasp resulted in flights being made early in 1918 with rotaries - the 100 h.p. Monosoupape Gnome and the 110 h.p. le Rhone.

To distinguish it the Gnome version was referred to as the Bantam Mk.II, while the F.K.23, a smaller version, became the Bantam Mk.I. The Mk.I was bedevilled by dangerous spinning characteristics but the design’s speed and manoeuvrability resulted in an initial batch being ordered, with several alterations which went most of the way to eliminating the early faults. After nine Bantams had been constructed production was stopped when the A.B.C. Wasp was withdrawn as a production unit owing to persistent trouble with it. Armament of the Bantam was scheduled to be a pair of fuselage-mounted Vickers guns.

Показать полностью

F.Mason The British Fighter since 1912 (Putnam)

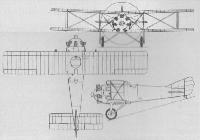

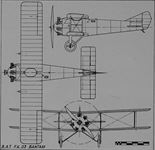

B.A.T. F.K.22 and F.K.23 Bantam

In 1917 Samuel Waring (later Lord Waring of Foots Cray) founded the British Aerial Transport company (B.A.T.) of Willesden, London, and secured the services of Frederick Koolhoven - late of Armstrong, Whitworth - as chief designer; he brought with him Bob Noorduyn, also of Dutch descent, as his chief draughtsman. Accordingly the aircraft which came to be produced by the new company continued to bear the initials applied to those designed by Koolhoven for his previous employer.

These new designs were all to be radical by accepted British standards, but nonetheless represented a realistic approach to fighter design. All the fighters were to be of wooden monocoque construction with split-axle undercarriage, and all but the last wartime design (the Basilisk) were to be characterized by the upper wing being located on top of and attached directly to the top of the fuselage. All were to be high performance aircraft.

The first Koolhoven design for B.A.T. was the F.K.22, an aircraft intended for the 120hp ABC Mosquito, but this engine failed to advance beyond bench testing, so the airframe was altered to take the 170hp ABC Wasp, but this also failed to come up to early expectations, the aircraft being temporarily referred to as the Bantam Mk I. In the end the F.K.22, B9945, underwent trials in February 1918 at Martlesham Heath powered by a 100hp Gnome monosoupape rotary, being designated the B.A.T. F.K. 22 Bantam Mk II.

The Bantam’s fuselage was a true monocoque structure with three-ply birch sheet wrapped round ash formers to provide a near-elliptical cross-section; the tail fin was built integrally with the fuselage. Each wing was constructed in three sections, only the outer sections having dihedral. Both centre sections were attached directly to the fuselage, the top wing incorporating a large circular aperture so the pilot’s head protruded above the upper surface. Ailerons were fitted on upper and lower wings, and wooden interplane struts were employed.

Despite the earlier reference to the Bantam Mk I, this was correctly applied to an entirely new design, which Koolhoven referred to as the F.K.23. It was smaller than the F.K.22, but the same basic form of monocoque construction was applied although the upper wing was now built as a single structure and possessed no dihedral. The lower wing was still made in three sections, with dihedral on the outer sections, and with no stagger.

Because the aircraft’s centre of gravity was fairly far aft and the fuselage relatively short, the tail control surfaces possessed a short moment, a deficiency that became all too obvious during spin recovery; the Bantam’s spin was vicious and rotation accelerated quickly, so that coarse and powerful use of the controls was essential. One or two aircraft were lost from spins and Maj Christopher Draper, a noted exponent of the Bantam, was fortunate to escape without injury when he spun a Bantam into the ground - thanks to the great strength of the fuselage structure.

The Bantam Mk I was very fast and highly manoeuvrable, and earned a small production order for twelve aircraft, to be powered by the 170hp ABC Wasp I. It underwent some re-design, the rudder being increased in area to assist spin recovery, steel tubular interplane struts fitted and dihedral introduced to the upper wing. Wasp I- and II-powered Bantams were submitted for evaluation in October 1918 and March 1920 under the new Air Ministry Specification series No 1A (later termed the Directorate of Research Type 1) and produced a sparkling performance; the latter version returned a maximum speed of 150 mph at sea level, and a time to 10,000 feet of just under seven minutes.

