C.Barnes Bristol Aircraft since 1910 (Putnam)

The Bristol M.R.1 Metal Biplane

Some of the earliest pioneers of flying, including the Wright Brothers and Louis Bleriot, had been makers and riders of bicycles before their first attempts at aviation, and the materials and methods of bicycle construction were well known to aircraft builders from the beginning. Thin-walled carbon-steel seamless tubing, brazed or soldered into machined sockets, bolted together and braced with piano-wire, must have seemed the logical aircraft structure to military engineers desiring to attain serviceability in such aircraft as they considered to be practicable. Many attempts were made to design aeroplanes along these lines, such as the official R.E.5 and R.E.7, but always the weight was excessive, and if very thin-walled tubes were chosen, they would not stand up to manhandling on the ground because they buckled too easily. When the first useful aluminium alloys were produced, having a strength-weight ratio better than mild steel, they were found to be very easily corroded and impossible to braze or solder. Vickers Ltd. were among the first in the field with their all-metal monoplanes based on the patents of Robert Esnault-Pelterie, and in 1911 Sir George White had commissioned in France a monoplane of steel-tube construction designed by Gabriel Voisin, but it was far too heavy to fly.

The Company's interest in metal construction continued, and in July 1914 they undertook the detail design and construction of four all-metal derivatives of the B.E.2c, called the B.E.10. The aerodynamic design of this two-seater biplane was by a syndicate of Farnborough designers led by H. P. Folland and included such refinements as full-span trailing edge flaps to reduce landing speed. After the outbreak of war, the urgent need for quantity production of the B.E.2c at Filton caused the B.E.10 to be abandoned early in 1915, when the few components and details already manufactured were delivered to the Royal Aircraft Factory for mechanical testing.

During the ensuing 12 months, aircraft production all over the country expanded enormously and the authorities foresaw the risk, if war continued, of a severe shortage of timber suitable for aircraft manufacture; already stocks of Grade A silver spruce were declining and Grade B was being substituted wherever safety allowed. In July 1916 Capt. Barnwell drafted the revised layout of the R.2A reconnaissance biplane to match the 190 h.p. Rolls-Royce engine, thereby creating the Bristol Fighter. The need for a reconnaissance two-seater still remained for use where enemy air support was not paramount, and, as such fronts were mainly in a tropical climate, there seemed to be a strong case for adopting metal construction.

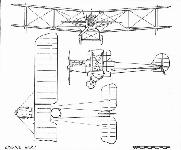

With the shortcomings of the B.E.10 design in mind, he approached the problem logically and drew on his early training on the Fairfield shipyard. He believed that duralumin sheet could be used in a monocoque structure if properly protected by a good quality marine varnish and adopted this method for the fuselage of the M.R.1, as the metal biplane was designated. The fuselage was built up in four sections bolted together; the front section was a semi-monocoque open channel with channel-section struts at each frame bracing the top longitudinals to the centre of the bottom frame member. This carried the engine bulkhead and bearers at its forward end and the tanks and centre section struts above and below. The next section aft was similar and contained the pilot's cockpit, with a Vickers gun and ammunition box above. The third section was a self-contained parallel-sided monocoque unit carrying the observer's seat with a Scarff gun mounting above, and the tapered monococque rear fuselage boom was bolted to the back of this section; the design was so arranged that the observer's cockpit section could be left out altogether and the aircraft then became a single-seater to which wings of smaller area could be attached. This versatility would have been a valuable investment in a machine for which a long storage life was envisaged, but in fact the contract awarded on 2 November 1916 was for only two prototypes for evaluation and mechanical test.

