O.Thetford, P.Gray German Aircraft of the First World War (Putnam)

Zeppelin-Lindau (Dornier) Rs II

Dornier's Rs II differed considerably from his first machine. Construction began in December 1915, and the first flight was made on 30th June 1918. The lower wings were now no more than rudimentary, and this flying-boat was, in effect, a monoplane. The shortening of these wings obviated the tendency for the tips to "dig in", as had been experienced with the Rs I when anything like a swell was running. It had been found, after initial trials, that the widened hull of the Rs II had ample lateral buoyancy of itself. The hull, which was mainly metal skinned except for some of the decking, which was fabric, was also drastically shortened and the tail surfaces carried on tubular steel outriggers. Initially these were of biplane format, but were later modified to monoplane surfaces with twin fins and rudder, both above and below the tailplane.

Engine arrangements were originally as in the first machine, but later power was increased to four engines, and these were mounted in tandem pairs in two power-eggs between the wing and fuselage. Two massive pairs of steel vee struts on each side braced the fabric-covered wing, with its horn-balance ailerons, to the top longeron.

After its trial programme was completed this flying-boat (No. 1433) was dismantled in order that resources might be devoted to the Rs III.

Engines, three 240 h.p. Maybach Mb IV. Span, 33.2 m. (108 ft. 11 1/4 in.). Length, 23.88 m. (78 ft. 4 1/4 in.). Area, 257 sq.m. (2,776 sq.ft.). Weights: Empty, 7,100 kg. (15,620 lb.). Loaded, 9,300 kg. (20,460 lb.).

After modification: Engines, four 240 h.p. Maybach Mb IV. Span. 33.2 m. (108 ft. 11 1/4 in.). Length, 21.7 m. (71 ft. 2 3/8 in.). Area, 257 sq.m. (2,776 sq.ft.). Weights: Empty, 7,180 kg. (15,796 lb.). Loaded, 10,000 kg. (22,000 lb.). Speed, 130 km.hr. (81.25 m.p.h.).

G.Haddow, P.Grosz The German Giants (Putnam)

Dornier Rs.II

Spurred on by the sudden loss of the Rs.I, Dornier and his staff worked vigorously to complete their second flying-boat, the Dornier Rs.II. The design and construction drawings for the aircraft had been prepared during 1915, and the relatively short construction time suggests that portions of the Rs.II had already been completed prior to the destruction of the Rs.I. Although built of the same materials, steel and aluminium, the Rs.II design had little else in common with its predecessor. The most important change was the broad hull, which was the first step towards Dornier's distinctive and practical inherently-stable hull designs. Other changes included a broad, low-aspect-ratio upper wing, an open tail boom structure and an unusual tail configuration.

It is interesting to speculate on the reasons why Dornier continued with the buried-engine system after it had failed in the Rs.I. It is surmised that the transmission had been completed and perhaps even bench-tested and that consideration of expense and expediency warranted giving the buried-engine system another chance. However. Dornier was not satisfied with remotely-driven propeller systems, and he began a series of experiments in early 1916 to thoroughly investigate the feasibility of other propeller and engine arrangements. The first experiment, an examination of the efficiency of the tandem engine lay-out, was conducted by Dornier's long-time associate, Dipl.-Ing. Schulte Frohlinde. In the test the engine were mounted back to back on a large test stand and the thrust of individual tractor and pusher propeller was compared with the thrust of the propellers running in tandem. The tandem arrangement, contrary to expectations, was found to have a negligible thrust loss, and this fact had important consequences for the R .II and many subsequent Dornier types. This system was used on many Dornier aircraft throughout the Thirties until the end of World War II.

Initially, the Rs.II was powered by three 240 h.p. Maybach HS (or Mb.IV) engines mounted within the hull and driving three pusher propellers supported between the upper wing and hull on a lattice-girder framework. The engine radiators were mounted as a wide slab on top of the hull behind the pilot's cockpit.

The upper wing had a very low aspect ratio of 5:1 in order to distribute the great weight of the aircraft over a small beam length. The wing was mounted above the hull by two great N strut at the centre section. The bottom apex of the N was a pivot point from which ran two V struts that supported the outer wing structure. As with the Rs.I, the length of the forward leg of the N could be changed to vary the angle of incidence of the wings. The small lower wings were used, in Dornier's words, primarily to support wingtip floats, but initial flotation tests proved these floats unnecessary and they were removed. This marked the origin of the Dornier inherently stable flying-boat hull, which was destined to be a Dornier trade-mark for many years. The small stub wings were retained for the amount of extra lift they provided, but they were discarded on succeeding flying-boat designs.

Three built-up girder spars of triangular section formed the primary wing structure, which included the Dornier practice of aluminium ribs spaced fairly wide apart. The wing fabric was sewn to special eyelets attached to the framework at evenly spaced intervals. This method of holding down fabric proved very successful and later found application in airships. The ailerons were unbalanced. To improve lateral control at near stalling speeds the tip incidence was "washed-out".

