В.Кондратьев Самолеты первой мировой войны

РАФ FE.8 / RAF FE.8

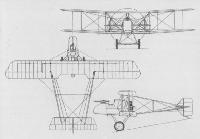

После ухода Джеффри Де Хэвилленда с авиазавода РАФ конструкторское бюро этого предприятия возглавил Джон Кенуорт. Под его руководством осенью 1915 года был разработан один из первых в Великобритании одноместных истребителей под индексом FE.8. Самолет создавался под ощутимым влиянием DH.2, однако Кенуорт поставил перед собой задачу добиться более высоких, чем у конкурентной машины, летных данных.

Постройка прототипа завершена в октябре. Самолет представлял собой двухстоечный биплан смешанной конструкции с толкающим винтом. Открытая хвостовая ферма сварная из стальных труб, крылья и оперение деревянные с полотняной обшивкой, носовая гондола с фанерно-дюралевым покрытием. В целом самолет получился более аэродинамичным, чем DH.2, и это позитивно сказалось на его летных данных, особенно - на скороподъемности.

Во время одного из испытательных полетов прототип разбился в аварии, но в декабре был готов второй экземпляр, который успешно прошел испытания. В январе следующего года самолет запущен в серию. Всего построено 300 экземпляров. 245 выпустил авиазавод фирмы "Даррак", остальные - завод концерна "Виккерс" в Вейбридже. Большинство из них оснащалось 100-сильными ротативными двигателями "Гном моносупап", но на некоторые ставили 110-сильные "Роны" 9J или "Клерже".

Поначалу на FE.8, как и на DH.2, установили подвижный пулемет "Льюис", однако затем его стали жестко закреплять в курсовом положении.

Серийные FE.8 появились в боевых частях лишь в августе 1916 года, почти на восемь месяцев позже, чем истребители Де Хэвилленда, и это сыграло в их судьбе роковую роль. Прогресс военной авиации тогда шел настолько быстрыми темпами, что машина Кенуорта, так же, как и BE.12, морально устарела еще до отправки на фронт. Немецкие "Альбатросы" превосходили ее по всем статьям.

К концу 1916 года англичане поняли, что, несмотря на ряд преимуществ (хороший обзор и отсутствие необходимости в синхронизации оружия), схема истребителя с толкающим винтом и ферменной хвостовой частью фюзеляжа бесперспективна.

Тем не менее, до весны 1917-го FE.8 состояли на вооружении нескольких британских авиачастей, в частности ими были полностью укомплектованы 40-й и 41-й истребительные дивизионы RFC, дислоцированные во Франции.

Точку в карьере машины поставил бой 9 марта 1917-го, когда "Альбатросы" D.III из эскадры Рихтхофена без потерь сбили пять из девяти встреченных ими над фронтом FE.8, а остальные совершили вынужденные посадки. Вскоре после этого самолет был снят с вооружения. 40-й дивизион переоснастили французскими "Ньюпорами", а 41-й - "Де Хэвиллендами" DH.5.

ЛЕТНО-ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Размах, м 9,60

Длина, м, 7,22

Высота, м 2,80

Площадь крыла, кв.м 20,20

Сухой вес, кг 440

Взлетный вес, кг 670

Двигатель "Рон"

мощность, л. с. 110

Скорость максимальная, км/ч 151

Скорость подъема на высоту

2000 м, мин.сек 9,10

Дальность полета, км 375

Продолжительность полета, ч 2,5

Потолок, м 4420

Вооружение 1 пулемет

Показать полностью

А.Шепс Самолеты Первой мировой войны. Страны Антанты

RAF F.E.8 1916 г.

