Книги

Putnam

A.Jackson

De Havilland Aircraft since 1909

107

A.Jackson - De Havilland Aircraft since 1909 /Putnam/

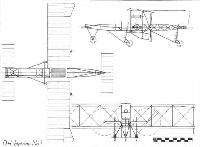

De Havilland Biplane No. 1

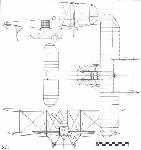

This was a single seat biplane of cotton covered, white wood construction with a fixed tailplane, front elevator, uncompensated ailerons, a large rudder above the tailplane but no fixed fin. It was braced with piano wire and mounted on an undercarriage of bicycle tubing with four bicycle wheels. The pilot sat in a wicker chair with a lever on the left which controlled the elevator, one on the right which moved the rudder, and a footbar connected to the ailerons.

The four cylinder, horizontally opposed, water-cooled engine, designed by Geoffrey de Havilland and made by the Iris Motor Company at Willesden, developed 45 h.p. at 1,500 r.p.m. It weighed 2 cwt. and was mounted at right angles to the direction of flight in order to drive two pusher propellers with adjustable aluminium blades through steel shafting and bevel gears.

There were no working drawings but the aircraft was completed from rough sketches early in 1909 in a rented workshop off Bothwell Street, Fulham, London, with the assistance of F. T. Hearle and of Mrs. De Havilland who sewed on the cotton covering. In May 1909 it was taken on a Commer lorry to Seven Barrows near Newbury, Berks, but over six months elapsed before undercarriage, propeller drive, engine and control adjustments were finished so that fast taxying could be attempted whenever the wind was calm.

It flew for the first and only time in December 1909 after a downhill takeoff into wind. Without pilot training and deprived of instinctive control by his complex system of levers, de Havilland overcorrected when he felt himself airborne and pulled the nose up so steeply that the wing spars failed and the aircraft broke up when it crashed from a height of 15 ft. The designer was uninjured and the engine was salvaged.

SPECIFICATION AND DATA

Construction: By G. de Havilland and F. T. Hearle at Bothwell Street, Fulham, London, S.W.6

Power Plant: One 45 h.p. de Havilland / Iris

Dimensions:

Span 36 ft. 0 in. Length 29 ft. 0 in.

Wing area 408 sq. ft.

Weights: All-up weight 850 lb.

This was a single seat biplane of cotton covered, white wood construction with a fixed tailplane, front elevator, uncompensated ailerons, a large rudder above the tailplane but no fixed fin. It was braced with piano wire and mounted on an undercarriage of bicycle tubing with four bicycle wheels. The pilot sat in a wicker chair with a lever on the left which controlled the elevator, one on the right which moved the rudder, and a footbar connected to the ailerons.

The four cylinder, horizontally opposed, water-cooled engine, designed by Geoffrey de Havilland and made by the Iris Motor Company at Willesden, developed 45 h.p. at 1,500 r.p.m. It weighed 2 cwt. and was mounted at right angles to the direction of flight in order to drive two pusher propellers with adjustable aluminium blades through steel shafting and bevel gears.

There were no working drawings but the aircraft was completed from rough sketches early in 1909 in a rented workshop off Bothwell Street, Fulham, London, with the assistance of F. T. Hearle and of Mrs. De Havilland who sewed on the cotton covering. In May 1909 it was taken on a Commer lorry to Seven Barrows near Newbury, Berks, but over six months elapsed before undercarriage, propeller drive, engine and control adjustments were finished so that fast taxying could be attempted whenever the wind was calm.

It flew for the first and only time in December 1909 after a downhill takeoff into wind. Without pilot training and deprived of instinctive control by his complex system of levers, de Havilland overcorrected when he felt himself airborne and pulled the nose up so steeply that the wing spars failed and the aircraft broke up when it crashed from a height of 15 ft. The designer was uninjured and the engine was salvaged.

SPECIFICATION AND DATA

Construction: By G. de Havilland and F. T. Hearle at Bothwell Street, Fulham, London, S.W.6

Power Plant: One 45 h.p. de Havilland / Iris

Dimensions:

Span 36 ft. 0 in. Length 29 ft. 0 in.

Wing area 408 sq. ft.

Weights: All-up weight 850 lb.

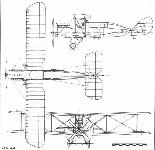

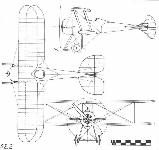

De Havilland Biplane No. 2

A two seater of spruce and ash construction with interconnected tail and front elevators, balanced ailerons and simplified undercarriage, built in the same Fulham workshop. The engine, salvaged from Biplane No. 1, drove a single pusher propeller and a first successful flight of 1/4 mile was made by de Havilland at Seven Barrows on September 10, 1910.

In December it went by road to Farnborough where, after a one hour acceptance flight on January 14, 1911, it was purchased by the War Office for ?400 and restyled F.E.I (Farman Experimental). It was repeatedly modified and de Havilland flew it on March 31 with a larger tailplane and rear elevator; and again on April 11 with wing and aileron extensions, 65 sq. ft. in area, which were removed and refitted several times.

Trials over the measured course on Laffan's Plain on May 15 gave the maximum speed as 38 m.p.h. but with the extensions fitted, aileron drag made the aircraft unstable in yaw, partially cured on May 26 by installing new rudders above and below the tailplane. It flew again on July 3 with the front elevator removed but this pushed the CG too far back, corrected next day by moving back the upper mainplane.

Geoffrey de Havilland carried many passengers in this aircraft, including Harold Bolas and Lt. J. T. Ridge on May 5. He completed 80 miles of circuit flying with 17 officers and men of the London Balloon Company on July 28 and three days later reached an altitude of 1,000 ft. On August 2 he flew to Laffan's Plain with Lt. Ridge who then taxied the machine and flew a few yards. During his next lesson on August 5 the aircraft nosed over in a freshening wind but when Lt. Ridge took it out again on August 15 after repairs, a broken bolt loosened two cylinders. The historic engine was beyond repair and the aircraft did not fly again.

SPECIFICATION AND DATA

Construction: By G. de Havilland and F. T. Hearle at Bothwell Street, Fulham, London. S.W.6

Power Plant: One 45 h.p. de Havilland / Iris

Dimensions:

Span 33 ft. 6 in. Length 29 ft. 0 in.

Wing area 356 sq. ft.

Weights: All-up weight 1,000 lb.

Performance: Maximum speed 38 m.p.h. Endurance 1 hour 20 minutes

A two seater of spruce and ash construction with interconnected tail and front elevators, balanced ailerons and simplified undercarriage, built in the same Fulham workshop. The engine, salvaged from Biplane No. 1, drove a single pusher propeller and a first successful flight of 1/4 mile was made by de Havilland at Seven Barrows on September 10, 1910.

In December it went by road to Farnborough where, after a one hour acceptance flight on January 14, 1911, it was purchased by the War Office for ?400 and restyled F.E.I (Farman Experimental). It was repeatedly modified and de Havilland flew it on March 31 with a larger tailplane and rear elevator; and again on April 11 with wing and aileron extensions, 65 sq. ft. in area, which were removed and refitted several times.

Trials over the measured course on Laffan's Plain on May 15 gave the maximum speed as 38 m.p.h. but with the extensions fitted, aileron drag made the aircraft unstable in yaw, partially cured on May 26 by installing new rudders above and below the tailplane. It flew again on July 3 with the front elevator removed but this pushed the CG too far back, corrected next day by moving back the upper mainplane.

Geoffrey de Havilland carried many passengers in this aircraft, including Harold Bolas and Lt. J. T. Ridge on May 5. He completed 80 miles of circuit flying with 17 officers and men of the London Balloon Company on July 28 and three days later reached an altitude of 1,000 ft. On August 2 he flew to Laffan's Plain with Lt. Ridge who then taxied the machine and flew a few yards. During his next lesson on August 5 the aircraft nosed over in a freshening wind but when Lt. Ridge took it out again on August 15 after repairs, a broken bolt loosened two cylinders. The historic engine was beyond repair and the aircraft did not fly again.

SPECIFICATION AND DATA

Construction: By G. de Havilland and F. T. Hearle at Bothwell Street, Fulham, London. S.W.6

Power Plant: One 45 h.p. de Havilland / Iris

Dimensions:

Span 33 ft. 6 in. Length 29 ft. 0 in.

Wing area 356 sq. ft.

Weights: All-up weight 1,000 lb.

Performance: Maximum speed 38 m.p.h. Endurance 1 hour 20 minutes

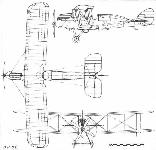

De Havilland D.H.1

Geoffrey de Havilland's first design after joining the Aircraft Manufacturing Co. Ltd. as Chief Designer in June 1914, was a two seat reconnaissance biplane armed with a forward firing machine gun. Following contemporary practice, it was a twin boom, two bay, wire braced biplane of fabric covered wooden construction and the mainplanes were of the normal two spar type, wire braced internally. A pusher layout was chosen to give the observer/gunner the maximum possible arc of fire from the front cockpit, and the design included three unusual features; coil springs in the undercarriage to absorb landing shocks, an elementary form of oleo leg to damp out the rebound, and the provision of air brakes. These were in the form of rotatable auxiliary aerofoils protruding some three feet on each side of the nacelle just behind the front centre section struts. The diversion of all available supplies of its intended engine, the 120 h.p. watercooled Beardmore, to F.E.2 and R.E.5 production resulted in the 70 h.p. aircooled Renault being fitted instead.