As Barnwell and Frise were under extreme pressure to get the Bristol Fighter into quantity production, the detail design of the M.R.1 was handed over to W. T. Reid, who faithfully translated Barnwell's ideas into metal, using relatively small amounts of mild steel. The duralumin monocoque fuselage was one of the first examples of double-skin construction, the smooth outer skin being riveted to a longitudinally corrugated inner skin. The original wing structure was a direct adaptation from wood to duralumin, using duplicated plates on edge to form the spars, but this was found to be much too flexible on test and in the end wing design and construction were sub-contracted to The Steel Wing Company of Gloucester, who had developed a method of using rolled high-tensile steel strip and had already produced successful sample steel wings for the B.E.2d and Avro 504. Two other methods, using both steel and duralumin, the subject of patents by the Krieger Electric Car Syndicate and a Mr. Mayrow, respectively, were also tested.

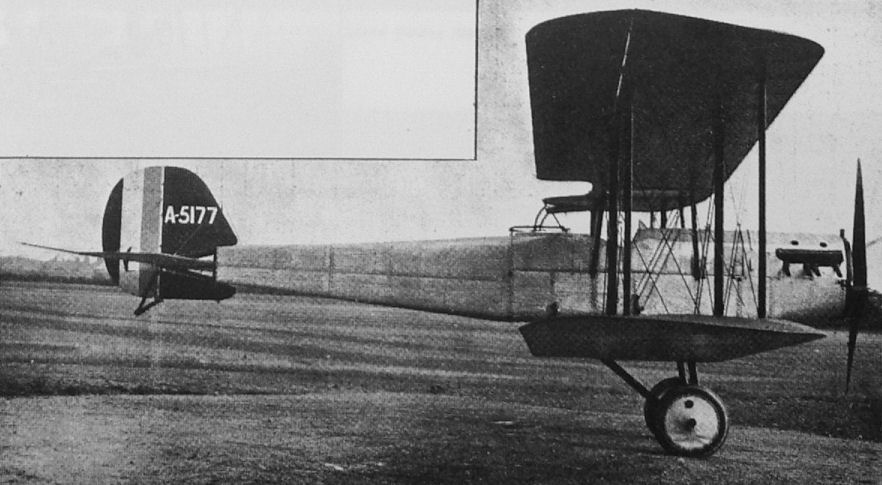

By mid-1917 the first M.R.1, No. 2067 (A5177), was complete except for the wings, which were making slow progress at Gloucester, and it was decided to build a set of conventional wooden wings (with upper ailerons only) so as not to delay flight tests. The latter were entirely successful and A5177 was handed over to the Air Board on 23 October 1917, its contract price of ?2,000 having been reduced to ?1,600 on account of the wooden wings. The second M.R.1, No. 2068 (A5178), was delayed until late in 1918 before receiving its metal wings, but was then successfully flown, a Wolseley Viper engine of 180 h.p. being fitted instead of the 140 h.p. French Hispano-Suiza of the first machine. After the Armistice A5178 was piloted frequently by Capt. Barnwell, and eventually it was accepted to delivery to the Royal Aircraft Establishment; it was flown to Farnborough by Capt. Barnwell personally on 19 April 1919, but on arrival he collided with a pine tree near the North Gate of the R.A.E. and crashed on the aerodrome, bringing down the top of the tree with the aeroplane. He was shaken, but otherwise unhurt; the M.R.1, however, was considerably damaged and no attempt was made to repair it. Meanwhile, A5177 (renumbered A58623) was being structurally tested and much valuable information on metal construction was gleaned from it. For its day, the M.R.1 was a considerable technical achievement, its disposable load amounting to more than 40% of its all-up weight. Moreover, it had been constructed almost entirely without using specialised tools and equipment, and the necessity of developing these for quantity production was perhaps the most valuable of the lessons learned.