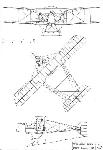

В 1915 году до появления синхронизатора командованием RFC был заказан истребитель с толкающим винтом. Подобные самолеты проектировали фирмы "Де Хевилленд" и "Виккерс". RAF F.E.8 - двухстоечный ферменный биплан смешанной конструкции. Гондола имела каркас из стальных труб и обшивку из алюминиевых панелей. Ферма изготавливалась из стальных труб с растяжками из стальной профилированной ленты. Крылья двухлонжеронные, деревянной конструкции, обтянутые полотном. Стойки из стальных профилированных труб. Элероны устанавливались на обоих крыльях.

Двигатель 7- или 9-цилиндровый воздушного охлаждения, звездообразный, ротативный "Гном-Моносупап" (100 л. с.), "Рон" (110 л. с.) или "Клерже" (110 л. с.) Винт деревянный, четырехлопастной. Оперение деревянной конструкции, обтянутое полотном. Шасси двухстоечное с резиново-шнуровой амортизацией. Вооружение - 1 пулемет "Льюис" в носовой части гондолы. Выпущено около 200 экземпляров, состоявших на вооружении до середины 1917 года.

Однако машина не имела преимуществ перед самолетами противника и использовалась в основном на второстепенных участках фронта.

Показать полностью

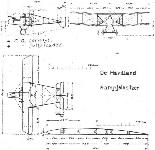

P.Hare Royal Aircraft Factory (Putnam)

F.E.8

By mid-1915 it had become evident that the Royal Flying Corps was in fairly urgent need of a single-seater fighter (or 'Scout', in contemporary parlance), both to afford some protection to its vulnerable two-seaters and to take the war to the enemy by attacking German aircraft.

Such a machine obviously needed to be equipped with a forward-firing gun, placed within easy reach of the pilot so that it could be loaded and any jams could be cleared. As the Allies still lacked a workable gun synchronisation system, the only practicable solution was to make the new machine a pusher, despite the drag penalty and consequent reduction in performance.

The aeroplane which the Farnborough team, headed by John Kenworthy, designed to fill this role was broadly similar in concept to its closest 'rival', the D.H.2, produced contemporaneously by the Aircraft Manufacturing Company, where Geoffrey de Havilland was then chief designer, but it differed almost totally in detail.

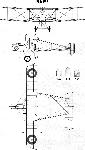

The single tubular tailboom previously employed in the F.E.3 and F.E.6 was abandoned, despite its reduced drag, because its structural integrity was still far from proven. Instead, conventional steel-tube tailbooms were employed, but these were arranged to meet, unconventionally, at the tailplane spar, rather than at the sternpost. They thus formed a vee in elevation and not, as was common, in plan. The tailplane incidence was adjustable, although only on the ground and, to reduce overall weight and control forces, the rudder and elevator ribs were of duralumin. The nacelle, which was of conventional appearance, was built upon a triangulated framework of welded steel tubing which eliminated any need for internal bracing wires, the shape of its duralumin covering being maintained by wooden formers. The high-aspect-ratio, two-bay wings were rigged with five degrees of dihedral outboard of the wide centre section. Ailerons spanned all four outer wing panels, and on the early F.E.8s no spanwise balance cables were fitted, the ailerons being returned to their normal position by rubber bungees.

Power was provided by a 100hp Gnome monosoupape rotary driving a four-blade propeller which, for some inexplicable reason, was fitted with a conical spinner.

Instrumentation was typically spartan, comprising only a tachometer, altimeter, airspeed indicator, transverse clinometer, watch holder, compass, and fuel pressure gauge (this being vital as no gravity tank was fitted, and the engine would cut out if the pressure within the tank fell too low. A hand pump was provided for emergency use).

The first prototype, 7456, made a brief initial flight on 15 October 1915, before any armament was fitted. Its pilot on that occasion was Frank Goodden, who was entirely satisfied with the new scout. Four days later he took it up for an hour and a half, exploring its handling characteristics to the full.