The prototype, designated Airco D.H.1, was completed and flown at Hendon in January 1915 and the designer showed his confidence in it by taking off without any preliminary straight hops and at once commencing to circle. He also piloted it during tests which not only showed it to be inherently stable and capable of being flown 'hands off' but also that the air brakes were ineffective. They were consequently removed. A small number of production D.H.1s were then built but these had the more normal type of rubber cord shock absorbers in the undercarriage, forward facing exhaust pipes and the front cockpit coaming lowered to the top longerons to improve the pilot's view and to permit free rotation of the single Lewis gun on its pillar mounting. Five of these aircraft reached Royal Flying Corps training units during 1915.

Production on a larger scale was delayed until the 120 h.p. Beardmore was available in quantity but was finally undertaken by Savages Ltd. At King's Lynn in order to leave Airco free to develop newer types. With the Beardmore engine the machine carried the designation D.H.1A and was identified by the upright six cylinder engine, the large radiator behind the pilot's head and the gravity fuel tank mounted under the port upper wing root. The prototype D.H.1A, which bore the R.F.C. serial 4606, was converted from an Airco-built D.H.1. Although 73 D.H.1s and D.H.1As were delivered to the Royal Flying Corps, they saw little war service and in 1916 six were shipped to the Middle East Brigade for operational use by No. 14 Squadron. Home Defence squadrons received 24 and a further 43 went to training units such as No. 35 Reserve Squadron, Northolt and No. 199 Training Squadron. The type remained operational until early in 1917 after which it was relegated to second line duties until finally withdrawn from service at the end of 1918.

SPECIFICATION AND DATA

Manufacturers:

The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9

Savages Ltd., King's Lynn, Norfolk

Power Plants:

(D.H.1) One 70 h.p. Renault

(D.H.1A) One 120 h.p. Beardmore

Dimensions, Weights and Performances:

D.H.1 D.H.1A

Span 41 ft. 0 in. 41 ft. 0 in.

Length 28 ft. 11 5/8 in. 28 ft. 11 1/4 in.

Height 11 ft. 4 in. 11 ft. 2 in.

Wing area 426 1/4 sq. ft. 426 1/4 sq. ft.

Tare weight 1,356 lb. 1,610 1b.

All-up weight 2,044 lb. 2,340 lb.

Maximum speed 80 m.p.h. 90 m.p.h.

Initial climb 350 ft./min. 600 ft./min.

Service ceiling - 13,500 ft.

Production: Prototype and 100 production aircraft with R.F.C. serial ranges 4600-4649 and A1611-A1660.

Geoffrey de Havilland's first design after joining the Aircraft Manufacturing Co. Ltd. as Chief Designer in June 1914, was a two seat reconnaissance biplane armed with a forward firing machine gun. Following contemporary practice, it was a twin boom, two bay, wire braced biplane of fabric covered wooden construction and the mainplanes were of the normal two spar type, wire braced internally. A pusher layout was chosen to give the observer/gunner the maximum possible arc of fire from the front cockpit, and the design included three unusual features; coil springs in the undercarriage to absorb landing shocks, an elementary form of oleo leg to damp out the rebound, and the provision of air brakes. These were in the form of rotatable auxiliary aerofoils protruding some three feet on each side of the nacelle just behind the front centre section struts. The diversion of all available supplies of its intended engine, the 120 h.p. watercooled Beardmore, to F.E.2 and R.E.5 production resulted in the 70 h.p. aircooled Renault being fitted instead.

The prototype, designated Airco D.H.1, was completed and flown at Hendon in January 1915 and the designer showed his confidence in it by taking off without any preliminary straight hops and at once commencing to circle. He also piloted it during tests which not only showed it to be inherently stable and capable of being flown 'hands off' but also that the air brakes were ineffective. They were consequently removed. A small number of production D.H.1s were then built but these had the more normal type of rubber cord shock absorbers in the undercarriage, forward facing exhaust pipes and the front cockpit coaming lowered to the top longerons to improve the pilot's view and to permit free rotation of the single Lewis gun on its pillar mounting. Five of these aircraft reached Royal Flying Corps training units during 1915.

Production on a larger scale was delayed until the 120 h.p. Beardmore was available in quantity but was finally undertaken by Savages Ltd. At King's Lynn in order to leave Airco free to develop newer types. With the Beardmore engine the machine carried the designation D.H.1A and was identified by the upright six cylinder engine, the large radiator behind the pilot's head and the gravity fuel tank mounted under the port upper wing root. The prototype D.H.1A, which bore the R.F.C. serial 4606, was converted from an Airco-built D.H.1. Although 73 D.H.1s and D.H.1As were delivered to the Royal Flying Corps, they saw little war service and in 1916 six were shipped to the Middle East Brigade for operational use by No. 14 Squadron. Home Defence squadrons received 24 and a further 43 went to training units such as No. 35 Reserve Squadron, Northolt and No. 199 Training Squadron. The type remained operational until early in 1917 after which it was relegated to second line duties until finally withdrawn from service at the end of 1918.

SPECIFICATION AND DATA

Manufacturers:

The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9

Savages Ltd., King's Lynn, Norfolk

Power Plants:

(D.H.1) One 70 h.p. Renault

(D.H.1A) One 120 h.p. Beardmore

Dimensions, Weights and Performances:

D.H.1 D.H.1A

Span 41 ft. 0 in. 41 ft. 0 in.

Length 28 ft. 11 5/8 in. 28 ft. 11 1/4 in.

Height 11 ft. 4 in. 11 ft. 2 in.

Wing area 426 1/4 sq. ft. 426 1/4 sq. ft.

Tare weight 1,356 lb. 1,610 1b.

All-up weight 2,044 lb. 2,340 lb.

Maximum speed 80 m.p.h. 90 m.p.h.

Initial climb 350 ft./min. 600 ft./min.

Service ceiling - 13,500 ft.

Production: Prototype and 100 production aircraft with R.F.C. serial ranges 4600-4649 and A1611-A1660.

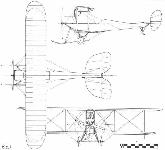

De Havilland D.H.2

As First World War military authorities were slow to realise its importance, no British interruptor gear had been developed to permit the use of a machine gun firing forward through the airscrew of a tractor aeroplane. The D.H.2 single seat fighter was consequently a pusher and resembled a scaled down D.H.1, its main components being similar but smaller versions of those of the earlier type. It was an unstaggered two bay biplane of orthodox fabric covered wooden construction, powered by a 100 h.p. Gnome Monosoupape rotary aircooled engine, using tubular steel instead of wooden tail booms and employing a steerable tail skid. The prototype D.H.2, first flown by Geoffrey de Havilland on June 1,1915, proved to be tail heavy but next day, with 30 lb. of ballast in the nose, he reached 3,500 ft. in 5 minutes - a truly remarkable rate of climb for those days. On June 3rd it went back into the works for the nacelle to be moved 4 inches forward and the gun and a larger rudder fitted, after which large scale production for the Royal Flying Corps was wholly undertaken in the Airco factory at Hendon and four hundred D.H.2s were ultimately delivered. These carried a single Lewis gun on a flexible mounting in front of the pilot, necessitating a slightly reshaped nacelle, and a few were fitted with the 110 h.p. Le Rhone rotary in place of the Gnome. R.F.C. pilots were quick to learn the technique of aiming the whole aeroplane at their targets and thereafter used the Lewis gun as a fixed weapon. Sensitivity of control, a limited speed range, and the inexperience of pilots, resulted in a number of early accidents through spinning, while others were caused by structural damage following the disintegration of the rotary engines in flight. In time however, its many lurid soubriquets gave way to an appreciation of its immensely strong structure and delightful handling qualities, so that it became a fully aerobatic fighting machine of great merit. The first squadron to use the D.H.2 operationally was No. 24, commanded by Major Lanoe G. Hawker who led his twelve machines from Hounslow to St. Omer on February 7, 1916. Within three months No. 29 and No. 32 Squadrons had also been re-equipped and sent to France and their D.H.2s, together with those of No. 24 Squadron, took part in the Battle of the Somme and fought continuously against the Fokker monoplane and other enemy fighters until the early part of 1917. A total of 266 served with the British Expeditionary Force in France, where they formed part of the equipment of Nos. 5, 11, 16 and 18 Squadrons and contributed handsomely to the establishment of Allied air supremacy.

Among the many epic events in the fighting life of this historic aircraft, three were of outstanding importance, the first on July 1, 1916 when Major L. W. B. Rees, Commanding Officer of No. 32 Squadron, won the Victoria Cross for a single-handed attack on a formation of ten German two seaters which lost two of their number. Later that year, on October 28th, a D.H.2 of No. 24 Squadron was the unwitting cause of the death of the leading German fighter pilot Oswald Boelcke. While diving to attack the D.H.2, Boelcke's Albatros was struck by the undercarriage of another of his flight and dived into the ground when the mainplanes came off. A few weeks afterwards, on November 23rd, another well-known German pilot, Manfred von Richtofen, shot down Major Lanoe G. Hawker in his D.H.2 after one of the longest single combats of the war. In 774 combats, the D.H.2s of No. 24 Squadron destroyed 44 enemy aircraft.

Two D.H.2s were issued to Home Defence squadrons and on June 17, 1917, a machine from the Orfordness Experimental Station, flown by Capt. R. H. M. S. Saundby, took part in an attack on the Zeppelin L.48. When ousted from the Western Front by the D.H.5 and other tractor fighters, thirty-two D.H.2s were despatched to the Near East where they saw service in Palestine with No. 17 and No. 111 Squadrons and in Macedonia with No. 47 Squadron and the R.F.C. R.N.A.S. Composite Fighting Squadron. At home, one hundred D.H.2s were issued to training units including No. 10 Reserve Squadron at Joyce Green, but by the autumn of 1918 all D.H.2s had been struck from R.A.F. charge.