The crew was situated near the bow in a large open cockpit protected by a raised streamlined coaming. The central and rear hull section contained the buried engines and fuel tank. The hull was built of steel bulkheads and stringers. The sides and bottom of the hull were covered with duraluminium, whereas fabric was used for portions of the decking. The tail was supported by an uncovered box framework composed of four tubular booms joined by a series of vertical and horizontal struts reinforced by diagonal cables. The two lower booms ran directly into the end of the hull, while the upper booms were attached to a combination lattice-girder V-strut structure. The lattice girders continued the boom line and were anchored deep in the hull. The tail was left uncovered to avoid buffeting from the water pray, which Rs.I taxying trails had shown to be unpleasantly high and heavy. The tail assembly consisted of a small fixed tailplane mounted to the upper booms. Two rudders, which were rather small for an aircraft this size, were hinged between the booms below the tailplanes. An all-flying biplane cellule was awkwardly hinged behind the rudders and took the place of elevators. The tail assembly does not seem to have been thoroughly engineered, and its appearance suggests that structural simplicity was forfeited for questionable control advantages.

Such was the appearance of the Dornier Rs.II when it left the Seemoos hangar for its taxying trials on 17 May 1916. Test pilot Schroter recalls the event:

Graf Zeppelin was present to observe the launching. With him aboard his motorboat Wurttemberg were Dornier, Oberingenieur Durr, Generaldirektor Colsman. Direktor Winz and Dr. Eckener. At my request Ing. Schulte-Frohlinde occupied the co-pilot's position. With the engines throttled back, I taxied to the Swiss side of the lake, there we turned and, heading into a mild breeze, I gave full throttle. The Rs.II sped forward, but the speed obtained was insufficient to raise the hull on to its step in such placid water conditions. Later the Wurttemberg attempted to break up the water surface for us, but it was useless and the Rs.II was brought back to the hangar.

A total of six water-borne tests were conducted during which it became necessary to increase the rudder area to improve manoeuvrability. This was done by adding a tall third rudder between the tail booms and controlled by cables attached to the outer two rudders. The Rs.II was now ready for its maiden fight.

Schroter continues:

On the next attempt (30 June 1916) we had a sufficient wind. Aboard, besides myself, were Schulte-Frohlinde, Dr.-Ing. Adolf Rohrbach, Ing. Lindner, and four engine mechanics. After manoeuvering into position, I opened the throttles and we sped over the lake. I gave a slight tug on the controls, the Rs.II raised on its step. The wind had helped. With precise motion, I gently pulled the wheel toward my chest. Now a springy jump from wave to wave. The jolts ceased; we were in the air. How easy it all was, almost as if I had a fully-proven aircraft in my hands.

Carefully I prepared to land. With throttled engines, the Rs.II willingly lowered its nose and glided to a landing. A sudden splash, a lurch forward and we came to a halt.

Triller, a Dornier mechanic who also was aboard the Rs.II on its first fight, described the event somewhat differently:

On 30 June 1916 the Rs.II was ready for its maiden fight. Aboard were Schroter (pilot), Schulte-Frohlinde and myself. The aircraft at the time weighed 7045 kg. The first two takeoff attempts were made with the angle of incidence set at one degree and two degrees respectively. On the third attempt with the angle of incidence increased to three degrees, the Rs.II rose into the air on its maiden flight at 07.30 hours. Two more flights were made that day.

Three further flight proved the need for further modification. The lattice-girders that held the upper booms were replaced by large-diameter metal tubes to give the tail structure greater rigidity and strength. Also, the area of the central rudder was reduced and fixed fins fitted between the boom ends to improve seaworthiness, changes were made to the hull's planing surface.

On 17 July 1916 the modified Rs.II was ready to continue its test programme. These tests were not entirely satisfactory. Various incidence settings were tried to improve take-off qualities. In fight the aircraft reacted well to the elevator and rudder but was sluggish in answering to the ailerons. With the starboard engines throttled back no sinking or stalling was observed, even so, in this condition full rudder was insufficient to maintain straight flight. Trouble was experienced with the port transmission, which vibrated regularly, and it was the failure of this that put an end to the first part of the Rs.II story.

Schulte-Frohlinde reported:

At 10 to 12 metres altitude after 1/2 minute fight duration, the port propeller broke. Mr. Schroter quickly cut the throttle and we found ourselves at once on the water. Since the hull had remained water tight we were in no danger.

About the incident, Schroter wrote later:

We had drifted and took off again when the middle propeller transmission broke loose and severely damaged the tail boom. We were lucky to land safely in a confusion of torn and bent struts and loose wires.

It was decided to completely rebuild the Rs.II, and the work, which was started in July, was finished on 5 November 1916. On the next day Bruno Schroter, by now the most experienced giant sea plane test pilot, flew the new Rs.II on its maiden flight. The rebuilt RS.II was virtually a new aircraft, now powered by four engines mounted above the fuselage in a tandem configuration, which Schulte-Frohlinde had thoroughly tested and proven. The propellers were driven through reduction gears and the engines were initially left uncowled. The changed engine location required altering the upper tail boom attachment structure to avoid the propeller arcs. Therefore, the booms were attached to two corners of a triangular tube frame, the third corner of which was joined to a single tube fixed to the centre decking of the hull. The unusual biplane elevator cellule was retained, but a broad fin and rudder of greatly increased area were fitted to improve manoeuvrability on the water. For the same reason, the hull section was refined, and the step moved farther aft to reduce the take-off run, which in spite of these changes still remained too long.