The Wasp was never popular in the RAF and, as there appeared to be sufficient Snipes in storage for demands of the foreseeable future, there was no call to increase the production order. Of the twelve production aircraft built, eight were eventually sold to private owners, and one (F1660) was sent to America for tests and evaluation; two of the civil aircraft finished up in Holland. The last two aircraft of the production order (F1663 and F1664) were held in storage until 1920, when they were assembled as J6579 and J6580 with Wasp II engines for various tests at the RAE and A & AEE; after the engine failed in J6580, a 200hp Armstrong Siddeley Lynx was fitted, but both aircraft were finally struck off charge in January 1922.

Type: Single-engine, single-seat, two-bay biplane fighter.

Manufacturer: The British Aerial Transport Co Ltd, Willesden, London.

Air Ministry Specification: No 1A of 1918.

Powerplant: Bantam Mk 1.170hp ABC Wasp I; 200hp ABC Wasp II; Bantam Mk II. 100hp Gnome monosoupape; 100hp Le Rhone.

Dimensions: Production Bantam I. Span, 25ft 0in; length, 18ft 5in; height, 6ft 9in; wing area, 185 sq ft.

Weights: Production Bantam I. Tare, 833lb; all-up, 1,321lb.

Performance: Production Bantam I (Wasp I). Max speed, 128 mph at sea level; climb to 10,000ft, 9 min; service ceiling, 20,000ft.

Armament: Two synchronized 0.303in Vickers machine guns mounted low down on the sides of the nose.

Prototypes: Six B.A.T.22s ordered, B9944-B9949; only B9944 and B9947 confirmed as being completed.

Production: Twelve B.A.T.23s ordered, F1653-F1664; F1663 and F1664 became J6579 and J6580 respectively.

Показать полностью

W.Green, G.Swanborough The Complete Book of Fighters

B.A.T. F.K.22 (BANTAM II) UK

The first design by Frederick (Frits) Koolhoven after joining the British Aerial Transport Company (B.A.T.), the private-venture F.K.22 single-seat fighter flown in September 1917 was of wooden construction with a monocoque fuselage. Powered by a 120 hp A.B.C. Mosquito six-cylinder radial engine, it displayed sufficient promise to win an official contract for a batch of six development aircraft. The first and third of these were powered by the 170 hp A.B.C. Wasp seven-cylinder radial (F.K.22/1) and the second by a 100 hp Gnome Monosoupape nine-cylinder rotary (F.K.22/2), the remaining three eventually being completed as prototypes for the F.K.23. The F.K.22/2, retroactively named Bantam II, was the first to fly, commencing its trials in December 1917 and being delivered to Martlesham for official trials on 19 January 1918. Armament comprised two synchronised 0.303-in (7,7-mm) Vickers guns, and this prototype, later re-engined with a 110 hp Le Rhone 9J nine-cylinder rotary, was eventually assigned to the Central Flying School at Upavon. The fate of the two F.K.22/Is is unknown and the following details relate to the F.K.22/2 in Monosoupape-engined form.

Max speed, 100 mph (161 km/h) at 10,000 ft (3 050 m).

Time to 10,000 ft (3 050 m), 16.8 min.

Service ceiling, 14,500 ft (4 420 m).

Empty weight, 866 lb (393 kg).

Loaded weight, 1,260 lb (571 kg).

Span, 24 ft 8 in (7,52 m).

Length, 20 ft 8 in (6,30 m).

Height, 7 ft 5 in (2.26 m).

Wing area, 230 sq ft (21,37 m2).

B.A.T. F.K.23 (BANTAM I) UK

The first prototype F.K.23 was originally ordered as the fourth of a batch of six development F.K.22s, and while retaining the wooden structure with monocoque fuselage, it embodied extensive redesign. Overall span and wing area were reduced to 20 ft (6,09 m) and 160 sq ft (14,86 m2) respectively, and the tail surfaces were redesigned. Armament comprised two synchronised 0.303-in (7,7-mm) Vickers guns and power was provided by a 170 hp A.B.C. Wasp I, flight testing being initiated in May 1918. Two further prototypes (originally ordered as the fifth and sixth F.K.22s) were similarly powered, but dimensionally larger, and after further redesign resulting from initial flight trials, a batch of 12 F.K.23 Bantam Is was ordered, the first of these being delivered to the RAE at Farnborough on 26 July 1918. At least nine Bantam Is were completed, one of these being sent to France and evaluated at Villacoublay in the late summer of 1918. One example was sent to the USA for evaluation at Wright Field, but this fighter's principal shortcoming was the poor reliability of its Wasp I engine.

Max speed, 128 mph (206 km/h) at 6,500 ft (1 980 m).

Time to 10,000 ft (3050 m), 9.0 min.

Endurance, 2.25 hrs.

Empty weight, 833 lb (378 kg).