By early November 7456 had been equipped with a Lewis machine gun pointing through an opening in the extreme nose, and capable of being swivelled through an arc of up to 30° in any direction via a linkage connected to the pilot's sighting device. On 8 November it was flown to the Central Flying School at Upavon for service trials. The school's report was most favourable, describing it as manoeuvrable, easy to land, and possessing excellent stability. The gun installation found less favour because it was inaccessible and unnecessarily complex. It was thought simpler merely to fix the gun and aim the whole aeroplane at the enemy. A week later the F.E.8 was returned to the Factory by the famous prewar display pilot B C Hucks, who had the great misfortune to crash-land and damage it beyond economical repair. The engine, which was undamaged, was removed for use in the second prototype, 7457, which was already under construction and which first flew on 19 December, piloted by Frank Goodden.

Trenchard considered its 2 1/4hr endurance to be insufficient, and it was therefore decided to increase the fuel tankage from 24 to 29 gallons. The gun mounting, which had been widely criticised, was changed to a fixed position on the cockpit rim, similar to that of the D.H.2. Wooden racks were provided on the cockpit sides for spare ammunition drums. These modifications were incorporated in production machines, the first order for which had been placed with the Darracq Motor Engineering Company on 11 October, four days before the type's first flight.

To forestall any possible problems, should supplies of the Gnome Monosoupape prove troublesome, experimental installations were made of a 110hp Le Rhone and of a Clerget of similar power so that any difficulties in substituting these engines should be solved in advance. In practice, however, it was airframes which proved to be a problem. Deliveries were delayed for a variety of reasons, not the least of which was the fact that this was Darracq's first venture into aircraft manufacture. Therefore it was October 1916 before a complete squadron, No 40, was in service on the Western Front, although the first six machines had been pressed into use at the beginning of August.

Allegations that the F.E.8 was prone to spin caused considerable concern, especially among the many recently qualified pilots whose training was, at best, somewhat basic. Therefore, during August 1916, Frank Goodden carried out a series of trials in which he deliberately spun an F.E.8 in both directions, recovering easily on each occasion by employing the standard method (centralise the controls, push the stick forwards to gain airspeed, then apply opposite rudder if required). His report stated that the aeroplane was perfectly stable, and that he had only been able to initiate each spin by 'misuse' of the controls. The report, together with the story of the trials, which passed quickly down the 'grapevine' throughout the RFC, did much to stop the rumours and to restore pilots' confidence in their mounts.

A rather more justified criticism of the aeroplane was made in respect of the rubber bungees connected to the ailerons, which broke much too frequently. On 30 August it was decided to replace the bungees with a balance cable, not only on all future machines, but retrospectively on those already in service. The fuel system was also criticised by squadron pilots, as it often proved difficult to maintain the necessary pressure, particularly when the tank was nearly full. To resolve this, a small gravity tank was fitted internally within the centre section, fed from the main tank under pressure and itself feeding directly to the engine. The D.H.2 tank was also tried, mounted externally below the upper wing centre section, but although it was streamlined it caused an unacceptable reduction in speed and the internal tank was standardised.

Later, when it was discovered that the duralumin ribs in the elevators were reacting with the dope and causing the fabric to rot, new control surfaces with steel ribs were designed. As a temporary measure while the new elevators were being manufactured, some machines were fitted with D.H.2 elevators, their hinge type and position being modified as required to make them fit.

Almost 300 F.E.8s were eventually built, and the type remained in service at least until July 1917. By that time it was long obsolete, but it enjoyed the dubious distinction of being the last pusher scout to see active service on the Western Front.

Powerplant: 100hp Gnome Monosoupape rotary

Dimensions:

span 31ft 6in;

chord 4ft 0in;

gap 4ft 6in;

wing area 214 sq ft;

dihedral 5°;

length 23ft 0in;

height 9ft 2in.

Weights:

895lb (empty);

1,346lb (loaded)

Performance:

max speed 94mph at sea level;

ceiling 14,500ft;

climb 9 1/2min to 6,000ft;

endurance 2 1/2hrs.

