P.Lewis British Aircraft 1809-1914 (Putnam)

Eastbourne Aviation Company Monoplane

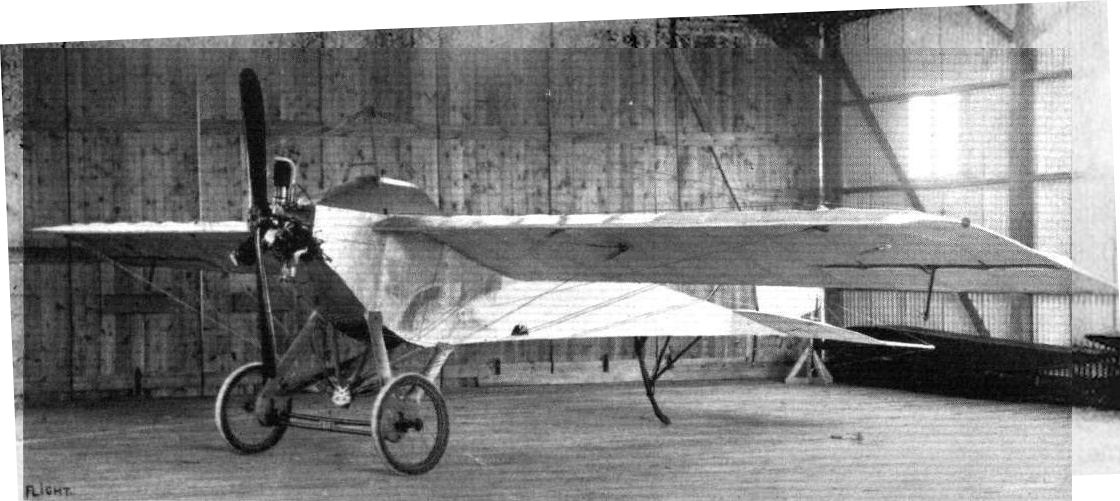

The E.A.C. Monoplane was the first of four designs to be built by the Eastbourne Aviation Company of Eastbourne, Sussex, which was founded by F. B. Fowler, who took his Royal Aero Club Aviator's Certificate No. 175 on 16th January, 1912, flying one of his own flying-school's Bleriots. On 29th October, 1912. Mons. E. L. Gassier, a Swiss pupil of the school, passed the tests for his certificate No. 350 using a Bleriot also.

An interest in designing led Emile Gassier to join the Company and, assisted by Fowler, he drew up a single-seat tractor monoplane which was built during 1913. The engine chosen was the three-cylinder 35 h.p. Anzani radial, which was mounted on the nose of a rectangular-section fuselage, the deep belly of which tapered to a horizontal knife-edge at the tail, and which was metal-covered as far back as the rear of the cockpit.

A one-piece elevator was fitted, operating below the cut-out in the rudder, which was strut-braced to the top of the fuselage in the absence of a fixed fin. The parallel-chord wings were mounted just below the upper longerons, and were unusual in that inter-connected ailerons were embodied in place of the warping more commonly employed in monoplanes at that time, and this eliminated the twisting strains inherent in the warping system. The result was a great improvement in flying characteristics. The flying wires were connected to an under-fuselage cabane, relieving the undercarriage of such additional stresses, while the landing loads were taken by the wires supported by the struts in front of the cockpit. Springing of the undercarriage axle was devised by allowing it to move vertically in slots cut in the vee-struts against rubber cord in tension. The Anzani engine drove a Rapid propeller of 7 ft. diameter. The machine was very pleasant to fly; anticipated private orders were prevented by the War.

SPECIFICATION

Description: Single-seat tractor monoplane. Wooden structure, fabric covered.

Manufacturers: Eastbourne Aviation Co. Ltd., Eastbourne, Sussex.

Power Plant: 35 h.p. Anzani.

Dimensions: Span, 29 ft. 2 ins. Length, 21 ft. Wing area, 135 sq. ft.

Performance: Cruising speed, 50 m.p.h.

Показать полностью

M.Goodall, A.Tagg British Aircraft before the Great War (Schiffer)

Deleted by request of (c)Schiffer Publishing

EASTBOURNE AVIATION Co. Ltd. (KB. Fowler, Managing Director; E.L. Gassier, Chief Designer, St. Anthony's Hill, Eastbourne, Sussex)

This was one of the small manufacturers, which evolved from a flying training school established by F.B. Fowler in 1911, with himself as instructor. Mon E.L. Gassier was a Swiss pupil, who continued with the company as chief designer and pilot.

Monoplane

This was a single-seat monoplane of conventional design, built during 1913. No fin was fitted and lateral control was by ailerons. It was intended for advanced pupils and private owner use, but only one was built because of lack of demand due to the impending war.

Power: 35hp Anzani three-cylinder air-cooled fan-type radial.

Data

Span 29ft.2in.

Chord 4ft 11 in

Area 135 sq ft

Area tailplane 14 sqft

Area elevator 10 sq ft

Area rudder 7 sq ft

Length 21ft

Height 8ft in flying attitude

Показать полностью

Журнал Flight

Flight, May 3, 1913.

THE E.A.C. MONOPLANE,

A NEW machine has been added to the list of British built aeroplanes. The monoplane in question has been designed for the Eastbourne Aviation Co., Ltd., by Mr. E. L. Gassier, who has had considerable experience in this direction, besides being a practical engineer and an able pilot, so that, although the machine is an experimental one, it should be fairly certain to give a good account of itself.