Loaded weight, 1,321 lb (599 kg).

Span, 25 ft 0 in (7,62 m).

Length, 18 ft 5 in (5,61m).

Height, 6 ft 9 in (2,06 m).

Wing area, 185 sq ft (17,18 m2).

Показать полностью

J.Bruce British Aeroplanes 1914-1918 (Putnam)

B.A.T. F.K.22 and F.K.23 Bantam

THE British Aerial Transport Co. was founded in 1917 by Samuel (later Lord) Waring, and the new concern took over premises in Hythe Road, Willesden, previously occupied by the Joucques Aviation Co. The firm’s chief designer was Frederick Koolhoven, who had left Sir W. G. Armstrong, Whitworth & Co., Ltd., to join the B.A.T. Co.; and the first aircraft built to his design by his new firm was the F.K. 22, a small single-seat fighter which was appropriately named the Bat.

The F.K.22 embodied some features which became characteristic of the Koolhoven-designed B.A.T. types, but which were regarded as unconventional in Britain. The fuselage was a wooden monocoque and the fin was built integral with it; the birch three-ply skin was applied to ash formers, and the cross-section was a near-ellipse. The pilot sat with his head protruding through a circular hole in the upper centre-section, which was attached directly to the fuselage. Each wing was made in three parts, all approximately equal in length. The spars were of spruce, and the underside of the lower centre-section was covered with birch three-ply. Only the outer panels of the mainplanes had dihedral, and ailerons were fitted to both upper and lower wings. Wooden interplane struts were used.

The undercarriage was of the divided-axle type which was used on all subsequent B.A.T. types of the war period: in the F.K. 22 it occupied the complete width of the lower centre-section. The vees were built up of seven laminations of spruce, and incorporated vertical coil springs for shock absorbers. The undercarriage therefore had a wide track and independently sprung wheels. The rudder had a horn balance.

The power unit for which the F.K. 22 was designed was the 120 h.p. A.B.C. Mosquito. This was a six-cylinder air-cooled radial engine. Unfortunately for the B.A.T. F.K. 22, the Mosquito proved to be unsuccessful in its bench tests.

It seems that, about the time when the F.K.22 airframe was complete and the failure of the A.B.C. Mosquito was known, it was decided to modify the design to take a later and more powerful A.B.C. radial engine which had appeared. This engine was the Wasp, a seven-cylinder radial of 170 h.p. The modified aircraft was renamed the Bantam. The A.B.C. Wasp was designed by Granville Bradshaw and was submitted to the Government in October, 1917. The engine was designed for ease of production, and performed quite well on its early trials, for it gave 170 h.p. for a weight of only 290 lb. Its early success (although enough to encourage its designer to press his newer design, the Dragonfly, upon the Government) was not continued.

However, the original F.K.22 airframe was flown, powered by rotary engines. Fitted with a 100 h.p. Gnome Monosoupape, an F.K.22 was tested at Martlesham Heath in February, 1918, and the machine numbered B.9945 was also flown with a 110 h.p. Le Rhone. Official documents refer to the Gnome-powered version as the Bantam Mark II, presumably on the analogy of such designations as the Avro Manchester Mk. II and Sopwith Cobham Mk. II. The designation Bantam Mk. I was applied to the Wasp-powered machine.

The analogy was not complete, however, for the relationship between Bantams Mk. II and Mk. I was much less close than the relationship between the corresponding marks of Manchester and Cobham. The Bantam Mk. I was in fact a new design and was given a new type number, F.K.23, by its designer. When the first Bantam Mk. I appeared, it differed markedly in appearance from the F.K.22 as exemplified by B.9945.

The new machine was considerably smaller than the F.K.22, and the wing area was greatly reduced. Again the upper wing was attached directly to the fuselage and there was a hole for the pilot’s head and shoulders, but the wing was made in one piece and was quite flat. The lower wings alone had dihedral and were attached to a centre-section of short span. As on the F.K.22, wooden interplane struts were fitted. The vee-struts of the undercarriage were directly under the inner interplane struts.

A monocoque fuselage of new design and good aerodynamic form was used. Its basic structure consisted of four ash longerons bearing spruce formers round which sheets of plywood were wrapped. The low aspect-ratio triangular fin was built integral with the fuselage, and the rudder was a plain surface with a straight vertical trailing edge.

The monocoque fuselage was officially viewed with some suspicion. Although many contemporary German aeroplanes had fuselages built on that principle, the idea was still regarded as somewhat revolutionary in Britain at the time of the Bantam’s appearance.