SPECIFICATION AND DATA

Manufacturers: The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9.

Power Plants:

One 100 h.p. Gnome Monosoupape

One 110 h.p. Le Rhone

Dimensions:

Span 28 ft. 3 in. Length 25 ft. 2 1/2 in.

Height 9 ft. 6 1/2 in. Wing area 249 sq. ft.

Weights and Performances:

Gnome Le Rhone

Tare weight 943 lb. 1.004 lb.

All-up weight 1,441 lb.* 1,547 lb.

Maximum speed 93 m.p.h. 92 m.p.h.

Climb

to 6,500 ft. 12 mins. 12mins.

Service ceiling 14,000 ft. -

Endurance 2 3/4 hours 3 hours

* Prototype 1,310 lb.

Production: R.F.C. serials 4732 (prototype), 5916 to 6015. 7842 t o 7941,8725, A2533 to 42652, A4764 to A4813, A4988 to A5087. Not all delivered.

As First World War military authorities were slow to realise its importance, no British interruptor gear had been developed to permit the use of a machine gun firing forward through the airscrew of a tractor aeroplane. The D.H.2 single seat fighter was consequently a pusher and resembled a scaled down D.H.1, its main components being similar but smaller versions of those of the earlier type. It was an unstaggered two bay biplane of orthodox fabric covered wooden construction, powered by a 100 h.p. Gnome Monosoupape rotary aircooled engine, using tubular steel instead of wooden tail booms and employing a steerable tail skid. The prototype D.H.2, first flown by Geoffrey de Havilland on June 1,1915, proved to be tail heavy but next day, with 30 lb. of ballast in the nose, he reached 3,500 ft. in 5 minutes - a truly remarkable rate of climb for those days. On June 3rd it went back into the works for the nacelle to be moved 4 inches forward and the gun and a larger rudder fitted, after which large scale production for the Royal Flying Corps was wholly undertaken in the Airco factory at Hendon and four hundred D.H.2s were ultimately delivered. These carried a single Lewis gun on a flexible mounting in front of the pilot, necessitating a slightly reshaped nacelle, and a few were fitted with the 110 h.p. Le Rhone rotary in place of the Gnome. R.F.C. pilots were quick to learn the technique of aiming the whole aeroplane at their targets and thereafter used the Lewis gun as a fixed weapon. Sensitivity of control, a limited speed range, and the inexperience of pilots, resulted in a number of early accidents through spinning, while others were caused by structural damage following the disintegration of the rotary engines in flight. In time however, its many lurid soubriquets gave way to an appreciation of its immensely strong structure and delightful handling qualities, so that it became a fully aerobatic fighting machine of great merit. The first squadron to use the D.H.2 operationally was No. 24, commanded by Major Lanoe G. Hawker who led his twelve machines from Hounslow to St. Omer on February 7, 1916. Within three months No. 29 and No. 32 Squadrons had also been re-equipped and sent to France and their D.H.2s, together with those of No. 24 Squadron, took part in the Battle of the Somme and fought continuously against the Fokker monoplane and other enemy fighters until the early part of 1917. A total of 266 served with the British Expeditionary Force in France, where they formed part of the equipment of Nos. 5, 11, 16 and 18 Squadrons and contributed handsomely to the establishment of Allied air supremacy.

Among the many epic events in the fighting life of this historic aircraft, three were of outstanding importance, the first on July 1, 1916 when Major L. W. B. Rees, Commanding Officer of No. 32 Squadron, won the Victoria Cross for a single-handed attack on a formation of ten German two seaters which lost two of their number. Later that year, on October 28th, a D.H.2 of No. 24 Squadron was the unwitting cause of the death of the leading German fighter pilot Oswald Boelcke. While diving to attack the D.H.2, Boelcke's Albatros was struck by the undercarriage of another of his flight and dived into the ground when the mainplanes came off. A few weeks afterwards, on November 23rd, another well-known German pilot, Manfred von Richtofen, shot down Major Lanoe G. Hawker in his D.H.2 after one of the longest single combats of the war. In 774 combats, the D.H.2s of No. 24 Squadron destroyed 44 enemy aircraft.

Two D.H.2s were issued to Home Defence squadrons and on June 17, 1917, a machine from the Orfordness Experimental Station, flown by Capt. R. H. M. S. Saundby, took part in an attack on the Zeppelin L.48. When ousted from the Western Front by the D.H.5 and other tractor fighters, thirty-two D.H.2s were despatched to the Near East where they saw service in Palestine with No. 17 and No. 111 Squadrons and in Macedonia with No. 47 Squadron and the R.F.C. R.N.A.S. Composite Fighting Squadron. At home, one hundred D.H.2s were issued to training units including No. 10 Reserve Squadron at Joyce Green, but by the autumn of 1918 all D.H.2s had been struck from R.A.F. charge.

SPECIFICATION AND DATA

Manufacturers: The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9.

Power Plants:

One 100 h.p. Gnome Monosoupape

One 110 h.p. Le Rhone

Dimensions:

Span 28 ft. 3 in. Length 25 ft. 2 1/2 in.

Height 9 ft. 6 1/2 in. Wing area 249 sq. ft.

Weights and Performances:

Gnome Le Rhone

Tare weight 943 lb. 1.004 lb.

All-up weight 1,441 lb.* 1,547 lb.

Maximum speed 93 m.p.h. 92 m.p.h.

Climb

to 6,500 ft. 12 mins. 12mins.

Service ceiling 14,000 ft. -

Endurance 2 3/4 hours 3 hours

* Prototype 1,310 lb.

Production: R.F.C. serials 4732 (prototype), 5916 to 6015. 7842 t o 7941,8725, A2533 to 42652, A4764 to A4813, A4988 to A5087. Not all delivered.

De Havilland D.H.3.

The D.H.3, Capt. Geoffrey de Havilland's third design for the Aircraft Manufacturing Co. Ltd., which appeared in 1916, was a large two bay biplane capable of bombing German industrial centres. Contrasting in every way with his previous small pusher fighters but owing something to the Royal Aircraft Factory's F.E.4, in the early design of which Capt. De Havilland had collaborated, the D.H.3 was equipped with two 120 h.p. Beardmore water-cooled engines in nacelles between the mainplanes. The long, slender, wire braced Warren girder fuselage was built of spruce, covered with plywood at the forward end and carried low to the ground on a wide track, short legged undercarriage. A pair of bumper wheels was provided under the nose. The four bladed, nine foot diameter pusher airscrews were carried clear of the mainplane trailing edges by short extension shafts and the D.H.3 was also the first aeroplane to feature the graceful curving rudder which was to become characteristic of almost every future de Havilland design. As might be expected on so large an aeroplane it was necessary to ensure good handling qualities by using an elevator with generous horn balances. The crew of three consisted of the pilot in an open cockpit just ahead of the mainplanes, and front and rear gunners whose cockpits were each equipped with two Lewis gun pillar mountings. For its day the D.H.3 had a very lively performance and when engaged on long range duties could carry a military load of 680 lb. and fuel for eight hours.

Only the prototype was built and this carried no serial number. A second version, carrying R.F.C. serial 7744, was powered by two 160 h.p. Beardmore engines and so modified as to warrant the designation D.H.3A. These modifications included the cutting back of mainplane trailing edges in order to obviate the use of engine extension shafts, while to lighten the controls still further, the rudder was given increased balance area. An order was placed for 50 production D.H.3As but when the first, A5088, was still under construction, the War Office shortsightedly cancelled the contract in the belief that strategic bombing of Germany was unnecessary and that the twin engined bomber was impracticable. Both prototypes were flown by pilots of the Upavon evaluation unit but were then relegated to the dump behind the Hendon hangars. It is said that the prototype D.H.3s were actually burning on the factory scrap heap on July 7, 1917 while London was being bombed by their German counterpart, the Gotha. This and later bombardments encouraged a rapid change of official attitude which resulted in the D.H.3 being redesigned and eventually built in quantity as the D.H. 10.

SPECIFICATION AND DATA

Manufacturers: The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9.

Power Plants:

(D.H.3) Two 120 h.p. Beardmore

(D.H.3A) Two 160 h.p. Beardmore

Dimensions:

Span 60 ft. 10 in. Length 36 ft. 10 in.

Height 14 ft. 6 in. Wing area (D.H.3) 793 sq. ft. (D.H.3A) 770 sq. ft.

Weights:

Tare weight (D.H.3) 3,980 lb.

All-up weight (D.H.3) 5.810 lb . (D.H.3A) 5,776 lb.

Performance: (D.H.3)

Maximum speed 95 m.p.h. Initial climb 550 ft./min.

Endurance 8 hours Range 700 miles

Production:

Prototypes - D.H.3 unmarked, D.H.3A serial 7744

Others - 7745 and A5088 unfinished, A5089 to A5137 cancelled

The D.H.3, Capt. Geoffrey de Havilland's third design for the Aircraft Manufacturing Co. Ltd., which appeared in 1916, was a large two bay biplane capable of bombing German industrial centres. Contrasting in every way with his previous small pusher fighters but owing something to the Royal Aircraft Factory's F.E.4, in the early design of which Capt. De Havilland had collaborated, the D.H.3 was equipped with two 120 h.p. Beardmore water-cooled engines in nacelles between the mainplanes. The long, slender, wire braced Warren girder fuselage was built of spruce, covered with plywood at the forward end and carried low to the ground on a wide track, short legged undercarriage. A pair of bumper wheels was provided under the nose. The four bladed, nine foot diameter pusher airscrews were carried clear of the mainplane trailing edges by short extension shafts and the D.H.3 was also the first aeroplane to feature the graceful curving rudder which was to become characteristic of almost every future de Havilland design. As might be expected on so large an aeroplane it was necessary to ensure good handling qualities by using an elevator with generous horn balances. The crew of three consisted of the pilot in an open cockpit just ahead of the mainplanes, and front and rear gunners whose cockpits were each equipped with two Lewis gun pillar mountings. For its day the D.H.3 had a very lively performance and when engaged on long range duties could carry a military load of 680 lb. and fuel for eight hours.

