Книги

Centennial Perspective

M.Schmeelke

Zeppelin-Lindau Aircraft of WW1

250

M.Schmeelke - Zeppelin-Lindau Aircraft of WW1 /Centennial Perspective/ (42)

On July 31st 1918 a squadron from the naval air station base Zeebrugge sighted an enemy armored cruiser that was covered by a Curtiss flying boat and a land-based single-seat aircraft. The German squadron attacked both aircraft, downing the Curtiss.

A German airfield on the western front in early 1918. Even the light combat aircraft had to be placed on a platform of wooden planks to prevent them from sinking into the soft ground.

The Junkers monoplane J1, whose first flight took place on December 12th, 1915. Due to its construction of steel and sheet iron only, the J1 proved to be too heavy, and therefore unsuitable for combat.

The Junkers J 1 (an internal company designation) was the first Junkers aircraft to fly. It was a two-seat testbed for Junker's all-metal structural technology, and the Junkers J 2/E.II fighter was developed from this aircraft.

The Junkers J 1 (an internal company designation) was the first Junkers aircraft to fly. It was a two-seat testbed for Junker's all-metal structural technology, and the Junkers J 2/E.II fighter was developed from this aircraft.

The Junkers J11 competed with the Zeppelin Cs.I. It used corrugated duralumin panels and was not the more advanced stressed skin structure of the Zeppelin Cs.I.

Zeppelin (Ja) C.I / C.II

Due to the imminent reduction in airship orders beginning in 1917, Luftschiffbau Zeppelin management had to search for new products in order to utilize the company's full production capacity. In 1918, the Zeppelin company employed 11,500 workers in Friedrichshafen. The danger was that should these well-educated specialist workers be underemployed, they would he reassigned to the military or other companies, or simply leave. Some of this could be compensated by shifting workers to other operations; for example, the LZ foundry began to cast crankcases for the Maybach Motorenbau Mb IVa engine, or to the Lindau factory. In addition, Colsman planned an expansion of the aircraft business.

Two subsidiaries of LZ, the ZWL and the aircraft hangar in Staaken, had already successfully established themselves. Now Colsman wanted LZ's Friedrichshafen hangar to take a larger role in producing aircraft for the army and navy.

In the summer of 1917, Colsman assigned LZ engineer Paul Jaray to design a C-Type for the air force. Jaray, who was born in Vienna, had studied mechanical engineering in Vienna and Prague. He came to Friedrichshafen in 1912 as one of the first specialists in aerodynamics - a topic that would interest him his entire life. In 1914 he moved to LZ, where he participated in the construction of various airships, and could spend time intensely researching aerodynamics.

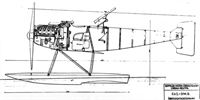

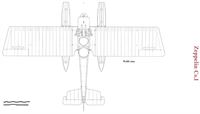

On June 30th, 1917, Paul Jaray began development of the Zeppelin C.I, a two-seater high-altitude surveillance aircraft. Within 14 days he had drafted a blueprint of a prototype. This two-seater biplane "showed the most consequential consideration of all new regulations to achieve most economical flight", as it was explained in the craft's description. In addition,

“[...] its use as a military and a passenger aircraft employs all of the characteristics of modern aircraft - speed, excellent climbing characteristics, comfortable, light handling, maneuverability, gliding potential, good visibility, and extraordinary safety with significant elasticity of the shock-absorbing parts. From the standpoint of aerodynamics and stability, the design is a fortunate combination of all the current aviation construction and light metal expertise. As a result, the overall value of this type (but also of its parts) is a leader among current aircraft. ”

The advertising and technical department of LZ did not exaggerate here. The Zeppelin-Jaray C-aircraft did indeed show extraordinary technical parameters for 1917, such as an altitude ceiling of 8,000 meters and a top speed of 210 kilometers per hour. The aircraft owed its speed to Jaray's aerodynamics research, which flowed into its design. On August 18th 1917, 30 workers began building the Zeppelin (Ja) C.I. However, the first two pre-serial construction fuselages in the hangar were made of wood. This two-seater biplane with a wingspan of 12 meters and a fuselage length of 6.9 meters was powered buy a 260 HP Maybach Mb IVa engine.

The fuselage, referred to internally as "Aircraft 1", was covered in wood veneer. Only Aircraft 2 was given fabric coverings over openings on the sides and top of the fuselage. In addition to the lower weight, these openings could be used as maintenance access for the fuselage. This was surely also changed on Aircraft 1 later. Since these two aircraft were primarily used for LZ's testing purposes, various cooling systems, exhaust collectors, and propellers were tested out on them. In addition, clear Cellon was tested on the upper wing to increase the pilot's upward visibility. Since these pre-serial aircraft carried no official designation, they cannot be tracked.

The wing and tail constructions, spars, ribs, and rudders of the prototypes were already made of duraluminum, which was produced at the ZWL in Reutin, and covered with fabric as was the usual case at the time. On October 17th, 1917, in a record time of two months, the Zeppelin (Ja) C.I took off for its maiden flight in Lowental. The company pilot Hausmann was satisfied with the fight characteristics, and with an operating weight of 1,500 kg (empty weight 1,000 kg) the C.I reached a top speed of 210 kilometers per hour. In the following days, Hausmann made several more test flights, focusing on the maneuverability of the aircraft as well as dives and spins.

At the same time the wooden aircraft were being constructed in the hangars of the LZ, Dornier's engineers in Lindau began to work on transferring Jaray's plans to build a metal fuselage. The all-metal aircraft was designated C.II.

The LZ hangar in Friedrichshafen was not able to begin serial construction - it could only be done in collaboration with the ZWL in Lindau. Colsman therefore assigned additional workers from Luftschiffbau to ZWL.

On December 8th, 1917, Luftschiffbau Zeppelin GmbH received a binding order for six test C-aircraft, three each of ZWL C.I and Zeppelin C.II, from IdFlieg's flight master:

“Subject: Delivery of test aircraft.

With the approval of the war ministry dated November 23rd, 1917, I issue the company with the order of the delivery of 3 - three - pieces test C-aircraft for 160 HP Mercedes engines and 3 - three - pieces test C-aircraft for 260 HP Maybach engines.

With complete accessories for aircraft and power plants, as well as installation of MGs.

The aircraft will carry the military designations C 15800 through 15805/17.

The installation of F.T. (??) - or photography equipment, the installation of the MG, the delivery of shell feeding equipment is included in the price. ”

On December 14th, 1917, LZ answered with the following letter:

“We confirm with thanks the receipt of the order to deliver 3 test C-aircraft with 260 HP Maybach engines. The confirmation of the 3 test C-aircraft with 160 HP Mercedes engines will follow from our Zeppelin Factory in Lindau. For the three test aircraft with 260 HP Maybach engines, we have noted the military designations of 15803/17, 15804/17 and 15805/17. We will assume delivery dates for the light metal aircraft of early, mid-, and end-February 1918.”

