O.Thetford, P.Gray German Aircraft of the First World War (Putnam)

Linke-Hofmann R II

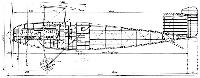

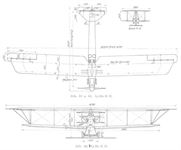

The experience gained with the R I prototypes led to the development of the R II which appeared in 1918. It was a considerably larger aeroplane and to an altogether different conception, based on an approximate three times enlargement of an orthodox single-engined biplane. In this machine the four engines were arranged in two pairs side-by-side, the front pair facing rearwards, and all were coupled to a central gearbox which drove the huge airscrew - some 22 ft. 8 in. in diameter - at 545 r.p.m.

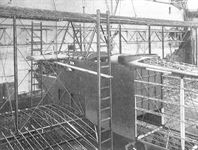

Two prototypes were scheduled, R 55/17 and R 58/17, but in the event only the former ever flew and then only after the Armistice. Wooden construction with fabric covering was featured with most of the forward fuselage ply-covered. The undercarriage consisted of a neat steel-tube vee chassis - unusual in so large an aircraft and again steel-shod wheels with multiple steel springs were used.

It proved possible to fly the machine on two engines. The average fuel/payload arrangement gave a flight duration of approximately seven hours, but by careful adjustment of crew and fuel carried an extended duration of 30 hr. at 74 m.p.h. was estimated as being obtainable. Engines, 4 X 260 h.p. Mercedes D IVa. Span, 42.16 m. (138 ft. 4 in.). Length, 20.316 m. (66 ft. 7 7/8 in.). Height, 7.1 m. (23 ft. 3 5/8 in.). Area, 320 sq.m. (3,443 sq.ft.). Weights: Empty, 8,000 kg. (17.640 lb.). Loaded, 12,000 kg. (26,460 lb.). Speed, 130 km.hr. (81.25 m.p.h.). Climb, 1,000 m. (3,280 ft.) in 8 min., 2,000 m. (6,560 ft.) in 20 min. Duration, 7 hr. Armament, provision for two dorsal and one ventral machine-gun positions.

Показать полностью

G.Haddow, P.Grosz The German Giants (Putnam)

Linke-Hofmann R.II

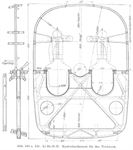

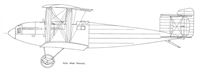

The poor showing of the R.I led Linke-Hofmann along a radically different line of approach. The outcome of their efforts was an aircraft that must surely rank among the unique in aviation history. If wind-tunnel tests were not conclusive in providing an answer to the question of size, why not build a giant version of the efficient and well-proven single-engined biplane? In the hope that flight and performance characteristics could be reproduced, an almost exact copy was built, with the exception that it was three times larger than normal. It is quite impossible to grasp the immense size of the R.II 55/17 just from photographs. (For some reason, no photographs exist with men standing near the aircraft to give a feeling of scale.) The single airscrew, the pilots' cockpit, the gun mounts and the conventional landing gear all trick the unsuspecting eye. Proper scale can best be demonstrated by mentally placing a 6 foot man next to the 5 foot diameter wheels or the 23 foot diameter Garuda propeller. It is believed that the R.II was the largest single-propeller aircraft ever built.