The wing gap was decreased and the wing struts now met the hull about halfway down the sides instead of on top. The only change in the upper wing was to fit aerodynamic balancing surfaces to the ailerons. The lower stub wings were entirely reconstructed with rounded tips and decreased chord. They were placed well aft on the hull and given pronounced dihedral to prevent them from dipping into the water. Tests proved that the Rs.II had adequate stability in wind force 5, although the bottom wing did come in contact with the water under these extreme conditions.

The old experimental Maybach motors in the Rs.II gave no end of trouble during the test programme, much to the irritation of the naval test pilot Lt. Tille. He complained about the galling of pistons and leaking cylinder-heads. The cause of the latter mishap was attributed to the forced slipstream cooling of the uncowled Maybach engines, rather a paradox, for generally the great problem of the Maybach engines was overheating. However, when the engines were cowled and tested again the complaint voiced was that the radiators were too small. In addition, raw material shortages were making themselves felt; spark plugs burned through and valve seats and parts failed regularly, seriously retarding the flight programme.

Lt. Tille wrote the following report about the Rs.II after he had flown the machine in November 1916:

The flight characteristics, with the exception of a few minor points, are thoroughly satisfactory. The seaworthiness is satisfactory, with exception of the take-off and landing phases. A slight widening of the hull to increase lateral stability is recommended. To insure adequate take-off capability, a complete reconstruction of the hull is absolutely necessary. And last but not least the effect of salt water on duraluminium must be exhaustively investigated.

Lt. Tille was convinced of the future of the R-flying boat when he concluded by saying: "A new flying-boat, built using lessons learned and to be learned, promises the beginning of a development cycle which will extend the flying-boat far beyond the borders of present-day performance characteristics." A prophetic statement indeed, for a flying-boat was, in a few years time, to be the first heavier-than-air machine to cross the Atlantic. On the other hand, with the same optimism shown by Army staff officers at the time, Admiral von Capelle, Commander of the German High Seas Fleet, prematurely expected the arrival of the Rs.II on the coast and he wrote on 28 December 1916: "It is believed an R-flying-boat now under test on Lake Constance will soon come to the coast for further tests. It will then be seen how the R-seaplane can be developed and in what direction." As it turned out, the hopes of the Naval High Command were never fulfilled, for only a single R-seaplane was placed in limited operational service during the war.

Dornier and his staff began to work on their third giant flying-boat, using much of the valuable data gathered from the Rs.II test programme. During May 1917, while practising landings, the Rs.II came down hard on the water, breaking the central boom support. The pilot did not notice that the tail hung by only four cables and attempted to take-off again. The sagging tail forced the Rs.II back on to the water, causing the cables to snap. The lower booms broke and the tail sank to the bottom of Lake Constance. But the hull remained absolutely water-tight during these severe landings and proved to Dornier the soundness of its construction.

By July 1917 the cumbersome tail unit had been replaced by a cleaner design consisting of a single tailplane with finely-formed fins and rudders mounted at the end of each boom. The new boom structure was much stronger and of simpler design. At a later date the wingspan was slightly lengthened to increase lift, the effect being to enclose the ailerons in the wingtip outline.

Up to the summer of 1917 the RS.II carried out a large number of experimental flights. In the period 23-26 June 1917 it was thoroughly evaluated by the SVK (Seeflugzeugs-Versuchs-Kommando - Seaplane Testing Command). During these, the Rs.II was used to investigate the effect of various engine-off configurations on flight performance. For instance, on Lake Constance it was found possible to take-off and slowly climb with one forward engine off. It was also definitely proven that the efficiency of the pusher propeller was higher when the forward engine was shut off than the efficiency of the tractor propeller with the rear engine off.

The Rs.II was easy to manoeuvre on the water, and took-off after a 20-30 second run, but in horizontal flight proved to be very tail heavy. Nevertheless, the flight characteristics were considered quite sufficient for long-range reconnaissance missions. The maximum level speed was remarkable, 128 km.h. had been attained over Lake Constance.

By August 1917 preparations were completed to deliver the Rs.II to the Naval seaplane base at Norderney for seaworthiness tests on the North Sea. An emergency supply depot with tools, spares and fuel had been established at Duisberg on the Rhine in case of a forced landing. Essentially, all that remained was for the Rs.II to complete a 6-hour simulated delivery flight over Lake Constance as required by Naval authorities. Plagued by minor but recurring engine failures (especially the valves) and the increasingly deteriorating quality of aviation fuel, the programme dragged on. The fuel was so poor that engine revolutions were often reduced some 50 to 70 r.p.m., which prevented the Rs.II from achieving optimum delivery conditions. With much difficulty sufficient high-grade fuel was collected, and sometime in August 1917 the Rs.II finally took-off on its practice delivery flight. It had been in the air about 2 hours when, at 1100 metres, number 4 engine backfired violently. As Navy mechanic Blume went to investigate he was thrown into a corner of the hull by flying propeller splinters. Engines number 4 and number 1 (which had completely lost its propeller) were shut off and the Rs.II descended safely in a slow glide.