The partial assembly of the Zepp. (Ja) C.II military numbers 15803 through 15805/17 made of aluminum took place in Lindau Reutin. According to the description, the "fuselage was made of a duraluminum lattice. In the engine area as a rotation paraboloid towards the rear in a square cross-section with lightly curved side walls.

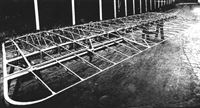

The wings, top 12 meters, bottom 11.6 meters (divided by the fuselage) were made of two duraluminum spars each, with riveted ribs, also of duraluminum. The elevator and the rudder as well as the tail skid were also of duraluminum.”

The construction description says that the engine was a Maybach Mb IVa engine, with LZ cooling system and Jaray propeller (LZ-Pi 61/62). The C.II (Ja) had a special starter that allowed the engine to start without external help. In anticipation of its use as a civilian aircraft as well, the surveillance seat as well as the MG mount could be replaced with a comfortable passenger seat.

All of the parts for Dornier's first serially produced aircraft were completed in Lindau-Reutin by March 1918. The assembly and fabric covering took place in Friedrichshafen at LZ. Less than five months after the prototype's first flight, on March 10th, 1918, the aircraft was flown in Lowental. On March 11th, 1918, IdFlieg approved and accepted it. An order for 20 combat-ready trial aircraft, with the military designations of C.5500 through 5519/18 followed. These aircraft were completed by the end of November at ZWL and LZ. Internally, the C.II airplanes were sequentially numbered (C.II/1 through C.II/20). But none of these made it to combat. C.II/2 was used as a test aircraft in Adlershof, and C.II/4 burst into flames upon landing at the Lilienthal airfield in Berlin.

In 1920, LZ purchased back the remaining aircraft from the German Army Peace Commission of the Weimar Republic. Through a mediator, 20 Zeppelin (Ja) C.II were sold to the Swiss Air Force, where they remained in service until October 1927. That means that at least three more Zeppelin (Ja) C.II were built before the construction ban as dictated by the Treaty of Versailles was instituted.

Three airplanes of Paul Jaray's final design, the Zeppelin C.IV, were also built: Military designations 12255 through 12257/18. The last remaining aircraft of this type, with the internal company number 01, was destroyed in a fire as a result of welding work in a hangar at the aviation museum at Le Bourget near Paris on May 17th, 1990.

Camouflage Painting of the Zeppelin (Ja) C.I / C.II

The Zeppelin Jaray prototype aircraft C.I and C.II received the usual airship fabric covering delivered by the company's own subsidiary Ballonhullengesellschaft mbH ("Balloon covering association") in Berlin Tempelhof.

For aerodynamic reasons, or for a smooth surface, the fabric had a protective covering of Cellon or stretching lacquer. It was mixed with iron oxide (1.5%) and aluminum powder (3%):

“[...] For the textile covering, one used varnished linen, which was sewn onto the ribs with a special technique. "

After the first two coats, it was smoothed by what was then called "glass paper", now known as sanding paper.

The duraluminum parts of the C.II, such as the engine cover, struts, and shafts, remained unpainted. The national emblems and other markings were applied according to the construction and delivery regulations of the army. Only the C.II series aircraft, which had the military designations 5500 through 5519/18, received the three-color camouflage coverings from the Ballonhullengesellschaft mbH.

Specifications of Zeppelin-Lindau Aircraft

Type Length, m Span, m Height, m Chord, m Propeller Manufact. Armament

(guns) Weight, kg Motor Crew

C.I 7.60 10.50 2.84 LZ-Jaray 1 fixed, 1 flex 696 Daimler D III 2

C.II 7.92 12.00 3.58 1.80 LZ-Jaray 1 fixed, 1 flex 1,000 Maybach Mb IVa 2

Military Numbers of Dornier-ZWL Aircraft

Military Designation Manufact. Type Class Engine Notes

15800-15802/17 ZWL (Do) C.I DIIIa

15803-15805/17 Zepp. C.II Mb IVa

5500-5519/18 C.II Mb IVa 20 aircraft sold to Switzerland

12255-12257/18 Zepp C.IV Last aircraft, burned in Paris 5/17/1990

Due to the imminent reduction in airship orders beginning in 1917, Luftschiffbau Zeppelin management had to search for new products in order to utilize the company's full production capacity. In 1918, the Zeppelin company employed 11,500 workers in Friedrichshafen. The danger was that should these well-educated specialist workers be underemployed, they would he reassigned to the military or other companies, or simply leave. Some of this could be compensated by shifting workers to other operations; for example, the LZ foundry began to cast crankcases for the Maybach Motorenbau Mb IVa engine, or to the Lindau factory. In addition, Colsman planned an expansion of the aircraft business.

Two subsidiaries of LZ, the ZWL and the aircraft hangar in Staaken, had already successfully established themselves. Now Colsman wanted LZ's Friedrichshafen hangar to take a larger role in producing aircraft for the army and navy.

In the summer of 1917, Colsman assigned LZ engineer Paul Jaray to design a C-Type for the air force. Jaray, who was born in Vienna, had studied mechanical engineering in Vienna and Prague. He came to Friedrichshafen in 1912 as one of the first specialists in aerodynamics - a topic that would interest him his entire life. In 1914 he moved to LZ, where he participated in the construction of various airships, and could spend time intensely researching aerodynamics.

On June 30th, 1917, Paul Jaray began development of the Zeppelin C.I, a two-seater high-altitude surveillance aircraft. Within 14 days he had drafted a blueprint of a prototype. This two-seater biplane "showed the most consequential consideration of all new regulations to achieve most economical flight", as it was explained in the craft's description. In addition,

“[...] its use as a military and a passenger aircraft employs all of the characteristics of modern aircraft - speed, excellent climbing characteristics, comfortable, light handling, maneuverability, gliding potential, good visibility, and extraordinary safety with significant elasticity of the shock-absorbing parts. From the standpoint of aerodynamics and stability, the design is a fortunate combination of all the current aviation construction and light metal expertise. As a result, the overall value of this type (but also of its parts) is a leader among current aircraft. ”

The advertising and technical department of LZ did not exaggerate here. The Zeppelin-Jaray C-aircraft did indeed show extraordinary technical parameters for 1917, such as an altitude ceiling of 8,000 meters and a top speed of 210 kilometers per hour. The aircraft owed its speed to Jaray's aerodynamics research, which flowed into its design. On August 18th 1917, 30 workers began building the Zeppelin (Ja) C.I. However, the first two pre-serial construction fuselages in the hangar were made of wood. This two-seater biplane with a wingspan of 12 meters and a fuselage length of 6.9 meters was powered buy a 260 HP Maybach Mb IVa engine.