Only the prototype was built and this carried no serial number. A second version, carrying R.F.C. serial 7744, was powered by two 160 h.p. Beardmore engines and so modified as to warrant the designation D.H.3A. These modifications included the cutting back of mainplane trailing edges in order to obviate the use of engine extension shafts, while to lighten the controls still further, the rudder was given increased balance area. An order was placed for 50 production D.H.3As but when the first, A5088, was still under construction, the War Office shortsightedly cancelled the contract in the belief that strategic bombing of Germany was unnecessary and that the twin engined bomber was impracticable. Both prototypes were flown by pilots of the Upavon evaluation unit but were then relegated to the dump behind the Hendon hangars. It is said that the prototype D.H.3s were actually burning on the factory scrap heap on July 7, 1917 while London was being bombed by their German counterpart, the Gotha. This and later bombardments encouraged a rapid change of official attitude which resulted in the D.H.3 being redesigned and eventually built in quantity as the D.H. 10.

SPECIFICATION AND DATA

Manufacturers: The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9.

Power Plants:

(D.H.3) Two 120 h.p. Beardmore

(D.H.3A) Two 160 h.p. Beardmore

Dimensions:

Span 60 ft. 10 in. Length 36 ft. 10 in.

Height 14 ft. 6 in. Wing area (D.H.3) 793 sq. ft. (D.H.3A) 770 sq. ft.

Weights:

Tare weight (D.H.3) 3,980 lb.

All-up weight (D.H.3) 5.810 lb . (D.H.3A) 5,776 lb.

Performance: (D.H.3)

Maximum speed 95 m.p.h. Initial climb 550 ft./min.

Endurance 8 hours Range 700 miles

Production:

Prototypes - D.H.3 unmarked, D.H.3A serial 7744

Others - 7745 and A5088 unfinished, A5089 to A5137 cancelled

De Havilland D.H.4

The Airco D.H.4 day bomber, the prototype of which was numbered 3696 and first flew at Hendon in August 1916, was without question one of the outstanding aeroplanes of the First World War. Its fabric covered, wire braced, spruce and ash structure was typical of the day but the front fuselage, housing the cockpits and main fuel tanks, was strengthened with a plywood covering. Mainplanes and tailplane followed the usual two spar layout but the spars were lightened by spindling between the ribs and the tailplane was fitted with variable incidence gear. Rubber cord suspension was used in the undercarriage (two 6 ft. 9 in. lengths wound into nine turns for each wheel), and the fin and rudder conformed to the de Havilland family shape first used on the D.H.3. Standard armament consisted of one synchronised forward firing Vickers gun mounted on top of the fuselage, single or twin Lewis guns on a Scarff ring for the observer, and two 230 lb. and four 112 lb. bombs were carried in racks under the fuselage and wings respectively.

The prototype was fitted with a 230 h.p. B.H.P. six cylinder watercooled engine and was unique in having rear centre section struts which raked sharply forward. Production D.H.4s had the rear struts shortened and made parallel to the front and were powered by a variety of engines, including the 200 h.p. R.A.F. 3A, 230 h.p. Siddeley Puma, 250 h.p. Rolls-Royce III and 260 h.p. Fiat. Pilots were warned not to damage the airscrew by taking off with the tail too high, so that when more powerful engines such as the 375 h.p. Rolls-Royce Eagle VIII were developed and larger airscrews were needed, it was necessary to fit a taller undercarriage and this eventually became standard on all D.H.4s. The incidence was also increased to shorten the landing run. All these engines were cooled by frontal radiators except the Fiat, first installed in A7532, the radiator for which was between the front undercarriage legs, permitting the use of close fitting engine cowlings in the manner of the later D.H.9. In addition to the modified undercarriage, late production D.H.4s also had the rear Scarff ring raised to improve the field of fire and the rear decking was made fiat. Orders were placed with Airco and six sub-contractors for some 1,700 D. H.4s, of which 1,449 were actually delivered.

Pilots who flew the D.H.4 were unanimous in praise of its fine handling qualities, wide speed range and a performance which made it almost immune from interception. No previous aeroplane had had so wide a speed range (45-143 m.p.h. On the Eagle VIII version) and pilots' notes emphasised its slow speed docility, recommending that the approach be made at 60 and the touch down at 50 m.p.h. Operating at heights above 15,000 ft. the D.H.4 could outfly contemporary single seat fighters but if caught was usually an easy victim because the cockpits were so far apart that in the noise of battle Gosport tubes were useless as a means of coordinating defence and the aircraft went down in flames when bullets punctured the 60 gallon fuel tank between the seats. Late in 1917 fire hazards were much reduced when the pressurised fuel system was replaced by two wind driven pumps on top of the fuselage behind the pilot.

The first D.H.4s in France, delivered by air to No. 55 Squadron on March 6, 1917, were first used operationally at Valenciennes on April 6. As an R.A.F. Squadron at the end of the war, it bombed munitions factories at Frankfurt, Mannheim and Stuttgart but French and Belgian based D.H.4s were not entirely employed as day bombers but also made high level photographic reconnaissance flights, fighter sweeps and anti-Zeppelin and submarine patrols. The majority of naval D.H.4s were among 150 built under sub-contract by the Westland Aircraft Works. They were Eagle powered and fitted with twin, instead of single front guns and also a raised Scarff ring mounting for the rear gunner, but increases in weight and parasitic drag somewhat impaired their performance. The first D.H.4 to be built at Yeovil was flight tested by B. C. Hucks in April 1917 and delivered in France the next morning. Coastal patrols were also undertaken by R.N.A.S. Squadrons and at least one D.H.4 was experimentally fitted with twin floats for this task. No. 202 Squadron also took a complete set of oblique and vertical photographs of Zeebrugge in preparation for the historic raid of April 22-23, 1918 during which the Mole was bombed with great daring by Wg. Cdr. Fellowes flying a D.H.4. To No. 217 Squadron fell the honour of sinking the German submarine U.B.12 on August 12, 1918. R.N.A.S., Great Yarmouth, was armed with D.H.4s, one of which was ditched in the North Sea on September 5, 1917 after an unsuccessful attack on the Zeppelin L.44, the crew being picked up by flying boat. On August 5, 1918 however, A8032 piloted by Major Egbert Cadbury shot down L.70 when 41 miles N.E. of base, from a height of over 16,000 ft. The Home Defence D.H.4s were operated far over the North Sea and efforts were made at the M.A.E.E., Isle of Grain, to equip them with flotation gear or as an alternative, hydrovanes and wing tip floats for use after the undercarriage was jettisoned. These devices were developed and test flown by Harry Busteed using D.H.4s A 7457 and D1769. The latter was also used for trailing mine experiments and hydrovanes were also fitted to an American built DH-4 at McCook Field, Dayton, Ohio. Two D.H.4s, one of which was numbered A2168, were fitted with H pounder Coventry Ordnance Works quick firing anti-Zeppelin guns. In 1917-18 the type was used overseas in small numbers as shown on page 67, while in the period 1919-21 many went as Imperial Gifts to assist the formation of air forces in Canada (12 aircraft) and South Africa (e.g. serials 26 and 401). Airco-built D.H.4s A7893 and A7929, taken to New Zealand in 1919 by Col. A. V. Bettington. were stationed at Sockburn and A7893, piloted by Capt. T. Wilkes and L. M. Isitt was the first aircraft to fly over Mt. Cook.

As an engine test bed the D.H.4 made a major contribution to Allied technical superiority and among the several experimental installations were those of the 300 h.p. Renault 12Fe in A2148, the 400 h.p. Sunbeam Matabele in A8083, the 353 h.p. Rolls-Royce G and the Ricardo-Halford inverted supercharged engine. One of the new American 400 h.p. Liberty 12 engines was fitted into a British built D.H.4 delivered at McCook Field in August 1917. It first flew with the Liberty on October 29th of that year and heralded the mass production of the D.H.4 in America. By the Armistice 3,227 had been constructed, 1,885 of which were shipped to France and by the end of 1918 the total of American built DH-4s had risen to 4,587, or more than three times the British production of 1,449. Eventually, the three American contractors delivered 4,846 examples of the DH-4, but after the war they were disposed of in considerable numbers to the Nicaraguan and other Latin American army air services.

Financial depression virtually stopped the procurement of new American aircraft during the postwar years but maintenance funds permitted a considerable rebuilding programme. This gave rise to over 60 DH-4 variants, many of which remained on the active list for nearly a decade. The majority of such variants received an American-style hyphenated model number, commencing with DH-4A, applied to the single Dayton-Wright DH-4 which was fitted in July 1918 with an improved fuel system by the Engineering Division of the Army's Department of Aircraft Production. This aircraft should not be confused with the British cabin conversion designated D.H.4A. In October 1918, more extensive modifications by the Engineering Division produced the DH-4B in which the pilot's cockpit was moved back next to that of the gunner. One DH-4B, piloted by Lt. Maynard, won the New York-Toronto Aerial Derby on August 25, 1919 in a flying time of 7 hours 45 minutes. The total of such conversions made in 1918-24 reached 1,540 when the two final rebuilds were made by the de Havilland Aircraft Co. Ltd. to the order of Maj. Davidson for the use of Naval and Military Attaches of the U.S. Embassy in London. These aircraft, c/n 138 and 139, were test flown by Hubert Broad in August 1926 and based at Kenley and Stag Lane respectively in full U.S. military markings until replaced by a D.H.60 Moth in 1927.