Показать полностью

P.Lewis The British Fighter since 1912 (Putnam)

At the same time as the D.H.2 was being evolved at Hendon, to the South at Farnborough J. Kenworthy was at work in the precincts of the Royal Aircraft Factory on a contemporary single-seat pusher fighter - the F.E.8. The time taken from conception to realization of the D.H.2 was remarkably short as the dedicated Airco staff, under the energetic George Holt Thomas, applied their resources to producing the prototype as quickly as possible. The F.E.8 was not quite as lucky as, although design work had been initiated in May, 1915, the prototype first saw the light of day during the following October and ensuing troubles delayed its introduction into service. The F.E.8’s span was slightly greater than that of the D.H.2, while its weight using the same engine - the 100 h.p. Monosoupape Gnome - was a little less than that of the de Havilland machine; the speed at sea level was approximately the same for both, the F.E.8 reaching 94 m.p.h. compared with the D.H.2’s 93 m.p.h. The F.E.8, as a two-bay pusher biplane, possessed little of the pleasingly-proportioned appearance which the well-rounded, balanced lines of the D.H.2 presented to the eye. Instead, the Factory product was by comparison square-cut, angular and spindly. The prototype F.E.8’s four-blade propeller was embellished with a pointed spinner of generous size which could have had but a negligible effect upon performance and which was subsequently deleted on production examples. The F.E.8’s all-important armament was a single Lewis gun which, on the prototype, was installed at a low level in the nose of the nacelle. Except for the short exposed nose portion of the barrel, the gun was completely contained within the nacelle and was intended to be remotely controlled by the pilot seated above and behind it. Accessibility was poor, particularly so in flight and the gun was consequently elevated to a normal location on top of the coaming. Only a month after its appearance the first F.E.8 was wrecked in a crash in November, 1915, Service Trials in France being delegated to the next example which was completed in time to cross the Channel in December. Pilots who flew it liked the machine and their recommendations resulted in its immediate adoption for the R.F.C. Production, however, was unpleasantly slow in getting under way, six months passing before the first arrived to do battle over the Front. Alternative trial engine installations were the le Rhone and Clerget, both of 110 h.p., but any advantage in performance which they may have offered was of little benefit to a type which was out-dated by the time that it reached operational status.

Показать полностью

F.Mason The British Fighter since 1912 (Putnam)

R.A.F. F.E.8

Designed under the leadership of the Royal Aircraft Factory’s chief draughtsman, John Kenworthy, the F.E.8 was born shortly before the appearance of a successful British gun interrupter gear and was therefore, of necessity, a pusher biplane scout. Generally regarded as possessing more pleasing lines than the business-like Airco D.H.2, the F.E.’s performance was extraordinarily similar; like the D.H.2, production of the F.E.8 was spurred by the growing number of German fighting scouts over the Western Front.

The prototype F.E.8, possibly allotted the number 7456, was first flown in about October 1915, but crashed the following month; a second prototype, possibly 7457, was hurriedly constructed and rushed to France, where it was favourably commented upon - prompting the immediate raising of production sub-contracts with private manufacturers, namely the Darracq company and Vickers.

However, delays in establishing these production lines resulted in the F.E.8 not reaching fighter squadrons in France until June 1916, the first being two aircraft with No 29 Squadron at Abeele, commanded by Maj E L Conran. The first to be fully equipped with F.E.8s was No 40 Squadron which, commanded by Maj Robert Loraine (one of the original RFC pilots, and later Lt-Col, DSO, mc), arrived at St Omer in August.

It was in the late summer of 1916 that reports filtered back to the Factory that the F.E.8 was suffering a spate of spinning accidents, and that the aircraft was attracting an ill-reputation in this respect, being referred to as the ‘spinning incinerator’. It was quickly established that, although pusher aircraft tended to spin more readily from the stall, the F.E.8 possessed spinning characteristics not significantly different from other aircraft. The indefatigable Factory pilot, Maj Frank Goodden, deliberately spun an F.E.8 three times in each direction from no more than 3,500 feet, and recovered by applying the customary control movements. The fact was that RFC pilots were still not, in 1916, being instructed in spin recovery as a matter of routine during their flying training.

