В.Кондратьев Самолеты первой мировой войны

СИМЕНС-ШУККЕРТ R-I / SIEMENS-SCHUCKERT R-I

Впервые столкнувшись на фронте с российскими гигантами "Илья Муромец", немцы еще осенью 1914 года предприняли попытку скопировать эту машину. Шведский инженер Форсманн на фирме Сименс-Шуккерт начал постройку четырехмоторного аэроплана, полностью повторявшего конструктивную схему аппарата Сикорского. Самолет прошел испытания в мае 1915-го, но был признан неудачным. 110-сильные двигатели оказались слишком слабыми, а выбранное Форсманном удлинение крыла - недостаточным для нормального полета.

В декабре 1914-го братья Франц и Бруно Штеффены на той же фирме спроектировали гигантский аэроплан совершенно иной, оригинальной схемы. Аппарат выглядел очень своеобразно: высокий фюзеляж с большой застекленной кабиной раздваивался в задней части наподобие ласточкиного хвоста. Сужающиеся к концам балки треугольного сечения соединялись между собой стойками и расчалками.

Три двигателя "Бенц" размещались внутри фюзеляжа и вращали посредством сложной системы передач два винта большого диаметра, установленные перед крыльями. Специальные муфты сцепления позволяли отключать любой из двигателей.

Каркас самолета выполнялся из дерева и тонкостенных стальных труб. Обшивка передней и центральной части фюзеляжа дюралевая, на остальных поверхностях - полотно. Экипаж - 4 человека: 2 пилота и 2 механика.

Аэроплан, названный "Сименс-Шуккерт" G-I, впервые поднялся в воздух в мае 1915 года. Позднее, в связи с появлением категории "R", самолет переименовали в R-I. Испытания показали, что летать он может, но технические данные (даже без бомб) были крайне низкими. Аппарат использовался только для экспериментов и учебных целей.

ДВИГАТЕЛИ

R-I - 3 Бенца" Bz.III по 150 л.с.

Показать полностью

O.Thetford, P.Gray German Aircraft of the First World War (Putnam)

Siemens-Schuckert Steffen R I

In December 1914 Siemens-Schuckert began construction of a series of seven "fork-tail" three-engined Giants designed by Bruno and Franz Steffen. All machines were generally similar, differing mainly in engine installation and wing span, as reference to data below will show. The fork-tail feature was to allow a clear field of fire to the rear. All three engines were mounted inside the nose, with facilities for minor repairs during flight; power was transmitted to two tractor airscrews through a series of shafts and gears.

R I. Serial R 1/15. Engines, three 150 h.p. Benz Bz III. Span. 28 m. (91 ft. 10 1/2 in.). Length, 17.5 m. (57 ft. 5 1/8 in.). Height, 5.2 m. (17 ft. 3/4 in.). Area, 138 sq.m. (1,490 sq.ft.). Weights: Empty, 4,000 kg (8,800 lb.). Loaded, 5,200 kg. (11,440 lb.). Speed, 110 km.hr. (68.75 m.p.h.). Climb, 2,000 m. (6,560 ft.) in 35 min. Duration, 4 hr. Notes: First flew May 1915, accepted July 1915. Tried at the Front, but not operational. Trainer only.

<...>

Показать полностью

G.Haddow, P.Grosz The German Giants (Putnam)

SSW R.I

In December 1914, after the agreement between SSW and the Steffen brothers was concluded, work began on the Steffen centrally-engined design eventually to be known as the SSW R.I 11/15. Because adequate space and man-power were available, it was decided to employ the facilities of the SSW-Dynamowerk in Berlin, and throughout the war this location remained the center of SSW R-plane activities. Work on the R.I proceeded swiftly, so that in early 1915 it was possible to ship the component parts to Neumunster for assembly. The Neumunster location was picked to keep the existence of the R.I secret, at least until after initial test flights.

The SSW R.I was the prototype of the Steffen-designed SSW R-planes, of which a total of seven were built. Later machines had the same configuration and differed only in size and detail. The R.I was the first German R-plane equipped with internally or centrally mounted engines. Although the Steffen brothers developed the central-engine concept prior to the existence of Idflieg R-plane specifications, it represented another solution to the problem of servicing the engines in flight.