American conversions fell into two main categories - specialized versions for military purposes, the surviving designations for which are listed in an accompanying table, and experimental conversions of the early DH-4B, mainly as engine testbeds or trial installations aircraft. Military models included the DH-4B-2 trainer, sometimes known as the Blue Bird, the DH-4B-5 two passenger Honeymoon cabin transport devised by the Engineering Division of the Bureau of Aeronautics, and ambulance versions for one or two stretchers. Two of the last named, U.S. Marine serials A5811 and A5883, were used in 1922 in the island of Haiti, starting point of the longest flight in U.S. history up to that time, made in 1924 by two U.S. Army DH-4Bs which successfully covered the 10,953 miles to San Francisco and back.

DH-4 variants remained in military service with the U.S. Army, Navy and Marines until 1929, one DH-4B-3 being re-engined with a Packard 2A-1500 by the U.S. Navy at Quantico in 1926, but the last of the major variants had already appeared in 1924. They were built for the Corps Observation role, three by the Boeing company and one by Atlantic. The Boeings were ungainly sesquiplanes using steel DH-4M-1 fuselages and thick section wings of new design. The first, designated XCO-7, became the XCO-7A when fitted with a wide track undercarriage but crashed and was replaced by the XCO-7B, a similar machine powered by a 420 h.p. Liberty V-1410 experimental inverted engine. These prototypes scarcely resembled the DH-4B at all but the origins of the remaining Corps Observation conversion, XCO-8, could hardly be mistaken, being a reproduction of an undesignated conversion made in 1922 by the Gallaudet Aircraft Corporation which fitted a standard Liberty powered DH-4B with the mainplanes and N type interplane struts from a Loening COA-1 amphibian. The true XCO-8 was an exactly similar conversion made two years later by the Atlantic company.

Steel tube fuselages were built by the Boeing and Atlantic companies in 1920-25 to extend the useful lives of these veterans under the designations DH-4M, DH-4M-1 and DH-4M-2, 186 of which were by Boeing and at least 135 by Atlantic. Considerable interest was aroused when two reworked and specially modified DH-4s took off from Rockwell Field, San Diego, California on June 27, 1923 to conduct one of the first flight refuelling experiments. Lts. Lowell Smith and Paul Richter remained airborne for 6 1/2 hours, during which time they were refuelled twice by hose from the DH-4 flown by Lts. Hine and Seifert. After minor adjustments they kept aloft for 37 1/4 hours on August 27-28th and landed only when fog prevented further contact with the tanker. On December 13, 1923 a DH-4 with supercharged Liberty, piloted by Lt H. Harris and carrying a passenger, climbed to an altitude of 27,000 ft. over McCook Field, increased later to 30,500 ft., reached in 69 minutes in a special DH-4B, N.A.C.A. 8, fitted with a Roots type supercharger behind the engine. In 1927 a DH-4M-2, N.A.C.A. 25, with Model II Roots blower, reached 26,500 ft. in 51 minutes using camera recorded automatic observer equipment in an enclosed rear cockpit.

SPECIFICATION AND DATA

Manufacturers:

The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9

F. W. Berwick and Co. Ltd., Park Royal, London, N.W.10

Glendower Aircraft Co. Ltd., 54 Sussex Place, South Kensington, London, S.W.7

Palladium Autocars Ltd., Felsham Road, Putney, London, S.W.15

The Vulcan Motor and Engineering Co. (1906) Ltd., Southport, Lanes.

Waring and Gillow Ltd., Cambridge Road, Hammersmith, London, W.6

Westland Aircraft Works, Yeovil, Somerset

SABCA, Haren Airport, Brussels, Belgium (15 built in 1926 for Belgian Air Force)

Atlantic Aircraft Corporation, Teterboro, New Jersey, U.S.A.

Boeing Airplane Company, Seattle, Washington, U.S.A.

The Dayton-Wright Airplane Co., Dayton, Ohio, U.S.A. (3,106 built)

The Fisher Body Corporation, U.S.A. (1,600 built)

Standard Aircraft Corporation, Elizabeth, New Jersey, U.S.A. (140 built)

Power Plants:

One 200 h.p. R.A.F. 3A

One 230 h.p. B.H.P.

One 230 h.p. Siddeley Puma

One 250 h.p. Rolls-Royce Mk. III or M k. IV

One 260 h.p. Fiat

One 275 h.p. Rolls-Royce Eagle VI

*One 300 h.p. Renault 12Fe

*One 300 h.p. Wright H

*One 300 h.p. Packard 1A-1116 o r 1A-1237

*One 320 h.p. Armstrong Siddeley Jaguar I

One 325 h.p. Rolls-Royce Eagle VII

*One 353 h.p. Rolls-Royce G

One 375 h.p. Rolls-Royce Eagle VIII

*One Ricardo-Halford supercharged engine

One 400 h.p. Liberty 12

*One 400 h.p. Sunbeam Matabele

*One 420 h.p. Liberty V-1410

One 435 h.p. Liberty 12A

*One 435 h.p. Curtiss D-12

*One 525 h.p. Packard 2A-1500

* Experimental installation

Dimensions, Weights and Performances:

(a) British

B.H.P. Puma Rolls III Eagle VIII RAF. 3A Fiat Liberty 12

Span 42 ft. 4 5/8 in. 42 ft. 4 5/8 in. 42 ft. 4 5/8 in. 42 ft. 4 5/8 in. 42 ft, 4 5/8 in. 42 ft. 4 5/8 in. 42 ft. 6 in.

Length 30 ft. 8 in. 30 ft. 8 in. 30 ft. 8 in. 30 ft. 8 in. 29 ft. 8 in. 29 ft. 8 in. 30 ft. 6 in.

Height 10 ft. 1 in. 10 ft. 1 in. 10 ft. 5 in . 11ft. 0in, 10 ft. 5 in. 10 ft. 5 in. 10ft. 3 5/8 in.

Wing area 434 sq. ft. 434 sq. ft. 434 sq. ft. 434 sq. ft. 434 sq. ft. 434 sq. ft. 440 sq. ft.

Tare weight 2,197 lb. 2,230 lb. 2,303 lb. 2,387 lb. 2,304 lb. 2,306 lb. 2,391 lb.

All-up weight 3,386 lb. 3,344 lb. 3,313 lb. 3,472 lb. 3,340 lb. 3.360 lb. 4,297 lb.

Maximum speed 108 m.p.h. 106 m.p.h. 119 m.p.h. 143 m.p.h. 122 m.p.h. 114 m.p.h. 124 m.p.h.

Initial climb 700 ft./min. 1,000 ft./min. 925 ft./min. 1,350 ft./min. 800 ft./min. 1,000 ft./min.

Ceiling 17,500 ft. 17,400 ft. 16,000 ft. 22,000 ft. 18,500 ft. 17,000 ft. 17,500 ft.

Endurance 4 1/2 hours 4 1/2 hours 3 1/2 hours 3 3/4 hours 4 hours 4 1/2 hours 3 hours

(b) American

DH-4B DH-4M-1 DH-4M-2 XCO-7 XCO-7A XCO-7B XCO-8

Engine Liberty 12A Liberty 12A Liberty 12A Liberty 12A Liberty 12A Liberty V-1410 Liberty 12A

Span 42 ft. 5 1/2 in. 42ft. 5 1/2 in. 42 ft. 5 1/2 in. 45 ft. 0 in. 45 ft. 0 in. 45 ft. 0 in. 45 ft. 0 in.

Length 29ft. 11 in. 29 ft. 11 in. 29ft. 11 in. 30ft. 4 in. 30ft. 4 in. 30ft. 11 in. 30ft. 0in.

All-up weight 4,600 lb. 4,595 lb. 4,595 lb. 4,798 lb. 4,800 lb. 4,652 lb. 4.680 lb.

Maximum speed 124 m.p.h. 118 m.p.h. 118 m.p.h. 130 m.p.h. 122 m.p.h. 130 m.p.h.

De Havilland D.H.4 (Civil)

Several million pounds worth of war surplus aircraft, including hundreds of D.H.4s, the majority brand new from the Airco and Waring and Gillow factories, were acquired by Handley Page Ltd. in 1919-20 and later reconditioned by the Aircraft Disposal Co. Ltd. at Croydon to become the postwar equipment of the air forces of Spain (14 aircraft), Belgium, Greece, Japan and other small nations. With few exceptions these were powered by the 375 h.p. Rolls-Royce Eagle VIII engine and those for Spain and Belgium were flown out in the autumn of 1921 under temporary civil marks by many well known pilots of the day, including F. T. Courtney, H. Shaw, E. D. Hearne, F. J. Ortweiler, C. D. Barnard, E. L. Foot and Norman Macmillan. In Spain the D.H.4 formed the main equipment of the Air Force training establishment at Cuatros Vientos and was used extensively in the Moroccan War.