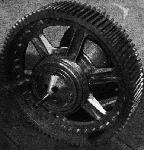

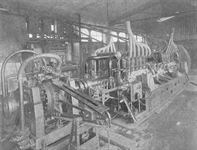

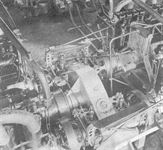

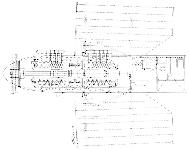

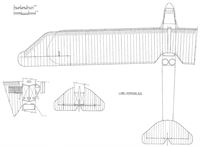

The four coupled 260 h.p. Mercedes D.IVa engines which drove this huge propeller were located in the nose of the R.II. They were arranged in a port and starboard pair with crankshafts facing each other. Each engine had its own friction and ratchet-lock clutch coupled to a heavily-dimensioned drive gear which lay between them. These two gears were in turn coupled to a robust 2 1/2 foot diameter central spur gear which drove a 9 inch diameter torque tube (at 545 r.p.m.) that ran between the forward engines to the propeller hub. Massive universal joints and sliding couplings were fitted to absorb vibrations and misalignments. Large as it was, this sturdy system represented the simplest of all the coupled four-engined drives. It consisted of a total of three gears as compared with the seven to ten gears on other centrally powered R-planes. As was the case with most coupled drives, this one was exhaustively investigated on an indoor test stand. It was claimed that this well-engineered assembly was very reliable in flight.

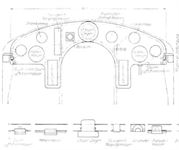

The radiators were mounted as small stub wings within the wing-gap, and an oil cooler was affixed above the engine-room decking. The rectangular fuselage was constructed of wood and was cable-braced throughout. The pilots' cockpit was situated below the upper wing trailing edge, which was cut away to improve the view. Located immediately aft were two dorsal machine-gun positions placed side by side in the width of the fuselage. The nose was plywood-covered back to the gun positions, and the remainder was covered with fabric. The wings were of all-wood construction and of equal chord, and ailerons were fitted to the upper wing only. The large biplane tail comprised three fins and rudders, and both upper and lower tailplanes were fitted with elevators.

The undercarriage was simple and robust and represented the culmination of Linke-Hofmann's engineering efforts to produce a reliable landing gear for giant aircraft. Two massive steel-tyre wheels were supported by a multi-coil spring shock absorber. The efficiency of this configuration proved itself in January 1919. Due to a blanket of snow over the countryside the pilot misjudged the extent of the airfield and landed short of the field in marshy ground. The wheels broke through the thin layer of frozen crust and the aircraft rolled over two ditches before coming to a halt within a distance of 79 feet. The wheels had sunk 12 inches into the ground without the machine overturning. It was impossible to move the R.II under its own power, and a steam tractor was required to pull it out. The large, heavy wheels did present some difficulties, however, and Linke-Hofmann engineers did consider using a "vaned" wheel which the airstream would spin, thereby reducing landing shocks.

Although the R.55 and R.56 were slated for delivery in July 1918, the R.55 did not make its first flight until January 1919. The major cause of the delay was the development of a suitably matched propeller. In a report dated September 1918, we read that: "The transmission of the R.55 ran perfectly during ground tests, but the propeller proved to be too small. It is expected the aircraft will fly with a new propeller in the middle of next month." The manufacturing problems involved in constructing a 23 ft. diameter propeller must have been formidable. Very likely it was the lack of a suitable propeller which delayed the first flight of the R.55 until 1919.

The R.56 was almost completed but never flew. As in other later R-plane projects, it had been planned to add a Brown-Boveri supercharger geared to the rear of the central spur gear.

For a time, Waldemar Roeder was second pilot during the R.55 test flights. Here is how he recalls a queer aspect of the R.55 in flight.

It was my good fortune to fly with test pilot Wicoreck. Since the designer had chosen to keep the propeller tip velocity equal to that of smaller diameter, higher rpm propellers, that of the R.55 turned at only 545 rpm. It was an extraordinary sensation to be pulled through the air by a propeller that was turning so slowly.

Judging from contemporary accounts, the R.II was easy to fly, having approximately the characteristics of a single-engined type. All controls were placed in ball bearings and were aerodynamically balanced, enabling the plane to be flown literally single-handed during gusty weather in January 1919.

