A.Jackson De Havilland Aircraft since 1909 (Putnam)

Royal Aircraft Factory S.E.1

The first type designed under Geoffrey de Havilland's direction after his appointment to Farnborough was a canard pusher biplane which, at a time when little money was being spent on new aeroplanes, had to be described as the rebuild of a crashed Army Bleriot monoplane. In fact, nothing but the Bleriot's 60 h.p. E.N.V. engine was used in its construction.

Two bay biplane wings were mounted at the rear end of a long, narrow nacelle, with twin rudders on outriggers behind and a front wing, or elevator, in the extreme nose. It received Royal Aircraft Factory designation S.E.1, signifying Santos Experimental initially but later it came to mean Scouting Experimental.

Roll-out took place at 5 a.m. on June 7, 1911 but the wheels were too far aft of the CG, causing the front skids to dig into the ground when taxying and it was next day, after adjustments, before a first straight flight of about a mile was possible. Longer straight flights followed on June 10 when it was said to be fast and to climb well but it was not exactly a successful aeroplane and a flight to Laffan's Plain on June 28 showed that the hinge line of the front wing was too far ahead of the c.p. and progressive reductions in area were necessary before the S.E. 1 became stable in pitch. Turns were difficult and although side area was reduced by stripping fabric from the sides of the nacelle, real improvement was only achieved when the all-moving front wing was replaced by a fixed aerofoil with trailing edge elevator.

Geoffrey de Havilland, its only pilot up to that time, flew it for the last time on August 16, 1911 when he made two return trips to Laffan's Plain with a misfiring engine. This was put right but two days later, on August 18, Lt. T. J. Ridge, Assistant Superintendent of the Royal Aircraft Factory but a pilot of only limited experience, stalled it off a gliding turn over Farnborough, spun it and was killed.

SPECIFICATION AND DATA

Construction: By the Royal Aircraft Factory, Farnborough, Hants.

Power Plant: One 60 h.p. E.N.V. Type F.

Dimensions:

Span 38 ft. 6 in. Length 29 ft. 0 in.

Height 11 ft. 6 in. Wing area 400 sq. ft.

Weights: All-up weight 1,200 lb.

Показать полностью

P.Hare Royal Aircraft Factory (Putnam)

S.E.1

The first aeroplane built at Farnborough after the hiatus which followed the dismissal of Cody and Dunne came about as a result of a subterfuge, for the War Office denied the Factory the right to design and build aeroplanes. In the late summer of 1910 a Bleriot XII of uncertain history was being operated on Salisbury Plain by a group of Army officers led by Lt Cammell (to whom ownership of the machine has sometimes been attributed), and towards the end of the year suffered considerable damage in a crash, eventually finding its way to Farnborough for repair. One of Bleriot's less-successful designs, the machine was reputed to be very tricky to fly, and although officially known as B1 it was popularly known as the Man-Killer. Mervyn O'Gorman therefore sought War Office permission to redesign the Bleriot and to include controls of the Farman type, so that it might be flown by anyone familiar with the Farman. Such permission was granted, and the Farnborough design team, led by de Havilland and F M Green, set to work on the 'S' class machine which previous study had led O'Gorman to believe would prove most successful.

The result of their endeavours, the S.E.1, bore little resemblance to the tractor monoplane from which it was allegedly 'reconstructed', being a canard pusher biplane and, although the shape of its wings was at least reminiscent of those of the Bleriot, the only actual link between the two machines was the 60hp ENV 'F' engine.

The new machine made its first outing at dawn on 7 June 1911, when de Havilland made some taxying trials and broke two wheel spokes in the process. Therefore the wheels were moved forward to improve the balance. At the same time the twin rudder outriggers were shortened by three feet, bringing the rudders closer to the fuselage, because they were found to be vibrating and causing the mainplanes to flex. At 5.30am the following morning de Havilland made the first flight, even though the undercarriage problem was not yet entirely resolved. The machine flew about a mile, but its propeller shaft was found to have twisted. Following another outing on the 10th, de Havilland decided to restore the wheels to their original positions and to fit a skid under the forward elevators.

The fore and aft stability was reported as good, but de Havilland thought the elevators to be too powerful. After the S.E.1's next flight, made on 28 June, their area was reduced by cutting four inches from their trailing edges. However, on 3 July de Havilland recorded that they were still too powerful, and arranged construction of a new canard surface. He also recorded that he was experiencing difficulty in turning, and had the body stripped of fabric to reduce forward keel area, but this made little improvement and the fabric was therefore reinstated. The earlier shortening of the rudder outriggers had clearly been a contributory factor to this problem, and by the 14th an additional rudder had been installed on the nose of the machine, operating in conjunction with those at the rear. At the same time the new elevators were fitted and the dihedral reduced. While turning was now improved, the S.E.1's designer/test pilot was still not satisfied, recording his opinion that the rear rudders appeared to be too sensitive. In addition, the radiators, which were on the fuselage sides, were found to boil over whenever the machine was at rest.

