В.Кондратьев Самолеты первой мировой войны

СИМЕНС-ШУККЕРТ R-II - R-VII / SIEMENS-SCHUCKERT R-II - R-VII

Аэроплан, названный "Сименс-Шуккерт" G-I, впервые поднялся в воздух в мае 1915 года. Позднее, в связи с появлением категории "R", самолет переименовали в R-I. Испытания показали, что летать он может, но технические данные (даже без бомб) были крайне низкими. Аппарат использовался только для экспериментов и учебных целей.

Такая же участь постигла и две последующие машины братьев Штеффенов - R-II и R-III. На них варьировались типы двигателей, дорабатывались редукторы, подбиралось оптимальное соотношение площади и размаха крыльев.

На R-III впервые установили вооружение. В месте раздвоения хвостовых балок оборудовали стрелковую точку с широким диапазоном обстрела. Еще одна турель находилась на крыше фюзеляжа за остеклением кабины и третья - в носовой части, над передним двигателем. Механики-мотористы при необходимости должны были занимать места у пулеметов. Позднее решили, что мотористов не стоит отвлекать от их прямых обязанностей, и в состав экипажа ввели двоих стрелков.

Первым бомбардировщиком Сименс-Шуккерта, попавшим на фронт, стал R-IV. Он впервые оторвался от земли в конце января 1916 года. Летные характеристики машины признали недостаточными для боевого применения на западном фронте, но вполне пригодными для восточного. Дело в том, что по числу истребителей русская авиация намного уступала англо-французской. Зенитное прикрытие войск также было слабее, чем на Западе.

В сентябре 1916-го R-IV начал совершать с аэродрома Вильно (Вильнюс) дневные и ночные налеты на позиции русских войск и тыловые объекты. До конца года к нему прибавились еще два аппарата - R-V и R-VI. Последний гигант фирмы Сименс-Шуккерт под номером R-VII прибыл на фронт в феврале 1917-го.

Самолеты объединили в 501-ю эскадру тяжелых бомбардировщиков. Вскоре ее перебросили на аэродром Альт-Ауц под Ригой. Оттуда "Сименс-Шуккерты" совершили около 20 налетов на позиции русских войск, причем средняя величина бомбовой нагрузки в расчете на одну машину составляла всего 170 кг за вылет.

В сентябре 1917 года "Сименс-Шуккерты" сняли с вооружения и переклассифицировали в учебные машины. В этом качестве они применялись до конца войны. За время пребывания на фронте 501-я эскадра не понесла боевых потерь, но один самолет (R-V) в феврале 1917-го разбился при посадке из-за технических неполадок.

ДВИГАТЕЛИ

R-II и R-VII - 3 "Мерседеса" D.IVa по 260 л.с.

R-III, R-IV, R-V и R-VI - 3 "Бенца" Bz.IV по 220 л.с.

ВООРУЖЕНИЕ

3 турели с пулеметами "Парабеллум", до 500 кг. бомб

ЛЕТНО-ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Размах, м 33,44

Длина, м 18,5

Площадь крыла, кв.м 210,0

Сухой вес, кг 5700

Взлетный вес, кг 7960

Скорость максимальная, км/ч 130

Дальность полета, км 560

Время набора высоты, мин/м 27/2000

Потолок, м 3700

Показать полностью

O.Thetford, P.Gray German Aircraft of the First World War (Putnam)

Siemens-Schuckert Steffen R I

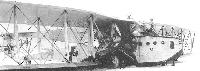

In December 1914 Siemens-Schuckert began construction of a series of seven "fork-tail" three-engined Giants designed by Bruno and Franz Steffen. All machines were generally similar, differing mainly in engine installation and wing span, as reference to data below will show. The fork-tail feature was to allow a clear field of fire to the rear. All three engines were mounted inside the nose, with facilities for minor repairs during flight; power was transmitted to two tractor airscrews through a series of shafts and gears.

<...>

R II. Serial R 2/15. Engines, three 260 h.p. Mercedes D IVa. Span, 38 m. (124 ft. 8 1/4 in.). Length, 18.5 m. (60 ft. 84, in.). Height, 4.6 m. (15 ft. 1 1/8 in.). Area, 233 sq.m. (2,516 sq.ft.). Weights: Empty, 6.150 kg. (13,530 lb.). Loaded, 8,460 kg. (18,612 lb.). Speed, 110 km.hr. (68.75 m.p.h.). Climb, 2,000 m. (6,560 ft.) in 23 min. Duration, 4 hr. Notes: First flew end of 1915, when original Maybach engines had been replaced by Mercedes. Span increased. Accepted 26th June 1917. Trainer only.

R III. Serial R 3/15. Engines, three 220 h.p. Benz Bz IV. Span, 34.33 m. (112 ft. 7 3/4 in.). Length, 17.7 m. (58 ft. 0 7/8 in.). Height, 4.6 m. (15 ft. 8 1/8 in.). Area, 177 sq.m. (1,912 sq.ft.). Weights: Empty, 5,400 kg (11,880 lb.). Loaded, 6,820 kg. (15,004 lb.). Speed, 132 km.hr. (82.5 m.p.h.). Climb, 2,000 m. (6,560 ft.) in 35 min. Duration, 4 hr. Notes: Benz engines substituted for original Maybachs. Span decreased. Accepted December 1916. Training duties only.

R IV. Serial R 4/15. Engines, three 220 h.p. Benz Bz IV. Span, 37.6 m. (123 ft. 4 1/2 in.). Length, 18 m. (59 ft. 0 3/4 in.). Height, 4.6 m. (15 ft. 1 1/8 in.). Area, 201 sq.m. (2,171 sq.ft.). Weights: Empty, 5,450 kg. (11,990 lb.). Loaded, 6,900 kg. (15,180 lb.). Speed, 130 km.hr. (81.25 m.p.h.). Climb, 2,000 m. (6,560 ft.) in 36 min. Duration, 4 - 5 hr. Armament, four machineguns. Notes: Benz engines substituted for original Maybachs. Span increased. Crew, four. Accepted August 1916. Operational with Rfa 501 at Vilna on Russian Front. Used for radiator experiments.

R V. Serial R 5/15. Engines, three 220 h.p. Benz Bz. IV. Span, 34.33 m. (112 ft. 7 3/4 in.). Length, 17.7 m. (58 ft. 0 7/8 in.). Height, 4.6 m. (15 ft. 1 1/8 in.). Area, 177 sq.m. (1,912 sq.ft.). Weights: Empty, 5,300 kg. (11,600 lb.). Loaded, 6,766 kg. (14,885 lb.). Speed, 132 km.hr. (82.5 m.p.h.). Climb, 2,000 m. (6,560 ft.) in 36 min. Duration, 4 hr. Armament, four machineguns. Notes: Benz engines substituted for original Maybachs. Decreased span. Accepted August 1916. Crew,six. Operational with Rfa 501 at Vilna.