The fuselage, referred to internally as "Aircraft 1", was covered in wood veneer. Only Aircraft 2 was given fabric coverings over openings on the sides and top of the fuselage. In addition to the lower weight, these openings could be used as maintenance access for the fuselage. This was surely also changed on Aircraft 1 later. Since these two aircraft were primarily used for LZ's testing purposes, various cooling systems, exhaust collectors, and propellers were tested out on them. In addition, clear Cellon was tested on the upper wing to increase the pilot's upward visibility. Since these pre-serial aircraft carried no official designation, they cannot be tracked.

The wing and tail constructions, spars, ribs, and rudders of the prototypes were already made of duraluminum, which was produced at the ZWL in Reutin, and covered with fabric as was the usual case at the time. On October 17th, 1917, in a record time of two months, the Zeppelin (Ja) C.I took off for its maiden flight in Lowental. The company pilot Hausmann was satisfied with the fight characteristics, and with an operating weight of 1,500 kg (empty weight 1,000 kg) the C.I reached a top speed of 210 kilometers per hour. In the following days, Hausmann made several more test flights, focusing on the maneuverability of the aircraft as well as dives and spins.

At the same time the wooden aircraft were being constructed in the hangars of the LZ, Dornier's engineers in Lindau began to work on transferring Jaray's plans to build a metal fuselage. The all-metal aircraft was designated C.II.

The LZ hangar in Friedrichshafen was not able to begin serial construction - it could only be done in collaboration with the ZWL in Lindau. Colsman therefore assigned additional workers from Luftschiffbau to ZWL.

On December 8th, 1917, Luftschiffbau Zeppelin GmbH received a binding order for six test C-aircraft, three each of ZWL C.I and Zeppelin C.II, from IdFlieg's flight master:

“Subject: Delivery of test aircraft.

With the approval of the war ministry dated November 23rd, 1917, I issue the company with the order of the delivery of 3 - three - pieces test C-aircraft for 160 HP Mercedes engines and 3 - three - pieces test C-aircraft for 260 HP Maybach engines.

With complete accessories for aircraft and power plants, as well as installation of MGs.

The aircraft will carry the military designations C 15800 through 15805/17.

The installation of F.T. (??) - or photography equipment, the installation of the MG, the delivery of shell feeding equipment is included in the price. ”

On December 14th, 1917, LZ answered with the following letter:

“We confirm with thanks the receipt of the order to deliver 3 test C-aircraft with 260 HP Maybach engines. The confirmation of the 3 test C-aircraft with 160 HP Mercedes engines will follow from our Zeppelin Factory in Lindau. For the three test aircraft with 260 HP Maybach engines, we have noted the military designations of 15803/17, 15804/17 and 15805/17. We will assume delivery dates for the light metal aircraft of early, mid-, and end-February 1918.”

The partial assembly of the Zepp. (Ja) C.II military numbers 15803 through 15805/17 made of aluminum took place in Lindau Reutin. According to the description, the "fuselage was made of a duraluminum lattice. In the engine area as a rotation paraboloid towards the rear in a square cross-section with lightly curved side walls.

The wings, top 12 meters, bottom 11.6 meters (divided by the fuselage) were made of two duraluminum spars each, with riveted ribs, also of duraluminum. The elevator and the rudder as well as the tail skid were also of duraluminum.”

The construction description says that the engine was a Maybach Mb IVa engine, with LZ cooling system and Jaray propeller (LZ-Pi 61/62). The C.II (Ja) had a special starter that allowed the engine to start without external help. In anticipation of its use as a civilian aircraft as well, the surveillance seat as well as the MG mount could be replaced with a comfortable passenger seat.

All of the parts for Dornier's first serially produced aircraft were completed in Lindau-Reutin by March 1918. The assembly and fabric covering took place in Friedrichshafen at LZ. Less than five months after the prototype's first flight, on March 10th, 1918, the aircraft was flown in Lowental. On March 11th, 1918, IdFlieg approved and accepted it. An order for 20 combat-ready trial aircraft, with the military designations of C.5500 through 5519/18 followed. These aircraft were completed by the end of November at ZWL and LZ. Internally, the C.II airplanes were sequentially numbered (C.II/1 through C.II/20). But none of these made it to combat. C.II/2 was used as a test aircraft in Adlershof, and C.II/4 burst into flames upon landing at the Lilienthal airfield in Berlin.

In 1920, LZ purchased back the remaining aircraft from the German Army Peace Commission of the Weimar Republic. Through a mediator, 20 Zeppelin (Ja) C.II were sold to the Swiss Air Force, where they remained in service until October 1927. That means that at least three more Zeppelin (Ja) C.II were built before the construction ban as dictated by the Treaty of Versailles was instituted.

Three airplanes of Paul Jaray's final design, the Zeppelin C.IV, were also built: Military designations 12255 through 12257/18. The last remaining aircraft of this type, with the internal company number 01, was destroyed in a fire as a result of welding work in a hangar at the aviation museum at Le Bourget near Paris on May 17th, 1990.

Camouflage Painting of the Zeppelin (Ja) C.I / C.II

The Zeppelin Jaray prototype aircraft C.I and C.II received the usual airship fabric covering delivered by the company's own subsidiary Ballonhullengesellschaft mbH ("Balloon covering association") in Berlin Tempelhof.

For aerodynamic reasons, or for a smooth surface, the fabric had a protective covering of Cellon or stretching lacquer. It was mixed with iron oxide (1.5%) and aluminum powder (3%):

“[...] For the textile covering, one used varnished linen, which was sewn onto the ribs with a special technique. "

After the first two coats, it was smoothed by what was then called "glass paper", now known as sanding paper.

The duraluminum parts of the C.II, such as the engine cover, struts, and shafts, remained unpainted. The national emblems and other markings were applied according to the construction and delivery regulations of the army. Only the C.II series aircraft, which had the military designations 5500 through 5519/18, received the three-color camouflage coverings from the Ballonhullengesellschaft mbH.

Specifications of Zeppelin-Lindau Aircraft

Type Length, m Span, m Height, m Chord, m Propeller Manufact. Armament

(guns) Weight, kg Motor Crew

C.I 7.60 10.50 2.84 LZ-Jaray 1 fixed, 1 flex 696 Daimler D III 2

C.II 7.92 12.00 3.58 1.80 LZ-Jaray 1 fixed, 1 flex 1,000 Maybach Mb IVa 2

Military Numbers of Dornier-ZWL Aircraft

Military Designation Manufact. Type Class Engine Notes

15800-15802/17 ZWL (Do) C.I DIIIa

15803-15805/17 Zepp. C.II Mb IVa

5500-5519/18 C.II Mb IVa 20 aircraft sold to Switzerland

12255-12257/18 Zepp C.IV Last aircraft, burned in Paris 5/17/1990

Zeppelin C.II 5507/18 in provisional 'bubble' camouflage.

