D.James Westland aircraft since 1915 (Putnam)

Wagtail

Although the Royal Air Force had not been founded until 1 April, 1918, during the last few months of the 1914-18 War a number of new single-seat fighters designed to meet the RAF Type I Specification were nearing completion. Among those companies producing prototypes was Westland whose small design team, led by Robert Bruce and Arthur Davenport, had been considering the design of a small fighter during the latter half of 1917. One of the requirements of the outline Type I Specification for a light fighter was that it should have an engine delivering 50 hp more than the 130 hp Clerget rotary engine in the Sopwith Camel. This increase in power, plus the smaller size implicit in the 'light fighter' description, was aimed at producing a performance which would exceed that of the Camel, both in terms of maximum speed and rate of climb, with improved handling characteristics.

At about the time when this specification was issued the Air Board was examining a recently-introduced experimental seven-cylinder air-cooled radial engine. Designed by Granville Bradshaw who had founded ABC Motors, the successor to ABEC (All British Engine Company), it weighed 290 lb, was of 657 cu in capacity and produced 170 hp. Named Wasp, it was engineered throughout for easy production; however, one of its design features, which was the use of copper-plated steel cooling fins on the cylinders, was to contribute to its future unreliability. It was this engine which the Westland design team had in mind for possible use in its private venture light fighter, provisionally known as the Hornet, and which was to power it when built as the Wagtail.

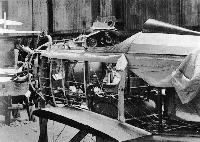

Of conventional external appearance and construction, the Wagtail had a wooden girder type fuselage. rectangular in section for most of its length, with light wood fairings to provide shape. Spruce longerons of square-section were employed with staggered vertical and horizontal spacer struts tapering to fit into square cups in light steel fittings bolted to the longerons. These fittings also carried attachment lugs for the swaged rods which braced each bay of the fuselage structure. The braced tailplane and fin were of similar wooden construction while the elevators and rudder were of metal. The rear fuselage aft of the cockpit, which was located under the upper wing trailing-edge, was fabric covered and removable fabric covered panels enclosed the cockpit and the forward fuselage, wire-braced engine mounting ring with four attachment plates was carried on inwardly curved extensions of the longerons with the entire nose and engine having removable metal top and side panel and a metal cowling through which the Wasp's seven cylinders protruded. Inverted-V main undercarriage legs of spruce carried a cross-axle with bungee rubber shock absorbers and a curved tailskid was mounted below the tailplane leading-edge. The main spars of the constant-chord single-bay wings were of ash with cross-braced drag struts and the spruce ribs of RAF 15 aerofoil section were built up from three-ply webs with spruce capping strips.

The Type I Specification stressed the need for a good all-round view for the pilot; thus the flat wide-span upper centre-section - a feature to minimise the spar bending moment - had a large trailing-edge semi-circular cut-out above the cockpit, and was supported on two pairs of outwardly-canted struts. Constant-chord wide-span ailerons were carried on both the upper and lower wings which, in the prototype Wagtail, C4291 , had the same 2 1/2 deg dihedral and were wire-braced. The wings and tail unit were fabric-covered. In this aircraft too the fin had a long dorsal extension well in front of the tailplane leading-edge. Control wires to the ailerons and rudder ran inside the wings and fuselage but were carried externally to the elevator. Fuel was carried in a 26 gal fuselage-mounted tank in front of the cockpit, two synchronised Vickers .303 in guns were mounted on top of the fuselage and oxygen equipment was located in the cockpit.

Originally six Wagtails were ordered by the Air Board and allocated the serials C4290-96 but the contract was later reduced to three aircraft, C4291-93. Construction of the first Wagtail airframe was completed by the end of February 1918 with production of two more, C4292 and 4293, well in hand; however C4291's Wasp engine was still awaited from the manufacturer. During this period Capt F Alexander, Royal Flying Corps, was attached to Westland Aircraft Works to fly the Wagtail. With operational experience he believed that the cut-out in the prototype's centre-section should be larger. Because a modification at that stage would have delayed the first flight, a re-designed centre-section was first fitted, as a trial installation, to the incompleted third aircraft. The three central rib aft of the front spar and the centre-section trailing-edge were removed leaving a wide aperture spanned only by the nosing and the rear spar. This new centre-section was mounted six inches lower than on the prototype and in order to use the same length faired tubular steel interplane struts and bracing wire, the lower wings were re-rigged flat and the upper wings given 5 deg dihedral. While the modified centre-section improved the pilot's view, what was not quantifiable or immediately recognisable was the effect the loss of wing area had upon wing lift and air flow disturbance.

The first flight date of 4291 has not been established; however, it is known that it took place early one morning in April 1918, and that the Wagtail's handling characteristics were such that they inspired apt Alexander to execute a loop. This test flight also suggested that there was insufficient rudder area to counteract the nose-down effect of the fin in a side-slip; in order to minimise the time and cost involved in building a larger rudder, it was decided to cut back the fin to about half of its length. Meanwhile, work on fitting the modified centre-section and fin to the second and third aircraft was in progress.

Within a week or so the first of many engine snags, which were to plague the Wasp, were encountered and it was removed from C4291 for return to the manufacturer. Much of the trouble stemmed from valve and cylinder design and cooling. When C4291 's engine was returned to Yeovil it was fitted to the second Wagtail, C4292, which had the modified centre-section and wings and was nearer completion than the third airframe. With this engine test flying was resumed on 29 April; but soon afterwards this Wagtail was badly damaged while in a canvas Bessoneaux hangar at Yeovil which had caught fire when an employee had been endeavouring to prove that he could extinguish a lighted cigarette in a can of petrol!

With the arrival of two more Wasp engines the third Wagtail was quickly completed, enabling it to fly early in March, and work on modifying the prototype's centre-section and fin was pressed forward. On 8 May C4293 was flown to the Aircraft Experimental Establishment at Martlesham Heath for 'fighter trials' with a number of different propellers. Unfortunately, after a badly executed landing on 18 May, the Wagtail nosed over on rough ground damaging the engine and undercarriage. After repairs this aircraft was transferred to the Royal Aircraft Factory at Farnborough on 27 May, only a few days before it was renamed Royal Aircraft Establishment, a name it was to retain for the ensuing 70 years. There it was used by the RAE and ABC to investigate the source of the Wasp's problems; but the programme was short-lived for two weeks later all trials of Wasp-powered aircraft - which included the Sopwith Snail and the BAT Bantam - were halted. However, it is recorded that, in July 1918, C4293 was at Martlesham Heath for 'motor trials' but for how long is not known.