The R.II could carry a maximum useful load of 7000 kg. for an all-up weight of 15,000 kg. Flying on two engines with reduced payload (2400 kg.), it was calculated that 9 1/2 hour flights could be made. The bomb load was carried on external wing racks, though internal stowage was planned. The crew consisted of two pilots, one navigator, one radio operator and two gunner/mechanics. No details are known concerning the end of R.55, other than a report that it crashed before completing its test programme. Perhaps pieces of the R.55 or R.56 were shipped to England. According to a November 1920 issue of F1ugsport, the Inter-Allied Control Commission confiscated the fuselage of a Linke-Hofmann R-plane and sent it to the Isle of Grain for study.

The authors were puzzled by the box-like shape hanging from struts beneath the fuselage as shown in contemporary plans. Was this an early version of the retractable "dust-bin" turret or auxiliary fuel tank? A patent search proved it to be the former, a semi-retractable turret which would allow the gunner to enter while the machine was in the air. There is no indication that the turret was fitted to the prototype, but rather that it was a refinement planned for later series.

For commercial purposes a cabin for twelve passengers was planned situated immediately aft the pilots' cockpit. However, Armistice restrictions prevented further development of the R.II, ending the story of a most unusual aircraft.

Colour Scheme and Markings

The overall finish was printed camouflage fabric, with the wing-ribs and fuselage stringers taped in a similar manner to R.40/l6. Engine cowling panels were painted all one colour, probably grey or perhaps olive-green. Full chord Latin crosses were painted on the wingtips and fuselage sides, but none on the tail. The serial number printed white appeared on both sides of the forward cowling.

SPECIFICATIONS

Type: Linke-Hofmann R.II

Manufacturer: Linke-Hofmann Werke A.G., Breslau

Engines: Four 260 h.p. Mercedes D.IVa engines

Dimensions:

Span upper, 42•16 m. (138 ft. 4 in.)

lower, 33•96 m. (111 ft. 5 in.)

Chord, 4•8 m. (15 ft. 9 in.)

Gap, 4•5 m. (14 ft. 9 in.)

Length, 20•32 m. (66 ft. 8 in.)

Height, 7•1 m. (23 ft. 3 1/2 in.)

Tailspan,7 m. (22 ft. 11 1/2 in.)

Chord, 2•59 m. (8 ft. 6 in.)

Gap, 2•4 m. (7 ft. 101' in.)

Wheel track, 4 m. (13 ft. 1 1/2 in.)

Wheel diameter, 1•5 m. (4 ft. 11 in.)

Propeller diameter, 6•9 m. (22 ft. 7 1/2 in.)

Areas: Wings, 320 sq. m. (3443 sq. ft.)

Weights:

Empty, 8000 kg. (17,640 lb.)

Useful load, 4000 kg. (8820 lb.)

Loaded, 12,000 kg. (26,460 lb.)

Wing Loading: 37•8 kg./sq. m. (7,8 lb./sq. ft.)

Performance:

Maximum speed, 130 km.h. (80'8 m.p.h.)

Duration, 7 hrs.

Climb,

1000 m. (3281 ft.) in 8 mins.

2000 m. (6562 ft.) in 20 mins.

3000 m. (9843 ft.) in 45 mins.

Ceiling, 3200 m. (10,499 ft.) in 120 mins.

Armament: Provision for two dorsal and one ventral machine-gun positions

Service Use: None

Cost: 450,000 marks

Показать полностью

J.Herris German Aircraft of Minor Manufacturers in WW1. Vol II (A Centennial Perspective on Great War Airplanes 50)

Linke-Hofmann R.II

After the failure of the R.I, the R.II was a much more conventional design. The R.II airframe looked like a very large conventional biplane. The four coupled 260 hp Mercedes D.IVa engines were retained but now geared to drive a single propeller at the nose. Again, a pair of engines were mounted on each side of the aircraft, and they were attached to a single gearbox with 2 1/2 foot diameter drive gear that drove the single propeller via a 9-inch torque tube. A failed engine could be de-clutched from the gearbox. Two aircraft, R.55/17 and R.56/17, were ordered.