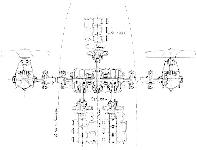

The three 150 h.p. Benz Bz.III engines chosen to power the R.I were mounted on engine bearers which formed a foundation for the forward fuselage section. Two engines were placed side by side in the extreme nose with their crankshafts facing aft. Each engine was connected to a common gearbox through a combination leather-cone and centrifugal-key clutch. The third engine, similarly connected, was mounted behind the gear-box on a lower level and facing forward. The purpose of the leather-cone clutch was to friction-start the propellers from a standing position. As soon as a certain number of revolutions were reached, the centrifugal-key clutch engaged automatically and the leather cone clutch was disengaged by the mechanic. If an engine were to slow down or stop the centrifugal clutch would automatically decouple below a certain minimum number of engine revolutions. The common gear-box was designed for minimum weight using the lightest possible gears. As a result, the gear-tooth pressures were fairly high. Although difficulties were experienced with the clutch system, the gear-box proved to be reliable and trouble-free when carefully serviced and attended in all of the Steffen-designed R-planes.

Two transmission shafts transferred the power from the gear-box to the propeller gear housings mounted on struts between the wings. Vibrations and misalignments were compensated by laminated spring couplings and universal joints.

Three slab-shaped radiators composed of a series of small tubes were fitted around the nose of the machine.

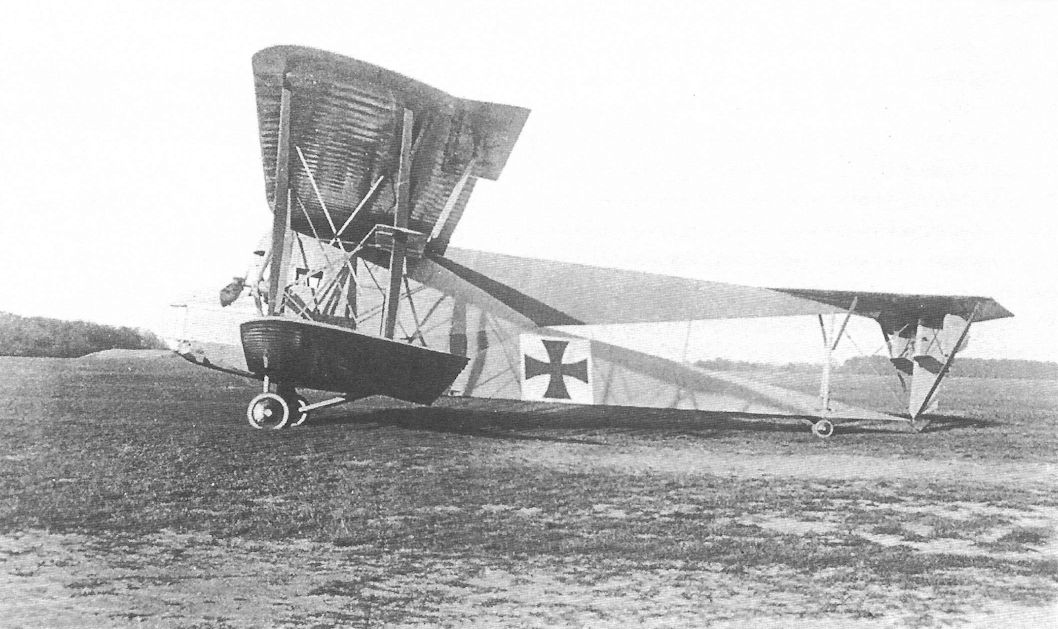

Externally the R.I and its successors possessed one unmistakable feature: a curious forked fuselage formed by two triangular, tapering tail booms. This configuration allowed a wide field of fire to the rear from beam-mounted machine-guns; although in the R.I the gun openings were paneled over. In 1916 SSW was granted a patent for a novel device to change the angle of incidence of the tail. By means of a large hand-screw the distance between adjacent apexes of the tail-boom triangles could be adjusted, resulting in a lowering or raising of the tail. This feature, however, was not employed, and it has not been determined to what extent it influenced the designers to use the split tail structure.