The Bantam B.9947 was at Hendon in February, 1918. Unfortunately, the type proved to have disastrous spinning characteristics. The gap was narrow because the upper wing had been placed on top of the fuselage in order to give the pilot the best possible view; there was no stagger; the centre of gravity was rather far aft; and the stubby little fuselage gave a comparatively short moment arm for the fin and rudder.

The Bantam’s spin began at a normal speed but rapidly accelerated until it reached a phenomenal rate of autorotation, from which it could be brought out only by vigorous use of the controls. Accidents occurred with Bantams owing to their spinning characteristics. Major Christopher Draper, one of the most noted exponents of the type, spun into the ground at Hendon in one of the prototypes. He survived the crash, thanks to the great strength of the Bantam’s fuselage, which came out of the crash remarkably well.

After a second accident had occurred in which a Bantam had spun into the ground, the Accidents Investigation Sub-committee of the Aeronautical Research Committee requested that experiments be conducted to determine the cause of the crashes. It was shown that the Bantam’s unusual behaviour in a spin was attributable chiefly to the position of the centre of gravity which, at 42 per cent chord, was too far aft; and to the combination of zero stagger with an unusually small gap/chord ratio (0,81).

However, the Bantam was fast and highly manoeuvrable, and a small production batch was ordered. The production machines had a re-designed wing structure and a revised tail-unit: enlarged horizontal surfaces were fitted, the rudder was increased in area, and there was a corresponding reduction in the area of the fin. The new wings were of greater span and area, and both were given equal dihedral angles. The interplane struts were of steel tube. This version, which was the best-known form of the design, had the same type number F.K.23.

These modifications did much to cure the trouble, and the Bantam did well in all its Service trials. Only nine production Bantams, numbered F.1653 to F. 1661, were built, however. The A.B.G. Wasp was noted for its capricious behaviour, and it was decided not to proceed further with the production of that engine. Deprived of its power unit, the Bantam had perforce to be withdrawn from production also.

A single Bantam fuselage was built for the Admiralty and was exposed for several months on Inverkeithing Dock to test its resistance to widely varying climatic conditions. When returned to the works for inspection the fuselage was found to have suffered very little deterioration.

Shortly after the war, Lord Waring felt obliged to reduce his aviation interests and the B.A.T. company was virtually disbanded, although technically it was amalgamated with the Alliance Aeroplane Co., Ltd., of Acton, and the British Nieuport & General Aircraft Co., Ltd., of Cricklewood, two other concerns which had been founded by Lord Waring.

In the meantime, one of the Bantams had been fitted with the more powerful A.B.C. Wasp II, which delivered 200 h.p. After the merger of the firms, this machine was put through a series of trials by Captain L. R. Tait-Cox, the Nieuport test pilot. The top speed was increased to 146 m.p.h. at 10,000 feet, and the rate of climb was correspondingly improved.

At least one Bantam went to America, where it was flown at Wright Field with American markings. Its American serial number was A.S.94111, and it bore the Wright Field Project Number P.167 on the rudder.

Seven Bantams went on to the British Civil Register after the Armistice. They were registered K.123 (later G-EACN), K.125 (G-EACP), K.154 (G-EAFM), K.155 (G-EAFN), G-EAJW, G-EAMM and G-EAYA. K.123 and K.125 were entered in the 1919 Aerial Derby, in which they were flown by Clifford Prodger and Major Draper. K.125 had its lower wing clipped just outboard of the inner bay of interplane struts, the extensions of the upper mainplane being braced by long struts.

In 1924 G-EAYA (formerly F.1661) was bought by Frederick Koolhoven and was taken by him to Holland. There it was fitted with a 200 h.p. Armstrong Siddeley Lynx engine, and was said to have attained a speed of 246 km/hr (about 154 m.p.h.).

SPECIFICATION

Dimensions:

Bantam Mk. II (Gnome) Bantam Mk. I prototype Production

Bantam

Span 24 ft 8 in. 20 ft 25 ft

Length 20 ft 8 in. - 18 ft 5 in.

Height 7 ft 5 in. - 6 ft 9 in.

Chord 4 ft 11 in. 4 ft 3 ft 11 1/4 in.

Gap 4 ft 3 in. 3ft 3ft 3 1/2 in

Stagger Nil Nil Nil

Dihedral, upper 2° Nil 2° 30'

Dihedral, lower 2° 2° 2° 30'

Incidence, upper 2° 2° -

Incidence, lower 2° 2° -

Span of tail 6 ft 6 in. 6 ft 7 in. 9 ft 2 in.