R VI. Serial R6/15. Engines, three 220h.p. Benz Bz IV. Span, 33.36m. (109 ft. 5 5/8 in.). Length, 17.7 m. (58 ft. 0 5/8 in.). Height, 4.6 m. (15 ft. 1 1/8 in.). Area, 171 sq.m. (1,847 sq.ft.). Weights: Empty, 5,250 kg. (11.550 lb.). Loaded, 6,800 kg. (14,960 lb.). Speed, 132 km.hr. (82.5 m.p.h.). Climb, 2,000 m. (6,560 ft.) in 36 min. Duration, 4 - 6 hr. Armament, four machineguns. Notes: Benz engines substituted for original Maybachs. Decreased span. Crew six. Operational with Rfa 501 at Vilna.

R VII. Serial R7/15. Engines, three 260 h.p. Mercedes D IVa. Span, 38.44 m. (126 ft. 1 1/2 in.). Length, 18.5 m. (60 ft. 8 1/2 in.). Height, 4.6 m. (15 ft. 1 1/8 in.). Area, 210 sq.m. (2,268 sq.ft.). Weights: Empty, 5,700 kg. (12,540 lb.). Loaded, 7,960 kg. (17,512 lb.). Speed, 130 km.hr. (81.25 m.p.h.). Climb, 2,000 m. (6,560 ft.) in 27 min. Duration, 4 hr. Armament, four machine-guns. Notes: Benz engines substituted for original Maybachs. New wings and rib section of increased span. Crew six. Accepted February 1917. Operational with Rfa 501 at Vilna.

Показать полностью

G.Haddow, P.Grosz The German Giants (Putnam)

SSW R.II to R.VII

The promise shown by the success of the Steffen-designed SSW R.I bore fruit when Idflieg awarded SSW a provisional contract for six improved bombers on 10 June 1915, barely three week after the maiden flight of the R.I. The final contract, signed on 26 June 1915, called for six aircraft powered by 240 h.p. Maybach HS engines to be delivered completely equipped at a cost of 170,000 marks each exclusive of engines. The delivery specifications established by Idflieg for these aircraft read as follows:

Required Performance:

Speed: 135 km.h.

Climb:

2000 metres in 35 mins.

3000 metres in 70 mins, from sea-level

Take-off Run: 150 metres

Landing Run: 200 metres (a landing run of 150 metres preferred)

Useful Load: about 2450 kg., broken down as-

Fuel: 1000 kg. fuel for 6 hours, but tanks large enough to contain 8 hours fuel

Armament: 300 kg. (one machine cannon at 200 kg. and two machine-guns at 100 kg.)

Crew: 450 kg. (5 per ons at 90 kg.)

Bombs: 500 kg.

Armour for pilot: 200 kg.

The new aircraft shall parallel the construction of the demonstrated test machine with the following changes:

The engine-room must have in-flight accessibility (the engine-room under the pilots' seats accessible in a bent-over posture). The remaining areas should have a clear height of 175 cm. (5,7 feet) to permit the engine mechanic to work on all part of the engines.

In contrast to the arrangement in the prototype, each engine must be capable of being stopped in flight, inspected, re-started and re-coupled into the drive system. Cruising capability shall be maintained on alternate paired engines. The engines shall be equipped with separate controls for the engine mechanic. For the pilots' position central throttle levers for all three engine (as in the prototype) are adequate.

The cooling system shall be common to all engines, with provision for witching and disconnecting its various components. The inlet and outlet water temperatures must be controllable from the pilots' position.

Passage to and from the pilots' cabin, all gun positions and engine-room is mandatory. A telephone loudspeaker or similar device shall be provided to transmit commands to all positions.

Flying characteristics shall be such that the aircraft can be flown by one pilot on long flights without undue fatigue. Horizontal flight on two engines and a 1 to 25 glide ratio on one engine are required.

The acceptance of the aircraft, contrary to normal procedure, shall follow a flight of 6 hours with full load and the acceptance commission aboard. In addition, test flight shall be performed, during the course of which one and two engines shall be stopped.

Ability to take off on two engines with full crew, armament (excluding bombs) and 1 hour of fuel aboard would be desirable.

The company must guarantee gearing and transmission system against design, construction and material failures for 500 hours.

The construction of the aircraft shall adhere to the Construction and Delivery Specifications for Army Aircraft 1915 (BLV) and its general requirements.

The aircraft will be designated G.32-37/15. The first aircraft will be delivered by the end of September, the second by the end of October and the remainder thereafter in eight-day intervals. In case the Maybach engines are not available, then 220 h.p. Mercedes engines shall be used. The deadline for final delivery of the aircraft, provided the engines are promptly supplied, is 1 April 1916.

These specifications were not unreasonable, and SSW engineers, basing their opinion on the success of the R.I, felt confident that they could build machines to the above requirements within the time limits.

What the engineers could not know, however, was that the designated Maybach HS engine supplied by the Government would be utterly unfit for operational use. Basically a modified airship engine, the HS was prematurely placed into service, and it never did achieve a level of reliability required to power the more demanding heavier-than-air machines. In fact, the engine's operation even in airships proved to be marginal. Its shortcomings plagued SSW for nearly two years and delayed the R-plane's introduction into operational service to such an extent that eventually interest in further development of the Steffen design died out. The Maybach HS was truly the Achilles' heel of the SSW R-plane programme.

In the first aircraft tested (R.2, R.3 and R.4) it was immediately apparent that the HS engine possessed serious mechanical deficiencies not easily remedied. In addition, the engine was highly susceptible to overheating. Virtually every type of radiator configuration was tested at one time or another in the attempt to solve the overheating problem. For example, in the early R.2 three radiators were mounted atop each other in the extreme nose; in the R.4 aerofoil radiators were placed in the upper wing, and later the radiators were mounted on "doors" which could be swung into the slipstream as desired to provide the correct temperature gradients. Much to their consternation, SSW engineers spent much money and valuable time trying to save the ill-fated HS engine. Insisting that it was a firm of aircraft constructors, not engine developers, SSW finally scrapped the Maybach HS engines altogether.

Their place was taken by engines of proven reliability; the 220 h.p. Benz Bz.IV engines (actually rated at 210 h.p.), which powered the R.3 to R.5 aircraft, and the 260 h.p. Mercedes D.IVa engines, which were mounted in the R.2 and R.7.

Because the R-planes were either complete or at an advanced stage of completion, their reconstruction to accommodate Benz and Mercedes engines was costly and, more significant, time-consuming. The first modified aircraft to be completed were those fitted with Benz engines. Subsequent flight tests demonstrated that these machines were underpowered and could not meet Idflieg performance (climb and useful load) specifications. A as consequence, the wing area was enlarged by adding a so-called "supplementary bay" to the wings of the machines, including R.2 and R.7. The latter two aircraft were adequately powered, but the heavier Mercedes engines required strengthened engine bearers, centre-section structure and gear-box. The additional weight (about 400 kg.) required more wing area if the performance specifications were to be met.