Unfortunately, the colors used in the Zeppelin C.II 'bubble' camouflage are not known, so we offer these possibilities.

Unfortunately, the colors used in the Zeppelin C.II 'bubble' camouflage are not known, so we offer these possibilities.

Zeppelin C.II 5507/18 in provisional 'bubble' camouflage.

Unfortunately, the colors used in the Zeppelin C.II 'bubble' camouflage are not known, so we offer these possibilities.

Unfortunately, the colors used in the Zeppelin C.II 'bubble' camouflage are not known, so we offer these possibilities.

Zeppelin C.II 5507/18 in provisional 'bubble' camouflage.

Unfortunately, the colors used in the Zeppelin C.II 'bubble' camouflage are not known, so we offer these possibilities.

Unfortunately, the colors used in the Zeppelin C.II 'bubble' camouflage are not known, so we offer these possibilities.

Designed by Paul Jaray: C.I reconnaissance aircraft. Two prototypes have been built. The improved serial type was the Zep C.II.

Zeppelin C.II in German markings.

Zeppelin C.II in German markings.

The Zeppelin C.II aircraft at the airfield in Dubendorf. Serial No. 811 is visible with Hanriot H.D.1 fighters in the background.

The Swiss allocated serial Nos. 801 to 812, and 814 to 820 to the 20 C.II biplanes it received. According to J. Uresh in the official The Aircraft of the Swiss Air Force since 1914 (1975 Verlag Th. Gut & Co, Switzerland, 1974), the C.II biplanes were purchased clandestinely from the German authorities. They had never been flown and were transported in secret from Friedrichshafen to central Switzerland in 1920. In the middle of 1920, they were purchased by the Swiss military and taken to Dubendorf. The machine proved sturdy and were initially used for reconnaissance and high-altitude flying training. No. 816 crashed in October 1927, killing the crew. Metal fatigue was found to be the cause and the remaining aircraft were scrapped.

The Swiss allocated serial Nos. 801 to 812, and 814 to 820 to the 20 C.II biplanes it received. According to J. Uresh in the official The Aircraft of the Swiss Air Force since 1914 (1975 Verlag Th. Gut & Co, Switzerland, 1974), the C.II biplanes were purchased clandestinely from the German authorities. They had never been flown and were transported in secret from Friedrichshafen to central Switzerland in 1920. In the middle of 1920, they were purchased by the Swiss military and taken to Dubendorf. The machine proved sturdy and were initially used for reconnaissance and high-altitude flying training. No. 816 crashed in October 1927, killing the crew. Metal fatigue was found to be the cause and the remaining aircraft were scrapped.

Zeppelin C.II '808' in Swiss service.

This is one of the 19 Zeppelin C.II aircraft which were sold to Switzerland after the armistice.

This is one of the 19 Zeppelin C.II aircraft which were sold to Switzerland after the armistice.

Zeppelin C.II aircraft in the Hangar at Dubendorf. The Zepp.C.II with the Swiss ID 807 and 810 are in for maintenance, on the left of the photo one can recognize the frame of a C.II without the fabric covering.

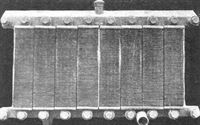

The wing of the Zeppelin C.II, military designation 15805/17, served for stress tests. Internally it was called aircraft number 4. The duraluminum structure of spars and ribs proved to be very stable.

Zeppelin C.II fuselage in storage at the Musee de l'Air in 1981 before fire destroyed the storage hangar where it was stored. It was originally obtained in 1921.

Zeppelin C.II in German markings after a rough landing; the limited damage shows the robustness of the metal structure.

Rs.I: The World's First Giant Flying Boat

The first buildings began to rise from the ground at the Seemoos compound in August 1914. In the beginning there was a small shed with two rooms for the design work, and a production hall, measuring 60 meters by 50 meters, and it had a height of about 30 meters. It was used for the production of parts and the assembly of the flying boats. To bring them into the water, a pully system was added, which led from the hangar into Lake Constance. The transportation car, mounted on rails, traveled about 100 meters into the lake. Initially the cable winch was hand-cranked, but later an electric motor was installed.

Until 1916, more and more buildings were erected in Seemoos, housing a mechanical workshop, a metal-working shop, storage, and technical offices.

While in August 1914 the Abt. Do team consisted of Claude Dornier, a designer, a master craftsman, and six workers, the department grew to 10 constructors and two designers by December. In the beginning of 1915 the workforce grew to 150 people.

As soon as the first buildings were complete, work began on the Rs.I and in January of the following year the construction of the giant flying boat began in earnest. Some of Claude Dornier's important colleagues included the engineers Rohrbach (boat), Ruleaux (cell), Schulte-Frohlinde (engines and controls), Klemm and Lupberger (aerodynamics), Schwengler (structural analysis), Messerschmitt (testing), and the workshop leaders Wild and Lenz.

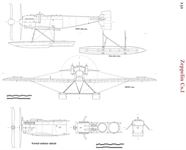

Rs.I was designed to be a biplane with a wingspan of 43.5 meters, and the upper and lower wings were to be connected with eight V-struts. The wings' bracing was swivel-mounted, so that the pitch angle between the wings and the hull of the boat could be changed in order to generate additional lift. The complete but yet uncovered wing was a technical masterpiece, which also impressed Professor Baumann when he visited Seemoos. The wings would be covered in fabric. Small wooden strips were attached to the aluminum alloy ribs so that the fabric could be attached with brass nails. The 29-meter-long hull also had a metal ribcage. Dornier chose duraluminum to cover the fuselage. Only the top and back parts of the boat, which would not directly come into contact with water, were to be covered in fabric.

Rs.I did not receive a camouflage paint scheme, but instead had a sea cruiser finish in a shade of green to protect it from the corrosive sea water. The steel sheet rivets were sealed with strips of fabric soaked in black tar.

Three 240 horsepower HS engines from the neighboring Maybach Motorenwerke powered the flying boat. In its first iteration, one of the engines was built into a nacelle at the center of the boat, and directly drove the propeller. Two further Maybach engines were attached with engine mounts, on either side of the hull, and powered propellers via an extension shaft. The cooling units of both hull engines were attached to the upper side of the hull, while the nacelle engine had a front radiator.

Count Zeppelin followed the construction of Rs.I closely and with great interest, and wanted to know every detail. After all, his company carried the entire financial burden of the project since the Reichs Naval Office had not (yet) placed an order.