Wheel track - - 7 ft 2 1/2 in.

Airscrew diameter - - 7 ft 10 1/2 in.

Areas (sq ft):

Wings 230 160 185

Ailerons: each 6 3-8 4-5

total 24 15-2 18

Tailplane 7 10-4 16-7

Elevators 10-5 5-85 6-3

Fin 2-5 3-5 2-85

Rudder 6 3-85 4-4

Weights (lb) and Performance:

Bantam Mk. II (Gnome) Bantam Mk. I (production)

Wasp I Wasp II

No. of Trial Report M.175 M.242 -

Date of Trial Report February, 1918 October, 1918 -

Type of airscrew used on trial P.3012 I.P.C.2414 -

Weight empty 866 833 -

Military load 50 130 -

Pilot 180 180 -

Fuel and oil 164 178 -

Weight loaded 1,260 1,321 -

Maximum speed (m.p.h.) at

6,500 ft - 128 -

10,000 ft 100 125-5 146

15,000 ft - 118 -

m. s. m. s. m. s.

Climb to

6,500 ft 9 05 5 10 - -

10,000 ft 16 50 9 00 - -

15,000 ft 43 00 17 05 - -

17,000 ft - - - - 16 00

Service ceiling (feet) 14,500 20,000 -

Endurance (hours) - 2 1/4 -

Tankage: Petrol (gallons) 17 22 -

Manufacturers: The British Aerial Transport Co., Ltd., Hythe Road, Willesden, London, N.W.

Power: Bantam Mk. I: 170 h.p. A.B.C. Wasp I; 200 h.p. A.B.C. Wasp II. Bantam Mk. II: 100 h.p. Gnome Monosoupape; 110 h.p. Le Rhone.

Armament: Two fixed Vickers machine-guns mounted low down on either side of the fuselage, firing between the lowest pair of cylinders on each side, and synchronised to fire forward through the revolving airscrew (i.e., on production Bantams).

Service Use: Only one B.A.T. aeroplane was delivered to a Training Unit during 1918. In February, 1918, the Bantam Mk. II, B.9945 was at Hounslow, and the Mk. I prototype, B.9947 was at Hendon. On October 31st, 1918, the R.A.F. had three unspecified B.A.T.s on charge: one was at an Aircraft Acceptance Park and two were at testing units. One production Bantam Mk. I went to America.

Serial Numbers: B.9944-B.9949: ordered under Contract No. A.S.25314. F.1653-F.1661.

Показать полностью

A.Jackson British Civil Aircraft since 1919 vol.1 (Putnam)

B.A.T. F.K.23 Bantam

The Bantam was a small single-seat fighter designed by Frederick Koolhoven and built at Willesden by the British Aerial Transport Co. Ltd. founded during the war by Samuel (later Lord) Waring. In its production form it was of mixed wood-and-metal construction with a monocoque plywood fuselage in which the pilot sat with his head through a hole in the upper mainplane. Only nine production Bantams F1653-F1661 were built, because the 170-h.p. A.B.C. Wasp I radial with which it was fitted paid the penalty of uncertain behaviour and went out of production.

Although the Bantam saw no war service, seven of the nine production machines were registered to the manufacturers for sporting purposes in 1919-21. None was granted a Certificate of Airworthiness, as these were not obligatory for single-seaters in those days, and the individual identity of only one is known. This was the last Bantam F1661, which had been built and first flown in September 1919 and exhibited in R.A.F. colours at the Olympia Aero Show in July 1920. It was repainted as the firm’s demonstrator G-EAYA in July 1921, but passed into the hands of C. P. B. Ogilvie at Willesden when B.A.T. closed down. In 1924 it was taken to Holland by its designer, who fitted it with a 200-h.p. Armstrong Siddeley Lynx engine.

Two others, K-154/G-EAFM and K-155/G-EAFN, built in April and May 1918 respectively, had the cumulative B.A.T. constructor’s numbers F.K. 23/16 and F.K. 23/18, but the remaining four are shrouded in anonymity. These were K-123/G-EACN, K-125/G-EACP, G-EAJW and G-EAMM, the first of which were built in April 1918. G-EAMM and the demonstrator ’YA had modified Wasp engines rated at 185-h.p. None achieved longevity, and they were mainly used for the Saturday afternoon and Bank Holiday pylon racing which drew the crowds at Hendon in 1919-20. The first Bantam K-123 was flown in the Aerial Derby at Hendon by Clifford Prodger on 21 June 1919 and at the First Air Traffic Exhibition in Amsterdam in the July by the well-known Major Christopher Draper. K-125 was a racing special with the lower mainplane clipped halfway along the outer bay and the resultant overhang of the upper mainplane braced with slanting struts. This frightening vehicle was flown in the Aerial Derby by Christopher Draper, who came second in the sealed handicap and fourth in the speed contest at 116-78 m.p.h.