Although wingspans of the SSW R-planes were increased from the original three-bay wing to four-, five- and six-bay wings, their general configuration remained constant throughout. The "supplementary bays" were inserted between the centre section (at a point outboard of the propeller housing struts) and the outer wing panels. In size and shape the extra bay or bays were essentially an extension of the centre section. The outer wing panels retained their original appearance, having swept-back leading edge, dihedral on the lower wings and upper wing overhang. The auxiliary balancing surfaces for aileron and elevator assist remained standard.

The airframes of all the Steffen-designed R-planes were characterized by the distinctive forked fuselage. The engines were all serviceable in flight, and although the fuselage was increased in size, the space for the engine mechanic remained cramped. His life was not an easy one. To quote from a contemporary account:

Because of the construction of the fuselage, it was hardly possible to make repairs on engines or gear-boxes without practically tearing the whole fuselage apart. It took a slim mechanic to fulfil the engine accessibility requirement. Winding his way between engines and fuselage demanded considerable skill in order to avoid an unpleasant contact with the glowing exhaust tacks. The severe space restriction greatly hampered the internal positioning of the exhaust stacks, with the result that a continual battle was fought with bursting exhaust pipes and burned-out gaskets. Duty in the engine-room might be compared to that in a submarine. The mechanic's world consisted of metal walls and oil-smeared portholes which provided him only view of the sky. The heat was often unbearable, and vapours issuing from frequent exhaust leaks added materially to the mechanic's discomfort.

In a report on the R.7. von Bentivegni, the commander of Rfa 501, complained about having to remove the cylinder-head of the left engine in order to renew the exhaust gaskets of the right. The engines were placed that close together!

The gear-box and power-transmission arrangement was an improvement over the prototype R.I, although it operated in the same manner. Von Bentivegni, whose squadron flew the SSW machines, wrote after the war that their greatest fault lay in the engine and drive installation. The three engines and their clutches did not rest on a unified engine mount, but rather on two separate supporting structures. Any shift in the support alignment produced engine misalignment, which in turn caused frequent drive failures. Extensive reinforcement of the drive installation and fuselage, combined with careful inspection after every flight, solved the problem to some extent.

At first the leather-cone friction clutches were operated by long levers extending into the pilots' cabin. It was impossible for the pilots to engage the cone clutch smoothly by means of the long lever. The resulting jerky motion and chatter caused heavy and uneven wear of the leather friction bands. Later on, the cone clutch was operated by the engine mechanic through a worm-screw hand-wheel, which appreciably prolonged its life. The centrifugal key clutch was burdened by weak key fastenings that often broke. Problems such as this were to be expected in new and unproven drive system. As time went on, modifications and improvements gradually evolved a reliable internal drive system which von Bentivegni considered fully serviceable and capable of being used in more powerful R-planes. Eventually the gear and clutch system proved to be quite satisfactory, particularly under conditions of careful inspection and servicing, as was the case when the aircraft were assigned to training commands.

In some eighty flights which he made in SSW R-planes, von Bentivegni experienced only a single propeller transmission failure. He regarded the propeller transmission as an excellent design. The transmission shaft (fitted with sliding and spring-band coupling) and its stiffener tubes were very robust, and the assembly was encased in a small streamlined aerofoil covering.

Von Bentivegni, in defence of the SSW machines, stated that it should not be forgotten that a considerable number of successful day and night mission were flown by these pioneering aircraft. Indeed, their flight characteristic were excellent. They were inherently stable and easy to fly. The concentration of weight provided by the central engine arrangement prevented centre-of-gravity travel when executing turns. To quote a former pilot: "The SSW machines handled like a two-seater."

All machines were equipped with twin doors in the nose to provide entry to the engine-room. The extensive cabin glazing varied in individual machines. It was not popular with the pilots because the Cellon (a type of celluloid) caused dazzle and had a tendency to mist over. Take offs, landings and bad-weather flights were invariably made with open windows to assure clear vision. The drag of the open cockpit must have been appreciable, for a noticeable increase in speed was reported when the windows were closed.

Although the delivery specifications called for one cannon and two machine-guns, full armament was rarely carried. The nose cannon was not fitted, and its heavy ring was replaced by a lighter machine-gun ring. Even so, only one or two machine-guns were carried on bombing missions, a the SSW R-planes generally flew with two-seater fighter escort that provided daytime protection. At night it is likely that no armament or escort was required. The weight saved was made up by loading extra bombs or fuel. The beam machine-gun arrangement consisted of a semicircular mounting that allowed the gun to be swung to either side. A third gun position was located between the upper wing spars above the fuselage. It is believed that all aircraft had a ventral gun position situated behind the rear engine. The 200 kg. armour for the pilots was eliminated to save weight. The undercarriage configuration of the R.I was retained, but was improved upon by having internal spring shock absorbers built into the forward strut.

The usual flight crew consisted of four persons: commander/navigator, two pilot and one engine mechanic. With the installation of wireless it is likely that a fifth crew member was carried. There is some indication that only the more powerful long-span machines (R.2, R.7 and possibly R.4) carried wireless equipment. Small propeller-driven generators attached to the upper wing provided power for this equipment, which did not have the range of the Staaken R-plane wireless transmitter. Nevertheless, highly useful and successful triangulation location experiments were performed with SSW R-planes on the Eastern Front. These formed a basis for the wireless navigation technique used by Staaken machines over London and the Western Front.

The original designations of the six SSW machines (G.32 to G.37/15) were changed to G.33 to G.38/15 on 13 July 1915, and as of 6 November 1915 the Riesenflugzeug (Giant aircraft) designation was applied for the first time. The SSW machines were allocated numbers R.2 to R.7/15, and each machine received a different type designation (R.II to R.VII) although initially they were intended to be alike.

The SSW R-planes were not accepted by Idflieg (Rea) in numerical order. Those aircraft fitted with Benz engines from the outset were delivered and accepted at an earlier date than the Maybach-powered aircraft whose engines had to be torn out and replaced.

SSW R.II 2/ 15

The R.2, first of the batch of six aircraft to be completed, made its maiden flight on 26 October 1915. This was undoubtedly a creditable achievement on the part of SSW, who took only four months from receipt of contract to build the R.2. Yet curiously enough the R.2 was the last machine to be accepted by the flying services. It was not only a victim of the recalcitrant Maybach engines but also of an extensive modification programme and hesitation by both SSW and Idflieg regarding the choice of replacement engines.

The records state that the R.2 was delivered on 20 November 1915, presumably to Doberitz for acceptance tests and inspection under military cognizance. In February 1916, after a series of fruitless flights punctuated by continual failures, the Maybach HS engines were removed and sent back to the manufacturer in Friedrichshafen. Furthermore, the centre section had been damaged when a landing gear collapsed, and the R.2 was returned to the Dynamowerk for repairs. During July 1916 SSW requested instructions from Idflieg on whether to re-install Benz or Mercedes engines. SSW had hoped to have the R.2 ready for flight at the end of the month. Mercedes engines were eventually chosen by Idflieg. By then, however, SSW was hampered by the shortage of skilled personnel, so it was decided to give priority to the completion of the R.5, R.6 and R.7, and the R.2 was placed in storage.