The first taxi tests, led by Hellmuth Hirth and naval pilot Erich Schroter on October 12th, 1915 on Lake Constance, showed the placement of the two side-mounted engines was problematic. On October 23rd, 1915 the backboard suspension in the hull broke, and the drive shaft was torn. The flapping propeller damaged the top wing so that Dornier was forced to mount all three engines in external nacelles between the upper and lower wings, so that they could propel the propellers with a direct drive.

This second iteration of the craft would allow the flying boat to reach a maximum taxi speed of 40-50 kilometers per hour during testing on Lake Constance, still 30-40 kilometers per hour slower than the calculated speed required for take-off.

Despite all their efforts, the 10.5 ton heavy flying boat did not rise out of the water. On the fifth try, on December 21st, 1915, a propeller broke. Heinrich Triller's report about the event reads:

“[...] The engines ran well, and the aircraft reached a high speed. I had the feeling it would take off from the water at any moment. After two minutes at full throttle, the middle Reschke Propeller snapped. I immediately stopped all three engines. The middle motor, including the nacelle, had already been torn from the structure. The split propeller had damaged the upper wing, including the starboard aileron and severely damaged the roof.

The reason the propeller broke was probably because the center engine's propeller was 50 centimeters longer than the others. This then bent during full throttle, swiped the mount, and likely caused the break. A motorboat towed the Rs.I to the shoreline. But here it could not be placed upon the carriage because earlier in the day, as the aircraft was being brought into the water, the carriage had jumped its tracks and rested two meters below the waterline. Despite all efforts, hindered by the ice-cold water and the high sea swells, it was not possible to return the carriage to the track that evening. The flying boat had to be anchored to a buoy on the lake. During the night, a foehn storm (a very windy, warm storm from the south) whipped up the waves to a meter high and more, which ripped the buoy from its anchorage and drove it and the craft toward land. The boat hit a rock, causing it to partially sink. The damage from the storm was so severe that it was impossible to even think of repairing it. Although the first experimental aircraft never actually made it into the air, it was still a groundbreaking design. The developers in Seemoos had learned a great deal and used that knowledge when they set out to build Rs.II.

Specifications of Zeppelin-Lindau Aircraft

Type Length, m Span, m Height, m Chord, m Propeller Manufact. Armament

(guns) Weight, kg Motor Crew

Rs.I 29.00 43.50 7.20 4.60 Garuda/Reschke 1 flexible 6,475 Maybach Mb IVa 240 hp 5

Rs.II 28.88 33.20 7.60 6.50 Lorenz 3.70 1 flexible 6,388 Maybach Mb IV/IVa 6

Rs.III 22.74 37.00 8.10 6.50 versch. 4 flexible 7,865 Maybach Mb IVa 6

Rs.IV 22.30 37.00 8.55 6.50 versch. 4 flexible 6,980 Maybach Mb IVa 6

The first buildings began to rise from the ground at the Seemoos compound in August 1914. In the beginning there was a small shed with two rooms for the design work, and a production hall, measuring 60 meters by 50 meters, and it had a height of about 30 meters. It was used for the production of parts and the assembly of the flying boats. To bring them into the water, a pully system was added, which led from the hangar into Lake Constance. The transportation car, mounted on rails, traveled about 100 meters into the lake. Initially the cable winch was hand-cranked, but later an electric motor was installed.

Until 1916, more and more buildings were erected in Seemoos, housing a mechanical workshop, a metal-working shop, storage, and technical offices.

While in August 1914 the Abt. Do team consisted of Claude Dornier, a designer, a master craftsman, and six workers, the department grew to 10 constructors and two designers by December. In the beginning of 1915 the workforce grew to 150 people.

As soon as the first buildings were complete, work began on the Rs.I and in January of the following year the construction of the giant flying boat began in earnest. Some of Claude Dornier's important colleagues included the engineers Rohrbach (boat), Ruleaux (cell), Schulte-Frohlinde (engines and controls), Klemm and Lupberger (aerodynamics), Schwengler (structural analysis), Messerschmitt (testing), and the workshop leaders Wild and Lenz.

Rs.I was designed to be a biplane with a wingspan of 43.5 meters, and the upper and lower wings were to be connected with eight V-struts. The wings' bracing was swivel-mounted, so that the pitch angle between the wings and the hull of the boat could be changed in order to generate additional lift. The complete but yet uncovered wing was a technical masterpiece, which also impressed Professor Baumann when he visited Seemoos. The wings would be covered in fabric. Small wooden strips were attached to the aluminum alloy ribs so that the fabric could be attached with brass nails. The 29-meter-long hull also had a metal ribcage. Dornier chose duraluminum to cover the fuselage. Only the top and back parts of the boat, which would not directly come into contact with water, were to be covered in fabric.

Rs.I did not receive a camouflage paint scheme, but instead had a sea cruiser finish in a shade of green to protect it from the corrosive sea water. The steel sheet rivets were sealed with strips of fabric soaked in black tar.

Three 240 horsepower HS engines from the neighboring Maybach Motorenwerke powered the flying boat. In its first iteration, one of the engines was built into a nacelle at the center of the boat, and directly drove the propeller. Two further Maybach engines were attached with engine mounts, on either side of the hull, and powered propellers via an extension shaft. The cooling units of both hull engines were attached to the upper side of the hull, while the nacelle engine had a front radiator.

Count Zeppelin followed the construction of Rs.I closely and with great interest, and wanted to know every detail. After all, his company carried the entire financial burden of the project since the Reichs Naval Office had not (yet) placed an order.

The first taxi tests, led by Hellmuth Hirth and naval pilot Erich Schroter on October 12th, 1915 on Lake Constance, showed the placement of the two side-mounted engines was problematic. On October 23rd, 1915 the backboard suspension in the hull broke, and the drive shaft was torn. The flapping propeller damaged the top wing so that Dornier was forced to mount all three engines in external nacelles between the upper and lower wings, so that they could propel the propellers with a direct drive.

This second iteration of the craft would allow the flying boat to reach a maximum taxi speed of 40-50 kilometers per hour during testing on Lake Constance, still 30-40 kilometers per hour slower than the calculated speed required for take-off.

Despite all their efforts, the 10.5 ton heavy flying boat did not rise out of the water. On the fifth try, on December 21st, 1915, a propeller broke. Heinrich Triller's report about the event reads:

“[...] The engines ran well, and the aircraft reached a high speed. I had the feeling it would take off from the water at any moment. After two minutes at full throttle, the middle Reschke Propeller snapped. I immediately stopped all three engines. The middle motor, including the nacelle, had already been torn from the structure. The split propeller had damaged the upper wing, including the starboard aileron and severely damaged the roof.