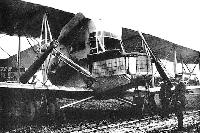

The fuselage completely filled the wing gap and descended abruptly at the wing leading edge to form a very high pilot's cabin commanding a fine view. At first the cabin was open, but later Cellon panels were fitted to the sides and top of the opening. The pilots' seats were situated above the central gear-box, and the third engine was located deep within the fuselage surrounded by two horizontal cylindrical fuel tanks. Possibly the open cockpit enclosure provided a means for flushing out vapors and heat generated by the buried engine. The clutch levers were mounted between the pilots, but on later machines the clutch was operated by the engine mechanic.

An upper gun position, located above and behind the pilots, consisted of an enclosed platform provided with a small access door. The R.I was delivered to early Idflieg specifications that called for 200 kg. armor for pilots and engines, but this requirement was dropped by Idflieg on 21 August 1915. The fuselage was constructed of wire-braced steel tubing covered with fabric, except in the nose section, where some duraluminium. panels were applied.

The three-bay wings were built entirely of wood with the exception of the internal wire bracing and the metal compression tubes between the spars. Ailerons were mounted on the upper wings only, but contrary to common practice, the controls actuated a small aerodynamic balancing surface mounted between the wings, which in turn controlled the ailerons.

A strut-braced triangular tailplane fitted with a one-piece elevator was affixed to the upper "prong" of the forked tail. The elevator was assisted by divided aerodynamic balancing surfaces in the same manner as the ailerons. The rudder was mounted between the "prongs" and was balanced by being hinged behind its leading edge and by small balancing surfaces.

The two separate undercarriage units consisted of a pair of wheels attached to two inverted V-struts which were fixed to the front and rear wing spars. A diagonal tube from the axle braced the undercarriage to the fuselage. The wheels were sprung by rubber shock cords, but an ingenious spring loaded double bell-crank device was also tried on the R.I. A small pair of steerable tail wheels took the place of the more usual tail skid.

Only a handful of men had flown aircraft with more than two engines when Bruno and Franz Steffen climbed behind the controls of the R.I to guide the machine on its maiden flight. It was a totally new experience for both men, and not knowing what to expect from such a large craft, their minds whirled with unanswered questions. However, as Bruno Steffen recalls, within a few minutes after taking off, they knew the R.I was a sound craft; it "sat" well in the air and showed no heaviness in any direction. Besides the tachometers, the brothers maintained a sharp watch on the gear-box thermometers which were climbing at a rapid rate. For safety's sake, they decided to land. The R.I. weighing 5 tons, landed with surprising ease, and as it rolled to a stop, Bruno and Franz Steffen looked at each other and smiled with relief. All previous anxieties of landing the heavy aircraft, a cause of worry to both men, had disappeared. This maiden flight took place on 24 May 1915.

The gear-box was dismantled to seek the cause for the overheating of the oil, and it was ascertained that the oil was too viscous to lubricate the gear teeth properly. The remedy consisted of installing a forced-circulation system and using a thinner grade of oil.

Next, a number of calibration flights were made to discover what the R.I could do. These embraced altitude flights made with varying loads, and in the final flight of the series the R.I reached an altitude of 3700 meters in 45 minutes carrying the specified load of 1200 kg. During speed trials at an altitude of 10 meters over a 5 kin. course, a top speed of 128 k.p.h was measured with full load.

One weakness discovered in the course of testing the R.I was the repeated failure of the propeller drive system due to vibration. In fact, a universal joint did snap at the far end of the transmission shaft. The engines were stopped in the nick of time to prevent the flailing shaft from causing fatal damage. The vibration problem was solved by adding stiffener tubes fore and aft of the transmission shafts. Other minor modifications were made to prepare the R.I for final acceptance flights.