SPECIFICATION AND DATA

Type: M.R.1

Manufacturers: The British & Colonial Aeroplane Co. Ltd., Brislington, Bristol

Power Plants: One 140 hp Hispano-Suiza

One 180 hp Wolseley Viper

Span: 42 ft 2 in

Length: 27 ft

Height: 10 ft 3 in

Wing Area: 458 sq ft

Empty Weight: 1,700 lb

All-up Weight: 2,810 lb

Max. Speed: 110 mph

Endurance: 5 hours

Accommodation: 2

Production: 2

Sequence Nos.: 2067,2068

Показать полностью

P.Lewis The British Fighter since 1912 (Putnam)

Two prototypes of an all-metal, two-seat fighter, designated M.R.1 and intended to eliminate the disadvantages attendant upon the usual wooden airframes under tropical conditions, were constructed following Barnwell’s basic layout for the project during July, 1916, with the detail design work undertaken by W. T. Reid. The engine chosen was the 150 h.p. Hispano- Suiza, the airframe that it powered being a two-bay biplane which was slightly larger overall than the F.2A and F.2B. The fuselage was mounted mid-way in the gap between the wings and was a stressed-skin monocoque covered with sheet aluminium. The pilot was provided with a single Vickers gun in the cowling while the gunner had a Lewis gun on a Scarff ring. Although tested comprehensively, the M.R.1 was not selected finally for production but is of note for its use of metal for the framework and the fuselage covering.

Показать полностью

F.Mason The British Fighter since 1912 (Putnam)

Bristol M.R.1

In mid-1916 the British & Colonial Aeroplane Co was asked by the War Office to examine the possibility of producing an all-metal version of the Bristol F.2A that would be more suitable for service in the Middle East than the contemporary wooden aircraft.

A preliminary scheme was prepared by Frank Barnwell in July that year, and this was later passed to W T Reid to develop into reality. Though by no means the first metal aeroplane in Britain or elsewhere, much of Reid’s work was of a truly pioneering nature, and the final design incorporated numerous innovative features that became the subject of patents held jointly by Reid and his employers.

Two prototypes were ordered, but the first, A5177, was not completed until October 1917, and was delivered initially with wooden wings. A5177 superficially resembled the Bristol F.2A, particularly as the lower wing section, located below the fuselage, was an open structure. Power was provided by a 150hp Hispano-Suiza mounted on steel tubular bearers bolted to the front of all four longerons. The fuselage was constructed in four sections, each a wire-braced steel tubular box girder, bolted together and covered with aluminium sheet. No attempt was made to include double-curvature sheeting, but local strengthening was achieved by riveting sections of corrugated aluminium on the inside of the skin, thereby maintaining a smooth external finish. The steel wings, built by the Steel Wing company of Cheltenham, were fabric covered (as were the tail surfaces), and the interplane and cabane struts were of steel tube, hot rolled to slim elongated section; Raf-wires were widely employed.

At one time it was intended to fit wings constructed on the Mayrow principle with composite steel and duralumin sub-structure and, although such wings were subjected to static tests, it is unlikely that they were flown on an M.R.1.

First flown by Capt Barnwell, A5177 was delivered to representatives of the Air Board on 23 October, but the steel wings were not completed until 1918, when the first set appeared on the second prototype, A5178, followed later on A5177. A5178 was also fitted with a 180hp Wolseley Viper engine.

Apart from the obvious lessons learned in the design of predominantly metal aeroplanes, the two M.R.1s provided a great deal of information about the specialised tools and manufacturing techniques essential for any large-scale switch to metal aircraft - a field in which their manufacturers would in due course take a leading part.

Type: Experimental single-engine, two-seat, two-bay biplane fighter.

Manufacturer: The British & Colonial Aeroplane Co Ltd, Brislington, Bristol.

Powerplant: One 150hp Hispano-Suiza engine driving two-blade propeller; also 180hp Wolseley Viper engine.

Structure: All-metal construction. Fuselage of steel tubular box-girder construction with aluminium semi-monocoque sheet covering. Two-spar wings using rolled high-tensile steel strip with fabric covering.

Dimensions: Span, 42ft 2in; length, 27ft 0in; height, 10ft 3in; wing area, 458 sq ft.

Weights: Tare, 1,700lb; all-up, 2,810lb.

Performance: Max speed, 110 mph at sea level; climb to 10,000ft, 20 min.

Armament: One synchronized 0.303in Vickers machine gun mounted to fire through tunnel in the top engine cowling; one Lewis gun with Scarff ring on rear cockpit amidships.