In November 1916 Idflieg requested an increase in operational altitude greater than the 3000 metres initially specified. The minimum altitude was set at 3500 metres, but it was stated that even higher altitudes would be desirable. SSW replied that the installation of Mercedes engines would hardly offer an improvement. Instead, they recommended fitting three Benz engines augmented by two additional Benz pusher engines mounted between the wings to increase the rated power from 630 to 1050 horse-power. SSW argued that this surely would enable the R.2 to reach 3500-4000 metres, and if the modification proved successful the other machines could be altered to the same configuration. Idflieg remained steadfast to the concept of engine accessibility when they wrote, "The R-plane is intended for long-range flights. The principle of engine accessibility during flight shall not be compromised."

Work on the R.2 was started again in early 1917, by which time it was possible to incorporate lessons learned from the Mercedes-powered R.7. The wings were entirely rebuilt to the six-bay layout by adding a two-bay "supplementary" section between the centre section and the outer wing panels. The spans of the lower and upper wing were equal, but the latter, a completely new structure, had greater chord. Both wings were equipped with ailerons controlled by the distinctive auxiliary SSW balancing surface. The tail surfaces were increased in size and strengthened by additional struts.

In a typical example of front-line and factory co-operation, Idflieg requested on 31 March 1917 that the R.2 be equipped with under-wing bomb racks for both 50 kg. and 100 kg. bombs. Operational flights had shown the R.7 to be capable of carrying six 50 kg. bombs in addition to its internal bomb load, and the R.2 was to be modified to carry either six 50 kg. or four 100 kg. bombs.

On 29 June 1917 the R.2 was delivered to Rea after performing an acceptance flight of 4 hours, during which it reached 3800 metres in 86 minutes carrying a 2310 kg. useful load. The flight was a noteworthy improvement over the other SSW machines, which could only attain 3000 metres with a 1400-1700 kg. useful load. However, the increased span and weight of the R.2 restricted its maximum speed and prevented it from competing with Staaken R-plane types then entering operational service. It was relegated to training duties at the R-plane school in Doberitz, and in June 1918 it was transferred to Rea Cologne, where it is known to have crashed later that year.

SSW R.III 3/15

The R.3 was completed about one month after the R.2, and following several test flights by Bruno Steffen was delivered to Doberitz on 30 December 1915. During subsequent flights extensive engine and radiator modifications were made, but these stop-gap measures could not cure the recurrent defects of the HS engines. The R.3 crashed in early 1916, and it is believed the HS engines were responsible. The damaged wings were replaced, but attempts at further flights with the HS engine were futile, and the R.3 was returned to the Dynamowerk to have its engines replaced. On 2 June 1916 SSW wrote Idflieg requesting permission to install Benz engines, but Idflieg answered that the R.3 was to remain in storage until SSW had available man-power and space. On 12 October 1916 a number of modifications, found useful in front-line service with the R.5 and R.6, were to be incorporated in the R.3. These included reinforcement of the tail to prevent in-flight vibrations; engine and gear-box thermometers for the mechanic; engine-room illumination so that the mechanic could service the engines during night flights, and provision for covering the radiators in flight. At the time the enlarged wingspan of the R.4, R.5 and R.6 had proved its value, and a similar section was added to the wing with increased chord. The Benz-powered R.3 was finally delivered to relaxed specifications (see SSW R.6), although Idflieg acknowledged that the machine was not capable of front-line service. The R.3 was delivered to Rea on 12 December 1916 and was accepted on the 21 December 1916. The machine performed a useful function as a trainer, and it was still in service on 23 February 1918.

SSW R.IV 4/15

The R.4 was perhaps the only aeroplane with Maybach HS engines ever to be accepted by the German Government. This feat was possible because the R.4 was singled out for extensive engine and radiator modifications in a special effort to prove the HS airworthy.

Factory delivery of the R.4 took place on 29 January 1916. Hardly had the test flights begun when it was necessary to exchange the original HS engines for new ones. Simultaneously the nose radiators were replaced by wing radiators and gravity fuel tanks were installed. According to SSW records, the HS-powered R.4 did not perform a useful flight until May 1916, but even then one of the cylinders turned blue from overheating. Nevertheless, SSW was hopeful that still larger radiators would solve the HS overheating problem, and suggested to Idflieg that further experiments with the HS engines should be made. On the other hand, SSW did not feel responsible for the defective engines, nor did it have the necessary personnel to perform engine-modification work. Consequently SSW asked Idflieg to accept the machine and continue the test programme on its own. Idflieg consented to an acceptance flight during which the R.4 was to climb to 3000 metres in 90 minutes with a useful load of 1810 kg. (For a breakdown of the useful load see R.7.) This requirement was passed by the R.4 on 27 August 1916, some six months after it was rolled out of the factory, and the machine was accepted by Rea on the same day. Some time during this period the wing bays of the R.4 had been increased to four by the addition of the usual supplementary bay.

In November 1916 the R.4 was under repair, probably as a result of a crash. The opportunity was SSW R.IV 4/15. taken to replace the HS engines with three Benz Bz.IV engines. Either concurrently or at a later date the wingspan was increased a second time and the final configuration resembled the five-bay wing of the R.7. The repair work was completed on 14 February 1917, and the first flight with Benz engines was made on 14 March 1917.

On 27 April 1917 the R.4 joined Rfa 501 at Vilna, where it performed several operational missions. It crashed in April 1917, but was repaired. When Rfa 501 was transferred to the Western Front the R.4 was left behind as a trainer with the R-Training Section in Vilna, where it is known to have been in early 1918, but was later flown back to Berlin. On 22 June the R.4 made a safe emergency landing between Spandau and Staaken; the damage was repaired two months later on 28 August 1918.

In 1917 the R.4 had been considered as a carrier for the SSW-developed wire-guided air-to-ground missiles. Although a special monoplane missile for large aircraft had been designed, the ground clearance of the R.4 was insufficient to allow its use as a carrier without extensive modification, and the idea was dropped.

SSW R.V 5/15

Though never actually powered by the HS engine, the history of the R.5 did not escape its influence. The R.5, virtually finished when the change to Benz engines was decided, had to be completely rebuilt, including the customary increase in wingspan. The R.5 left the factory in June 1916. Idflieg agreed to accept the R.5 to lower specifications than stipulated in the contract (see SSW R.6 for details).

The R.5 was delivered to Rea on 13 August 1916 and then flown to Rfa 501 to join the recently-arrived R.6. The account of the delivery flight has been preserved, and it makes an interesting catalogue of the R.5's virtues and defects. On 3 September 1916 the aircraft took off from Doberitz for a non-stop flight of 620 km. to Konigsberg via Schneidemuhl. The total load of 1836 kg. included the commander, Lt. Rau, a crew of five and ten auxiliary fuel tanks hung in the bomb racks, which, in addition to the main tanks, provided enough fuel for 6 1/2 hours duration. The flight was made at about 2000-2300 metres in varying overcast weather, but sight of the ground was fortunately never completely lost.