Because of the extensive damage suffered by engines, hull and wings from the volley of propeller fragments, the Dornier company recommended scrapping the Rs.II. Its parts were to be systematically tested and results applied to the design and calculation of new R-planes.

Although built before the Rs.III, the Rs.II was not placed on Naval status until late April 1917, some months after the Rs.III had been ordered. Consequently the Rs.II received a higher Naval number (1433) than the Rs.III (1431).

The Dornier Rs.II never did achieve the role intended for it: service tests on the North Sea. Even so, it was an extremely useful test bed. Valuable lessons learned from all its modifications were to have a great influence on Dornier's future work. The broad hull, the tandem engines, the sophisticated metal construction and the adaptability of design became Dornier hallmarks.

Colour Scheme and Markings

The national markings of the Dornier Rs.II consisted of the Patee cross on a square white background. The wingtip markings were rather small, occupying less than a third of the available wing chord. Although the earlier four-engined version had crosses on the tail, no tail markings were carried on the final version of R .II.

SPECIFICATIONS

Type: Dornier Rs.II (first version) Dornier RS.II (second version)

Manufacturer: Zeppelin-Werke Lindau G.m.b.H., Seemoos, Lake Constance

Engines: Three 240 h.p. Maybach HS (or Mb.IV) engines Four 245 h.p. Maybach Mb.IVa engines

Dimensions:

Span upper, 33•2 m. (108 ft. 11 in.) 33•2 m. (108 ft. 11 in.)

Chord, 6•5 m. (21 ft. 3 1/2 in.) 6•5 m. (21 ft. 3 1/2 in.)

Span lower, 15•96 m. (52 ft. 4 in.) 16•0 m. (52 ft. 6 in.)

Chord, 3•58 m. (11 ft. 9 in.) 3•58 m. (11 ft. 6 1/2 in.)

Length, 23•88 m. (78 ft. 4 in.) 23• 8 m. (78 ft. 4 1/4 in.)

Height, - 7•6 m. (24 ft. 11 1/2 in.)

Hull length, - 11•8 m. (38 ft. 8 1/2 in.)

Beam, - 4•15 m. (13 ft. 7 1/4 in.)

Hull height, - 2•15 m. (7 ft. 4 in.)

Areas:

Wing, 257 sq. m. (2765 sq. ft.) -

Wing upper, - 234•25 sq. m. (2521 sq. n.)

Wing lower, - 41•75 sq. m. (443 sq. ft.)

Tailplane, - 18•8 sq. m. (202 sq. ft.)

Elevators. - 8•1 sq. m. (87 sq. n.)

Rudder, - 11•60 sq. m. (125 sq. ft.)

Ailerons, - 14 q. m. (151 sq. ft.)

Weights:

Empty, 6475 kg. (14.275 lb.) 7278 kg. (16.045 lb.)

Loaded, 7323 kg. (16,144 lb.) 9158 kg. (20,190 lb.)

Wing Loading: - 33 kg./sq. m. (6'76 lb. sq. ft.)

Performance:

Maximum speed, 100-105 km.h. (62-65 m.p.h.) Maximum speed. 128 km.h. (79'5 m.p.h.)

Climb, - 2500 m. (8202 ft.) in 50 mins.

Fuel: 2000 litres (440 Imp. Gal.) 200 litres (440 Imp. Gals)

Service Use: None

M.Schmeelke Zeppelin-Lindau Aircraft of WW1 (A Centennial Perspective on Great War Airplanes 42)

Rs.II: The First Giant Flying Boat in the Air

The Rs.II was conceived as a biplane with a short lower wing, also known as a sesquiplane. Since April 1st 1916, when duraluminum profiles could be produced in large numbers, they were used for the Rs.II. As a result, the empty weight of the second flying boat was significantly lower than that of the first, at 6,169 kilograms. The Rs.I had weighed 7,500 kilograms.

Also, when covering the wings - the upper wing had a span of 32 meters, the lower wing 13.5 meters - Dornier tried a new approach. In order to attach the fabric to the metal airframe, grommets were built into the ribs so that the thread did not chafe, and they could be easily threaded with a needle or an awl. This simple but effective way of attaching fabric would also be used for later Dornier aircraft.

The three Maybach Mb IV engines could be salvaged from the wreck of the Rs.I. After a comprehensive manufacturer overhaul, Dornier initially placed them in the hull of the Rs.II. The power transfer, using shaft displacements and two gear drives on the pusher propellers, was similar to the Rs.I. The central configuration of the engines increased the aircraft's stability in the water and simplified the maintenance, but also caused a lot of problems that had also plagued its predecessor. The reason for this configuration, which was considered outdated, was likely the fact that design and construction on the Rs.II had already begun in 1915.

The boat entered the water of Lake Constance for its first tests on May 17th, 1916. The radiator, engines, and the boat were tested in a series of trial runs, where the speed never exceeded 26 km/h. Because the hull had been widened to 4.15 meters, it was no longer necessary to mount floats under the wings, thus creating the world's first inherently stable flying boat.