Prototypes: Two, A5177 and A5178 (first flight by A5177 in October 1917). One of these aircraft carried a spurious number, A58623, during ground tests in 1918. No production.

Показать полностью

J.Bruce British Aeroplanes 1914-1918 (Putnam)

Bristol M.R.1

WHILE the prototypes of the Bristol F.2A were still under construction, the British & Colonial Aeroplane Co. were asked to design a similar machine of all-metal construction, with a particular view to operations in or near the tropics where that form of construction would have considerable advantages over the conventional wire-braced wooden structures of the time.

The preliminary general layout was sketched by Frank Barnwell in July, 1916, but the development of the design was carried out by W. T. Reid. The completed design was known as the Bristol M.R.1.

In a general way, the M.R.1 resembled the F.2A: the fuselage was mounted midway in the gap between the wings; the lower centre-section was an open cross-braced structure; and the crew were accommodated close together. The fabric-covered wings were of orthodox appearance, but were of all-steel construction and were built by the Steel Wing Co. of Cheltenham. However, the first machine (A.5177) was delivered with wooden wings.

The fuselage was built in four sections, bolted together, but the basic structure was a wire-braced box girder made of steel tubing. The fuselage was covered with aluminium sheet which was strengthened locally by corrugated sheet aluminium riveted to the inside. This method of construction produced a smooth outer covering, but no attempt was made to work double curvature of the skin and, as a result, the M.R.1 had rather more severe lines than the F.2A. Interplane and undercarriage struts were of steel tubing.

Two prototypes were built, and were powered by the 150 h.p. Hispano-Suiza engine. Captain Barnwell flew the first a good deal for experimental purposes, and ultimately crashed it by flying it into a tree. The second machine (A.5178) was sent to the Aeronautical Inspection Directorate at Kingsway, and thereafter underwent static tests. This machine latterly bore the number A.58623 on its fuselage: this was not a genuine serial number, and the aeroplane was not flown with it.

At one time it was intended to fit the M.R.1 with wings built on the Mayrow principle, which embodied components of aluminium alloy, but it is uncertain whether this was ever done. A pair of Mayrow wings were made and were submitted for structural test, however.

SPECIFICATION

Manufacturers: The British & Colonial Aeroplane Co., Ltd., Brislington, Bristol.

Power: 150 h.p. Hispano-Suiza. Engine No. W.D.10109 was fitted to the first M.R.1, A.5177.

Dimensions: Span: 42 ft 2 in. Length: 27 ft. Height: 10 ft 3 in. Chord: 6 ft. Gap: 5 ft 11 in. Stagger: nil. Dihedral: 3° 30'. Incidence: 0°. Span of tail: 16 ft 3 in. Airscrew diameter: 8 ft 10 in.

Areas: Wings: upper 235 sq ft, lower 223 sq ft, total 458 sq ft. Ailerons: each 14-75 sq ft, total 59 sq ft. Tailplane: 27-8 sq ft. Elevators: 30 sq ft. Fin: 7-8 sq ft. Rudder: 8-25 sq ft.

Weights: Empty: 1,700 lb. Military load: 270 lb. Crew: 360 lb. Fuel and oil: 480 lb. Weight loaded: 2,810 lb.

Performance: Maximum speed at ground level: 110 m.p.h.; at 5,000 ft: 106 m.p.h.; at 10,000 ft: 98 m.p.h.

Climb to 5,000 ft: 8 min; to 10,000 ft: 20 min.

Tankage: Petrol: 50 gallons. Oil: 5 gallons.

Armament: One fixed Vickers machine-gun mounted centrally in a tunnel under the cowling, and synchronised to fire forward through the revolving airscrew; one Lewis machine-gun on Scarff ring-mounting on rear cockpit.

Production: Two prototypes were built under Contract No. 87/A/865.

Serial Numbers: A.5177-A.5178. The latter aircraft bore the number A.58623 at a later stage.