Today the only surviving Bantam relic is the derelict fuselage of K-123, which, after a period in storage at Willesden and Watford with C. P. B. Ogilvie, is now with the Shuttleworth Trust at Old Warden Park, Biggleswade.

SPECIFICATION

Manufacturers: The British Aerial Transport Co. Ltd., Willesden, London, N.W.

Power Plant: One 170-h.p. A.B.C. Wasp I.

Dimensions: Span, 25 ft. Length, 18 ft. 5 in. Height, 6 ft. 9 in. Wing area, 185 sq. ft.

Weights: Tare weight, 833 lb. All-up weight, 1,618 lb.

Performance: Maximum speed, 128 m.p.h. Initial climb, 1,250 ft./min. Ceiling, 20,000 ft. Range, 250 miles.

Показать полностью

Журнал Flight

Flight, May 22, 1919.

THE B.A.T. BANTAM

ALTHOUGH not, perhaps, possessing the interest of novelty, having been designed a matter of nearly two years ago, the B.A.T. Bantam nevertheless presents many features that are worthy of mention, somuch the more so as we have been prevented, during the War, from describing this machine. Its detail features will not, therefore, be so well known to a large proportion of FLIGHT readers as they deserve to be, and consequently we trust that the following descriptive article may be found of interest.

Mr. F. Koolhoven, the designer of the B.A.T. machines, was, as is well known, chief designer to Messrs. Armstrong, Whitworth and Co. for a considerable time, and produced, while with that firm, some very successful machines of widely differing types. Previous to that, Mr. Koolhoven was associated with the British Deperdussin Co. at their works at Highgate, where, in the years before the War, some very successful monoplanes were produced. Among these was, it may be remembered, a monoplane seaplane, the "Seagull," which, among other features, was remarkable for the monocoque construction of its body, a form of construction not often seen in this country in those days. The body structure was found to be remarkably strong and light, while possessing an excellent stream-line form. It is not, therefore, surprising to find that Mr. Koolhoven, having been successful with monocoque construction so long ago, still favours this method in his later machines, such as the Bantam and Basilisk. The detail construction has been somewhat changed, and, perhaps, one may not, strictly speaking, be justified in using the word monocoque in its usually accepted sense. However, in so far as having no internal bracing, except that provided by the fuselage covering, the B.A.T. Bantam, and also the Basilisk, may be said to have as one of its most noteworthy features a fuselage construction akin to the monocoque.

In the B.A.T. Bantam the fuselage construction consists essentially of a light framework, comprising six longitudinal members and a number of transverse formers built up of three-ply wood, the whole covered by a three-ply skin put on in bands some 3 ft. wide, lap-jointed where they meet. The outer and inner layers of this three-ply skin run longitudinally, while the middle layer is placed at an angle to the other two. The longitudinal members are of ash, and are placed as follows: one at the top, one at the bottom, and the other four forming the corners of the rectangle inscribed in the elliptical cross section of the body. The top and bottom longerons are of T section, while the other four are rectangular. Where the transverse formers are attached to the longerons the formers are reinforced for extra strength. The formers themselves are of L section, the ash base of the L lying against the fuselage covering. In section, the body of the Bantam changes from circular in front, through elliptical to narrow ellipse and vertical knife's edge at the stern. From a resistance point of view the shape would appear to be excellent.

At the rear the three-ply body covering is extended upwards to form the fixed vertical tail fin, the internal framework of which is integral with the body formers in this locality. The fixed tail plane is in two halves bolted to short spar roots built integral with the formers. A peculiarity of this design, which is somewhat similar to that of the Dep. "Seagull," is that the elevators do not go right up to the sides of the body, the space between the inner ends of the elevator flaps and the sides of the fuselage being occupied by a fixed portion of the tail plane. This will be clear from the plan view of the general arrangement drawings. As in the old Dep. monoplane, the elevator crank levers are housed inside the ply-wood fin, giving a very neat and clean appearance to the tail plane. The rudder is fabric-covered, as is also the tail plane and elevator, and forms, at its lower corner, a housing for the shock-absorbing spring of the tail skid. This skid turns with the rudder, but is so designed that, although superficially appearing to do so it does not transmit shocks to the tubular leading edge of the rudder, but to the fixed rudder post. For steering at low speeds on the ground, this arrangement is excellent, as the skid is capable of turning the machine at speeds so low that the rudder has not yet become operative. At the same time it would be difficult to imagine anything simpler or offering less resistance. As the angle of incidence of the tail plane of the Bantam is not made adjustable, the bracing of the tail consists simply of eight R.A.F. wires, four above and four below the tail plane.