Looking over the machine, one of the features which first attracts attention, is the presence of ailerons for the maintenance of lateral stability, instead of the method of wing warping usually adopted for that purpose. Although this is a departure from what has now come to be almost standard practice as regards monoplane construction, it is a system which works quite well in machines of the biplane type, and there is no apparent reason why it should not be equally successful when applied to monoplanes, especially when, as in this case, the ailerons are interconnected, so that when one is depressed the other is elevated a corresponding amount. At any rate, the system has much to recommend it, as it does away with the twisting strains imposed upon the wings where the wing-warping system is employed.

From the plan view of the machine it will be seen that the two main spars, which are of rectangular section ash, are placed very close together, so that the rear spar is placed about half-way along the chord. This method of construction imparts a certain amount of flexibility to the trailing edge and has, furthermore, the advantage that it allows a compression strut - in this case a very strong steel tube - to be interposed between the upper longerons of the fuselage in front of the pilot's seat for the purpose of resisting any tendency of the wings to bend the longerons of the body inwards.

Evenly spaced along the spars - except for the three ribs nearest the root, which are placed closer together than the rest - are the ribs, which have webs of three-ply wood, with top and bottom flanges of spruce and ash, respectively.

Very stout stranded cables, anchored to steel plates, which in turn are secured to the apex of the lower pylon by three bolts, take the weight of the machine when in flight, while another cable, running from the steel clip forming the anchorage for the inner lift wire on the rear spar, to the crank case of the engine, takes the drift of the wings.

The advantage of securing all the lift wires to a pylon, forming a separate unit instead of anchoring them to one of the members of the chassis, is that even should the latter become damaged through a rough landing, there is still a very good chance of the pylon remaining intact, so that the chassis may be repaired without in any way disturbing the stay wires.

Top bracing is effected by cables secured to the apex of a single A-shaped pylon of steel tubing of stream-line section. All the lift wires are duplicated, and it is worth noticing that each wire is anchored to a separate bolt.

As the rear spar is situated a considerable distance from the trailing edge, it has not been possible to hinge the ailerons to the rear spar, as is usually done, but a steel tube, situated roughly half-way between the trailing edge and the spar, serves as a pivot for the ailerons.

Stranded cables running from the lower aileron levers around pulleys on the outer steel clips of the front spar to the control lever operate the ailerons, which are interconnected by another cable running along the top of the front spar.

The body, which is of rectangular section, is very deep in the region around the pilot's seat and tapers to a horizontal knife edge at the back. The longerons are of ash and the struts and cross members are of spruce in the rear portion of the body while in the front part ash is employed.

Between the two main spars and on top of the body is situated the tank, which is divided longitudinally by a partition. The left-hand division contains 1 1/2 gallons of oil, whilst in the right-hand one are carried 6 gallons of petrol.

An aluminium casing, running from the nose of the machine up to the front of the tank, serves to deflect the air, and the rear end of the tank is made sloping, so as to serve as a dashboard.

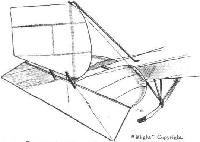

Well down in the deepest part of the body is the seat for the pilot, who controls the machine by means of a centrally pivoted lever, mounted on a rocking shaft. A sideways movement of the lever operates the ailerons, while a to-and-fro motion works the elevator. A foot bar actuates the rudder, which is situated wholly on top of the tail planes. The rudder crank levers are mounted on the lower end of the tube, around which the rudder is pivoted, so that the rudder wires are carried inside the body throughout their entire length.

The tail plane, which is semicircular in plan view, is flat on the underside, while the top surface is cambered. Hinged to its rear edge is an undivided elevator plane of ample proportions.

The empennage is protected from contact with the ground by a tail skid.

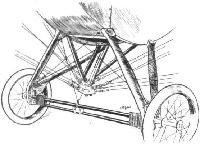

A landing chassis of very neat design supports the machine when on the ground. As will be seen from the accompanying sketch it consists of two pairs of ash V struts, separated at their lower extremities by a steel tube. The tubular axle passes through two slots immediately above this tube, from which it is sprung by means of rubber shock absorbers.

On to a steel capping plate, forming the nose of tin machine, is bolted the 35-h.p. V type Anzani engine, which at present furnishes the power. It drives directly a Rapid propeller of 7 ft. dia.

As has been said before, the machine is an experimental one and no attempt has been made to provide a "Show" finish, but the term finish used in this connection must not be confused with workmanship, which latter is of a very high class.

Flight, November 12, 1915.

CONSTRUCTIONAL DETAILS.-X.

<...>

Another form of simple Vee undercarriage is that of the Eastbourne Aviation Co.'s monoplane. In this machine the wheel track was comparatively wide, necessitating a differently-shaped apex of the "Vee." The two struts, it will be seen, converge a short distance above the wheel axle, and are here joined to a vertical block of wood, in which is cut a slot for the axle. The axle runs right across from side to side, buckling in the centre being prevented by a Vee formed by two wires as shown, while the rebound is taken by a rubber cushion secured to the tubular transverse member of the undercarriage. The cabane of steel tubes in the centre of the chassis does not, of course, form part of it, but serves as a support for the lift cables, the machine being a monoplane.

<...>

Показать полностью