Two Eagle powered D.H.4s were also used in a purely civil capacity on the Continental services of Aircraft Transport and Travel Ltd. late in 1919 as temporary crash replacements and two others were shipped to Australia by C. J. de Garis and there fitted with cockpits for two passengers behind the pilot. One of them, F2691/G-AUCM was erected and test flown at Glenroy on November 27, 1920 and piloted by F. S. Briggs with the owner as passenger, arrived at Perth on December 2nd after making the first Melbourne-Perth flight in two days. A week later it made the first Perth-Sydney flight, also in two days, and on January 16, 1921 became the first aircraft to fly from Brisbane to Melbourne in one day. Again piloted by F. S. Briggs it left Melbourne on September 9, 1921 to survey the route of the proposed North-South railway and covered 3,000 miles in exactly one month, becoming the first aircraft ever to land at Alice Springs. From August 1924 it carried mail on the Adelaide-Sydney service of Australian Aerial Services Ltd. with the name "Scrub Bird" and was still flying miners and supplies between Port Moresby and Lae, New Guinea for Bulolo Goldfields Ltd. in 1927.

C. J. de Garis sold the other D.H.4, F2682/G-AUBZ to R. J. P. Parer who flew it to victory in the first Australian Aerial Derby on December 28, 1920 at 142 m.p.h. It was then used for joyriding and other pioneering work until delivered to QANTAS at Longreach by rail on August 12, 1922. In the last two months of the year it covered over 5,000 air miles, mainly on the Charleville-Cloncurry mail service but was extensively damaged when it struck telephone wires while landing at Gilford Park station, south west of Longreach, on June 6, 1923. During repairs the two open passenger cockpits were roofed over to make an open-sided cabin and it first flew in this form in May 1924. It opened the extension service between Cloncurry and Camooweal on February 7,1925 piloted by Capt. L. J. Brain but, when ousted by the new D.H.50s at the end of 1927, was sold to Matthews Aviation Ltd. at Essendon Aerodrome, Melbourne where the fuselage was modified for joyriding with no less than four separate passenger cockpits behind the pilot. At this stage it was named "Cock Bird" on the fin but in 1930 it returned to taxi work with a full D.H.4A-style cabin with sliding windows as "Spirit of Melbourne". It was last in service with Pioneer Air Services who acquired it in September 1934.

In Canada, all 12 Imperial Gift D.H.4s were equipped with air to ground W/T sets for use on forestry patrol work by the Air Board Civil Operations Branch and in 1921 one of these aircraft made the first recorded geological reconnaissance flight piloted by F/Lt. A. W. Carter. From August 1920 their pilots spotted hundreds of forest fires and helped save millions of dollars worth of timber, operating mainly from an airstrip at High River, Alberta where the D.H.4's performance alone could combat wind ridden skies near the Rockies. Special skis were designed for winter flying and as late as 1924 these veterans continued to give photographic coverage of the district but by that time showed such deterioration that they were permanently grounded at the end of the season. The one exception, G-CYDM, still airworthy in 1927, was reworked to D.H.4B standard with underslung radiator and observation panels in the lower wing roots.

The D.H.4's greatest contribution to the embryo air transport industry however, was made in Europe by four machines supplied by Handley Page Ltd. to the Belgian concern Syndicat National pour l'Etude des Transports Aeriens (SNETA). In company with a number of D.H.9s, they ran spasmodically on the Brussels-London, Brussels-Paris and Brussels-Amsterdam services in 1920-21, and although their normal London terminal was Croydon, many flights terminated at Cricklewood for convenience of servicing. After the departure to Brussels of D.H.4 O-BABI on January 15, 1921, Cricklewood was used no more and the D.H.4's commercial life ended soon afterwards in two major crashes and the destruction of most of the SNETA fleet in a disastrous hangar fire at Brussels on September 27, 1921. An accompanying table lists all the civil D.H.4s for which records still exist.

Apart from two machines employed by Aircraft Transport and Travel Ltd. as temporary replacements for crashed D.H.4As, the standard D.H.4 saw little civilian service in England. On June 21, 1919 however, Marcus D. Manton came third at an average speed of 117-39 m.p.h. in the Aerial Derby at Hendon in K-142, a new aircraft with Rolls-Royce Eagle VIII, specially demilitarised by the Aircraft Manufacturing Co. Ltd. It competed against a 'one-ofF racing version registered K-141 and designated D.H.4R to signify D.H.4 Racer. This monster was built in ten days by an enthusiastic team led by F. T. Hearle who fitted a 450 h.p. Napier Lion with chin radiator, clipped the lower mainplane at the first bay and braced the overhanging portion of the upper wing by slanting struts. Without stagger and with the rear cockpit faired over, it was scarcely recognisable as a D.H.4 derivative but Airco test pilot Capt. Gerald Gathergood flew it twice round London in 1 hour 2 minutes and set up a British closed circuit record of 129-3 m.p.h. This was indeed a creditable day's flying by two machines which had left the ground for the first time only that morning! The one other British civil example was G-EAMU acquired by the shipping firm of S. Instone and Co. Ltd., primarily for the fast carriage of ship's papers but also accommodating two passengers in the open rear cockpit. With Capt. F. L. Barnard as pilot and appropriately named "City of Cardiff', it emulated the Aerial Derby machines by making its first flight on the morning of October 13, 1919, a return flight to the Welsh capital in the afternoon and its maiden trip to Paris the next day. During 1920 several trips were made to Paris, Brussels, Nice, and on one occasion, to Prague.

In America DH-4s with Liberty 12 motors went into regular service with the United States Postal Department on August 12, 1918 and from June 1919 onwards a considerable number of DH-4Bs and DH-4Ms were converted for the carriage of 400 lb. of mail in a watertight compartment that had once been the front cockpit. The aircraft was thereafter flown from the rear as a single seater. In addition, thirty machines were reconstructed by the Lowe, Willard and Fowler Engineering Company to have increased span, two 200 h.p. Hall-Scott L-6 watercooled engines outboard and a large mail compartment in the nose. One normal DH-4B, No. 299, was given a special fuselage having a cargo hold for 800 lb. of mail between the undercarriage legs. New wings of modified section were built by the Aeromarine Company and in 1922 No. 299 carried a record load of 1,032 lb. from New York to Washington at its economical cruising speed of 68 m.p.h. Other important and unusual DH-4 mailplanes included one fitted with Wittemann-Lewis unstaggered wings and strengthened centre section as well as several rebuilt by G. I. Bellanca with new, single bay, sesquiplane wings braced by his patent inclined lift struts. Pioneer mail pilots, not the least of whom was Charles Lindbergh, flew the DH-4s night and day in any weather between New York, Washington, Cleveland, Chicago and Omaha, finally linking the East and West coasts when the final section to San Francisco was opened in August 1920. The bass Liberty voice of the veteran DH-4s spanned the continent until 1927, by which time many had been equipped with large belly tanks giving incredible range, and enormous cone shaped floodlights for night landings in rough pasture at small townships en route. Surviving in the U.S.A. in 1987 were N249B (rebuilt 1961 68 with parts and engine recovered from its 1922 crash site in Utah) at the National Air and Space Museum. Washington; N489 at the Dayton U.S.A.F. Museum; and the Aireo-built A2169 (once used in films as NX3258). The last, formerly part of the 'Wings and Wheels' Collection was sold to a private owner from Georgia in 1981.

SPECIFICATION AND DATA

Manufacturers: The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9, and the sub-contractors.

Power Plants:

(D.H.4) One 375 h.p. Rolls-Royce Eagle VIII

(DH-4) One 400 h.p. Liberty 12

(D.H.4R) One 450 h.p. Napier Lion

Dimensions, Weights and Performances:

D.H.4 DH-4 D.H.4R

Span 42 ft. 4 5/8 in. 42 ft. 5 3/4 in. 42 ft. 4 5/8 in.

Length 30 ft. 6 in. 30 ft. 6 in. 27 ft. 5 in.

Height 11ft. 0 in. 10 ft. 3 5/8 in. 11ft. 0 in.

Wing area 434 sq. ft. 440 sq. ft.

Tare weight 2.387 lb.** 2,391 lb. 2,490 lb.

All-up weight 3,472 lb. 4,297 lb. 3,191 lb.

Maximum speed 143 m.p.h. 120 m.p.h.* 150 m.p.h.

Landing speed 50 m.p.h. 60 m.p.h.*

Initial climb 1,300 ft./min. 1,000 ft./min.*

Ceiling 23.500 ft. 19,500 ft.

Endurance 3 3/4 hours 3 hours

* No. 299 modified: 115 m.p.h., 50 m.p.h., 800 ft./min. respectively.

** G-AUBZ with cabin: 2,403 lb. Cruising speed. 85 m.p.h.

The Airco D.H.4 day bomber, the prototype of which was numbered 3696 and first flew at Hendon in August 1916, was without question one of the outstanding aeroplanes of the First World War. Its fabric covered, wire braced, spruce and ash structure was typical of the day but the front fuselage, housing the cockpits and main fuel tanks, was strengthened with a plywood covering. Mainplanes and tailplane followed the usual two spar layout but the spars were lightened by spindling between the ribs and the tailplane was fitted with variable incidence gear. Rubber cord suspension was used in the undercarriage (two 6 ft. 9 in. lengths wound into nine turns for each wheel), and the fin and rudder conformed to the de Havilland family shape first used on the D.H.3. Standard armament consisted of one synchronised forward firing Vickers gun mounted on top of the fuselage, single or twin Lewis guns on a Scarff ring for the observer, and two 230 lb. and four 112 lb. bombs were carried in racks under the fuselage and wings respectively.