The reason the propeller broke was probably because the center engine's propeller was 50 centimeters longer than the others. This then bent during full throttle, swiped the mount, and likely caused the break. A motorboat towed the Rs.I to the shoreline. But here it could not be placed upon the carriage because earlier in the day, as the aircraft was being brought into the water, the carriage had jumped its tracks and rested two meters below the waterline. Despite all efforts, hindered by the ice-cold water and the high sea swells, it was not possible to return the carriage to the track that evening. The flying boat had to be anchored to a buoy on the lake. During the night, a foehn storm (a very windy, warm storm from the south) whipped up the waves to a meter high and more, which ripped the buoy from its anchorage and drove it and the craft toward land. The boat hit a rock, causing it to partially sink. The damage from the storm was so severe that it was impossible to even think of repairing it. Although the first experimental aircraft never actually made it into the air, it was still a groundbreaking design. The developers in Seemoos had learned a great deal and used that knowledge when they set out to build Rs.II.

Specifications of Zeppelin-Lindau Aircraft

Type Length, m Span, m Height, m Chord, m Propeller Manufact. Armament

(guns) Weight, kg Motor Crew

Rs.I 29.00 43.50 7.20 4.60 Garuda/Reschke 1 flexible 6,475 Maybach Mb IVa 240 hp 5

Rs.II 28.88 33.20 7.60 6.50 Lorenz 3.70 1 flexible 6,388 Maybach Mb IV/IVa 6

Rs.III 22.74 37.00 8.10 6.50 versch. 4 flexible 7,865 Maybach Mb IVa 6

Rs.IV 22.30 37.00 8.55 6.50 versch. 4 flexible 6,980 Maybach Mb IVa 6

The Rs.I in a handling dolly. (Airbus Group)

The sole, experimental long range Zeppelin-Lindau Rs I flying boat was wrecked in a storm on 21 December 1915 before it could be flight tested. This three 240hp Maybach Mb IV-engined craft was the first of a series of one-off giant flying boats made feasible through the extensive use of light alloys, a field in which their creator, Prof Dr Claudius Dornier, one of Count Zeppelin's brighter proteges, had specialised.

The sole, experimental long range Zeppelin-Lindau Rs I flying boat was wrecked in a storm on 21 December 1915 before it could be flight tested. This three 240hp Maybach Mb IV-engined craft was the first of a series of one-off giant flying boats made feasible through the extensive use of light alloys, a field in which their creator, Prof Dr Claudius Dornier, one of Count Zeppelin's brighter proteges, had specialised.

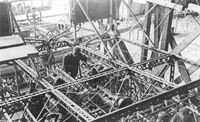

Close-up of the modified engine layout of the Dornier Rs.I. The Reschke propellers on the Rs.I were fitted with brass edges to protect them from water hammering. (Airbus Group)

The Rs.I in front of the hangar in Seemoos in October 1915. (Airbus Group).

The Dornier Rs.I was the first all-metal giant flying boat completed and provided valuable information for subsequent designs despite being wrecked in a storm after taxi trails but before first flight.

The Dornier Rs.I was the first all-metal giant flying boat completed and provided valuable information for subsequent designs despite being wrecked in a storm after taxi trails but before first flight.

The modified Dornier Rs.I on the transportation wagon outside the hangar at Seemoos in December 1915.

The Rs.I after the modification of the propellers. The bulge of the hull was a stopgap measure to widen the fuselage to make room for the dual control cockpit where pilots sat next to each other. (Airbus Group)

The central strut, between the two workers, was used to change the pitch of the wings. (Airbus Group)

The pilots'seats in the Rs.I, including steering wheels and operating levers. On the top of the fuselage there was an 80-centimeter wide space to attach an MG turret. (Airbus Group)

After the accident on October 23rd, 1915, the Rs.I is placed on the carriage. The top wing had been damaged by the propeller. (Airbus Group)

The original form of the Dornier Rs.I with two buried engines. The damage done to the upper wing trailing edge by the shattering of the port propeller can be seen. Photo taken 23 October 1915.

The wreck of the Rs.I after the foehn-storm. The engineer Lupberger oversaw dismantling the flying boat, as all usable parts and the engines were salvaged and re-used on the Rs.II. (Airbus Group)

Rs.II: The First Giant Flying Boat in the Air

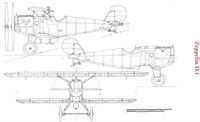

The Rs.II was conceived as a biplane with a short lower wing, also known as a sesquiplane. Since April 1st 1916, when duraluminum profiles could be produced in large numbers, they were used for the Rs.II. As a result, the empty weight of the second flying boat was significantly lower than that of the first, at 6,169 kilograms. The Rs.I had weighed 7,500 kilograms.

Also, when covering the wings - the upper wing had a span of 32 meters, the lower wing 13.5 meters - Dornier tried a new approach. In order to attach the fabric to the metal airframe, grommets were built into the ribs so that the thread did not chafe, and they could be easily threaded with a needle or an awl. This simple but effective way of attaching fabric would also be used for later Dornier aircraft.

The three Maybach Mb IV engines could be salvaged from the wreck of the Rs.I. After a comprehensive manufacturer overhaul, Dornier initially placed them in the hull of the Rs.II. The power transfer, using shaft displacements and two gear drives on the pusher propellers, was similar to the Rs.I. The central configuration of the engines increased the aircraft's stability in the water and simplified the maintenance, but also caused a lot of problems that had also plagued its predecessor. The reason for this configuration, which was considered outdated, was likely the fact that design and construction on the Rs.II had already begun in 1915.

The boat entered the water of Lake Constance for its first tests on May 17th, 1916. The radiator, engines, and the boat were tested in a series of trial runs, where the speed never exceeded 26 km/h. Because the hull had been widened to 4.15 meters, it was no longer necessary to mount floats under the wings, thus creating the world's first inherently stable flying boat.

But it seemed that Dornier's second flying boat also did not want to leave the water.

Claude Dornier turned to Prof. Baumann in Gotha, since he had significantly more experience in building giant flying boats. He travelled to Gotha on May 30th, 1916 and Prof. Baumann wrote the following in a letter dated May 29th, 1916:

“[...] tomorrow Mr. Dornier will come from Friedrichshafen to get some advice, now, finally after he blew 1,000,000 Mark. His newest craft (Rs.II) travels at 20 km/h and is not even contemplating flying[...]”m

It's not clear how much Prof. Baumann could help Claude Dornier. But it was clear to all that with a flying boat of this size and design, Dipl.-Ing. Dornier was breaking completely new ground, and had to do a great deal of pioneering work first. Prof. Bauman's experience building giant aircraft such as the Gotha G-Types might be able to help.

Between May 20th and June 8th, the front of the fuselage step was laid, the redundant bomb bays were rebuilt and a spare radiator was inserted. The boat still did not take off. The elevator, including the box-shaped control unit which could be adjusted in flight, was also altered. In its final form, the vertical stabilizer was made of two movable rudders without a pre-stage, and an elevator fin.