Just short of Schneidemuhl, the halfway mark, Lt. Rau noticed that the thrust ball bearing of the left leather-cone friction clutch was running hot. The clutch was immediately disengaged, but not in time to prevent disintegration of the bearing cage in a shower of red-hot parts and sparks. However, the centrifugal key clutch was still intact, and as it was not necessary to have the cone clutch engaged simultaneously, Lt. Rau chose to fly on.

The flight report digresses to advocate the placing of the clutch levers in the mechanic's position. The reason given was that only the mechanic could determine the degree of "clutching" necessary to friction-start a decoupled engine in flight, while simultaneously adjusting the ignition and other engine controls. Using a proposed worm-screw hand-wheel (instead of the long extension lever for the pilots), the mechanic could carefully adjust the cone friction clutch to the required degree, thereby reducing wear and tear on the clutch.

During regular flight the cone friction clutch would be disengaged, but during a landing or gliding manoeuvre (when the engines are throttled down) the cone friction clutch would be engaged in case the centrifugal key clutch should decouple. The potential danger in having the pilots operate the clutch was clearly demonstrated during the landing at Konigsberg. The engines were throttled down and the centrifugal key clutches automatically disengaged. However, the left engine, with its broken and previously disengaged cone friction clutch, robbed of its flywheel action, promptly stalled. Although the cone friction clutch was still serviceable, the pilots were too busy fighting the strong ground air currents to concern themselves with the clutch. It is possible they had not even noticed the engine stall in the tension and noise. The mechanic had, but he was powerless to take remedial action, as the clutch lever was located in the cockpit.

It is a tribute to the flying qualities of the Steffen-designed R-plane that the R.5 handled excellently in the strong turbulence even though one engine had stopped. The aircraft landed at Konigsberg after a flight of 4 hours and 50 minutes.

On the next day the R.5 flew to Vilna via Kowno, a distance of about 340 km. The trip required less fuel, and one extra passenger was taken along. The R.5 climbed to 1500 metres in 18 minutes with a load of 1755 kg., a creditable performance. The broken cone clutch was used only for the take-off, and it was disengaged as soon as the R.5 was in the air. The machine landed in Vilna in 2 hours and 38 minutes and made the trip at an average speed of 128 km/h. The repairs on the clutch were begun at once, and the defect was traced back to a loose bolt in the coupling of the right engine which had wandered through the gear-box to cause the bearing failure in the left engine. The complete gear-box had to be disassembled to replace the bearing, and this required its removal from the aircraft. To do so, either the two front engines and the nose cowl or the rear engine and one fuel tank had to be removed.

The R.5 flew a number of bombing missions with Rfa 501 during the turn of the year 1916. The Operational History (page 22) mentions some of the problems encountered by the R.5 and includes one report of a raid on Iza by the R.5.

During the week of 14 February 1917 the R.5 was severely damaged in a faulty night landing and was dismantled for shipment back to Doberitz, where its parts were stored as spares for Rea.

SSW R.VI 6/15

Unlucky throughout its career, the R.6 was still one of the most successful SSW R-planes. Not only was it the first aircraft of the R.2-7 series to reach squadron service but during its flight tests it achieved an unacknowledged world record.

Like the R.5, the R.6 was partially complete when the change to Benz engines required fuselage modification and an increase in wingspan. There is some evidence that the wing was not enlarged until after the record-breaking flight described below. The R.6 left the Dynamowerk on 25 April 1916 and performed a number of successful test flights under Bruno and Franz Steffen. After fitting wing radiators, the R.6 performed a 6-hour factory flight (possibly with military observers on board). SSW was hopeful that Idflieg would accept the R.6 on the strength of this flight.

The flight was a remarkable one, for the R.6 piloted by Bruno Steffen carried a pure useful load of 2400 kg. for a duration of 6 hours. The flight constituted a world record at the time, but the war prevented any publicity of the event or promulgation of the record.

A former member of the SSW engineering staff, Hans Heitmann vividly recalls his participation in a 6-hour flight, although he is not sure of the aircraft's designation. At any rate, such flights were not without their exciting moments, as the following account will testify. One has to admire the almost nonchalant attitude of the crew, to whom a minor failure or accident was routine. In today's high-bred aircraft similar happenings would be due cause for an immediate emergency landing. The flight described below could well have been the memorable 6-hour record of the R.6.

Because of the heavy load and the lack of wind, the take-off run was prolonged. During the take-off I was stationed near the rear engine. While we were still gathering speed the hose leading to the radiator burst, dousing my legs with water. I stopped the leak with a handy oil rag and quickly wrapped wire around this compress, reinforced it with friction tape and secured it with another layer of wire. This make-shift patch lasted the entire flight, and we had only lost 2 litres of water. By then we were airborne and no one aboard had noticed anything amiss. You may imagine the disgrace if we had been forced to cancel the flight after barely reaching 100 metres altitude.

But even better things were to come. From the beginning to end we were able to stay aloft only because of timely emergency repairs. I do not remember the exact sequence of incidents, but perhaps the enclosed messages which we passed back and forth will provide a clue. The engine noise made it impossible to talk and be understood; consequently every 15 minutes we handed a message to the pilots with information regarding engine revolutions, engine, gear-box oil and water temperatures.

The exhaust pipes of the front engines were separated by no more than the thickness of a sheet of paper for about 1 metre. Here too, a pipe split open, spewing poisonous exhaust fumes into the engine-room. A special ring fashioned from wire was wrapped around the red-hot pipe and twisted tight with a short stick, thereby squeezing the opening shut. This repair lasted for the remainder of the flight, although it did re-open a millimetre or two.

Shortly thereafter we became aware that the left engine was using oil faster than the other two engines. Inspection showed that an oil pipe near the base of the crankshaft housing had fractured. The leak was stopped with a wooden plug. But how long had the engine run without oil? We drew off oil from the other engines and filled the left engine, a task that kept one of us busy for the rest of the flight.

The flight was almost over and the pilot had idled the engines to descend for the landing. Suddenly he notified us that the left engine was dead. We had not noticed it. Undoubtedly the engine had run too long without oil and the pistons had seized. The idled left engine, not able to overcome the friction of the pistons, had reduced its speed to a point where the centrifugal clutch had automatically disengaged and the engine had stopped. Spark plugs were taken out, oil was poured into the cylinders and slowly we began to turn the engine using the friction clutch. After a moment we replaced the plugs and "clutch-turned" the engine as the pilot gave gas. The engine started, came to 1550 r.p.m. and did not complain again until we shut it off in the hangar. We had endured the 6-hour flight! Never again during acceptance and even factory flights did an SSW machine experience so many mishaps.

Notwithstanding the load-carrying and duration record, the rate of climb and ceiling of the R.6 was still marginal. Two climb tests performed under Idflieg surveillance (8 and 14 June 1916) gave such poor results that Idflieg relaxed the delivery specifications. The useful load was reduced from 2450 kg. to 1410 kg. now made up of:

Fuel 490 kg.

Gear-box oil 110 kg.

Engine oil 40 kg.

3 machine-guns 150 kg.

Crew (four) 320 kg.

Bombs 250 kg.

Miscellaneous 50 kg.