Показать полностью

H.King Armament of British Aircraft (Putnam)

M.R.I. Though a notable structural advance, the metal-built M.R.I of 1916 carried the same armament as the Bristol Fighter and this was similarly disposed. The fuselage was built in sections, the second embodying the cockpit. Vickers gun and ammunition box and the third the observer's seat with the Scarff ring-mounting above it.

Показать полностью

Jane's All The World Aircraft 1919

The Bristol all-metal biplane is more or less an all-metal Bristol " Fighter " with sundry modifications and was designed primarily for use in countries where extremes of heat and cold might have a detrimental effect on woodwork.

Metal has entirely replaced wood in the construction, the fuselage being constructed of aluminium and steel and can be easily dismantled for transport and storage purposes. The wings, which are unstaggered are of all-steel construction. The fuselage is slung between the planes, as in the Bristol " Fighter," but the lower centre section is completely cut away, leaving the two main spar tubes, to which are attached, the two lower centre section struts.

Specification.

Type of machine Two-seater Biplane.

Name or type No. of machine All Metal M.R.I.

Purpose for which intended Fighting and Reconnaissance.

Span 42 ft. 2 in.

Gap 5 ft. 11 In.

Overall length 27 ft.

Maximum height 10 ft. 3 In.

Chord 6 ft.

Total surface of wings 458 sq. ft.

Area of ailerons 39 sq. ft.

Total area of tail 27.8 sq. ft.

Span of tail 16 ft. 3 in.

Area of elevators 30 sq. ft.

Area of rudder 8.25 sq. ft.

Area of fin 7.8 sq. ft.

Engine type and h.p. 170 h.p. Wolseley "Viper"

Airscrew, diam., pitch and revs. 8 ft. 10 in. diam., 6 ft. 7 in. pitch, 1,700 r.p.m.

Weight of machine empty 1,700 lbs.

Load per sq. ft. 6.13 lbs.

Weight per h.p. 16.5 lbs.

Petrol tank capacity In gallons 50 gallons.

Oil tank capacity In gallons 5 gallons.

Performance.

Speed low down 110m.p.h.

Speed at 5,000 feet 106 m.p.h.

Speed at 10,000 feet 98 m.p.h.

Landing speed 47 m.p.h.

Показать полностью

Журнал Flight

Flight, January 23, 1919.

"MILESTONES"

The Bristol "All-Metal" Biplane

From the earliest days of aviation the question of wood versus metal construction has been the subject of discussion, and both methods have had their supporters. Up till the present, however, the wood construction has been predominating, at any rate in this country. Particular interest therefore attaches to the few examples of the metal construction method that have been built. Among these is the Bristol type MR.1, shown in the accompanying illustrations. At the present moment we cannot, unfortunately, publish constructional details of this machine, this must be reserved until another time, but several interesting facts emerge from an inspection of the tables of particulars. Thus it will be seen that although the All-Metal machine is of somewhat larger dimensions than the Bristol Fighter, the loaded weight of the two machines is practically the same. Against this must be put the fact that the MR.1 has a 170 h.p. Hispano engine, while the F2B has a 260 h.p. Rolls-Royce. The All-Metal carries, however, slightly more fuel than does the B.F. The loading per sq. ft. is somewhat smaller for the larger machine, but the load per horse-power is considerably greater, thus accounting for the fact that the MR.1 has not so good a performance as the F2B. It might be added that the weight, empty, of the B.F., is 1,750 lbs., and that of the MR.1 1,700 lbs. It may, therefore, safely be concluded from these particulars that there is no reason to suppose that an all-metal aeroplane cannot be built as light, or nearly so, as one constructed in the ordinary way of wood. There can be little doubt that for use in tropical climates, such as will be encountered by the post-War commercial aeroplane, the metal construction will be better able to withstand the changes in temperature than will one built largely of wood, and while we should not care to assert that the days of wood construction for aeroplanes are over, we do think that metal construction will be more general in the future than it has been in the past.

Показать полностью