The coupled engines were extensively tested on a factory test stand. Careful design and construction made the drive system very reliable. For one thing, the drive system was simpler and more robust than that of the R.I.

The radiators were mounted as small stub wings between the main wings. The forward fuselage was plywood covered and the aft fuselage was covered with printed camouflage fabric. The pilot's cockpit was located below the upper wing trailing edge and two dorsal gunners were mounted aft of this cockpit. The wings were constructed of wood with fabric covering. The landing gear was strong and simple, resembling that of much smaller airplanes. The wheels and tires were again made of metal.

Lack of a suitable propeller delayed its maiden flight from July 1918 when the airframe was scheduled to be complete to January 1919. The large propeller rotated at 545 RPM compared to 1200-1400 RPM of smaller aircraft with no reduction gear. A box-like structure under the fuselage shown in drawings was planned as a semi-rectratcable ventral turret. However, it was not fitted to R.55. R.55 was easy to fly and had good flying characteristics. This was due to its conventional configuration and the fact its controls were placed in ball-bearings to minimize control friction. Despite its huge size, the R.55 could be flown with one hand during gusty weather. The R.II could carry a maximum useful load of 7,000 kg, impressive for the time. Cruising on two engines it was calculated that flights up to 9 1/2 hours long were possible.

The R.56 was nearly complete at the Armistice but was not finished and never flew. The R.56 was planned to use a Brown-Boveri supercharger geared from the rear of the central spur gear to increase climb and ceiling.

Schutte-Lanz R.II Specifications

Engine: 4 x 260 hp Mercedes D.IVa

Wing: Span, upper 42.16 m

Span, lower 33.96 m

Chord 4.8 m

Wing Area 320 m2

General: Length 20.32 m

Height 7.1 m

Empty Weight 8000 kg

Loaded Weight 12,000 kg

Maximum Speed: 130 km/h

Climb: 1000 m 8 min.

2000 m 20 min.

3000 m 45 min.

Ceiling 3200 m

Duration: 7 hours

Показать полностью

M.Dusing German Aviation Industry in WWI. Volume 1 (A Centennial Perspective on Great War Airplanes 84)

Linke-Hofmann Werke AG, Breslau (now Wroclaw), (Li)

Aircraft Development:

<...>

A second R airplane design, Li R.II, was undergoing flight tests at the end of the war. A total of 319 aircraft were manufactured in Linke-Hofmann factories.

Показать полностью

Журнал Flight

Flight, October 2, 1919.

THE LINKE-HOFMANN GIANT MACHINES

"The experience obtained with the Linke-Hofmann R I was taken advantage of in the design of

The Linke-Hofmann, R II,

the chief feature of which was a single tractor airscrew, driven by the four 260 h.p. Mercedes engines. The main figures relating to this machine are as follows :- Span, 138 ft. 6 in.; length, 67 ft.; height, 23 ft. 6 in.; wing area, 3,440 sq. ft.; weight empty, 17,600 lb.; useful load, 9,000 lb., including fuel for 7 hours' flight. The speed was the same as that of R I, i.e., 80 m.p.h.; with a useful load of 9,000 lb. the climb was 11,550 ft. in 2 hours. The airscrew, which was of 22 ft. 8 in. diameter, was driven by four Mercedes engines through a central drive. Even with only two engines running the machine flew well. For long-distance flying, by doing away with the military loads, and with the following crew, the range can be greatly increased; 2 pilots and luggage 440 lb., 2 engineers with luggage 440 lb.; 2 navigators with luggage 440 lb.; instruments and wireless 660 lb.; total, 1,980 lb. The machine is still capable of carrying another 13,400 lb. of fuel and oil (probably by sacrificing performance during the earlier part of the flight - Editor, FLIGHT), which is sufficient for a flight of 30 hours' duration at a cruising speed of 74 m.p.h., which would give it a range of 2,225 miles."