On June 9th, the boat reached a speed of 65 km/h for the first time, rose out of the water to the step and was on the verge of lifting off for the first time. Encouraged by this progress, Dornier added one small additional aid to the hull in the middle of June. During another test on June 26th, the upper transmission bearing broke. The testing could continue after repairs were complete on June 30th. The empty weight of the aircraft had increased to 6,388 kilograms, and the take-off weight to 7,045 kilograms. Nevertheless, on this, the seventh attempt, the Rs.II lifted off from the water effortlessly, at 80 km/h.

“[...] On the third attempt, at 7:30am, the aircraft rose out of the water for the first time. It was a blissful and calm feeling as the steps got longer and longer and then ended. Finally!

We flew about three minutes, two meters above the water, and on the second flight we reached an altitude of about 25 meters, and flew for four minutes. ”

On July 1st four flights were carried out, although on the final flight of the day the starboard gear shaft broke, and the attached engine, which was running without load, blew out.

After the repairs, testing was able to begin again on July 17th. On the last flight the port propeller ruptured, and heavily damaged the other two propellers, the upper wing, the port flaps, as well as a girder in the tail section. Still, the pilot was able to glide the Rs.II to a safe landing.

The constant problems with the remote operator caused Dornier to switch to a direct drive. Instead of placing the three engines underneath the propellers, four 260 horsepower Maybach Mb IVa direct drive engines were built into the aircraft in a so-called tandem configuration. Two by two engines were placed behind each other in a single nacelle. These propellers' power unit, configured as one pull and one push propeller, proved to be significantly more efficient than a single propeller.

In order to test the tandem drive, a test facility was built behind the Seemoos hangar. The engines were placed on an iron frame, one end of which was able to be pivoted around the axis, while a scale was placed on the other end. The experiments and measurements showed that the tractor engine had only about 70% of the performance of the pusher engine. This reduction in performance stemmed from the drag created by the top of the engine and the nacelle. On the pusher engine the air could flow through unhindered. Claude Dornier had calculated the engines' output ahead of time, but still this one showed better flight performance. This was also in part due to the larger radiators from the Suddeutsche Kuhler Fabrik (SKF), which were flexibly mounted. In order to regulate the temperature, fabric curtains could be closed between the cooling surface and the engine room.

At the same time, the entire instrument panel was modernized, including four tachometers (Morell), eight temperature sensors (Morell), a circuit breaker for each of the four engines, and four signal lamps. The Bosch-built throttle, which had been salvaged from the Rs.I, was replaced by one that had been built in-house.

After the rebuild, Rs.II began flying again on November 6th, and following a short take-off run of 52 seconds, the boat took off. The craft was significantly faster following the modifications and the extra engine.

As the flying boat was brought back to shore, the stick was damaged when it collided with the landing pier. Repairs had to be completed quickly because in the meantime Lieutenant Colonel Mans and Lieutenant Tille had arrived in Seemoos to continue the flight testing.

The future of the giant flying boats from Seemoos depended on the assessment of these two gentlemen. Until that point, all of the cost had been carried by LZ alone.

It is easy to imagine the crew's nervousness as the Rs.II was brought into the water at 7:45am on November 11th. Pilot's mate Erich Schroter also surely felt it, since Lt. Tille seemed to be unhappy with the performance so far, although Schroter was a very experienced airman.

“[...] On November 11th in the morning, I took the first flight as a guest, with the company’s aviator Schroter. I saw, by virtue of the fact that the pilot was busying himself with what seemed to me completely unnecessary work during the short, straight flight, as well as his fear of heights, that he was in no way a master of the aircraft. After a few minutes I gave him the order to land so that I could take the controls. The duration of the entire flight was about 30 minutes. The flights were interrupted by failures of the unreliable engines (these were old testing engines). The machinists on board were sometimes able to correct the irregularities in flight.

Pilot Schroter was taken out of the cockpit and replaced by the Airman First Class Fritz Dauke. He had arrived in Seemoos on November 12th from Warnemunde and on the next day he completed his first flight in the giant flying boat under the command of Lt. Tille:

“[...] On Monday, November 13th, I introduced the aviator Dauke to the aircraft. After a training flight the airman first class, whom I consider one of the most spirited aviators in my acquaintance, was able to fly the aircraft alone. ”

Until then, Dauke had only flown single-engine B- and C- floatplanes, so Lt. Tille flew with him in the Rs.II and explained the aircraft. Dauke then completed a first solo flight of the Rs.II on his own with no problem. This also was a testament to the accomplished construction of the Rs.II, despite persistent technical problems.

In their reports for the RMA the naval master builder Schmedding and Lt. Tille concluded that the Rs.II “was not quits combat-ready ... But could, with some practice, be flown by an average aviator ... and could unquestionably be developed for some long-distance military reconnaissance missions (10 hours). ”

The development or rebuild would include modifications to the shape of the hull. The fuselage was to be lengthened, so that the tail boom could be shortened and placed higher. The tail had often touched the water upon takeoff. In addition, watertight bulkheads would be built into the hull. Lt. Tille did not consider the boat combat-ready in its current form.

In the following weeks, further Rs.II test flights were interrupted by engine defects, piston damage, valve breakage, and leaky lines.

On April 28th, 1917 the central strut of the tail construction broke upon landing, so that the entire tail boom was hanging on just four cables. The pilot had not noticed the break, and wanted to take off again. The craft lifted off but was immediately pushed back into the water because the tail had shifted down, creating a nose-heavy situation. During the rough landing two further cables snapped so that the entire tail was resting on the water surface. Following a redesign of the tail boom, the Rs.II was able to take flight again in June 1917.

After all of these improvements, the Rs.II could be easily maneuvered, despite its 9.2-ton weight. After about 20-30 seconds of acceleration, she easily lifted out of the water. The top speed in horizontal flight was 128 km/h, the highest altitude reached was 1,800 meters. Although the Rs.II always was a bit tail-heavy, the flying characteristics were mature enough that a naval commission approved the Rs.II in July 1917 in Seemoos.

An accident occurred during the approval and acceptance process, which foreman Heinrich Triller described in the Dornier Post in 1936:

“[...] our giant flying boat Fs.II [Rs.II] stood in the hangar, ready to be approved. The gentlemen of the commission, naval and flight officers, were all there. The hangar doors were open and I did a short test of the four Maybach engines. Everything was well: the engines ran at about 500 rpm, and I wanted to give the signal to transport the aircraft into the water, as one of our helpers ran up from behind on the port side and waved at me. Suddenly I stopped in surprise. The man climbed up on the craft from behind, and seemed to not be aware of the running propellers. I shouted, waved the man away and reached for the ignition switch but it was too late. The machine shuddered, as if someone had hit it with a hammer. I shut my eyes tightly so that I would not see the horrifying sight, because two years earlier one of our workers was decapitated on the test rig. I breathed a sigh of relief when the man stood next to me, healthy and happy, and looked at me in surprise. He had nothing more than a bump on his head. All he wanted to do was to bring me my protective glasses, and excused himself [...]”