But it seemed that Dornier's second flying boat also did not want to leave the water.

Claude Dornier turned to Prof. Baumann in Gotha, since he had significantly more experience in building giant flying boats. He travelled to Gotha on May 30th, 1916 and Prof. Baumann wrote the following in a letter dated May 29th, 1916:

“[...] tomorrow Mr. Dornier will come from Friedrichshafen to get some advice, now, finally after he blew 1,000,000 Mark. His newest craft (Rs.II) travels at 20 km/h and is not even contemplating flying[...]”m

It's not clear how much Prof. Baumann could help Claude Dornier. But it was clear to all that with a flying boat of this size and design, Dipl.-Ing. Dornier was breaking completely new ground, and had to do a great deal of pioneering work first. Prof. Bauman's experience building giant aircraft such as the Gotha G-Types might be able to help.

Between May 20th and June 8th, the front of the fuselage step was laid, the redundant bomb bays were rebuilt and a spare radiator was inserted. The boat still did not take off. The elevator, including the box-shaped control unit which could be adjusted in flight, was also altered. In its final form, the vertical stabilizer was made of two movable rudders without a pre-stage, and an elevator fin.

On June 9th, the boat reached a speed of 65 km/h for the first time, rose out of the water to the step and was on the verge of lifting off for the first time. Encouraged by this progress, Dornier added one small additional aid to the hull in the middle of June. During another test on June 26th, the upper transmission bearing broke. The testing could continue after repairs were complete on June 30th. The empty weight of the aircraft had increased to 6,388 kilograms, and the take-off weight to 7,045 kilograms. Nevertheless, on this, the seventh attempt, the Rs.II lifted off from the water effortlessly, at 80 km/h.

“[...] On the third attempt, at 7:30am, the aircraft rose out of the water for the first time. It was a blissful and calm feeling as the steps got longer and longer and then ended. Finally!

We flew about three minutes, two meters above the water, and on the second flight we reached an altitude of about 25 meters, and flew for four minutes. ”

On July 1st four flights were carried out, although on the final flight of the day the starboard gear shaft broke, and the attached engine, which was running without load, blew out.

After the repairs, testing was able to begin again on July 17th. On the last flight the port propeller ruptured, and heavily damaged the other two propellers, the upper wing, the port flaps, as well as a girder in the tail section. Still, the pilot was able to glide the Rs.II to a safe landing.

The constant problems with the remote operator caused Dornier to switch to a direct drive. Instead of placing the three engines underneath the propellers, four 260 horsepower Maybach Mb IVa direct drive engines were built into the aircraft in a so-called tandem configuration. Two by two engines were placed behind each other in a single nacelle. These propellers' power unit, configured as one pull and one push propeller, proved to be significantly more efficient than a single propeller.

In order to test the tandem drive, a test facility was built behind the Seemoos hangar. The engines were placed on an iron frame, one end of which was able to be pivoted around the axis, while a scale was placed on the other end. The experiments and measurements showed that the tractor engine had only about 70% of the performance of the pusher engine. This reduction in performance stemmed from the drag created by the top of the engine and the nacelle. On the pusher engine the air could flow through unhindered. Claude Dornier had calculated the engines' output ahead of time, but still this one showed better flight performance. This was also in part due to the larger radiators from the Suddeutsche Kuhler Fabrik (SKF), which were flexibly mounted. In order to regulate the temperature, fabric curtains could be closed between the cooling surface and the engine room.

At the same time, the entire instrument panel was modernized, including four tachometers (Morell), eight temperature sensors (Morell), a circuit breaker for each of the four engines, and four signal lamps. The Bosch-built throttle, which had been salvaged from the Rs.I, was replaced by one that had been built in-house.

After the rebuild, Rs.II began flying again on November 6th, and following a short take-off run of 52 seconds, the boat took off. The craft was significantly faster following the modifications and the extra engine.

As the flying boat was brought back to shore, the stick was damaged when it collided with the landing pier. Repairs had to be completed quickly because in the meantime Lieutenant Colonel Mans and Lieutenant Tille had arrived in Seemoos to continue the flight testing.

The future of the giant flying boats from Seemoos depended on the assessment of these two gentlemen. Until that point, all of the cost had been carried by LZ alone.

It is easy to imagine the crew's nervousness as the Rs.II was brought into the water at 7:45am on November 11th. Pilot's mate Erich Schroter also surely felt it, since Lt. Tille seemed to be unhappy with the performance so far, although Schroter was a very experienced airman.

“[...] On November 11th in the morning, I took the first flight as a guest, with the company’s aviator Schroter. I saw, by virtue of the fact that the pilot was busying himself with what seemed to me completely unnecessary work during the short, straight flight, as well as his fear of heights, that he was in no way a master of the aircraft. After a few minutes I gave him the order to land so that I could take the controls. The duration of the entire flight was about 30 minutes. The flights were interrupted by failures of the unreliable engines (these were old testing engines). The machinists on board were sometimes able to correct the irregularities in flight.