Total 1410 kg.

The specified climb with this load was 3000 metres in 90 minutes. The fuel tanks were to carry a reduced quantity for 4 hours duration. The heavy cannon ring was discarded, the starter motor and battery were to be either eliminated or included in the useful load calculations.

The R.6 (and later the R.5 and R.3) passed these reduced climb and load requirements and was delivered to Rea on 20 July 1916. On 7 August the R.6 was delivered to Rfa 501 after having landed at Kowno to repair a failing engine. Its first bombing mission, made in the daytime, was against the Russian railroad station at Molodeczne. During October 1916 the R.6 and R.5 were fitted with two bomb containers inside the rear fuselage, each holding five 12•5 kg. P.u.W. bombs. This installation made the aircraft tail-heavy and changed its trim after the bombs were released. It was replaced by external racks (for eleven 12•5 kg. bombs) placed underneath the fuselage closer to the centre of gravity.

The R.6 was dogged by misfortune during its operational career. On 26 November 1916 it took off in company with the R.5 to bomb Iza, but was forced to land due to a leaking compression cock. The R.6 survived an in-flight fire caused by a burned-through engine and made an emergency landing on 11 December 1916. The substitute engine did not arrive at Vilna until 9 January 1917. At the time it was more desirable to place this engine into the R.5, which also was grounded. But the engine, fitted with a flange for the R.6 gear-box, was not interchangeable with the R.5, and the squadron report ended with a plea for standardization of parts.

Records list the R.6 as damaged in March and again in the summer of 1917. In November 1917 the R.6 was considered to be of no further use and was dismantled.

SSW R.VII 7/15

The R.7, initially to be powered by Maybach engine, was the first SSW R-plane to receive Mercedes engines. Existing documents concerning the history of the R.7 are not entirely consistent, and there is a possibility that Benz engines were considered prior to installation of the Mercedes engines. A SSW factory report dated 2 June 1916 stated that the R.7 equipped with Benz engines would be ready to leave the Dynamowerk on 24 June 1916. However, an Idflieg document dated 17 June 1916 asks SSW to expedite the installation of the 260 h.p Mercedes engines in the R.7. It is assumed that a decision was made in the interim period to equip the R.7 with the more powerful Mercedes engines.

This change required extensive reconstruction to strengthen the airframe and drive assembly to accept the heavier and longer Mercedes D.IVa engines In the process, fuel tanks, propellers, landing gear and the forward fuselage section had to be modified or rebuilt. Completely new wings were fabricated, featuring heavier spars and a new rib section.

The span was increased to a five-bay configuration by the addition of two "supplementary" bays. The tailplane area was increased and the elevator was divided to allow clearance for an enlarged rudder. Large slab radiators were mounted on each side of the fuselage between the wings.

On 11 November 1916 Idflieg pressed SSW to accelerate the completion of the R.7, for in the interest of R-plane development it was a matter of urgency to have a Mercedes-powered machine completed as soon as possible. The main section of the R.7 left the factory on 20 November 1916 and was shipped to Doberitz for assembly. To explain the delay, SSW countered by stating that the change to Mercedes engines had required new wing spars and wings, new strengthened engine bearers and an enlarged fuselage with a modified interior layout. During the R.7 modification programme, SSW stated, the R.3, R.4, R.5 and R.6 had been completed and the R.I repaired. Yet only four months had passed from the time the engines were delivered, in spite of a greatly reduced number of available skilled workers.

The R.7 was test-flown on 15 January 1917 and made two acceptance flights; one on 21 January, during which it reached 300 metres in 66 minutes (useful load unknown) and a second flight on 1 February (useful load unknown) during which it reached 2500 metres in 2 hours and 51 minutes. The reduced useful load specified by Idflieg for the R.7 (R.2 and Maybach-powered R.4) was as follows:

Fuel 640 kg.

Gear-box oil 110 kg.

Engine oil 40 kg.

3 machine-guns 150 kg.

Crew (four) 320 kg.

Bombs 500 kg.

Miscellaneous 50 kg.

Total 1810 kg.

The original wings were found to be too heavy, and some time during the tests the R.7 was fitted with completely new wings of lighter construction.

Rea took delivery of the R.7 on 11 February 1917, and within two weeks, on 26 February, it was flown to Rfa 501 in Vilna. There the aircraft was thoroughly inspected and the exhaust manifolds were found to be in poor shape, necessitating immediate replacement of the right and rear manifolds and temporary patching of the left. Other field modifications included fitting an easy to open and close window in the Cellon canopy; painting the underside of the wings grey for night protection; relocating the Anschutz artificial horizons inside the Cellon canopy because it was difficult to read through the thick Cellon windows; installing reading lights for all the controls; installing an Atmos and a balloon variometer in the cabin and an airship compass in the commander's position.

The greater power of the R.7 made it possible to carry a bigger bomb load. In addition to the factory-instailed internal rack for six 50 kg. Karbonit bomb, racks for twelve 12•5 kg. P.u.W. bombs were added beneath the fuselage behind the landing-gear struts. Additional rack for three 50 kg. P.u.W. bombs were also fitted under each wing between the fuselage and the propeller strut. With all racks filled the bomb load came to 750 kg.

Modifications were finished by 8 March 1917, and the R.7 was reported now ready for flight. Two days later a take-off attempt failed when newly-fallen, heavy snow prevented the R.7 from gathering sufficient speed. On 12 March 1917 the R.7 made its first flight from the Rfa 501 airfield.

The flight attitude, particularly while gliding or in gusty air, was not as satisfactory as that of the other SSW R-planes assigned to Rfa 501. It was felt that the large span and increased chord in relationship to the short fuselage had a detrimental influence on the R.7’s flight characteristics. None of the instruments operated properly during the flight, but this was to be expected from untested and uncalibrated equipment.

A wireless sender and receiver was installed in the R.7. Three ground stations picked up signals transmitted by the R.7 while it was in the air. It had been arranged beforehand that these stations would attempt to determine the aircraft's bearing, which they did correctly. Here was the beginning of the triangulation technique used later by Staaken R-planes to fix their positions over enemy territory. No return signals were received by the R.7 because of vibrations in the improperly suspended receiver. In the urgency to deliver the R.7 to the front it had been equipped with unsuitable propeller. Consequently the flight was terminated in 46 minutes because a more exact determination of the machine's capabilities was not feasible.

The R.7 started on it first operational mission on 15 March 1917. Just short of leaving the ground a sharp crack was heard, followed by severe shaking of the entire engine assembly. It was found that the spur gear of the left engine had disintegrated, which was traced back to a failure of two key plates in the centrifugal clutch. The critical structure, assembled from two pieces, was replaced by a part fabricated from a single metal block. This field modification proved to be very satisfactory and found use in other SSW R-planes.

The R.7 participated in bombing missions until the summer of 1917, when Rfa 501 was transferred to the Western Front. From then on the R.7 was attached to the R-Training Section in Vilna, and is known to have been there in January 1918.