The prototype Wagtail, meanwhile, had been re-engined and the airframe modifications had been embodied. It flew again at about the same time that Wasp investigations ceased; nevertheless it went to the RAE thereafter and is recorded as having been at Martlesham Heath during August for evaluation against other fighters, presumably the Camel, Snail and Bantam. Then, on 6 November it went to the Aircraft Armament and Gunnery Experimental Establishment at Orfordness for gun firing trials. By this time not only was the War finished but all flying trials with Wasp-powered light fighters had been terminated and production of this engine been cancelled. Nevertheless, like Charles II, the Wagtail/Wasp combination was 'an unconscionable time dying' and on 29 January, 1919, the rebuilt airframe of the second aircraft, C4292, arrived by road at Martlesham Heath where it was to remain at least until 1920.

In spite of numerous problems with the Wasp, ABC continued to develop this engine and one of the Wagtails is reported to have flown with a 200 hp Wasp II. But this was not the end of Wagtail production for in 1920 two more Wagtails were ordered, powered by the new 150 hp Armstrong Siddeley Lynx seven-cylinder air-cooled radial engine. Serialled J6581 and J6582, airframe modifications included shortening the fuselage by removing the metal-panelled bay aft of the engine to maintain the centre of gravity with the heavier Lynx, changing the shape of fin and rudder to a 'comma' shape and fitting a stronger main undercarriage to suit the increased all-up weight. These two aircraft were flown at the RAE and at Martlesham Heath until about 1922, some record indicating that at least one, J6582, having also been powered by a Wasp II.

Description: Single-seat light biplane fighter. Wood/metal construction with fabric and metal covering.

Accommodation: Pilot in open cockpit.

Powerplant: One 170 hp ABC Wasp seven-cylinder air-cooled normally-aspirated radial engine driving a two-blade 7 ft 4 in diameter wooden propeller.

Armament: Two fixed synchronised Vickers .303 in machine-guns mounted on top of the fuselage, with 1,000 rounds of ammunition.

Dimensions: Span 23 ft 2 in: length 18 ft 11 in; height 8 ft 0 in; wing area 190 sq ft.

Weights: Empty 746 lb; loaded 1,330 lb.

Performance: Maximum speed at 10,000 ft 125 mph; landing speed 50 mph; climb to 5,000 ft in 3.5 min, to 17,000 ft in 17 min; service ceiling 20,000 ft.

Production: Five Wagtail built by Westland Aircraft Work, Yeovil, Somerset, during 1917-20.

Показать полностью

P.Lewis The British Fighter since 1912 (Putnam)

Westland’s contribution to the series of R.A.F. Type 1 prototype fighters was provided by their design team of Bruce and Davenport and appeared in 1918 as the Wagtail. An appealing and shapely little biplane of 23 ft. 2 in. span, it mounted the 170 h.p. A.B.C. Wasp 1 engine, a unit which was one of the troublesome radials of the last part of the 1914-18 War. Construction of the Wagtail followed the usual form for a wood and fabric biplane but in its finely-conceived and balanced proportions the machine possessed an attractiveness matched by few others. Two Vickers guns on the front decking provided the Wagtail’s firepower and its maximum speed at 10,000 ft. was 125 m.p.h. Five were constructed but as prototypes only.

Показать полностью

F.Mason The British Fighter since 1912 (Putnam)

Westland Wagtail

Designed under the leadership of Robert Bruce and Arthur Davenport, the Westland Wagtail was a private venture essay in the light fighter concept, undertaken during the winter of 1917-18 and shortly afterwards submitted to meet the new Type IA Specification which called for an aircraft to be powered by a 180hp engine, and returning better performance and handling than the Sopwith Camel - which at that time was expected to be phased out of service in 1919.

Almost simultaneously the new 170hp ABC Wasp I seven-cylinder radial engine appeared and, from the outset, attracted considerable interest among aircraft designers on account of its relatively high power/weight ratio of 0.59 bhp/lb. The Wagtail was accordingly designed for this engine. Its structure was strictly orthodox with wooden boxgirder fuselage with spruce longerons and curved upper decking provided by fairings and stringers. Twin ash spars and spruce ribs of RAF 15 section provided the structure of the moderately staggered wings, with upper and lower ailerons. The cockpit was located approximately above the mid-chord line of the lower wing, while the upper wing was generously cut away both between the main spars and on the trailing edge. Twin synchronized Vickers guns were mounted, widely separated, on the nose.

Six prototype Wagtails, C4290-C4295, were ordered by the Air Board in February, principally to conduct engine trials with the new Wasp engine (which was already encountering serious mechanical faults). The fuselage of the first airframe was employed for structural tests - possibly at Farnborough. This order was reduced to three flying prototypes, C4291-C4293, late in March, this despite the fact that all five remaining airframes were well advanced.

First flight of the Wagtail C4291 was made by Capt F Alexander RFC in April 1918, after which the aspect ratio of the fin was reduced, and this modification was introduced on the other two prototypes. The second Wagtail also flew before the end of April, but was extensively damaged when its Bessoneaux hangar was burned down in the famous fire caused when an employee endeavoured to prove that it was possible to extinguish a lighted cigarette by dropping it into a tin of petrol. C4293 was delivered to Martlesham Heath on 8 May for trials, but was damaged in a landing accident there; hurriedly repaired, it was flown to Farnborough for investigation into the engine problems. A fortnight later, however, work was suspended on Wasp-powered aircraft while the manufacturers undertook a redesign of the copper-finned cylinders and of the valve gear.

The second Wagtail, C4292, was rebuilt and fitted with a 200hp Wasp II (with steel-finned cylinders), only to be struck off charge at Martlesham Heath in February 1920. Later that year, two further Wagtails, J6581 and J6582, were ordered and, although these used many components of the two cancelled airframes (C4294 and C4295), the new prototypes differed somewhat from the earlier aircraft. Both were fitted with Wasp II engines at Farnborough in March 1921, before having 150hp Armstrong Siddeley Lynx seven-cylinder radial engines installed. Because of this engine’s greater weight, a nose bay was removed, thereby shortening the nose but maintaining the aircraft’s centre of gravity within limits. A revised fin replaced the former truncated surface, and a strengthened undercarriage was fitted. In this form J6581 was first flown on 15 September 1921, and was followed by J6582 on 7 October. Both aircraft were grounded and struck off charge in August 1922.

Type: Single-engine, single-seat, single-bay biplane light fighter.