These flights took place some time in June 1915, and the three-man Idflieg acceptance commission arrived at Neumunster to participate in a combined acceptance deliver flight. Bruno Steffen, as pilot, had purposely kept 600 kg. free in hopes of being allowed to carry seven passengers (some sources say nine). His wish was granted, and after the useful load and passengers were weighed and verified, the R.I took off for Doberitz. Steffen had placed two light armchairs in the cabin and hidden a bottle of champagne in a corner.

After take-off his sole attention was fixed on reaching the acceptance altitude in the specified time, not an easy task in the sultry and bumpy summer weather. As he fought to achieve altitude, he noticed clouds and lightning ahead over Lubeck. This did not escape the acceptance commission, who asked Steffen to please avoid the storm. Steffen answered that he was very sorry, but he had to achieve the required altitude. In a short while the answer came from the commission, who stated that they could see from the barograph that the R.I would reach the altitude in the specified time and therefore it was not necessary to do so ... but to please avoid the storm.

The trip to Doberitz was smooth, and after the champagne cork was popped the atmosphere aboard the R.I became positively gay. Bruno Steffen remembers the surprised look on the faces of the officers and flyers who greeted the R.I at Doberitz as one passenger after another deplaned with their luggage.

The R.I made some twenty-four test flights prior to delivery to the military services. During one of these the R.I made an emergency landing at Neukolln with Lt. Hohndorf at the controls (15 July 1915). The reason was engine trouble, but the R.I managed to take-off again in the evening. It was delivered to the air services on 26 July 1915.

A little-known fact is that the R.I was initially ordered as a G-type aircraft and was designated as the SSW G.I 31/15. On 13 July 1915 the designation was changed to G.I 32/15, and this was again changed to its final designation, R.I 1/15, on 6 November 1915.

Shortly after its delivery, the R.I was on a training flight piloted by Oberleutnant Krupp and Feldwebel Hebart with Bruno Steffen aboard as instructor when it crashed at Johannisthal. It had barely taken the air when one engine after the other failed, forcing the machine to drop from about 8 meters height. The lives of the five crew members were saved, but there was considerable damage to the R.I. The cause of the crash was traced back to foreign matter in the fuel tanks, which raised suspicions of sabotage. The date of this incident was August 1915, and the R.I was still under repair on 27 September 1915, but by 13 October 1915 the R.I was at Slonim attached to Feldfliegerabteilung 31. It did not carry out any bombing raids, for continual mishaps and technical problems made the R.I unsuitable for operational service.

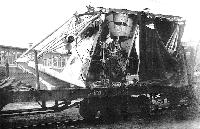

In March 1916 the R.I had been dismantled and placed on flatcars for shipment back to Berlin. The fuselage was wrecked in the old Spandau fortress due to lack of clearance caused by a slight shift of the railroad tracks. The fuselage was repaired and the R.I performed useful service as a trainer attached to the Training Section of the Rea at Doberitz from the middle of 1916 until 1918, possibly until the Armistice.

Parts of the indestructible R.I were preserved in a Berlin Museum until World War II, when they were completely destroyed by Allied bombers.

Built with no prior experience in constructing large multi-engined aircraft, the long lived R.I was a tribute to the sound engineering and technical know-how of the Steffen brothers and their associates at SSW. It is a fact that no other centrally-powered R-plane was as successful as the Steffen-designed R-planes, of which the R.I was the prototype, and no other R-plane can lay claim to such a long service record as that enjoyed by the robust R.I.

Color Scheme and Markings:

The R.I had an overall dull buff appearance. Large Patee crosses on white backgrounds were painted on the outer sides of the wings at half-span position. The fuselage markings were painted near the root of the lower boom. No markings were applied to the tail.

Manufacturer: Siemens-Schuckert Werke G.m.b.H., Siemensstadt, Berlin

Type: SSW R.I

Engines: Three 150 h.p. Benz Bz.III engines

Propeller Revolutions: 900 r.p.m.

Dimensions:

Span 28 m. (91 ft. 10 in.)

Length 17.5 m. (57 ft. 5 in.)

Height 5.2 m. (17 ft. 1 in.)

Areas:

Wings 138 sq. m. (1485 sq. ft.)

Weights:

Empty 4000 kg. (8820 lb.)