The year 1917 saw the end of the developmental cycle of the Steffen-designed R-planes. In retrospect they were rather remarkable aircraft. Designed in 1914/15, the intrinsic qualities of manoeuvrability, ruggedness and reliability permitted the SSW R-planes to serve as trainers until the end of the war. It is a tribute to the safety of these aircraft that not one life was lost in them. Unquestionably, the SSW R-planes were the most successful of the internally-powered R-planes produced by Germany during the war, even though they were underpowered.

Von Bentivegni felt that the experiences of the first years should have been applied to the development of improved types. It certainly would have been possible. For example, the R.2, a type designed in 1914/15, after numerous modifications and improvements climbed to almost 4000 metres with a full war load.

Why, then, were the Steffen-designed SSW R-planes not developed further? It is difficult to pinpoint any major reason, but rather a number of factors were responsible for the lack of interest in furthering the Steffen design. In the first place, the early death of one of the designers during the critical year of 1916 robbed the project of much impetus, Franz Steffen crashed to his death on 26 June 1916 In the SSW E.II, an aircraft he had designed. Secondly, SSW had suffered heavy financial losses in frustrated attempts to make the R-planes fly with the deficient Maybach HS engine; not to mention the costly and time-consuming modifications required to change over to different engines. Disillusioned and seeing that time was running out, SSW and Steffen turned to a much more profitable, if not more exciting, area of work. In late 1916 they began to construct in large quantities the beginning of a line of high-performance single-seat fighters. These endeavours continued at an ever-increasing pace until the war's end. The demand for fighters was enormous, and virtually all of the SSW resources were placed behind the fighter programme to the detriment of the R-plane.

Colour Scheme and Markings

All six SSW R-planes left the factory in a natural clear dope finish. Serial numbers (R.2, R.3, etc.) were painted in small black figures on both sides of the forward fuselage. The aluminium panels on top of the forward fuselage section were painted black as an anti-dazzle aid. The cross Patee without the usual borders or backgrounds was painted on the wingtips, on the lower boom of the fuselage and on the rudders. As the aircraft reached operational status they may have been repainted. The R.2 in the final form was painted in a dark colour; its wings were covered with a pattern of large regular hexagons, and the Latin cross was painted on the wings and lower boom. The underside of the R.7 wings were painted a grey colour after it attained operational status.

Показать полностью

J.Herris Siemens-Schuckert Aircraft of WWI (A Centennial Perspective on Great War Airplanes 12)

SSW R.II - R.VII

Based on the successful launch of the SSW R.I, on June 10, 1915, Idflieg gave SSW a contract to build six more R-planes. These were initially designated G.32-37/15, then changed to G.33-38/15, and finally to R.II 2/15 to R.VII 7/15. The specification required a maximum speed of 135 km/hr (a small increase over the R.I's speed), climb to 2,000 meters in 35 minutes and 3,000 meters in 70 minutes carrying a useful load of 2,450 kg, a crew of five like the R.I, and fuel for an endurance of six hours. Specified armament was a cannon in the forward turret and two machine guns, one in the dorsal position and another in the ventral position, plus 600 kg of bombs. However, the cannon was never fitted and a lighter mount for a machine gun was installed. Armor to protect the pilot was initially specified, but Idflieg later dropped this requirement to save weight.

Idflieg required the aircraft to maintain level flight on the power of two engines, and wanted, but did not require, the aircraft to be able to take off on the power of two engines with full crew and armament (less bombs) and one hour of fuel.

Idflieg also specified a strict aircraft delivery schedule. The first was to be delivered by the end of September, 1915, the second by the end of October, and the remaining four aircraft at eight-day intervals thereafter. The deadline for final delivery of all aircraft in the order was April 1, 1916.

These SSW R-planes were designed to use three 240 hp Maybach HS engines, the most powerful aero-engines then available. Originally designed for airship use, the Maybachs proved unable to withstand the more rigorous demands of aircraft use, especially prolonged running at maximum power during take-off and lengthy climbs to altitude. Engine failures were depressingly common and greatly impeded flight testing. In fact, the engine's reliability was marginal even in airships. Finally the aircraft had to be re-designed to use either the 200 hp Benz Bz.IV or the 260 hp Mercedes D.IVa six-cylinder engines. This was a major problem because the central engine location was integral with the structure, and the engine bearers, clutch, and central transmission system all had to be re-designed for the new engines, causing a great deal of additional work. Overall, the Maybach engine debacle delayed delivery of these aircraft by nearly two years.

The lower-power Benz engines were installed in R.III, R.IV, and R.V. Flight tests soon revealed that these aircraft were under-powered and could not meet Idflieg’s climb and useful load requirements. Wing span and area of these aircraft had to be enlarged for more lift to compensate for the lower power of the Benz engines.

The more powerful Mercedes engines were installed in R.II and R.VII. However, the greater weight of the Mercedes engines again meant the wing span and area had to be enlarged, this time to compensate for the weight increase.

These aircraft, originally designed with three bays of struts, had to have wings enlarged to four, five, or even six bays due to the increased span needed for greater wing area. These "supplementary bays" were installed between the wing center section and the outboard wing sections. The variety of engines, wing variations, and other changes during development meant that no two of these aircraft were alike.

To facilitate in-flight engine servicing and repairs, the engine room was enlarged and each engine was fitted with a separate clutch to enable a failed engine to be de-coupled and stopped while the running engines continued to power the propellers. If the mechanic could repair the engine in flight, it could be restarted and re-engaged with the clutch to power the transmission and propellers.

However, despite the enlarged engine room, the space was still very cramped, impeding the mechanic's ability to service the engines in flight. In flight the engine room was hot and often filled with hot, toxic gases from exhaust leaks. The mechanic had to avoid contact with hot exhaust manifolds, which was not easy during flight. The forward engines were so close together that the cylinder head of the left engine had to be removed to provide enough room to replace the exhaust gaskets on the right engine!

Another problem with the complex, centralized power system with internal engines was that any engine or transmission repairs were hardly possible without practically tearing the whole fuselage apart. Additionally, misalignment of assemblies caused frequent drive failures. Lengthy, painstaking development work eventually resolved most of these problems, resulting in reasonable reliability. The SSW R-planes eventually flew a significant number of successful day and night missions. However, the delays meant that, by the time the SSW R-planes arrived at the front, more modern Zeppelin-Staaken R-planes with decentralized power were also in service and gave greater reliability with less development effort. On the positive side, the SSW R-planes had excellent flying characteristics.

R.II 2/15

This was the first aircraft of this batch to be completed and flown, its first flight being on October 26, 1915. However, R.II used the ill-fated Maybach engines, and test-flight experience soon required their replacement. After discussion, Idflieg decided on installation of 260 hp Mercedes D.IVa engines, but by then a shortage of skilled workmen caused SSW to focus on completion of R.V-R.VII and R.II was temporarily stored until the workforce could get to it.

Work finally restarted in early 1917. By then SSW had experience with the Mercedes-powered R.VII and the R.II was completely rebuilt with extended-span wings and enlarged tail surfaces. The R.II was finally delivered to REA on June 29, 1917, but by that time it was not able to compete with the new Staaken R-planes and was relegated to training at the R-plane school at Doberitz. In 1918 it was transferred to REA Cologne and later crashed.