Manufacturer: The Westland Aircraft Works, Yeovil, Somerset.

Air Ministry Specification: RAF IA of 1918 (later D of R Type I)

Powerplant: One 170hp ABC Wasp I seven-cylinder air-cooled radial engine driving two- blade propeller; later 200hp Wasp II, and 150hp Armstrong Siddeley Lynx.

Structure: All-wood primary construction with fabric covering; steel elevator and rudder.

Dimensions: Span, 23ft 2in; length, 18ft 11in; height, 8ft 0in; wing area, 190 sq ft.

Weights: (Wasp I). Tare, 746lb; all-up, 1,330lb.

Performance: (Wasp I). Max speed, approx 130 mph at sea level, 125 mph at 10,000ft; climb to 10,000ft, 7 min 30 sec; service ceiling, 20,500ft; endurance, 2 1/2 hr.

Armament: Two synchronized 0.303in Vickers Mk I machine guns on nose with 1,000 rounds of ammunition.

Prototypes: Six ordered, C4290-C4295; C4290 used for ground tests; C4291-C4293 built and flown (C4291 first flown by Capt F Alexander in April 1918); C4294 and C4295 cancelled, but their components were used in two further prototypes, J6581 and J6582 (first flown with Lynx engines on 15 September 1921).

Показать полностью

W.Green, G.Swanborough The Complete Book of Fighters

WESTLAND WAGTAIL UK

A contemporary of the Sopwith Snail and the BAT Bantam, the Wagtail was similarly designed to comply with the A.1(a) Specification drawn up by the Air Board in 1917 to define its requirements for a single-seat fighter. Emphasis was to be placed upon manoeuvrability and climb, with the ability to achieve 135 mph (217 km/h) at 15,0 ft (4 570 m) when carrying oxygen equipment and three machine guns. Like its competitors, the Wagtail was powered by the 170 hp ABC Wasp I seven-cylinder radial, an engine that eventually thwarted further development of all three A.1(a) types. A well-proportioned, diminutive single-bay biplane, the Wagtail gained a contract for three prototypes late in 1917, and the first was flown in April 1918. Construction was of fabric-covered wood, with metal-framed rudder and elevators, and two synchronised 0.303-in (7,7-mm) Vickers guns were fitted. An overwing Lewis gun was planned, but not fitted to the prototypes. Whereas the first Wagtail to fly had equal dihedral (2 deg 30 min) on upper and lower wings, the second and third were completed (and the first later modified) to have a larger cutout in the upper wing centre section with 5 deg of dihedral on the outer panels of the upper wing and a flat lower wing. Destroyed in a fire at Yeovil soon after its first flight on 29 April 1918, the second Wagtail had to be replaced later that year; the third went to Martlesham Heath on 8 May, but problems with the Wasp limited flying. In October 1918, the engine was officially abandoned, and with it any plans to produce Wasp-engined aircraft. Two more Wagtails were ordered from Westland in 1919, to serve as test-beds for the 160 hp Armstrong-Siddeley Lynx seven-cylinder radial engine. Unarmed, these two aircraft were delivered to the RAE in September/October 1921. The following data for the Wasp-engined Wagtail include performance estimates.

Max speed, 125 mph (201 km/h) at 10,000 ft (3 050 m).

Time to 5,000 ft (1 525 m), 3.5 min.

Endurance, 2.5 hrs.

Empty weight, 746 lb (338 kg).

Loaded weight, 1,330 lb (603 kg).

Span, 23 ft 2 in (7,06 m).

Length, 18 ft 11 in (5,77 m).

Height, 8 ft 0 in (2,44 m).

Wing area, 190 sq ft (17,65 m2).

Показать полностью

J.Bruce British Aeroplanes 1914-1918 (Putnam)

Westland Wagtail

THE dainty little Wagtail was a single-seat fighter intended to operate at high altitude. Work on the design began in 1917, and the machine was designed around the new A.B.C. Wasp I radial engine of 170 h.p.

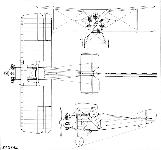

The first Wagtail appeared in 1918. It was a tiny equal-span biplane with fine lines and typical of its period as far as construction was concerned. The single-bay wings were slightly staggered, and originally the upper and lower wings were rigged with equal dihedral. The upper centre-section was fairly wide, and had a hole cut in it to improve the pilot’s upward view. The tail-unit was completely conventional, and the undercarriage was a simple vee structure. Sopwith practice was reflected in the use of a divided axle and independent springing (by means of the usual rubber cord) for each wheel.

The Wagtail was as manoeuvrable and manageable as it looked. On its first test flight, the test pilot (Captain Alexander) was so pleased with the little fighter’s flying qualities that he looped it.

The aircraft underwent some slight but noticeable modification. The rigging of the wings was altered: the upper wings were given five degrees of dihedral whilst the lower mainplanes were quite flat. This brought the centre-section closer to the fuselage and, in order to preserve the pilot’s forward and upward view, the size of the aperture in the centre-section was greatly increased and the entire trailing portion was removed.

A very practical feature of the Wagtail was the installation of the two Vickers guns where their breech mechanisms lay on either side of the cockpit: the pilot was therefore able to reach his guns easily when it was necessary to clear stoppages. In view of the Wagtail’s designed function as a high-altitude fighter oxygen equipment was installed.

Like the B.A.T. Bantam, the Wagtail suffered from the caprices of its A.B.C. Wasp engine, and the Armistice stopped development of the type. In the post-war years a Wagtail was experimentally fitted with an Armstrong Siddeley Lynx engine, presumably to air-test the power-unit. This aircraft had a shorter nose and a strengthened undercarriage.

SPECIFICATION

Manufacturers: The Westland Aircraft Works, Yeovil, Somerset.

Power: 170 h.p. A.B.C. Wasp I.

Dimensions: Span: 23 ft 2 in. Length: 18 ft 11 in. Height: 8 ft. Chord: 4 ft 6 in. Gap: originally constant at 4 ft 6 in.; later reduced to 4 ft at centre-section, 4 ft 6 in. at interplane struts. Stagger: 1 ft 6 in. Dihedral: originally 2° 30' on both mainplanes; later 5° on upper mainplane, nil on lower. Incidence: 2°. Span of tail: originally 9 ft, later reduced to 7 ft 10 3/4 in. Wheel track: 4 ft 8 in. Airscrew diameter: 2,590 mm (8 ft 6 in.).