Loaded 5200 kg. (11,466 lb.)

Wing Loading: 37.6 kg./sq. m. (7.7 lb./sq. ft.)

Performance:

Max speed 110 km.h. (68.4 m.p.h.)

Climb 2000 m. (6562 ft.) in 35 mins.

Ceiling 3700 m. (12,139 ft.) in 45 mins.

Duration 4 hours

Range 520 km. (323 miles)

Service Use: Eastern Front 1915-16 and training duties 1916-18

Cost: 100,000 marks

Показать полностью

J.Herris Siemens-Schuckert Aircraft of WWI (A Centennial Perspective on Great War Airplanes 12)

SSW R.I

In 1908 the Steffen brothers, Bruno and Franz, founded the Steffen aircraft works in Neumunster (near Kiel). After first building one airship, they built a series of airplanes, and in one of those, the Falke, Bruno Steffen broke the German endurance record in 1913. Additionally, they also operated a successful flying school. Despite their relative aviation success, they were called to serve in the army upon outbreak of war. Moreover, lack of capital also precluded further independent development, and in December 1914, after release from their regular military duties, the brothers joined SSW. The Steffens immediately started designing the SSW R.I, which made its first flight in May 1915.

The brothers decided that a design with centralized engines offered several important advantages. Concentrating the weight near the center of gravity would make the aircraft more maneuverable and, most importantly, the engines would be accessible to on-board mechanics during flight should repairs be needed. They also expected drag would be reduced, propeller efficiency would be improved, and the ability to shut down an engine in flight would extend range and endurance.

Another critical factor at the time was lack of ability to feather a propeller. To feather a propeller means to turn the propeller blades of an inoperative engine into the wind to stop rotation and reduce the drag as much as possible. This requires a controllable propeller having a pitch-change mechanism to rotate the propeller blades into the wind upon engine failure. However, such a propeller was not available during WWI; the propellers available were all fixed pitch. Upon engine failure, a fixed-pitch propeller continues to rotate as the aircraft's speed pushes the propeller forward, and such a 'wind-milling' propeller creates drag approximating that of a parachute of the same diameter. The result was that twin-engine aircraft and some multi-engine aircraft could not maintain flight after engine failure and a wind-milling propeller. Without a controllable propeller that could be feathered upon engine failure, centralizing the engines and using a clutch to decouple a failed engine from the propellers was one way to avoid a wind-milling propeller in case of engine failure. For this reason many R-planes were designed with central engine arrangements, and the SSW R.I was the first of these.

Originally designated SSW G.31/15, (G for Grossflugzeug [large aircraft]), the designation was changed to SSW G.I 32/15 and finally to SSW R.I 1/15 on November 6, 1915. The SSW R.I was a distinctive biplane with three 150 hp Benz Bz.III engines grouped together in the center fuselage. The engines were connected to a common gearbox via clutches. Two engines were mounted side by side in front of the gearbox on steel engine bearers that were part of the airframe, while the third engine was mounted behind and below it. Unfortunately, the clutch system of the R.I did not enable the mechanic to disengage a failed engine. The gearbox was reliable but there were issues with the clutch and transmission system. Three radiators were fitted around the nose.

The crew included a pilot, an aircraft commander acting as reserve pilot, two gunners, and one mechanic. The fuselage was unique; two triangular tail booms supported the rudder and tailplane. This provided a good field of fire to the rear, but the position was covered with fabric in the R.I. The pilot's cabin was open in front because the pilots insisted on feeling the wind in flight to help them control the airplane. This is not as odd as might be supposed given the limited flight instrumentation of the time; pilots depended on their senses, including the feel of the wind, the sound of the engines and the wind through the wires, etc., for important feedback on aircraft performance.

An upper gun position was located behind the pilots' seats, which were themselves located above the gearbox. This position was an enclosed platform with an access hatch. A ventral gun position was located between the robust landing gear assemblies; the gunner was prone and fired downward toward the rear. In addition to these machine gun positions, the aircraft commander and mechanic were given repeating carbines to help defend against attack. These were not very effective and were most useful as a morale booster.