Pilot Schroter was taken out of the cockpit and replaced by the Airman First Class Fritz Dauke. He had arrived in Seemoos on November 12th from Warnemunde and on the next day he completed his first flight in the giant flying boat under the command of Lt. Tille:

“[...] On Monday, November 13th, I introduced the aviator Dauke to the aircraft. After a training flight the airman first class, whom I consider one of the most spirited aviators in my acquaintance, was able to fly the aircraft alone. ”

Until then, Dauke had only flown single-engine B- and C- floatplanes, so Lt. Tille flew with him in the Rs.II and explained the aircraft. Dauke then completed a first solo flight of the Rs.II on his own with no problem. This also was a testament to the accomplished construction of the Rs.II, despite persistent technical problems.

In their reports for the RMA the naval master builder Schmedding and Lt. Tille concluded that the Rs.II “was not quits combat-ready ... But could, with some practice, be flown by an average aviator ... and could unquestionably be developed for some long-distance military reconnaissance missions (10 hours). ”

The development or rebuild would include modifications to the shape of the hull. The fuselage was to be lengthened, so that the tail boom could be shortened and placed higher. The tail had often touched the water upon takeoff. In addition, watertight bulkheads would be built into the hull. Lt. Tille did not consider the boat combat-ready in its current form.

In the following weeks, further Rs.II test flights were interrupted by engine defects, piston damage, valve breakage, and leaky lines.

On April 28th, 1917 the central strut of the tail construction broke upon landing, so that the entire tail boom was hanging on just four cables. The pilot had not noticed the break, and wanted to take off again. The craft lifted off but was immediately pushed back into the water because the tail had shifted down, creating a nose-heavy situation. During the rough landing two further cables snapped so that the entire tail was resting on the water surface. Following a redesign of the tail boom, the Rs.II was able to take flight again in June 1917.

After all of these improvements, the Rs.II could be easily maneuvered, despite its 9.2-ton weight. After about 20-30 seconds of acceleration, she easily lifted out of the water. The top speed in horizontal flight was 128 km/h, the highest altitude reached was 1,800 meters. Although the Rs.II always was a bit tail-heavy, the flying characteristics were mature enough that a naval commission approved the Rs.II in July 1917 in Seemoos.

An accident occurred during the approval and acceptance process, which foreman Heinrich Triller described in the Dornier Post in 1936:

“[...] our giant flying boat Fs.II [Rs.II] stood in the hangar, ready to be approved. The gentlemen of the commission, naval and flight officers, were all there. The hangar doors were open and I did a short test of the four Maybach engines. Everything was well: the engines ran at about 500 rpm, and I wanted to give the signal to transport the aircraft into the water, as one of our helpers ran up from behind on the port side and waved at me. Suddenly I stopped in surprise. The man climbed up on the craft from behind, and seemed to not be aware of the running propellers. I shouted, waved the man away and reached for the ignition switch but it was too late. The machine shuddered, as if someone had hit it with a hammer. I shut my eyes tightly so that I would not see the horrifying sight, because two years earlier one of our workers was decapitated on the test rig. I breathed a sigh of relief when the man stood next to me, healthy and happy, and looked at me in surprise. He had nothing more than a bump on his head. All he wanted to do was to bring me my protective glasses, and excused himself [...]”

After this accident, the final acceptance flight had to be delayed for a few days, until replacement propellers were delivered. The metal-covered wooden propeller had split along its entire length, the crack was about 10 millimeters wide. Low-quality fuel forced further delays. After the Rs.II's 23rd flight in July 1917, engine performance declined significantly, with each engine delivering 50-80 rpm less than normal, and it took an hour to reach an altitude of 2,000 meters. Since there was no technical defect on the flying boat structure or its engines, the fuel was tested in a laboratory. These tests confirmed the initial suspicion. Both LZ and Maybach had also received this inferior fuel. A test using 2/3 benzene and 1/3 gasoline did not improve the engine performance, causing immediate soot soiling. Many phone calls later, the Rhenania-Benzinwerke in Ludwigshafen was able to deliver appropriate fuel to Seemoos.

The combat readiness of the Rs.II would take place at the naval air station in Norderney. In order to simulate the flight to Norderney, Dipl.-Ing. Dornier ordered a six-hour test flight over Lake Constance on August 13th, 1917. The Rs.II would be fully armed, including a four-man crew, and outfitted as it would be in war. After 2 hours and 17 minutes of flight time, the aft port propeller, built and delivered by the company Behrend-Rugebrecht, broke. Flying parts smashed into the aft starboard propeller as well. Two struts on the tail boom were separated and spars and fabric covers were also damaged. The supports for the engine base as well as the trays of the rear engines were also torn open.

Despite this accident the pilot, Lt. Lech, was able to slowly glide and land the plane.

The heavy damage on the Rs.II prompted the Reichs Naval Department on August 21st, 1917 to order the craft to be scrapped, and to salvage the parts that could be re-used. The testing phase of the 1 1/2 year-old design was complete, and the development of the successor model, Rs.III, was already fairly advanced. Also, the obsolete lattice construction was finally retired. Engineers in Seemoos used parts of the Rs.II, such as spars, empennage and rudders for stress testing in order to gain knowledge for the new Rs.III. The SVK in Warnemunde used parts of the Rs.II, which the Navy had allocated the number 1433, such as the fuselage, for further testing. It was finally destroyed on June 3rd, 1918 during a stress test in Warnemunde.