Areas: Wings: 190 sq ft. Ailerons: each 6 sq ft, total 24 sq ft. Tailplane: originally 18-6 sq ft, later 15-5 sq ft. Elevators: originally 12-8 sq ft, later 9-5 sq ft. Fin: originally 3 sq ft, later 2-1 sq ft. Rudder: originally 3-3 sq ft, later 4-4 sq ft.

Weights: Empty: 746 lb. Military load: 185 lb. Pilot: 180 lb. Fuel and oil: 219 lb. Loaded: 1,330 lb.

Performance: Maximum speed at 10,000 ft: 125 m.p.h. Climb to 5,000 ft: 3 min 30 sec; to 10,000 ft: 7 min 30 sec; to 17,000 ft: 17 min. Endurance: 2 1/2 hours.

Tankage: Petrol: 26 gallons. Oil: 3 gallons.

Armament: Two fixed, forward-firing Vickers machine-guns mounted above the fuselage and synchronised to fire through the airscrew. Ammunition: 1,000 rounds. The original design envisaged the use of a Lewis gun mounted above the centre-section.

Production: Five Wagtails were built.

Serial Numbers: C.4291-C.4295, ordered under Contract No. 41838/1/17.

Показать полностью

H.King Armament of British Aircraft (Putnam)

Wagtail. A light single-seat lighter of 1918, the Wagtail earned its two Vickers guns externally immediately forward of the cockpit sides. The case chutes were very low in the fuselage in metal panels let in to the fabric covering and were canted down at an angle of about 45 degrees to the line of flight. The windscreen had a hole on the starboard side to receive the eyepiece of the Aldis sight. On the centre line was a ring-and-bead sight, with the bead immediately ahead of the windscreen. Westland gave the weight of' 'two guns, gear and 1,000 rounds' as 160 lb.

Показать полностью

Jane's All The World Aircraft 1919

The Westland "Wagtail" was designed in answer to a general demand for a fast, quick-climbing, general utility single-seater fighter.

It conforms in general arrangement with most other machines of this type.

The pilot's view is very good both upward and downward, more than half the centre section being left open. Main planes of equal span are fitted, the upper plane having a dihedral of 5 degrees, whereas the lower plane is flat, i.e., no dihedral.

THE WESTLAND "WAGTAIL."

Specification.

Type of machine Single-seater Tractor Scout.

Name and type No. of machine Westland "Wagtail."

Purpose for which Intended High altitude fighting.

Span 23 ft. 2 in.

Gap maximum At outer strut 4 ft. 6 in.

minimum Centre section 4 ft.

Overall length 18 ft. 11 In.

Maximum height 8 ft.

Chord 4 ft 6 in.

Total surface of wings 190 sq. ft.

Span of tail 7 ft. 10 3/4 In.

Total area of tall, incldg. elevators 25 sq. ft.

Area of elevators 9.5 sq. ft.

Area of rudder 4.4 sq. ft.

Area of fin. 2.1 sq. ft.

Area of each aileron 6 sq. ft.

Total area of ailerons 24 sq. ft.

Maximum cross section of body 7.1 sq. ft.

Horizontal area of body 29.3 sq. ft.

Vertical area of body 36.5 sq. ft.

Engine type and h.p. 170 b.h.p."Wasp" Fixed Radial.

Airscrew, diam., pitch and revs. Pitch 2070 m/m., diam. 2590 m/., revs. 1,900.

Weight of machine empty 965 lbs. (Including 219 lbs. for fuel and oil).

Weight of machine empty 746 lbs. (without fuel and oil)

Load per sq. ft Fully loaded 7 lbs.

Weight per h.p. 7.7 lbs.

Tank capacity In hours 2 1/2 hours at 15,000 feet.

Tank capacity In gallons Petrol 26 galls.; oil 3 galls.

Performance

Speed at 10,000 feet 125 m.p.h

Landing speed 50 m.p.h.

Climb.

To 5,000 feet 3 1/2 minutes.

To 10,000 feet 7 1/2 minutes.

To 17,000 feet 17 minutes.

Disposable load apart from fuel 365 lbs

Pilot 180 lbs

Two guns, gear & 1,000 rounds 160

Oxygen 25

Total weight of machine loaded 1,330 lbs.

Показать полностью

C.Owers British Aircraft of WWI. Vol.7: Experimental Fighters Part 3 (A Centennial Perspective on Great War Airplanes 81)

The Westland Wagtail

In 1917 the Air Board issued their Type A.1(a) Specification for a light fighter with an engine of 50 hp more than the 130-hp Clerget rotary engine that was fitted to the Sopwith Camel. The specification stressed the need for a good all-round view for the pilot and armour behind the pilot. Oxygen equipment was to be installed as high-altitude fighting was part of the specification. The maximum speed was to be not less than 135 mph at 15,000 feet, with an armament of twin Vickers machine guns with 250 rounds of ammunition. It was hoped to produce a machine that would be faster than the Camel and, hopefully, as manoeuvrable. Westland, like Sopwith with their Snail and BAT with their F.K.23 Bantam, considered the A.B.C. 170-hp seven-cylinder air-cooled Wasp radial engine as the power plant for their proposed scout to meet the A.1(a) specification.

Robert Bruce had wanted to design aircraft for Westland and with Arthur Davenport, as chief draughtsman, and W.A. Roiley, as the project designer, they built a small single-seat floatplane fighter for the Admiralty. The Westland N.1B was successful but the requirement lapsed when Sopwith Camels proved capable of being launched from capital ships. The Westland team had been working on the design of a light fighter since late 1917. Their design fitted the RAF specification and it was proceeded with as a private venture as the Westland Hornet according to surviving drawings, but emerged as the Wagtail when official names for aircraft were introduced in early 1918. It was proposed to power the fighter by the unproven A.B.C. Wasp seven-cylinder radial engine that promised 170-hp.

At its meeting of 18 December 1917, the Air Board Technical Department discussed the requirements of Sir Douglas Haig for the Expeditionary Force (E.F.) in France for the coming year. Present were Sir William Weir, General Trenchard, General Salmond, Mr Gibson, the CTD (Controller Technical Dept) and the D/C TD (Deputy Controller Technical Dept). Sir William Weir noted that the choice of machines and engines for “bulk” production could not be made at the present time as the known machines did not come up to the requirements of the E.F. A “choice could only be made at present for development purposes.” Trenchard said the unless the 170 A.B.C. single-seater fighter could carry the full armament and petrol specified by the E.F. (Expeditionary Force) it would be of no use to the E.F. It was decided that a conference would be held between Weir, Generals Trenchard, Salmond and Pitcher to discuss the question of what types were to be adopted. The meeting then agreed to “the placing of an order with Messrs. Westland Aircraft Co., for three experimental single seater machines for 170 h.p. A.B.C. Engines to A.l.A. Specifications.” The Wagtail was in direct competition with the Sopwith Snail and BAT F.K.23 Bantam, all powered by the same A.B.C. engine. It was agreed that “We will continue pushing this design as an experiment.”