The three-bay wings were built of wood and the fuselage was built of steel tubing; both were fabric-covered. Some aluminum panels partially covered the nose. Armor plating weighing 200 kg was originally specified but the armor was eliminated by Idflieg. To reduce the pilot's control forces the pilot controlled small auxiliary ailerons that in turn actuated the ailerons mounted on the upper wing. The rudder and elevators were similarly assisted by servo controls.

The R.I was built at the SSW Dynamowerk in Berlin, but the aircraft was disassembled and moved to the Steffens' facility in Neumunster for flight trials for secrecy. Piloted by the Steffen brothers, the R.I first flew on May 24, 1915, only five months after starting the design. The R.I proved to be stable and easily maneuverable, according to one pilot not unlike a typical two-seater.

The first flight was terminated early due to excessive gearbox oil temperature. Installation of forced oil circulation and switching to a lighter grade of oil remedied that problem. Failures of the u-joints in the propeller drive shafts occurred due to vibration; these were remedied by adding stiffener tubes fore and aft.

The R.I had a maximum level speed of 128 km/hr with full load and could maintain level flight on two engines with the third at idle. With only one engine running the R.I could glide 50 km starting from an altitude of 2,000 meters.

In June 1915 the R.I passed its acceptance flight while carrying seven passengers. Before final delivery to the Fliegertruppe on July 26 an additional 24 training and orientation flights were completed. During one of them, with Lt. Walter Hohndorf piloting, an engine problem forced an emergency landing, but the problem was quickly repaired and the flight was continued the same evening.

During a training flight in early August all three engines failed one after the other on take-off at only 8 meters altitude, resulting in a crash landing and severe damage to the R.I. Fortunately, the crewmen escaped injury. The cause was determined to be foreign matter in the fuel tanks that blocked fuel flow to the engines. The factory repaired the R.I and it flew again in late September, at which time it was sent to the Eastern Front for operational evaluation. At Warsaw the R.I had to be parked in the open in heavy rain. The wings absorbed gallons of rainwater and the R.I would not take off the next morning until the water was drained. Continuing on, the starboard transmission coupling broke and the R.I had to be sent back to Doberitz for repair on October 15. The R.I was returned to the Eastern Front but no bombing raids were undertaken due to continuing unreliability. It was feared the aircraft would be forced down in enemy territory. In March 1916 the R.I was dismantled and shipped back to the SSW factory in Berlin. Unfortunately, due to clearance problems it was damaged during transport.

In June 1916 SSW completed repairs to the R.I, after which it was assigned to train R-plane crews at Doberitz. A year-end report of 1917 by the REA (Riesenflugzeug Ersatz Abteilung - giant aircraft replacement unit) described the R.I as larger and heavier than before, possibly due to modifications during its factory repairs.

During 1917 the R.I performed 97 training flights and 26 orientation flights, an excellent record for this complex, early R-plane that was still in training service in late February 1918.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

Показать полностью

M.Dusing German Aviation Industry in WWI. Volume 2 (A Centennial Perspective on Great War Airplanes 85)

Siemens-Schuckert-Werke, Abt. Flugzeugbau, Siemensstadt b. Berlin (SSW)

Aircraft Development:

Siemensstadt:

<...>

After the outbreak of World War I, the aircraft designers Villehad Forssmann and the Steffen brothers from Neumunster offered their experience and plans to the SSW. Since the army administration also suggested a resumption of aircraft construction, an aircraft department was set up at the Siemens-Schuckert dynamo plan under the direction of Prof. Reichel. Forssmann immediately began designing a four-engine R airplane, while Franz Steffen went to work on an R airplane with a central engine system, in which the Idflieg was very interested.

Forssmann left at the beginning of 1916, after engineer Harald Wolff had previously taken over as head of the design office.

Under the leadership of Professor Reichel, Forssman began designing a four-engine R airplane as early as the end of 1914, while Franz Steffen turned his attention to an R airplane with a central engine arrangement and a split fuselage. After various modifications, both aircraft were accepted by the Army Administration. The design developed by Franz Steffen was used for series production.

<...>

Показать полностью