Nevertheless the F.E.8s clearly became outclassed in air combat within three months of their first arrival over the Western Front. Yet they continued in service, even though casualties increased sharply. No 40 Squadron was to suffer a disaster when, on 9 March 1917, nine F.E.8s were attacked by Jasta 11, led by Manfred von Richthofen. In a fight that lasted half an hour, eight of the British machines were forced down or destroyed, and the last aircraft crashed on landing.

The F.E.8 was ultimately withdrawn from operational service in July that year, when No 41 Squadron disposed of its aircraft in favour of Airco D.H.5s.

Type: Single pusher engine, single-seat, two-bay biplane scout.

Manufacturers: The Royal Aircraft Factory, Farnborough, Hants; The Darracq Motor Engineering Co Ltd, Fulham, London; Vickers Ltd (Aviation Department), Knightsbridge, London.

Powerplant: 100hp Gnome monosoupape rotary engine driving four-blade propeller (as standard); also 110hp Le Rhone and 110hp Clerget.

Dimensions: Span, 31ft 6in; length, 23ft 8in; height, 9ft 2in; wing area, 218 sq ft.

Weights: Tare, 895lb; all-up, 1,346lb.

Performance: Max speed, 94 mph at sea level; climb to 10,000ft, 17 min 30 sec; service ceiling, 14,500ft; endurance, 2 1/2 hr.

Armament: Prototype armed with remotely controlled 0.303in Lewis machine gun mounted low in the extreme nose of the nacelle. Production aircraft armed with spigot-mounted Lewis gun level with the pilot’s eyes.

Prototypes: Two; possibly Nos 7456 and 7457, built by the Royal Aircraft Factory, and first flown in about October 1915.

Production: 295 (245 by Darracq: Nos 6378-6477, A41-A65 and A4869-A4987; 50 by Vickers, Nos 7595-7644). Two aircraft, 3689 and 3690, were apparently allocated to the Admiralty but were probably not built.

Summary of Service: F.E.8s served with Nos 5, 29, 40 and 41 Squadrons, RFC, in France, and with various home-based training units.

Показать полностью

W.Green, G.Swanborough The Complete Book of Fighters

ROYAL AIRCRAFT FACTORY F.E.8 UK

Designed under the direction of John Kenworthy, the F.E.8 was the first single-seat fighter evolved as such at Farnborough, where the first of two prototypes was flown on 15 October 1915. Of pusher configuration to allow an uninterrupted forward field of fire for the 0.303-in (7,7-mm) Lewis gun, the F.E.8 was a two-bay equi-span biplane with a short fuselage nacelle to accommodate the gun, the pilot and a 100 hp Gnome Monosoupape nine-cylinder rotary engine, and four slender booms to carry the cruciform tail unit. Construction of the nacelle was of welded steel-tube with aluminium sheet covering; the wings and tail unit used conventional wooden spars and ribs with fabric covering. Trials with the second prototype in France in late 1915 led to a change in the gun installation, which was mounted within the nacelle nose and could be moved through a limited range by means of a control in the cockpit. Production F.E.8s, which began to appear in May and June 1916 from the factories of Darracq Motor Engineering at Fulham and Vickers at Weybridge, had a more practical gun mounting on the nose immediately ahead of the cockpit. Production totalled 220 by Darracq and 50 by Vickers. Service use by RFC squadrons in France began in August 1916, and, although soon obsolescent, the F.E.8 remained in service for a year, becoming the last single-seater of pusher configuration in general use. Trial installations of the 110 hp Le Rhone and 110 hp Clerget engines were made, but the Monosoupape remained the standard fit and the following data apply to this version.

Max speed, 94 mph (151 km/h) at sea level, 70 mph (113 km/h) at 10,000 ft (3050 m).