At an earlier meeting on 20 November, the machines that were proposed for the A.B.C. engine were discussed. “The British Aerial Transport Co have built two types of machines, one with heavy loading one with light.” These were the F.K.22 and F.K.23 Bantam. “The small machine had started flying and gave promising results, but engine trouble occurred and trials must wait for the engines. Sopwith and Westlands both have machines designed and built waiting for engines. If this engine is got right a very handy machine with performance 5% superior to Type 1 may be possible.”

It is usually stated that six Westland machines were ordered (C4290-C4295), but the order was reduced to three (C4291-C4293). However Minute 279/73 of the Air Board Technical Department’s 178th Meeting of 18 December 1917, recorded that an order be placed for only “three experimental fighter single seater machines for 170 h.p. A.B.C. Engines to A.I.A. Specifications” from Westland Aircraft Co. According to J.M. Bruce it is doubtful if C4290 was ever built as no reference to it has survived. It is considered that the previously published statement that six were initially ordered is false.

A full-size mock-up was ready for inspection by the fortnight ending 9 January 1918, “and various questions of armament settled.” The first airframe was ready by the end of February, but the Wasp engine had not been received. Two other airframes were well advanced at this time. At a meeting on 31 December 1917, General Trenchard had stated that the “A.B.C. 170 H.P. engine should be ruled out as an engine for single-seater fighting machines; and that no further development should be made in connection with small fighters.” In the light of Trenchard’s disapproval is interesting that the development of these machines was continued. Given that they were more or less ready, it may have been thought that they would provide important information as experimental machines.

The Wagtail was a small, neat looking biplane of conventional wood and fabric construction with constant chord equi-span wings. The fuselage was constructed around four square section spruce longerons and was of rectangular cross section for most of its length. It terminated in a vertical knife edge. The staggered horizontal and vertical spacer struts were tapered to fit into square cups welded to a wiring lug plate that were bolted to the longerons. To these fittings attached the swaged rods that cross braced the fuselage. Careful attention to detail meant that the metal fittings were for the most part identical. The flying-control assembly could be put together on a bench and dropped into the fuselage complete. The Wasp engine was mounted on a wire braced mounting ring with four attachment plates that connected to the inwardly curved extensions of the longerons. The engine was enclosed with metal top and side panels and a metal cowl through which the Wasp cylinders protruded. The rest of the fuselage was covered with fabric that had removable panels at the cockpit and forward fuselage.

The tailplane and fin were of wooden construction with metal framed rudder and elevators, all being fabric covered.

The inverted vee undercarriage struts were constructed of metal tubing with spruce fairings and the half axles were sprung with bungee rubber shock cord Sopwith fashion. 600 x 75 wheels were fitted. Shock was absorbed by bungee rubber shock cord. A curved moveable tailskid was mounted below the tailplane. The tailskid was steerable being mounted on a special skid post in front of the rudder post.

The constant chord single bay wings were of conventional construction around two ash spars. The aerofoil was a “high efficiency” RAF 15 section. The wide centre section had a large cut-out above the cockpit and the trailing edge was cut back to the rear spar in order to provide the best possible pilot’s view as detailed hereunder. Constant chord ailerons were carried on both upper and lower wings. C4291 had a dorsal fin. Control wires ran inside the wings and fuselage except for the elevators.

Armament comprised two synchronised Vickers .303 in machine guns mounted on top of the fuselage in front of the cockpit on steel brackets bolted to a wooden base. These guns “combined with the rapid manoeuvrability of the machine, make it a very dangerous enemy to tackle.” The chutes for the cases were low in the fuselage and were let into the fabric covering. 1,000 rounds of ammunition were provided and C4291 had provision for a Lewis gun to be mounted on the upper plane on a “special mounting designed to enable (the) gun to be rapidly lowered for loading purposes”. It appears that this gun was never mounted on the Wagtail. Ammunition was increased to 700 rounds per gun for the Wagtails that did not have the Lewis mounting. A 1.8 Aldis and a 3” ring and bead sights were fitted. A hole was provided in the starboard side of the windscreen for the Aldis sight eyepiece. Oxygen was provided for the pilot. Two petrol tanks were fitted, one under the pilot’s seat of 11-gallon capacity, and a 15 gallon one between the pilot and engine back plate above the pilot’s legs. The tanks had a total capacity of 20 gallons. A two-gallon oil tank was also fitted.

The Wagtail emerged as a compact aeroplane of pleasing lines. Great care had been taken to make for ease of construction. The majority of the fuselage fittings were identical, that, combined with the small number of machined parts, and the fact that the fuselage, chassis and wing attachments could be turned out as stampings, would “greatly facilitate rapid production.”

A mock-up of the “Westland. A.B.C. Wasp” was inspected around the New Year and “various questions of armament settled.”

The fortnightly Reports of the Technical Dept (T.6 - Design Branch) titled Aircraft Production Experimental Aircraft range from January 1918 to January 1919, and give a fortnightly account of the progress of experimental designs up to the Armistice, after which the reporting period was different. From these reports one can chart the progress from concept to a machine selected for production or rejection. With respect to the Wagtail the following sequence is recorded:

F/E 23.01.18. Westland A.B.C. Scout. Contract for three machines.

First machine now ready for engine, delivery of which is promised for 31st inst. Details of arrangements of guns, etc., have been settled, machine should be flying 10 days after receipt of engine. Strength calculations are in hand.

F/E 06.03.18. Westland Type B.N.1 “Wagtail” Wasp. First machine. Complete and awaiting engine which is promised 07.03.18.

F/E 20.03.18. Wagtail.

First machine. Complete and ready for engine which is now promised for 20.03.18.

Second machine. Now being erected.

Third machine. The centre section of this machine is being lowered by 6 in. in order to reduce the blind area. Stability being investigated.

F/E 03.04.18. Wagtail

First machine. Complete and ready for engine which is now promised for 09.04.18.

Second machine. With top plane lowered to give better visibility now being erected.

Third machine. Now being erected.

F/E 01.05.18. Wagtail.