In the next two weeks the front skids were moved back, the wheels were again repositioned, and stronger rubber cords were fitted to the undercarriage. Several half-turns were made on 1 August, and on the 16th de Havilland successfully flew it to Laffan's Plain and back twice. The day's flying was brought to a premature end by a choked carburettor.

Two days later Lt Theodore Ridge, the Factory's Assistant Superintendent, took the S.E.1 up for the first time, despite de Havilland's advice that he should not do so because it was still a tricky machine. Ridge, who is reputed to have been something of a martinet, ignored him, sideslipped while attempting a sharp turn and crashed, receiving injuries from which he died later the same day. Thus the Factory's first design had resulted in tragedy, and the Man-Killer had finally lived up to its name.

The type was presumably acknowledged to have been a failure, and the canard concept was not continued with, subsequent 'S.E.' types being of the 'scouting' rather than 'Santos' class.

Powerplant: 60hp ENV type 'F' water-cooled V-8

Dimensions:

span 38ft 0in;

dihedral 2 1/2;

wing area 382 sq ft;

length 29ft 0in;

height 11ft 6in.

Weights:

1,200lb (empty);

1,640lb (loaded).

Показать полностью

M.Goodall, A.Tagg British Aircraft before the Great War (Schiffer)

Deleted by request of (c)Schiffer Publishing

SE.1 biplane (Santos Experimental)

The 'reconstruction' of a Bleriot XII monoplane was the basis for a 'canard' biplane identified as SE. 1, due to its similarity in layout to the biplane, Type 14bis, of Santos Dumont. in which he made the first flight of a powered heavier-than-air machine in Europe.

This was the first original design from the Aircraft Factory after the reorganization, which followed the discontinuing of the work of Cody and Dunne under Col. Capper, the aircraft making its appearance in June 1911. After the repair of minor damage, which occurred when taxiing on 7 June 1911, the aircraft was flown the following day for about a mile. Geoffrey de Havilland was the pilot and largely responsible for the design, although Mervyn O'Gorman, the Superintendent and F.M. Green, the Chief Engineer of the Factory, exerted their influence on various aspects. Many changes were made in the course of testing the machine in June and July to improve the handling, particularly the tendency to sideslip.

The aeroplane that emerged from the Factory was rather different to earlier concepts outlined by O'Gorman in March 1911, and other sources in the technical press. It had a two bay wing structure, the top wing slightly greater in span than the bottom, with lateral control by warping sections in the top wings. Control in pitch was by a divided elevator mounted at the nose of the nacelle. The machine was mounted on a twin skid undercarriage with two wheels, on a rubber cord sprung axle, and with small tail skids at the ends of the main skids.

Power was provided by the ENV engine from the Bleriot, which drove a pusher propeller at two-thirds engine speed, through a chain and shaft. The engine was cooled by radiators mounted on either side of the nacelle, alongside the pilot's position.

The separate wire braced tail booms carried rudders of approximately the height of the wing gap. The boom lengths were shortened early in the trials and were planned to be lengthened again later. A supplementary nose mounted rudder was fitted at one stage and the fabric covering of the nacelle was temporarily removed without improvement in the yawing plane. Also the foreplane was later changed to provide a fixed portion with separate elevators.

The position of the wheels was varied and this change was accompanied by the deletion of the small tail skids, which were replaced by a tall sprung nose skid and additional vee-struts connecting the skids to the lower longerons and wing spars.

Despite these and possibly other alterations, de Havilland still regarded the machine as difficult to handle. However, on 18 August 1911, Lt. Ridge the Assistant Superintendent an inexperienced pilot, insisted on being allowed to fly the machine, which side slipped into the ground. Ridge succumbed from his injuries and the SE.l was destroyed.

Power: 60hp ENV type F eight-cylinder water-cooled driving a two-bladed propeller by chain and shaft at 2/3rds engine speed

Data

Span top 38ft

Span bottom 36ft

Chord 6ft

Gap 6ft

Area 382 sq. ft

Length 29ft short booms

Height lift 6in

Foreplane span 18ft 4in

Foreplane chord 4ft

Foreplane area 64 sq. ft

Weight 1,220lb.

Weight allup 1,640lb.