Service ceiling, 15,210 ft (4 636 m).

Endurance, 2.5 hrs.

Empty weight, 895 lb (406 kg).

Loaded weight, 1,346 lb (611 kg).

Span, 31ft 6 in (9,60 m).

Length, 23 ft 8 in (7,21m).

Height, 9 ft 2 in (2,79 m).

Wing area, 218 sq ft (20,25 m2).

Показать полностью

J.Bruce British Aeroplanes 1914-1918 (Putnam)

F.E.8

It has been said that the F.E.8 was inspired by the D.H.2. Certainly the two machines were similar in general appearance, but the design of the F.E.8 was begun in May, 1915, some months before the D.H.2 appeared. The Factory machine was much later in reaching the front, but that was no fault of the F.E.8, for the prototype was completed in October, 1915.

At that time, no satisfactory interrupter gear was available to British designers, and it was impossible to fit a forward-firing machine-gun to a tractor aeroplane without recourse to the crude expedient of applying steel deflector plates on the airscrew. Designers were therefore more or less compelled to resort to the pusher layout.

The F.E.8 was designed by Mr J. Kenworthy, and was one of the most handsome pusher fighters built during the war: it was a much better-looking aeroplane than the D.H.2. The very wide centresection was bounded on either side by the inboard pair of interplane struts, and was connected to the nacelle by a central cabane of two inverted vee struts. The tail-booms were attached to the extremities of the centre-sections, and converged in side elevation to the main spar of the tailplane. The fin and rudder were symmetrical about the tailplane, and the tail-skid was attached directly to the bottom of the rudder.

The engine was the 100 h.p. Gnome Monosoupape, and the prototype F.E.8 had a large pointed spinner fitted to the four-bladed airscrew. On the first machine, the Lewis gun was mounted low down in the nose with only a few inches of the barrel protruding, and was remotely controlled by the pilot. This arrangement gave rise to many difficulties, not least of which was the impossibility of clearing any stoppages, and in the production F.E.8s the gun was raised to the level of the pilot’s eyes. Spare ammunition drums were carried in external boxes on either side of the cockpit. The spinner was also discarded.

The F.E.8 was beset by several setbacks early in its career. The prototype crashed in November, 1915, and a second machine had to be hurriedly assembled from spare parts. It went to France in December for Service trials, and was immediately favourably received. Production was initiated without delay, but was severely hindered by difficulties with the contractors.

The first production F.E.8s in France were the two which were with No. 29 Squadron on July 1st, 1916, and the first F.E.8 squadron (No. 40) did not arrive on the Western Front until August, 1916. One Flight of the squadron reached France on August 2nd, and the remaining two Flights followed on August 25th. The only other unit to be completely equipped with the F.E.8 was No. 41 Squadron, which arrived in France on October 21st, 1916.

Soon after its introduction into the Service, the F.E.8 figured in a number of spinning accidents and might have acquired a reputation similar to that of the D.H.2 before it was properly understood. The phenomenon of spinning was still an unexplained mystery in 1916; and that provides the measure of the gallantry of that great pilot, Major Frank W. Goodden, who carried out spinning tests of the F.E.8 on August 23rd, 1916. He deliberately spun the machine three times in each direction from 3,500 feet, and each time regained full control by means of control movements which, decades later, were still being taught as the standard method of spin recovery.

With that unpleasant rumour scotched, the F.E.8 became quite popular with pilots, for it was a pleasant flying machine. It was tractable in the air, but rather stiffer on the controls than the D.H.2. Unfortunately, however, the F.E.8 was practically obsolete by the time it reached the front, and its pusher layout denied it the performance needed to meet contemporary German fighters.

On March 9th, 1917, nine F.E.8s of No. 40 Squadron were attacked by Jagdstaffel 11, led by Manfred von Richthofen. The fight lasted half an hour. Four F.E.8s were shot down and four others forced down damaged, whilst the pilot of the last machine was wounded. His F.E.8 caught fire before he landed, but he jumped clear just before the machine struck the ground.