The prototype was fitted with a 230 h.p. B.H.P. six cylinder watercooled engine and was unique in having rear centre section struts which raked sharply forward. Production D.H.4s had the rear struts shortened and made parallel to the front and were powered by a variety of engines, including the 200 h.p. R.A.F. 3A, 230 h.p. Siddeley Puma, 250 h.p. Rolls-Royce III and 260 h.p. Fiat. Pilots were warned not to damage the airscrew by taking off with the tail too high, so that when more powerful engines such as the 375 h.p. Rolls-Royce Eagle VIII were developed and larger airscrews were needed, it was necessary to fit a taller undercarriage and this eventually became standard on all D.H.4s. The incidence was also increased to shorten the landing run. All these engines were cooled by frontal radiators except the Fiat, first installed in A7532, the radiator for which was between the front undercarriage legs, permitting the use of close fitting engine cowlings in the manner of the later D.H.9. In addition to the modified undercarriage, late production D.H.4s also had the rear Scarff ring raised to improve the field of fire and the rear decking was made fiat. Orders were placed with Airco and six sub-contractors for some 1,700 D. H.4s, of which 1,449 were actually delivered.

Pilots who flew the D.H.4 were unanimous in praise of its fine handling qualities, wide speed range and a performance which made it almost immune from interception. No previous aeroplane had had so wide a speed range (45-143 m.p.h. On the Eagle VIII version) and pilots' notes emphasised its slow speed docility, recommending that the approach be made at 60 and the touch down at 50 m.p.h. Operating at heights above 15,000 ft. the D.H.4 could outfly contemporary single seat fighters but if caught was usually an easy victim because the cockpits were so far apart that in the noise of battle Gosport tubes were useless as a means of coordinating defence and the aircraft went down in flames when bullets punctured the 60 gallon fuel tank between the seats. Late in 1917 fire hazards were much reduced when the pressurised fuel system was replaced by two wind driven pumps on top of the fuselage behind the pilot.

The first D.H.4s in France, delivered by air to No. 55 Squadron on March 6, 1917, were first used operationally at Valenciennes on April 6. As an R.A.F. Squadron at the end of the war, it bombed munitions factories at Frankfurt, Mannheim and Stuttgart but French and Belgian based D.H.4s were not entirely employed as day bombers but also made high level photographic reconnaissance flights, fighter sweeps and anti-Zeppelin and submarine patrols. The majority of naval D.H.4s were among 150 built under sub-contract by the Westland Aircraft Works. They were Eagle powered and fitted with twin, instead of single front guns and also a raised Scarff ring mounting for the rear gunner, but increases in weight and parasitic drag somewhat impaired their performance. The first D.H.4 to be built at Yeovil was flight tested by B. C. Hucks in April 1917 and delivered in France the next morning. Coastal patrols were also undertaken by R.N.A.S. Squadrons and at least one D.H.4 was experimentally fitted with twin floats for this task. No. 202 Squadron also took a complete set of oblique and vertical photographs of Zeebrugge in preparation for the historic raid of April 22-23, 1918 during which the Mole was bombed with great daring by Wg. Cdr. Fellowes flying a D.H.4. To No. 217 Squadron fell the honour of sinking the German submarine U.B.12 on August 12, 1918. R.N.A.S., Great Yarmouth, was armed with D.H.4s, one of which was ditched in the North Sea on September 5, 1917 after an unsuccessful attack on the Zeppelin L.44, the crew being picked up by flying boat. On August 5, 1918 however, A8032 piloted by Major Egbert Cadbury shot down L.70 when 41 miles N.E. of base, from a height of over 16,000 ft. The Home Defence D.H.4s were operated far over the North Sea and efforts were made at the M.A.E.E., Isle of Grain, to equip them with flotation gear or as an alternative, hydrovanes and wing tip floats for use after the undercarriage was jettisoned. These devices were developed and test flown by Harry Busteed using D.H.4s A 7457 and D1769. The latter was also used for trailing mine experiments and hydrovanes were also fitted to an American built DH-4 at McCook Field, Dayton, Ohio. Two D.H.4s, one of which was numbered A2168, were fitted with H pounder Coventry Ordnance Works quick firing anti-Zeppelin guns. In 1917-18 the type was used overseas in small numbers as shown on page 67, while in the period 1919-21 many went as Imperial Gifts to assist the formation of air forces in Canada (12 aircraft) and South Africa (e.g. serials 26 and 401). Airco-built D.H.4s A7893 and A7929, taken to New Zealand in 1919 by Col. A. V. Bettington. were stationed at Sockburn and A7893, piloted by Capt. T. Wilkes and L. M. Isitt was the first aircraft to fly over Mt. Cook.

As an engine test bed the D.H.4 made a major contribution to Allied technical superiority and among the several experimental installations were those of the 300 h.p. Renault 12Fe in A2148, the 400 h.p. Sunbeam Matabele in A8083, the 353 h.p. Rolls-Royce G and the Ricardo-Halford inverted supercharged engine. One of the new American 400 h.p. Liberty 12 engines was fitted into a British built D.H.4 delivered at McCook Field in August 1917. It first flew with the Liberty on October 29th of that year and heralded the mass production of the D.H.4 in America. By the Armistice 3,227 had been constructed, 1,885 of which were shipped to France and by the end of 1918 the total of American built DH-4s had risen to 4,587, or more than three times the British production of 1,449. Eventually, the three American contractors delivered 4,846 examples of the DH-4, but after the war they were disposed of in considerable numbers to the Nicaraguan and other Latin American army air services.

Financial depression virtually stopped the procurement of new American aircraft during the postwar years but maintenance funds permitted a considerable rebuilding programme. This gave rise to over 60 DH-4 variants, many of which remained on the active list for nearly a decade. The majority of such variants received an American-style hyphenated model number, commencing with DH-4A, applied to the single Dayton-Wright DH-4 which was fitted in July 1918 with an improved fuel system by the Engineering Division of the Army's Department of Aircraft Production. This aircraft should not be confused with the British cabin conversion designated D.H.4A. In October 1918, more extensive modifications by the Engineering Division produced the DH-4B in which the pilot's cockpit was moved back next to that of the gunner. One DH-4B, piloted by Lt. Maynard, won the New York-Toronto Aerial Derby on August 25, 1919 in a flying time of 7 hours 45 minutes. The total of such conversions made in 1918-24 reached 1,540 when the two final rebuilds were made by the de Havilland Aircraft Co. Ltd. to the order of Maj. Davidson for the use of Naval and Military Attaches of the U.S. Embassy in London. These aircraft, c/n 138 and 139, were test flown by Hubert Broad in August 1926 and based at Kenley and Stag Lane respectively in full U.S. military markings until replaced by a D.H.60 Moth in 1927.

American conversions fell into two main categories - specialized versions for military purposes, the surviving designations for which are listed in an accompanying table, and experimental conversions of the early DH-4B, mainly as engine testbeds or trial installations aircraft. Military models included the DH-4B-2 trainer, sometimes known as the Blue Bird, the DH-4B-5 two passenger Honeymoon cabin transport devised by the Engineering Division of the Bureau of Aeronautics, and ambulance versions for one or two stretchers. Two of the last named, U.S. Marine serials A5811 and A5883, were used in 1922 in the island of Haiti, starting point of the longest flight in U.S. history up to that time, made in 1924 by two U.S. Army DH-4Bs which successfully covered the 10,953 miles to San Francisco and back.

DH-4 variants remained in military service with the U.S. Army, Navy and Marines until 1929, one DH-4B-3 being re-engined with a Packard 2A-1500 by the U.S. Navy at Quantico in 1926, but the last of the major variants had already appeared in 1924. They were built for the Corps Observation role, three by the Boeing company and one by Atlantic. The Boeings were ungainly sesquiplanes using steel DH-4M-1 fuselages and thick section wings of new design. The first, designated XCO-7, became the XCO-7A when fitted with a wide track undercarriage but crashed and was replaced by the XCO-7B, a similar machine powered by a 420 h.p. Liberty V-1410 experimental inverted engine. These prototypes scarcely resembled the DH-4B at all but the origins of the remaining Corps Observation conversion, XCO-8, could hardly be mistaken, being a reproduction of an undesignated conversion made in 1922 by the Gallaudet Aircraft Corporation which fitted a standard Liberty powered DH-4B with the mainplanes and N type interplane struts from a Loening COA-1 amphibian. The true XCO-8 was an exactly similar conversion made two years later by the Atlantic company.

Steel tube fuselages were built by the Boeing and Atlantic companies in 1920-25 to extend the useful lives of these veterans under the designations DH-4M, DH-4M-1 and DH-4M-2, 186 of which were by Boeing and at least 135 by Atlantic. Considerable interest was aroused when two reworked and specially modified DH-4s took off from Rockwell Field, San Diego, California on June 27, 1923 to conduct one of the first flight refuelling experiments. Lts. Lowell Smith and Paul Richter remained airborne for 6 1/2 hours, during which time they were refuelled twice by hose from the DH-4 flown by Lts. Hine and Seifert. After minor adjustments they kept aloft for 37 1/4 hours on August 27-28th and landed only when fog prevented further contact with the tanker. On December 13, 1923 a DH-4 with supercharged Liberty, piloted by Lt H. Harris and carrying a passenger, climbed to an altitude of 27,000 ft. over McCook Field, increased later to 30,500 ft., reached in 69 minutes in a special DH-4B, N.A.C.A. 8, fitted with a Roots type supercharger behind the engine. In 1927 a DH-4M-2, N.A.C.A. 25, with Model II Roots blower, reached 26,500 ft. in 51 minutes using camera recorded automatic observer equipment in an enclosed rear cockpit.