Max speed 55mph

Показать полностью

P.Lewis British Aircraft 1809-1914 (Putnam)

S.E.1

In December, 1910, a crashed Army Bleriot monoplane, known as "The Mankiller", was sent from Larkhill to the Balloon Factory at Farnborough for repair. At that time the funds allocated to the Factory did not extend to the building of new aircraft, and the arrival of the Bleriot presented an excellent opportunity to eager technicians. Authorization for reconstruction was soon forthcoming and was given in January, 1911. The work was carried out under Mervyn O'Gorman, the design being drawn up by Geoffrey de Havilland and F. M. Green, a team which was seen to have no qualms about putting its own ideas into practice when the S.E.1 saw the light of day. The aeroplane which had gone into the Factory as a tractor monoplane reappeared as a single-seat canard pusher biplane. The Bleriot's 60 h.p. E.N.V. "F" engine was used again, but in every other respect the machine was completely different and was the only aeroplane built in the S.E. (Santos Experimental) category.

A long nacelle projected forward of the unstaggered two-bay wings. At its rear the E.N.V. turned a large propeller in cut-outs at the trailing-edges: on the front of the nacelle was mounted a split elevator of fairly generous area. Fixed fins and tailplane were not used, the twin rudders being borne on short booms behind the main-planes. Lateral control was by means of wide-chord ailerons on the upper wings. Cooling of the engine was carried out by radiators mounted on each side of the cockpit. The undercarriage comprised a single pair of wheels whose axle was bound with rubber shock cords across the twin skids, which, in turn, were connected to the fuselage by three pairs of struts. The final member of the landing-gear was the long nose-mounted vertical skid which maintained the machine in a level attitude on the ground.

The S.E.1, however different it may have been in appearance from the Bleriot, inherited its forebear's death-dealing characteristics and crashed on 18th August, 1911, killing Lt. Theodore J. Ridge, the Assistant Superintendent at the Factory.

SPECIFICATION

Description: Single-seat canard pusher biplane. Wooden structure, fabric covered.

Manufacturers: H.M. Balloon Factory, Farnborough, Hants.

Power Plant: 60 h.p. E.N.V. "F"

Dimensions: Span, 38 ft. 6 ins. Length, 29 ft. Height, 11 ft. 6 ins. Wing area, 400 sq. ft.

Weight loaded, 1,200 lb.

Показать полностью

J.Bruce British Aeroplanes 1914-1918 (Putnam)

THE S.E. series began nominally with a peculiar canard biplane which appeared in 1911. It was named Santos Experimental No. 1, or S.E.1, after Santos Dumont; for the great Brazilian pioneer was regarded as the originator of the tail-first arrangement. The S.E.1 crashed on August 18th, 1911.

Показать полностью

Журнал Flight

Flight, July 15, 1911.

THE NEW ARMY BIPLANE.

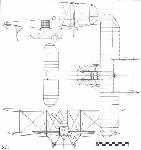

FOLLOWING up the details which we have already published regarding the experimental biplane, built in the Army aircraft factory at Farnborough, we are now able to give some photographs of it, as well as scale drawings, which give a very good idea of the machine in its present state. It is of course inevitable that, being an experimental machine, this latest production of the Farnborough factory should undergo a good deal of modification as the result of the tests which are being carried out with it, but we think our readers will appreciate these further details which we have been able to obtain. Although in several parts it is reminiscent of various successful types, the machine embodies many original features, and the actual performance of it will be watched with close attention by all engaged in the study of aviation.

It is unnecessary to give the dimensions in detail here as they are all clearly shown on the drawings, but it may be pointed out that the lower plane is 2 ft. less span than the upper one, while it also has a slight dihedral angle, as can be seen from the view from in front of the machine. Another point to which attention might be drawn is the substantial nature of the main struts. They are all of stream line section, and at the thickest part the dimensions are 5 ins. by 1 1/2 ins. All the sockets on the machine are of welded steel.

The details of the control mechanism are given in a separate sketch. By a backwards and forwards motion the control lever operates the elevator, while a sideways movement warps the ailerons, the connecting wires to which, on their way from the rocking lever, pass through the radiator. The ailerons have both the inside edges fixed to the main plane as on the Paulhan machine. It will be noticed that springs are fitted at the connection of the elevator rod with the control lever in order to damp out any sudden shocks on the elevator. The rudders are operated by means of a pedal. As we mentioned in our last issue, the rudders have been carried in nearer the main planes, in fact, their original position was nearly twice their present distance from the trailing edge. The propeller shaft is carried in bearings mounted on the upper framework of the fuselage and is geared down so that it normally runs at about 800 revolutions.

Since the initial appearance of the machine the undercarriage has been considerably altered, and in addition to placing the flexible skid at the forward end of the fuselage, four additional struts arranged "V" fashion have been fitted at the rear end of the main skids.

Показать полностью