Within a few weeks of this debacle, No. 40 Squadron was re-equipped with Nieuport Scouts; but with No. 41 Squadron the F.E.8 remained in service, the last pusher fighter in the field, until July, 1917. Among its last duties were trench-strafing sorties during the Battle of Messines in June, 1917.

The F.E.8 was also flown with the 110 h.p. Le Rhone and 110 h.p. Clerget engines, but the Monosoupape Gnome remained the standard power unit.

SPECIFICATION

Manufacturers: The Royal Aircraft Factory, Farnborough, Hants.

Other Contractors: The Darracq Motor Engineering Co., Ltd., Townmead Road, Fulham, London, S.W.6; Vickers, Ltd. (Aviation Department), Imperial Court, Basil Street, Knightsbridge, London, W.6 (production at the Weybridge works).� Power: 100 h.p. Gnome Monosoupape; 110 h.p. Le Rhone; 110 h.p. Clerget.

Dimensions: Span: 31 ft 6 in. Length: 23 ft 8 in. Height: 9 ft 2 in. Chord: 4 ft. Gap: 4 ft 6 in. Stagger: nil. Dihedral: 4. Incidence: 4. Span of tail: 10 ft 8-4 in. Wheel track: 5 ft 2 in. Airscrew diameter: 8 ft.

Areas: Wings: 218 sq ft. Tailplane: 14-5 sq ft. Elevators: 12 sq ft. Fin: 2-5 sq ft. Rudder: 6-5 sq ft.

Weights {lb) and Performance:

Engine Monosoupape Le Rhone Clerget

Date of Trial Report - April, 1916 -

Type of airscrew used on trial T.7928 T.7928 -

Weight empty 895 960 -

Military load 39 50 -

Pilot 180 180 -

Fuel and oil 232 280 -

Weight loaded 1,346 1,470 1,390

Maximum speed (m.p.h.) at

ground level 94 93-6 97

10,000 ft - 89 -

m. s. m. s. m. s.

Climb to

2,000 ft - - 2 10 - -

3,000 ft - - 4 15 - -

5,000 ft 7 30 - - - -

6,000 ft - - 8 20 - -

6,500 ft 11 00 - - - -

7,000 ft - - 10 10 - -

8,000 ft - - 12 10 - -

9,000 ft - - 14 00 - -

10,000 ft 17 30 17 15 - -

Service ceiling (feet) 14,500 - -

Endurance (hours) 21 - -

Tankage: Petrol: 29 gallons. Oil: 6 3/4 gallons.

Armament: One Lewis machine-gun on a bracket immediately in front of the cockpit.

Service Use: Western Front: R.F.C. Squadrons Nos. 5, 29, 40 and 41. Training: used at various training aerodromes, including No. 10 Reserve Squadron, Joyce Green and the Advanced Air Firing School at Lympne.

Production and Allocation: Serial numbers indicate that 297 F.E.8s were ordered, including the two prototypes which were built at the Royal Aircraft Factory in 1915. A total of 182 were delivered to the R.F.C.: of these, 147 went to the squadrons in France, two to Home Defence units in 1917, and the remainder to training units.

Serial Numbers: 3689-3690: allotted for F.E.8s, apparently for Admiralty. 6378-6477: built by Darracq. 7456- 7457: prototypes built by Royal Aircraft Factory. 7595-7644: built by Vickers. A.41-A.65. A.4869-A.4987 and A.5491: built by Darracq.

Notes on Individual Machines: Used by No. 40 Squadron: 6388, 6397, 6399, 6419, 6423, 6425, 6426, 6428, 6455, 6456, 6469, 7606, 7622 (also used by No. 41 Squadron), 7627, 7635, A.4871. Used by No. 41 Squadron: 6394, 6416, 6417, 6429, 6431, 6432, 6437, 6447, 6453, 6470, 6471, 7613, 7615, 7616, 7622 (also used by No. 40 Squadron), 7626, 7630, 7643, A.4870, A.4873, A.4915. Other machines: 6401: No. 10 Reserve Squadron. A.4944: Advanced Air Firing School, Lympne.