R.III 3/15

R.III was delivered about a month after R.II. However, R.III was also sabotaged by its Maybach engines and crashed in early 1916 due to their failure. At Idflieg’s direction, R.III was stored until SSW had the resources to rebuild it. Later in 1916 R.III was rebuilt with enlarged wing span, 200 hp Benz Bz.IV engines, a reinforced tail, and numerous detail improvements. Idflieg realized the modified R.III was not suitable for combat use and R.III was delivered to REA for training on December 12, 1916. It was still in training service in late February 1918.

R.IV 4/15

R.IV was singled out for extensive development of the Maybach HS engines and related modifications to prove these engines were flight-worthy, and as a result may have been the only airplane powered by these engines to be accepted by Idflieg. The R.IV was delivered on January 29, 1916, and immediately experienced severe engine problems, not performing a useful flight until May. Not being responsible for the engine problems, SSW asked Idflieg to accept R.IV and continue the test program. Idflieg agreed and accepted R.IV on August 27, 1916, after a flight was completed to lowered requirements. By this time the R.IV wing span had been enlarged.

The R.IV was repaired in November, perhaps as a result of a crash. At this time the Maybach engines were replaced by Benz Bz.IV engines and the wing span was again increased. The first flight of the rebuilt aircraft was on March 14, 1917. R.IV joined Rfa 501 at Vilna on the Eastern Front on 27 April and flew several operational missions. The R.IV was then used as a trainer at Vilna and later returned to Berlin and made a safe emergency landing near Spandau in June 1918. By the end of August it was again repaired.

R.V 5/15

R.V was nearly complete when it was decided to replace the Maybach HS engines with 200 hp Benz Bz.IV engines, requiring a complete rebuild. R.V was delivered to REA on August 13, 1916 and then flown to Rfa 501 at Vilna. This delivery flight was a true adventure characterized by clutch and engine failure. Repair required complete disassembly of the gearbox to reach a failed bearing.

R.V flew a number of bombing missions from late 1916 into early 1917. However, in mid-February R.V was severely damaged in a night landing accident. The remains were shipped back to Doberitz for use as spare parts for REA.

R.VI 6/15

R.VI was partially complete when it was decided to replace the Maybach HS engines with 200 hp Benz Bz.IV engines, again requiring a complete rebuild. This included an increased wing span. It was shipped from the factory on April 25, 1916. Several successful test flights were made at the factory, including one that established an unofficial world record of six hours in the air carrying a useful load of 2,400 kg. However, the secrecy required by the war prevented any publicity.

Despite this achievement, the climb and ceiling of the R.VI were marginal and the delivery requirements had to be relaxed to a climb to 3,000 meters in 90 minutes with a reduced useful load of 1,410 kg. R.VI passed these requirements, as R.III and R.V did later, and was delivered to REA on July 20, 1916, from which it was flown to Rfa 501 on August 7. R.VI performed is first operational bombing mission on September 3 but suffered an operational career checkered by mechanical problems and did not complete many operational missions. R.VI was dismantled in November 1917 as being of no further use.

R.VII 7/15

R.VII was the first aircraft of the batch to receive the 260 hp Mercedes D.IVa engines, a change that required extensive rebuilding to strengthen the airframe and power assembly for the larger, more powerful engines. In fact, completely new, larger, stronger wings had to be built and the tailplane had to be enlarged to compensate.

The R.VII was first test-flown on January 15, 1917. The wings were determined to be too heavy and during its test program new, lighter wings were fitted. R.VII was delivered to REA on February 11 and flown to Rfa 501 at Vilna on the 26th of that month. At Vilna a number of field modifications were made, including painting the wing undersurfaces gray for night operations and adding bomb racks for additional bombs, bringing its total bomb-load to 750 kg. R.VII made its first flight from Vilna on March 12, 1917 and its first operational flight on the 15th. However, failure of the spur gear of the left engine during take-off resulted in an aborted take-off.

After repair R.VII flew bombing missions into the summer of 1917 when Rfa 501 was transferred to the Western Front. R.VII was then used as a trainer at Vilna into January 1918.

Siemens-Schuckert R-Plane Specifications

Forssman R.I R.II (Orig.) R.II (Reblt.) R.III (Orig.) R.III (Reblt.)

Engines Mercedes(1) 3 x 150 hp Benz Bz.III 3 x 240 hp Maybach HS 3 x 260 hp Mercedes D.IVa 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV

Span 24 m 28 m 28.22 m 38.0 m 28.22 m 34.33 m

Wing Area 140 m2 138 m2 156 m2 233 m2 156 m2 177 m2

Length 16.5 m 17.5 m 17.7 m 18.5 m 17.7 m 17.7m

Height - 5.2 m 4.6 m 4.6 m 4.6 m 4.6 m

Empty Weight 3,250 kg 4,000 kg '5,350 kg 6,150 kg - 5,400 kg

Loaded Weight - 5,200 kg 7,150 kg 8,460 kg - 6,820 kg

Max. Speed: 115 km/h 110 km/h 130 km/h 110 km/h - 132 km/h

Climb: 2,000m - 35 min. - 23 min. - 35 min.

3,000m - - - 45 min. - -

Ceiling: - 3,700 m - 3,800 m - 3,000 m

Duration: - 4 hours 5 1/4 hours 4 hours - 4 hours

Notes: 1. Originally 4x110 hp Mercedes D.I, rebuilt to 2x110 hp Mercedes D.I + 2x220 hp Mercedes D.IV.

Siemens-Schuckert R-Plane Specifications

R.IV (Orig.) R.IV (Reblt.) R.V R.VI R.VII R.VIII

Engines 3 x 240 hp Maybach HS 3 x 200 hp Benz Bz.IV 3 x 200 hp Benz Bz.IV 3 x 200 hp Benz Bz.IV 3 x 260 hp Mercedes D.IVa 6 x 300 hp B&S BuS.IVa

Span 28.22 m 37.6 m 34.33 m 33.36 m 38.44 m 48 m

Wing Area 140 m2 201 m2 177 m2 171 m2 210 m2 440 m2

Length 17.7 m 18.0 m 17.7 m 17.7 m 18.5 m 21.6 m

Height 4.6 m 4.6 m 4.6 m 4.6 m 4.6 m 7.4 m

Empty Weight - 5,450 kg 5,300 kg 5,250 kg 5,700 kg 10,500 kg

Loaded Weight - 6,900 kg 6,766 kg 6,800 kg 7,960 kg 15,900 kg

Max. Speed: - 130 km/h 132 km/h 132 km/h 130 km/h 125 km/h (est.)

Climb: 2,000m - 36 min. 36 min. 36 min. 27 min. -

3,000m - 104 min. 102 min. - 66 min. -

Ceiling: - 3,050 m 3,000 m 2,950 m 3,200 m 4,000 m (est.)

Duration: - 4 hours 5 1/4 hours 4 hours -

Показать полностью