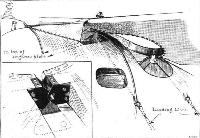

The pilot's cockpit is situated between two strong formers, serving as supports for the wing spars, and access to it is gained through a circular opening in the top plane. When the pilot is in his seat his eyes are about on a level with the spars of the top plane, and he therefore has a very good view in all directions except straight down, where the bottom plane obstructs the view to some extent, although no more so than on machines in which the pilot is less favourably situated as regards the top plane. The controls are of more or less usual type, consisting of a central control column terminating at the top in the standard handle, and of a foot bar for the rudder. The manner in which the controls work will be clear from the accompanying sketches. Although the fuselage of the Bantam is not of exceptionally great cross section, the pilot's cockpit is very roomy, this being one of the many advantages of the monocoque construction, which does not waste space on internal girders and bracing.

Mounted on a flat sheet steel capping plate over the extreme nose of the fuselage - the main structure of which is rectangular at this point, although made up to a circular section by the surrounding cowl - is the 170 h.p. A.B.C. "Wasp" engine. Slots in the cowling admit air to the cylinders, and the air escapes at the engine plate through various passages cut in the cowl. In so doing the air is forced to negotiate some rather sharp bends, which have, however, been avoided in a later type (the Basilisk), in which the air, after passing each cylinder, is allowed to escape via cone-shaped cavities in the engine cowling. The oil tank is mounted immediately behind the engine, while the main petrol tank, which has a capacity of 22 1/2 galls., is accommodated in the fuselage behind the pilot's cockpit.

With regard to the wings, these are mainly remarkable for a somewhat low gap-chord ratio. This is a consequence of the placing of the pilot so that his eyes shall be on a level with the top plane, in order to obstruct to as small extent as possible the view. It is not, we know, usual to consider the gap-span ratio of an aeroplane, although, to our way of thinking, this ratio may easily be of as great importance structurally as is the gap-chord ratio aerodynamically. Thus, in a very high aspect ratio wing structure the gap-chord ratio may be the normal (about 1), but the gap-span ratio very low. The result of this will necessarily mean a less favourable angle of the lift wires. This in turn will have its effect upon the number of struts which it is efficient to employ. Thus, in the B.A.T. Bantam, although the span is low, the small gap results in a low gap-span ratio, and it will be seen that if only one pair of struts was employed on each side, the angle of the lift wires would have been very flat. It was further desired to provide a wide wheel track which would ensure that the machine could not easily be overturned when doing sharp turns on the ground, and with the steerable tail skid this machine is capable of some very sharp turns at speeds which, although below the flying speed, are quite high enough to be dangerous with a narrow track undercarriage. The designer then made the bold step of securing both these desiderata by a radical departure from usual practice. This took the form of fitting two pairs of inter-plane struts on each side and attaching the undercarriage struts to the spars at the point where occur the inner pair of inter-plane struts. In this manner, not only was a good angle provided for the lift wires, and the free length of wing spars reduced, but the resulting track of the landing wheels was so wide as to practically exclude any possibility of turning over. There was, in the earlier days of flying, a prejudice against attaching the undercarriage to the wings instead of to the fuselage, the argument being that landing shocks might seriously strain the wing structure without this being apparent until the machine was taken for a subsequent flight. In the B.A.T., however, one has a very light machine and a very sturdy wing structure, so that this objection - which is probably a rather theoretical one, after all - need not cause any misgivings. We have never heard of any ill effects arising out of this feature of its design during the two years or so of the machine's existence.