Показать полностью

H.King Armament of British Aircraft (Putnam)

F.E.8. It is sometimes contended that the F.E.8, which was first constructed in 1915 and remained operational until July 1917, was the last pusher fighter in British service, though that distinction appears more rightly to belong to the F.E.2d, which was serving with No.20 Squadron until the autumn of 1917. As with other pusher types, the object of the design was to obviate the use of deflector plates or synchronising gear. A single Lewis gun was initially installed low in the nose of the metal nacelle, with the barrel projecting through a circular hole. This arrangement permitted the gun to be trained over small arcs in conjunction with a sighting bar ahead of the windscreen, control being by means of a pistol grip. This position of the gun rendered difficult the clearing of stoppages and the changing of magazines, and on production aircraft the gun was raised to the level of the pilot's eyes. The form of pillar mounting has been described by Oliver Stewart as 'slightly different' from that of the D.H.2. As on the similar de Havilland fighter, the spare ammunition magazines were carried in 'panniers' at the sides of the cockpit. The magazines were four in number.

Показать полностью

Журнал Flight

Flight, September 6, 1917.

A "DE HAVILLAND" SINGLE-SEATER FIGHTER.

AN interesting illustrated description of a British biplane, appears in a German aeronautical contemporary, which we are now able to reproduce. The data relating to the "de Havilland," so described by our contemporary, are preceded by the following interesting and characteristic remarks :-

"It was difficult for the English constructors to produce a machine equal to the German aeroplanes, especially as regards the production of a single-seater fighter. The main desiderata in such a machine were high speed, maneuverability, climb and a free field for a machine gun in a forward direction. As English aeronautical engineering was somewhat backward, especially with regard to firing through the propeller, the construction of a tractor single-seater with the engine in front had to be discarded. The result was therefore necessarily a fighter, with the screw at the rear and an open framework carrying the tail, and it was the little de Havilland single-seater which was ordered in large quantities by the British Army. As our readers know, early in 1916 these machines were rushed to the English Front, where whole squadrons were smashed through accidents."

"The de Havilland single-seater consists, as the accompanying illustrations show, of a central portion of 3.5 metres span, to which the wings are attached at a dihedral angle. There are two pairs of inter-plane struts on each side. To the point where occur the first pair of struts the tail booms are attached. Ailerons of 3.31 metres length are fitted to both planes. The ailerons are held flush with the trailing edge by rubber cords on the upper surface. The power plant consists of a 100 h.p. monosoupape driving a four-bladed screw of 2.34 metres diameter. In front of the motor are the petrol and oil tanks and the pilot's seat, and in front of the seat is a pivot for the movable machine gun. The weight of the machine empty is 476 kilogrammes, and with 2 1/2 hours' fuel, pilot and machine gun, it is 722 kilogrammes. The loading is thus 35.6 kilogrammes per square metre. In spite of the great resistance of the wing bracing, the machine attains a speed of 150 kilometres per hour."

Chief Characteristics of "De Havilland" Fighter.

Power plant, 100 h.p. Gnome Monosoupape; fuel, petrol 120 litres, oil 22 litres. Area of planes (inclusive of ailerons): Top plane, 10.7 sq. m.; bottom plane, 9.6 sq. m.; total, 20.3 sq. m. Ailerons, 4 x 1.47 sq. m.; elevators, 1.19 sq. m.; rudder, 0.67 sq. m. Angle of incidence: Main planes, 4.5°; tail plane, 0.8°. Weight, empty, 476 kg.; useful load, 246 kg.; total, 722 kg. Armament, one movable machine gun.

Показать полностью