SPECIFICATION AND DATA

Manufacturers:

The Aircraft Manufacturing Co. Ltd., Hendon, London, N.W.9

F. W. Berwick and Co. Ltd., Park Royal, London, N.W.10

Glendower Aircraft Co. Ltd., 54 Sussex Place, South Kensington, London, S.W.7

Palladium Autocars Ltd., Felsham Road, Putney, London, S.W.15

The Vulcan Motor and Engineering Co. (1906) Ltd., Southport, Lanes.

Waring and Gillow Ltd., Cambridge Road, Hammersmith, London, W.6

Westland Aircraft Works, Yeovil, Somerset

SABCA, Haren Airport, Brussels, Belgium (15 built in 1926 for Belgian Air Force)

Atlantic Aircraft Corporation, Teterboro, New Jersey, U.S.A.

Boeing Airplane Company, Seattle, Washington, U.S.A.

The Dayton-Wright Airplane Co., Dayton, Ohio, U.S.A. (3,106 built)

The Fisher Body Corporation, U.S.A. (1,600 built)

Standard Aircraft Corporation, Elizabeth, New Jersey, U.S.A. (140 built)

Power Plants:

One 200 h.p. R.A.F. 3A

One 230 h.p. B.H.P.

One 230 h.p. Siddeley Puma

One 250 h.p. Rolls-Royce Mk. III or M k. IV

One 260 h.p. Fiat

One 275 h.p. Rolls-Royce Eagle VI

*One 300 h.p. Renault 12Fe

*One 300 h.p. Wright H

*One 300 h.p. Packard 1A-1116 o r 1A-1237

*One 320 h.p. Armstrong Siddeley Jaguar I

One 325 h.p. Rolls-Royce Eagle VII

*One 353 h.p. Rolls-Royce G

One 375 h.p. Rolls-Royce Eagle VIII

*One Ricardo-Halford supercharged engine

One 400 h.p. Liberty 12

*One 400 h.p. Sunbeam Matabele

*One 420 h.p. Liberty V-1410

One 435 h.p. Liberty 12A

*One 435 h.p. Curtiss D-12

*One 525 h.p. Packard 2A-1500

* Experimental installation

Dimensions, Weights and Performances:

(a) British

B.H.P. Puma Rolls III Eagle VIII RAF. 3A Fiat Liberty 12

Span 42 ft. 4 5/8 in. 42 ft. 4 5/8 in. 42 ft. 4 5/8 in. 42 ft. 4 5/8 in. 42 ft, 4 5/8 in. 42 ft. 4 5/8 in. 42 ft. 6 in.

Length 30 ft. 8 in. 30 ft. 8 in. 30 ft. 8 in. 30 ft. 8 in. 29 ft. 8 in. 29 ft. 8 in. 30 ft. 6 in.

Height 10 ft. 1 in. 10 ft. 1 in. 10 ft. 5 in . 11ft. 0in, 10 ft. 5 in. 10 ft. 5 in. 10ft. 3 5/8 in.

Wing area 434 sq. ft. 434 sq. ft. 434 sq. ft. 434 sq. ft. 434 sq. ft. 434 sq. ft. 440 sq. ft.

Tare weight 2,197 lb. 2,230 lb. 2,303 lb. 2,387 lb. 2,304 lb. 2,306 lb. 2,391 lb.

All-up weight 3,386 lb. 3,344 lb. 3,313 lb. 3,472 lb. 3,340 lb. 3.360 lb. 4,297 lb.

Maximum speed 108 m.p.h. 106 m.p.h. 119 m.p.h. 143 m.p.h. 122 m.p.h. 114 m.p.h. 124 m.p.h.

Initial climb 700 ft./min. 1,000 ft./min. 925 ft./min. 1,350 ft./min. 800 ft./min. 1,000 ft./min.

Ceiling 17,500 ft. 17,400 ft. 16,000 ft. 22,000 ft. 18,500 ft. 17,000 ft. 17,500 ft.

Endurance 4 1/2 hours 4 1/2 hours 3 1/2 hours 3 3/4 hours 4 hours 4 1/2 hours 3 hours

(b) American

DH-4B DH-4M-1 DH-4M-2 XCO-7 XCO-7A XCO-7B XCO-8

Engine Liberty 12A Liberty 12A Liberty 12A Liberty 12A Liberty 12A Liberty V-1410 Liberty 12A

Span 42 ft. 5 1/2 in. 42ft. 5 1/2 in. 42 ft. 5 1/2 in. 45 ft. 0 in. 45 ft. 0 in. 45 ft. 0 in. 45 ft. 0 in.

Length 29ft. 11 in. 29 ft. 11 in. 29ft. 11 in. 30ft. 4 in. 30ft. 4 in. 30ft. 11 in. 30ft. 0in.

All-up weight 4,600 lb. 4,595 lb. 4,595 lb. 4,798 lb. 4,800 lb. 4,652 lb. 4.680 lb.

Maximum speed 124 m.p.h. 118 m.p.h. 118 m.p.h. 130 m.p.h. 122 m.p.h. 130 m.p.h.

De Havilland D.H.4 (Civil)

Several million pounds worth of war surplus aircraft, including hundreds of D.H.4s, the majority brand new from the Airco and Waring and Gillow factories, were acquired by Handley Page Ltd. in 1919-20 and later reconditioned by the Aircraft Disposal Co. Ltd. at Croydon to become the postwar equipment of the air forces of Spain (14 aircraft), Belgium, Greece, Japan and other small nations. With few exceptions these were powered by the 375 h.p. Rolls-Royce Eagle VIII engine and those for Spain and Belgium were flown out in the autumn of 1921 under temporary civil marks by many well known pilots of the day, including F. T. Courtney, H. Shaw, E. D. Hearne, F. J. Ortweiler, C. D. Barnard, E. L. Foot and Norman Macmillan. In Spain the D.H.4 formed the main equipment of the Air Force training establishment at Cuatros Vientos and was used extensively in the Moroccan War.

Two Eagle powered D.H.4s were also used in a purely civil capacity on the Continental services of Aircraft Transport and Travel Ltd. late in 1919 as temporary crash replacements and two others were shipped to Australia by C. J. de Garis and there fitted with cockpits for two passengers behind the pilot. One of them, F2691/G-AUCM was erected and test flown at Glenroy on November 27, 1920 and piloted by F. S. Briggs with the owner as passenger, arrived at Perth on December 2nd after making the first Melbourne-Perth flight in two days. A week later it made the first Perth-Sydney flight, also in two days, and on January 16, 1921 became the first aircraft to fly from Brisbane to Melbourne in one day. Again piloted by F. S. Briggs it left Melbourne on September 9, 1921 to survey the route of the proposed North-South railway and covered 3,000 miles in exactly one month, becoming the first aircraft ever to land at Alice Springs. From August 1924 it carried mail on the Adelaide-Sydney service of Australian Aerial Services Ltd. with the name "Scrub Bird" and was still flying miners and supplies between Port Moresby and Lae, New Guinea for Bulolo Goldfields Ltd. in 1927.

C. J. de Garis sold the other D.H.4, F2682/G-AUBZ to R. J. P. Parer who flew it to victory in the first Australian Aerial Derby on December 28, 1920 at 142 m.p.h. It was then used for joyriding and other pioneering work until delivered to QANTAS at Longreach by rail on August 12, 1922. In the last two months of the year it covered over 5,000 air miles, mainly on the Charleville-Cloncurry mail service but was extensively damaged when it struck telephone wires while landing at Gilford Park station, south west of Longreach, on June 6, 1923. During repairs the two open passenger cockpits were roofed over to make an open-sided cabin and it first flew in this form in May 1924. It opened the extension service between Cloncurry and Camooweal on February 7,1925 piloted by Capt. L. J. Brain but, when ousted by the new D.H.50s at the end of 1927, was sold to Matthews Aviation Ltd. at Essendon Aerodrome, Melbourne where the fuselage was modified for joyriding with no less than four separate passenger cockpits behind the pilot. At this stage it was named "Cock Bird" on the fin but in 1930 it returned to taxi work with a full D.H.4A-style cabin with sliding windows as "Spirit of Melbourne". It was last in service with Pioneer Air Services who acquired it in September 1934.

In Canada, all 12 Imperial Gift D.H.4s were equipped with air to ground W/T sets for use on forestry patrol work by the Air Board Civil Operations Branch and in 1921 one of these aircraft made the first recorded geological reconnaissance flight piloted by F/Lt. A. W. Carter. From August 1920 their pilots spotted hundreds of forest fires and helped save millions of dollars worth of timber, operating mainly from an airstrip at High River, Alberta where the D.H.4's performance alone could combat wind ridden skies near the Rockies. Special skis were designed for winter flying and as late as 1924 these veterans continued to give photographic coverage of the district but by that time showed such deterioration that they were permanently grounded at the end of the season. The one exception, G-CYDM, still airworthy in 1927, was reworked to D.H.4B standard with underslung radiator and observation panels in the lower wing roots.

The D.H.4's greatest contribution to the embryo air transport industry however, was made in Europe by four machines supplied by Handley Page Ltd. to the Belgian concern Syndicat National pour l'Etude des Transports Aeriens (SNETA). In company with a number of D.H.9s, they ran spasmodically on the Brussels-London, Brussels-Paris and Brussels-Amsterdam services in 1920-21, and although their normal London terminal was Croydon, many flights terminated at Cricklewood for convenience of servicing. After the departure to Brussels of D.H.4 O-BABI on January 15, 1921, Cricklewood was used no more and the D.H.4's commercial life ended soon afterwards in two major crashes and the destruction of most of the SNETA fleet in a disastrous hangar fire at Brussels on September 27, 1921. An accompanying table lists all the civil D.H.4s for which records still exist.