In the meantime, the financial questions between ZWL and the Reichs Naval Department were cleared up and the purchase and development costs of 300,000 Reichs Mark were transferred to the Abt. Do. The RMA's decision to stop construction of the Rs.II likely included the consideration that the company-internal competitor, Zeppelin-Werke GmbH Staaken, had flown its Staaken L aircraft from Staaken to Potsdam for delivery on August 10th 1917. It was assigned the Naval number 1432. This naval R-aircraft was on the verge of acceptance. At the Potsdam hangar, its wheels were replaced with floats. The design of the aluminum floats was developed together with the ZWL and the naval master constructor Schmedding, and were built in the hangar in Staaken. The carriage upon which the 12-meter-long floats were fastened for ground transport was a special construction. The engineers Scholler and Welker designed a "float bay" which had air chambers and floated on the water surface. In this way the yokes could be pushed over the floats and tightened with bolts.

The first water take-off of the Staaken L was on September 5th from Lake Havel. The aircraft was to be transferred to Warnemunde on November 12th, 1917, but was forced to land on the Saaler Lagoon due to an engine failure. After the repairs, she was flown to Warnemunde on November 14th. As the craft was fastened to the buoy, the specially built carriage could be attached, despite winds of 8-10 meters per second, and the Staaken rolled onto land and into the hangar under its own power. This was proof that large aircraft with massive measurements and weight that had until now been unknown, could be stationed and employed at the front.

In the following weeks, the aircraft was equipped with a radio and mast for the antenna. Larger fuel tanks extended its range to 10 hours. In addition, a lighting and a heating system were added. The aircraft went through rigorous testing in Warnemunde in the months that followed. The focus of these were long-distance flights as well as landing performance in various sea conditions. The maximum flight range of 10 hours could be extended when one of the engines was shut off.

On June 3rd, 1918, the Staaken L crashed during a radio testing flight over land near Warnemunde, and the entire crew was killed.

Specifications of Zeppelin-Lindau Aircraft

Type Length, m Span, m Height, m Chord, m Propeller Manufact. Armament

(guns) Weight, kg Motor Crew

Rs.I 29.00 43.50 7.20 4.60 Garuda/Reschke 1 flexible 6,475 Maybach Mb IVa 240 hp 5

Rs.II 28.88 33.20 7.60 6.50 Lorenz 3.70 1 flexible 6,388 Maybach Mb IV/IVa 6

Rs.III 22.74 37.00 8.10 6.50 versch. 4 flexible 7,865 Maybach Mb IVa 6

Rs.IV 22.30 37.00 8.55 6.50 versch. 4 flexible 6,980 Maybach Mb IVa 6

Military Numbers of Dornier-ZWL Aircraft

Military Designation Manufact. Type Class Engine Notes

M.N.1433 LZ (Do) Rs.II RC4MG Mb IVa x 4 Destroyed in Sep. 1917

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

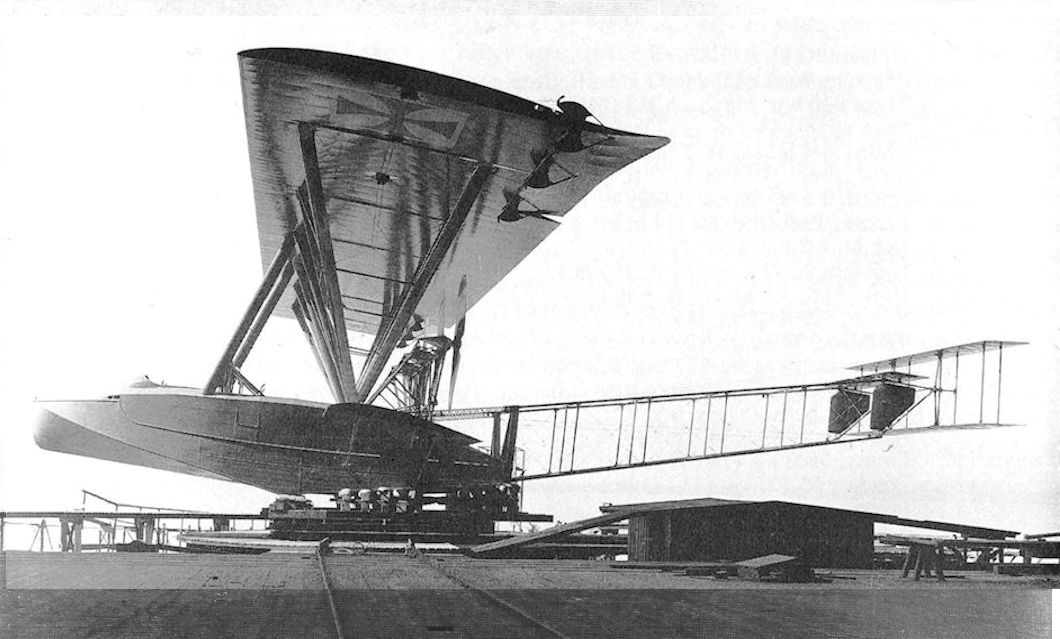

The Rs.II before its maiden flight on May 17th, 1916. (Airbus Group)