Flugsport then gives a glowing account of the ease with which the Linke-Hofmann R II starts and lands, these operations being, it is stated, quite unlike those of ordinary large machines and more like the handling of an ordinary two-seater. It is also pointed out that during flight there is a marked absence of vibration. All control organs are running in ball bearings so that they are very easy for the pilot to handle. It is said that on a cold day in January the machine was cruising round and round over the aerodrome in order not to lose itself, when one pilot put both his hands into his fur-lined boots while the other put his left hand into his pocket, the machine being steered in a circle by means of one hand. The view from the pilot's seat is said to be exceptionally good, owing to the high position, and the machine is very easy to land, partly on account of the good view, and partly because of the excellent gliding angle of the machine.

"The passengers," Flugsport continues, "are accommodated in an enclosed cabin behind and underneath the pilots' cockpit, this position being one of the safest in the whole machine in case of a crash. All the main weights being in front of the cabin, the safety of the passengers is assured, and in the case of the machine turning over on landing, or striking with a wing tip first, there are no heavy engines or tanks to fall on them. At present accommodation is being provided for 12 passengers.

"The risk of fire has been reduced to a minimum by placing all petrol leads and petrol pumps underneath the floor, where they are well away from any part of the engines which might give external sparks. A thorough ventilation of engine room and tank compartment ensures that there are no petrol vapours about, and any petrol leaking out of pipes, etc., flows through the bottom of the fuselage out into the open.

"The undercarriage, which is of the same simple Vee type as that of the Linke-Hofmann RI, has proved to be immensely strong. During a landing in the snow the wheels broke through the thin frozen crust and sank into the snow as deep as 12 in., the machine rolling over two ditches and coming to a standstill without turning over. Although the snow was shovelled away in front of the machine it was not possible to move it under its own power, and a snow plough had to be employed to get it back to its shed. According to all the experts who witnessed the landing, any other machine would have turned over. It will be seen from the above examples that the general reliability of the machine is excellent. It may further be added that not only can the machine remain in horizontal flight with only two engines running, but she has actually been known to climb on two motors. The useful load in that case was 5,300 lb.

"The advantages of multi-engined machines with only one airscrew may be summarised as follows: The propeller efficiency is very high, owing to the large diameter and slow running. The drive is of the simplest possible type, with only three spur wheels, which makes for greater reliability. The machine can continue its flight with three or even two engines running. On account of the central placing of the airscrew the danger of breakage of outrigger or interplane struts - in machines where the screws axe so mounted - does not exist, and the head resistance is considerably smaller. The single-screw type gives less weight. For instance, a multi-engined machine with shaft drive to two airscrews on the wings has 10 spur wheels and 9 shafts. The single screw type has three spur wheels and four shafts. The engine power is only transmitted through one pair of spur wheels; whereas in the twin-screw type it is transmitted through two pairs. This alone means a gain in efficiency of 3 to 5 per cent., or in other words, a gain of 30 to 50 h.p. The large propeller has stood up to its work splendidly, while, owing to its strong construction, it is practically weather-proof.

"A further great advantage is the simple two-wheeled Vee undercarriage, which gives small weight and also small air resistance. Springing is by means of steel springs instead of rubber shock absorbers. The undercarriage is absolutely reliable, even in heavy landings, with a side wind. The wheels are so large that the machine can even taxy across small ditches.

"The placing of the whole crew in the fuselage makes it possible for them to communicate with each other and to make themselves understood, which has the advantage of offering possibilities for reducing the number of the crew to a minimum. As there is only one central drive with four spur wheels, it is possible to build this so strong, without any undue addition in weight, that absolute reliability is provided. Even after allowing for a certain amount of patriotic enthusiasm, it would appear that the Linke-Hofmann R II is really a very serious attempt at improving the existing type of multi-engined aeroplane.

Показать полностью