First machine. Complete and awaiting new engine which is promised for 01.05.18. The first engine broke down and cylinders were returned to the makers for repair. The engine has now been transferred to the second machine.

Second machine. Commenced maker’s trials 29.04.18. and is ready to go to Martlesham for tests.

Third machine. Fuselage complete. Controls, instruments, etc., fitted. Planes being assembled.

Design completely passed for strength.

F/E 12.06.18 to F/E 21.08.18. Sopwith Snail, BAT Bantam and Westland Wagtail. Wasp. Trials suspended until engine troubles have been overcome.

F/E 04.09.18 to 16.10.18. Sopwith Snail, BAT Bantam and Westland Wagtail. Wasp. Trials suspended during development of the engine.

F/E 30.10.18. Sopwith Snail, BAT Bantam and Westland Wagtail. Wasp. Trials suspended as engine will not be put into production.� F/E 13.11.18. Sopwith Snail, BAT Bantam and Westland Wagtail. Wasp.

Snail Contact cancelled.

BAT Bantam Contract to be completed.

Westland Wagtail Wasp. Contract completed.

One of the RAF’s requirements for the Wasp powered fighter was a maximum all-round view. The Wagtail originally had a wide-span upper centre section that had a large semi-circular cut out in its trailing edge in order to give the pilot a good view. The fin extended well in front of the tailplane. Both the upper and lower wings had 2 1/2° dihedral. Capt F. Alexander was attached to the Westland Company to test fly the Wagtail. Before flight testing commenced Alexander suggested that the opening in the upper wing centre section be made larger based on his operational experience. On the redesigned centre section, the cut-out was made larger between the spars by removing the central three ribs giving an almost full width opening between the front and rear spars. The trailing edge was also dramatically cut back to the rear spar. This centre-section was fitted to C4293 as a trial and was mounted six inches lower. In order to use the same interplane struts and bracing wires the wings were re-rigged with the upper having a dihedral of 5° while the lower had no dihedral. This was to be standard for the type.

The first flight took place in April 1918, and it is assumed that this was C4291 with equal dihedral on both wings as there was not enough time to modify this machine. Alexander was so taken with the Wagtail’s performance that he executed a loop on the maiden flight. The fin was reduced in size to approximately half of its length, as there was insufficient rudder area. Apparently when side-slipped there was insufficient rudder to overcome the nose-down effect of the fin. It was thought that this would suffice rather than building a new rudder. It appears that the modification was successful.

Engine problems saw the cylinders returned to the manufacturer. When the Wasp engine was returned to Yeovil it was fitted to a Wagtail with the modified centre section. J.M. Bruce contends that this was C4293 that arrived at Farnborough from Martlesham Heath on 27 May 1918. According to D.N. James the engine was mounted in the second prototype, C4292, that had the modified centre section and wings and was nearer to completion. This seems unlikely given that the modifications were carried out on C4293 as recorded in the fortnightly reports as noted above. Whichever was the actual machine that was given the engine, testing of the Wagtail resumed on 29 April.

Unfortunately, C4292 was damaged in a fire when one of the ground crew tried to prove you could extinguish a cigarette in a can of petrol! According to Capt A.R. Boree, who carried out the trials of the first D.H.9A built by Westlands, a Wagtail was damaged in a canvas Bessoneaux hangar fire at Yoevil. Boree noted that there was lax discipline with the ground staff and he complained about the civilian staff pouring petrol into his machine while smoking. In order to demonstrate it was safe this individual put a lighted cigarette into a can of petrol. On this occasion it did not explode, however Boree was later told that this individual tried this trick again and it resulted in a hangar fire that burnt out the Wagtail. Whatever the truth, C4292 was completed and survived until at least 1920 when it still had the Wasp engine.

According to James the arrival of two more Wasp engines enabled the third prototype to be completed, flying in early March. The fortnightly report for 1 May 1918, notes that the third machine was not yet ready. On 8 May C4293 was flown to Martlesham Heath for trials with the Aircraft Experimental Establishment with different airscrews. On 18th the machine made a bad landing on broken ground suffering damage when it nosed over, damaging the engine and undercarriage. After repairs C4293 was transferred to the Royal Aircraft Factory (soon to be the Royal Aircraft Establishment - RAE) for investigation into the problems with the Wasp engine. Two weeks later all trials of Wasp powered aircraft, the Wagtail, Sopwith Snail and BAT Bantam, were terminated. C4293 had only made four brief flights at Farnborough on 27, 28 and 29 May 1918. The Wasp production program was cancelled in late October 1918 as its problems were seen to be insurmountable.

In May 1918, the Aeroplane Experimental Station, Martlesham Heath reported that it was testing the experimental Sopwith Snail, Westland Wagtail and BAT Bantam against the performance of the Sopwith F.1 110-hp Le Rhone Camel. The three Wasp powered scouts were also flown against the Martinsyde F.3 in mock combat.

W.H.K. Copeland, a Flight Commander with No.60 Squadron, tested the Wagtail at Martlesham Heath, and provided the following report on the machine: The Wagtail as a fighting scout is extremely satisfactory. Its performance is good and will probably be greatly improved when the engines are running better.

The visibility of this machine is excellent, and the few blind spots are overcome by its manoeuribility (sic), which is better than that of a Camel, being quicker on turns, and following controls immediately. The guns are in a very good position in front of the pilot on top of the fuselage and are easy to get at for the clearing of stoppages. All instruments are easily seen and all controls conveniently placed except the air cock on bottom of hand pump, which cannot easily be reached when strapped in.

When fully clothed the pilot is quite comfortable. Nothing fouls his arms, but at present his feet foul the top of the petrol tank and footboards.

The machine is easy to land and the landing speed is low.

In the notes accompanying this report the following comments were made:

There were two petrol tanks, one between the pilot and engine back plate above the pilot’s legs and one under the pilot’s seat. A pressure petrol supply system was employed.

The cockpit was comfortable when fully clothed, but toes fouled the front tank and heels the floor boards. It was notes that the CC gear was not yet fitted.

It was considered that the pilot could crawl out in the event of a turn-over.

The tailplane was adjustable on the ground only.

The tail skid was steerable.

The landing speed was slow and it was easy to land.

The guns were easy to access for stripping down and cleaning.

Copeland noted under “fouling” that the CC gear had not yet been fitted. It is presumed that therefore this gear may have caused fouling in other installations and was a consideration that had to be taken into account.

The Wagtail was flown in a mock fight against the Martinsyde F.3.