The single Zeppelin-Lindau Rs II giant, long range flying boat is seen here in its initial form with biplane tail. First flown on 30 June 1916 with its three 240hp Maybach Mb IVs buried within its short, broad-beamed hull, the problem of power losses in the transmission must have been serious, leading to the Rs II's beaching for modifications. Centred around the engines, this work saw the replacement of the three buried units by four similar engines, now mounted between the hull and the parasol wing in twin push/pull nacelles, with each engine driving its propeller directly. The opportunity was also taken, at this time, to modify the machine's tail unit. In this later form and known as the Rs IIb, the flying boat got airborne once more on 6 November 1916.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

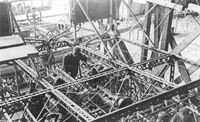

| The struts of the Rs.II received a meta! fairing to improve the aerodynamics. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| On May 17th, 1916, the Rs.II was lowered into Lake Constance for its first test. (Airbus Group)

|

|

G.Haddow, P.Grosz - The German Giants /Putnam/

|

| The Dornier Rs.II modified to have increased fin and rudder area, and employing tubular tail booms.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The Rs.II on the dock in Seemoos. For the stability of the hull in the water, two assistive floats were attached to the lower wings. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| Rs.II is towed by the yacht Wurttemberg.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| After the first test run, vents were built into the hull. It had become almost impossible for the machinists to do their jobs due to the enormous heat of the engines located in the hull. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The propeller's power unit, through tubular shafts and angular gearboxes, stemmed from airship construction.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The Rs.II takes off after the modifications to the tandem engines on November 6th, 1916. The engine nacelles had not yet been installed, so that any problems in the cooling or fuel lines could be immediately repaired. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

The Rs.II flies past the hangar in Seemoos in 1916 (Airbus Group).

The Zeppelin-Lindau Rs IIb, seen here in almost final form and only awaiting its four 240hp Maybachs to be encased in drag-reducing engine nacelles. Capable of reaching 81 mph top level speed at sea level, the Rs IIb had, by now, elicited sufficient naval interest to have been bought and issued with the serial 1433. Following flight testing, the machine was dismantled so that parts could be used in its successor, the Rs III.

|

|

G.Haddow, P.Grosz - The German Giants /Putnam/

|

| The Dornier Rs.II undergoing flight trials.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| First flight of a giant flying boat on June 30th, 1916. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| Rs.II flies over Lake Constance at an altitude of 25 meters.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The Pilot Schroter warms up the Maybach Mb IVa engines before take-off. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| Rs.II taxiing on Lake Constance on November 11th, 1916. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The Rs.II during testing by naval aviator Lt. Tille in mid-November 1916. He complained about the shape of the hull, which, in his opinion, caused too much drag. The tail construction was also criticized, because it touched the water during a steep take off.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The entire hull of the Rs.II was overhauled and prepared for the tandem engines. The aerodynamics were improved and it was painted grey-green. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The entire hull of the Rs.II was overhauled and prepared for the tandem engines. The aerodynamics were improved and it was painted grey-green. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The Rs.II after the modifications, on the turntable at Seemoos, November 1916. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| Rear view of the Rs.II.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The giant flying boat Rs.II was also called Flugschiff-Seemoos (Fs.II).

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| After its completion, the upper wing was hung from the ceiling of the hangar so that it could be lowered later, and attached to the struts. With a wingspan of 32 meters and a width of 7 meters, this assembly step had to be planned carefully. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The LZ-built fuel tanks in the hull of the Rs.II could hold 220 liters.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

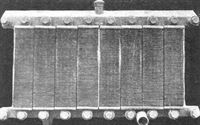

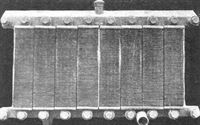

| The position of the Normal-Element radiator (NEK) over the fuselage of the Rs.II. Every cooling system had 10 components.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| The position of the Maybach Mb IV engines in the boat hull. Above them, the radiators from the Norddeutscher Kuhler-Fabrik, with eight cooling fins each for the port and starboard engines, as well as two radiators with four fins each for the central engine, were mounted via flexible suspension. Later these were replaced with products from SKF with 10 fins each, since the engines tended to overheat already during taxi. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| Detail views of the Rs.II

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| In addition to the water coolers, Rs.II also needed an oil cooling system.

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| For the modification of Rs.II to tandem propulsion, a testing rig was built behind the assembly hall. (Airbus Group)

|

|

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

|

| On August 13th 1917 during the acceptance flight for the Navy propeller numbers 1 and 4 failed. The flying fragments broke the tail off, but pilot Lt. Lech was able to land the craft on Lake Constance. (Airbus Group)

|

|

G.Haddow, P.Grosz - The German Giants /Putnam/

|

| Dornier Rs.II

|

|

G.Haddow, P.Grosz - The German Giants /Putnam/

|

| Dornier Rs.II (final form)

|