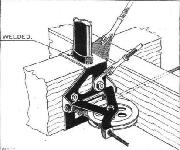

As regards the wing structure of the Bantam, this is designed along orthodox lines. The inter-plane struts, which are of elliptic cross-section steel tubes, are attached to the wing spars by a very neat and simple socket, and are held in place by a small split-pin. The manner of attaching the base plate of the socket to the wing spar is shown in one of the accompanying sketches. The wing bracing is effected by 1/4-in. B.S.F. R.A.F. wire, the lift and landing wires in the outer bay, and the landing wires in the inner bay being single. The lift wires in the inner bay are in duplicate, so as to withstand better not only the flying loads, but also the loads imposed upon the wing structure while landing. In order to minimize vibration and prevent the wires from twisting under the force of the wind a neat arrangement is provided at the points where lift wires and landing wires cross one another. In the outer bay this takes the form of a long tube, slotted at its ends to accommodate the crossed wires, which are locked in position by an "acorn" and a collar with a split-pin, as shown in one of our sketches. In the inner bay where, as already mentioned, the lift wires are in duplicate, two short tubes are employed, one for each three crossed wires, as shown in the sketch.

The lower planes are attached to short wing roots built into the body integral with two very strong formers - one in front of the pilot's cockpit and one behind it. The two halves of the top plane are bolted to the apex of the same two formers, the detail of this attachment being shown in one of the sketches. The landing wires of the inner bay are attached to lugs on the side of the fuselage, these lugs being further braced from the top of the formers by means of long sheet steel strips in the manner indicated in one of our diagrams. In this way the rigging of these landing wires is greatly facilitated, while the steel strips transmit the load to the top of the formers. As already mentioned, the top plane has cut in it a circular hole, through which the pilot enters the machine, and by means of which he obtains a very good view in all but a downward direction. Ailerons are fitted to all four wings, and are operated in the usual way. The return cable is passed inside the top plane, and is exposed for a short distance at the front edge of the hole in the top plane.

The undercarriage of the B.A.T. Bantam is, as already pointed out, of unusual design. The two strut Vees are attached, not to the fuselage, as is usual practice, but to the lower wing spars at the points where occur the inner pair of inter-plane struts. Each half of the divided axle is hinged to the body, and bent just before crossing the slot in the V struts. These are built up of multi-ply wood and bound with fabric, while the axles are circular section steel tubes, stream-lined with a hollow fairing of wood bound with fabric. A notable feature of this undercarriage is the absence of wire bracing of the two Vs. The function of bracing is performed by the axles, which really act as lateral radius rods for the Vs.

On each side of the struts there is mounted on the axle a steel quadrant which serves the double purpose of housing the rubber cords and acting as guides limiting the lateral shifting of the Vs. The whole makes a very neat and simple job, offering small resistance, and yet being quite strong. Whether this arrangement would be advisable in a large machine is, perhaps, open to discussion, but for a small, light machine like the Bantam it certainly would be difficult to improve upon.

The following particulars of performance, etc. should be of interest :- Weight of machine loaded, 1,335 lbs. Range, 425 miles. Speed near ground, 138 m.p.h.; at 10,000 ft., 134 m.p.h.; at 15,000 ft., 127 m.p.h. Climb to 10,000 ft., 7.2 mins.; to 15,000 ft., 14 mins. Ceiling, 25,000 ft.; landing speed, 50 m.p.h.; load/sq. ft., 7.2 lbs.; load/h.p., 7.85 lbs.; military load, 520 lbs.

Flight, June 26, 1919.

THE AERIAL DERBY

THE MACHINES

No. 1. - The B.A.T. Bantam, 170 h.p. A.B.C. Wasp

This machine, which was piloted by Mr. Clifford B. Prodger, is the standard Bantam. It has a monocoque body of excellent streamline shape, and is chiefly remarkable on account of the placing of the top plane low over the body and with no stagger in relation to the bottom plane. Also the undercarriage struts are attached to the bottom plane instead of, as is more usual, to the body direct. This placing of the chassis has the advantage of giving a very wide wheel track. The pilot is placed in a circular opening cut in the top plane, where his eyes are on a level with the plane. The view is, therefore, exceptionally good in all directions except straight down, where the bottom plane obstructs it to a certain, although small, extent. The machine is very fast, climbs well, and is manoeuvrable to a remarkable extent.

No. 3. - The B.A.T. Bantam, 170 h.p. Wasp

With the exception of the short bottom plane, and consequent difference in strutting, this machine is a standard Bantam, similar to No. 1. It was flown by Maj. Draper, who was to have flown the little new B.A.T. sporting two-seater, the F.K. 27. This machine, however, was not finished in time and hence Maj. Draper flew No. 3. This fact deprived Capt. Vaughan of a mount, and as the B.A.T. five-seater, F.K. 26, was slightly damaged on Saturday morning, she 'was not able to start in the race, and thus another B.A.T. pilot, Lieut. Turner, was without a machine when the race started.

Показать полностью