This fight was started about 4000 feet and ended up at about 1000 feet, the Martinsyde forcing the Wagtail down. On trying to get on each others tail, the Wagtail appeared to turn slightly quicker, but the Martinsyde could easily out climb it on turns thus having the advantage of height. The Wagtail came off banks, if anything quicker. The Martinsyde could have broken of (sic) the fight any time and got away but not so with the Wagtail. There is no mention of the Wagtail being flown against the BAT Bantam or Sopwith Snail, the other two contenders for the Wasp powered fighter specification, nor against the Sopwith Camel. A report was furnished of the Martinsyde flown against the Camel, and the Snail against the Camel, and, as recorded above, the Wagtail against the Martinsyde.

C4291 had been re-engined and modified to “standard” before it went to Farnborough during the summer and flow there during the autumn of 1918 presumably in the attempts to make the Wasp a reliable engine.

RAE Report K1360 of October 1918 reveals that C4291 was at the RAE for “Wasp engine development work.” After only one hour in flight it was found necessary to make several modifications to the aircraft.

Considerable vibration was observed throughout the wing system during flight, and an examination was made after landing. The condition of the attachments of the plate supporting the engine and also the fastenings of the wing spars to the fuselage was found to be such that the aeroplane was dismantled.

Inspection of the wings showed

Elongation of some of the bolts through the wing spars at the points of attachment to the centre sections. The stringers, which are of extremely light construction had bent so badly as to be no longer of any value and had broken at several points. This failure of the stringers was partially due to the bending of the compression rib at the fuselage end of the wings. This compression rib is of light construction and had deflected under the pull of the doped fabric and put end load on the stringers. If these stringers are to be of any value they should be stiffened considerably. The compression ribs are stiffened by struts at intervals, but none of these struts had been glued in position and some had not been fastened in any way but were pressed in tight between the flanges. The others were fastened with small nails through the flanges. In these circumstances the value of these struts and stiffeners was very limited.

The construction of the wings was further criticised. The spars were spindled out to a point very close to the end leaving a very small margin around the bolt hole for the bolt attaching the wings to the fuselage. There were two bolts at this point, one vertically for the wing attachment, the other horizontally to take the internal bracing wires. The small margin made it difficult to bush the holes in case they become elongated and “so leads to unnecessary scrapping of wings.”

In order to overcome these difficulties and continue with flying as soon as possible a number of modifications were made to the machine. The spindling of the spars was filled in for about five inches using carefully glued blocks of wood. The internal structure of the wings was strengthened.

The cross members at the rear of the engine bearer plate were made of spruce and the ends were found to be split and the bolt holes elongated. These were remade in ash and fitted with a strengthened bearer plate with modified stays fitted.

On 6 November C4291 was transferred to the Aircraft Armament and Gunnery Experimental Establishment at Orfordness for gun firing trials. E.R. It was here that Eugene R. Macdonald flew the Wagtail for the first time on 9 November. “Ripping machine” was his Log Book comment. He flew the machine again on 13 & 20 November and 9 December.

Despite the end of the war and the cancellation of the Wasp engine the rebuilt C4292 ended up at Martlesham Heath on 29 January 1919, where it remained until at least 1920 when it was still powered by a Wasp engine.

US Navy personnel visited the RAF Test Station at Martlesham Heath early in 1920 and reported on the testing methods in use there and on the latest fighting aircraft that were present. With respect to the single-seaters fitted with the A.B.C. Dragonfly they recorded the Westland Biplane, BST Basilisk, Nieuport “Night Hawke” and Siddeley Siskin, Sopwith Snark, Sopwith Dragon and the 300 hp Hispano powered Martinsyde. The Westland referred to would have been a Wagtail. This was reported to having a “Moderate performance - Excellent on controls - Very good visibility.”

The faults of the Wasp engine meant that there was no hope of the Wagtail going into production. What was not appreciated at the time was that the emphasis placed on a good pilot’s view that had led to the huge holes in the centre section actually caused eddying end losses and gave a lift distribution much less that a continuous wing. Later fighters, such as the Hawker Fury and Gloster Gladiator, had a good view for the pilot without the sacrifice of the centre section.

The Wagtail did not make the list of RAF Peace Establishment Type Machines of 25 November 1918, however in 1920 two more Wagtails were ordered. Powered by a 150 hp Armstrong Siddeley Lynx seven-cylinder air cooled radial, J6581 and J6582, featured a shorted fuselage wherein the bay aft the engine was removed to compensate for the weight of the heavier Lynx. The rudder was a comma shape and the duo had a strengthened undercarriage. They were flown to about 1922. Some records indicate that at least one was fitted with the Wasp II engine. A.B.C. had persevered with development of the Wasp engine and the 200-hp Wasp II was developed.

Report No.K.1682137 noted that J6591 was fitted with Lynx No. A.S.1/26480, and J6582 with No. A.S.4/26483. The difference between the Wasp and Lynx powered Wagtail was 258 lbs and “an increase in weight such as this on a small scout is extremely serious, so much so that it has been impossible to fly the Wagtail with Lynx engine in anything but an unloaded state. With full military load it would not only be below strength, but might also begin to show difficulties of control in the air.”

Weights in lbs

Wasp Lynx

Empty 832 Empty 1078

Petrol 30 gal 173 Petrol 173

Oil 2 1/2 gal 25 Oil 3 3/4 gal 37

Military load 335 Military load 333

Total 1365 Total 1623

Source: TNA AVIA 6/4232.

With respect to flying qualities the machine was described as “straight forward to handle in the air. Though sensitive, it does not seem so controllable as the Bat Bantam with Wasp engine. It is very quick on the ailerons, but in flight the rudder and ailerons are less simple to coordinate than in the Bat Bantam, and hence cannot be made to produce the rapidity of manoeuvre that is characteristic of the Bat.”

From what I remember of the Wagtail with Wasp engine, I think that the installation of the Lynx engine has produced a distinct deterioration of control; from which it may be inferred that if the aeroplane were loaded up to 1600 lbs. its controllability would deteriorate still further, especially at low speeds.

Under the heading Getting Off the following comments were made:

A noticeable feature is the marked turning tendency to starboard with the engine on. When the pilot is getting off, this turning tendency develops suddenly as the wheels leave the ground. The aeroplane should be allowed a full run and taken off carefully. It cannot be lifted into the air like a Sopwith Camel or Pup, neither does it jump into the air like a Bat. In this respect it shows the Nighthawk characteristics, only somewhat exaggerated. It is therefore difficult to take off down wind, and if pulled off the ground too soon is inclined to drop its starboard wing suddenly, and bump one wheel on the ground.

The machine was comparatively easy to land although some pilots thought that it was difficult to get enough up movement on the elevator to make a good tail down landing, “but opinion is divided on this point.” The wagtail sank rapidly when glided down slowly. It was “extremely harsh” on the tail skid.

With the Lynx engine the aeroplane was slightly nose heavy “which spoils the perfect sense of controllability which a pilot should feel with such a small scout.”

With the engine full on the machine required a considerable amount of port rudder, although the force necessary to neutralise the turning force was never large. The view was excellent.

Stability was “about neutral” longitudinally. While the machine had a fixed tail the amount of elevator to trim the machine at any speed was small. Laterally it was considered to be below the standard for a scout of this design, but control was good enough to prevent the pilot experiencing any difficulty in flying due to it, except in getting off when a wing dropped.

The aeroplane is extremely steady at all speeds in the air and there is little vibration due to the engine or other causes. It is also steady side-slipping or rolling, and feels comfortable when being dived or violently manoeuvred.

The cockpit was criticised as small and when the ammunition trays were fitted, they fouled the pilot’s legs. The control stick could not be moved forward with the hand at the top as the clearance between the stick and the dashboard was small. The stick was shortened two inches and the instrument board raised slightly to clear the oil tank and ammunition boxes. Another modification was the fitting of an additional back rest for the pilot.

The wing struts on both Wagtails bowed so badly that they had to be replaced. It was found that while they had been erected as marked, this was incorrect and they were reversed. Their bases were splayed to allow for the dihedral and they were bottoming on only one side. “As they were incorrectly marked this error could not have been discovered without dismantling the struts, the position of which according to their markings was correct.”

The Wagtail was the best of the three Wasp powered fighters. Test pilot Major Oliver Stewart, MC, AFC, found the Wagtail to be one of the most perfect flying machines ever produced. The Sopwith Snail had a similar performance but had other problems. The BAT Bantam was inferior on the climb and also had dangerous spinning characteristics. If the Wasp had proved to have been able to produce the horsepower to weight that it promised, then the Wagtail would have had a chance of meeting the specifications and been introduced as the first light weight fighter of the RAF. Unfortunately, like all the aircraft designed for the A.B.C. Wasp and Dragonfly engines, the Wagtail was let down by the engine and had no hope of production.

Westland apparently tried to market the Wagtail and Weasel overseas in 1920 which would explain the dual French/English booklet mentioned in the bibliography. Again, they had no success.

Comparison between "Bantam" "Snail" and "Wagtail."

Climb Bantam Snail Wac tail

Height in ft Time RofC Time RofC Time RofC

5,000 3.75 1165 3.7 1235 3.5 1300

10,000 8.9 805 8.25 960 7.8 995

15,000 17.3 440 14.4 690 13.9 690

17,000 - - 17.6 580 17.1 560

Speed @15,000 ft 111 mph 127 mph (1) 117 mph (1)

Pilot, lbs 180 180 180

Vickers guns, lbs 70 70 70

Deadweight, lbs 103 (2) 115 115

Fully Loaded, lbs 1,333 1,396 1,326

Notes: (1) Doubtful. (2) The deadweight is less as the wing structure was considered to be reducible by 20 lbs. Source: TNA AIR1/1153/204/5/2407

�

Westland Wagtail Specifications

Source 1.C4291 2. & 3. 7. 4. 8. 5. 6. Lynx

Span 23 ft 2 in 23 ft 2 in 23 ft 2 in 23 ft 2 in - - -

Length 18 ft 7 1/2 in 18 ft 11 in 18 ft 11 in 18 ft 11 in - - -

Height overall 8 ft 0 in 8 ft 0 in 8 ft 0 in 8 ft 0 in - - -

Gap 4 ft 6 in 4 ft 0 in to 4 ft 6 in - 4 ft 11 in 4 ft 11 in - 4 ft 11 in

Chord 4 ft 6 in 4 ft 6 in 4 ft 6 in 4 ft 6 in - - -

Stagger 1 ft 6 in 1 ft 6 in 1 ft 3 1/2 in 1 ft 6 in - - -

Incidence 2° 2° 2° 2° - - -

Dihedral

Top plane 2 1/2° 5° 5° 5° - - -

Lower plane 2 1/2° 0° 0° 0° - - -

Prop diameter - 8 fit 6 in 2,590 mm - - - -

Track - - - 4 ft 8 in - - -

Span tailplane 9 ft 0 in - 7 ft 10 3/4 in - - - -

Area in ft2

Tailplane - 15.4 - - - - -

Elevators - 9.5 9.5 - - - -

Fin - 2.1 2.1 - - - -

Rudder - 4.5 4.4 - - - -

Main planes (inc ailerons) 190 190 190 - - - -

Ailerons (each) 6 5.8 6 - - - -

Petrol, gallons - 26 26 - - - -

Oil, gallons - 3 3 - - - -

Weights in lbs

Empty - - 746 746 832 832 1078

Pilot - - 180 - 180 - -

Armament & 1,000 rounds - - 160 - - - -

2 Vickers - - - - 70 - -

Ammunition

(Bags) - - - - 85 - -

Oxygen - - 25 - - - -

Petrol 20 gall - - - - - 173 173

Petrol 24 gall - - - - 173 - -

Oil - - - - 25 25 37

Petrol & Oil - - 219 - - - -

Military load - - - - - 335 335

Total 1,330 1,330 1,330 - 1,365 1,623

Climb to

5,000 ft - 3min 5 sec 3 1/2 min - - - -

10,000 ft - 7 min 8 sec 7 1/2 min - 9 min 50 - -

15,000 ft - 13 min 9 sec - - 18 min 10 - -

17,000 ft - 17 min 1 sec 17 min - - - -

Speed in mph

At 10,000 ft - - - - 121 - -

At 15,000 ft - 117 - - 113 - -

Source:

1. Aeroplane Data Book.

2. Westland Aircraft - The Weasel, The Wagtail, Westland Aircraft.

3. Ballam, F & Gibbings, D. Westland Aircraft 1915-1926, (the Westlands Aircraft Collection Vol.1).

4. The Book of Westland Aircraft.

5 & 6. TNA AVIA 6/4232.

7. Janes All the World’s Aircraft, 1919 Edition.

8. TNA AVIA 6/5156. Report No. E.2324 on C4291.

Westland Wagtail Specifications (continued)

Source 1.C4291 2. &3. 7. 4. 8. 5. 6. Lynx

Endnotes

Показать полностью