After this accident, the final acceptance flight had to be delayed for a few days, until replacement propellers were delivered. The metal-covered wooden propeller had split along its entire length, the crack was about 10 millimeters wide. Low-quality fuel forced further delays. After the Rs.II's 23rd flight in July 1917, engine performance declined significantly, with each engine delivering 50-80 rpm less than normal, and it took an hour to reach an altitude of 2,000 meters. Since there was no technical defect on the flying boat structure or its engines, the fuel was tested in a laboratory. These tests confirmed the initial suspicion. Both LZ and Maybach had also received this inferior fuel. A test using 2/3 benzene and 1/3 gasoline did not improve the engine performance, causing immediate soot soiling. Many phone calls later, the Rhenania-Benzinwerke in Ludwigshafen was able to deliver appropriate fuel to Seemoos.

The combat readiness of the Rs.II would take place at the naval air station in Norderney. In order to simulate the flight to Norderney, Dipl.-Ing. Dornier ordered a six-hour test flight over Lake Constance on August 13th, 1917. The Rs.II would be fully armed, including a four-man crew, and outfitted as it would be in war. After 2 hours and 17 minutes of flight time, the aft port propeller, built and delivered by the company Behrend-Rugebrecht, broke. Flying parts smashed into the aft starboard propeller as well. Two struts on the tail boom were separated and spars and fabric covers were also damaged. The supports for the engine base as well as the trays of the rear engines were also torn open.

Despite this accident the pilot, Lt. Lech, was able to slowly glide and land the plane.

The heavy damage on the Rs.II prompted the Reichs Naval Department on August 21st, 1917 to order the craft to be scrapped, and to salvage the parts that could be re-used. The testing phase of the 1 1/2 year-old design was complete, and the development of the successor model, Rs.III, was already fairly advanced. Also, the obsolete lattice construction was finally retired. Engineers in Seemoos used parts of the Rs.II, such as spars, empennage and rudders for stress testing in order to gain knowledge for the new Rs.III. The SVK in Warnemunde used parts of the Rs.II, which the Navy had allocated the number 1433, such as the fuselage, for further testing. It was finally destroyed on June 3rd, 1918 during a stress test in Warnemunde.

In the meantime, the financial questions between ZWL and the Reichs Naval Department were cleared up and the purchase and development costs of 300,000 Reichs Mark were transferred to the Abt. Do. The RMA's decision to stop construction of the Rs.II likely included the consideration that the company-internal competitor, Zeppelin-Werke GmbH Staaken, had flown its Staaken L aircraft from Staaken to Potsdam for delivery on August 10th 1917. It was assigned the Naval number 1432. This naval R-aircraft was on the verge of acceptance. At the Potsdam hangar, its wheels were replaced with floats. The design of the aluminum floats was developed together with the ZWL and the naval master constructor Schmedding, and were built in the hangar in Staaken. The carriage upon which the 12-meter-long floats were fastened for ground transport was a special construction. The engineers Scholler and Welker designed a "float bay" which had air chambers and floated on the water surface. In this way the yokes could be pushed over the floats and tightened with bolts.

The first water take-off of the Staaken L was on September 5th from Lake Havel. The aircraft was to be transferred to Warnemunde on November 12th, 1917, but was forced to land on the Saaler Lagoon due to an engine failure. After the repairs, she was flown to Warnemunde on November 14th. As the craft was fastened to the buoy, the specially built carriage could be attached, despite winds of 8-10 meters per second, and the Staaken rolled onto land and into the hangar under its own power. This was proof that large aircraft with massive measurements and weight that had until now been unknown, could be stationed and employed at the front.

In the following weeks, the aircraft was equipped with a radio and mast for the antenna. Larger fuel tanks extended its range to 10 hours. In addition, a lighting and a heating system were added. The aircraft went through rigorous testing in Warnemunde in the months that followed. The focus of these were long-distance flights as well as landing performance in various sea conditions. The maximum flight range of 10 hours could be extended when one of the engines was shut off.

On June 3rd, 1918, the Staaken L crashed during a radio testing flight over land near Warnemunde, and the entire crew was killed.

Specifications of Zeppelin-Lindau Aircraft

Type Length, m Span, m Height, m Chord, m Propeller Manufact. Armament

(guns) Weight, kg Motor Crew

Rs.I 29.00 43.50 7.20 4.60 Garuda/Reschke 1 flexible 6,475 Maybach Mb IVa 240 hp 5

Rs.II 28.88 33.20 7.60 6.50 Lorenz 3.70 1 flexible 6,388 Maybach Mb IV/IVa 6

Rs.III 22.74 37.00 8.10 6.50 versch. 4 flexible 7,865 Maybach Mb IVa 6

Rs.IV 22.30 37.00 8.55 6.50 versch. 4 flexible 6,980 Maybach Mb IVa 6

Military Numbers of Dornier-ZWL Aircraft

Military Designation Manufact. Type Class Engine Notes

M.N.1433 LZ (Do) Rs.II RC4MG Mb IVa x 4 Destroyed in Sep. 1917

The Rs.II was conceived as a biplane with a short lower wing, also known as a sesquiplane. Since April 1st 1916, when duraluminum profiles could be produced in large numbers, they were used for the Rs.II. As a result, the empty weight of the second flying boat was significantly lower than that of the first, at 6,169 kilograms. The Rs.I had weighed 7,500 kilograms.

Also, when covering the wings - the upper wing had a span of 32 meters, the lower wing 13.5 meters - Dornier tried a new approach. In order to attach the fabric to the metal airframe, grommets were built into the ribs so that the thread did not chafe, and they could be easily threaded with a needle or an awl. This simple but effective way of attaching fabric would also be used for later Dornier aircraft.

The three Maybach Mb IV engines could be salvaged from the wreck of the Rs.I. After a comprehensive manufacturer overhaul, Dornier initially placed them in the hull of the Rs.II. The power transfer, using shaft displacements and two gear drives on the pusher propellers, was similar to the Rs.I. The central configuration of the engines increased the aircraft's stability in the water and simplified the maintenance, but also caused a lot of problems that had also plagued its predecessor. The reason for this configuration, which was considered outdated, was likely the fact that design and construction on the Rs.II had already begun in 1915.

The boat entered the water of Lake Constance for its first tests on May 17th, 1916. The radiator, engines, and the boat were tested in a series of trial runs, where the speed never exceeded 26 km/h. Because the hull had been widened to 4.15 meters, it was no longer necessary to mount floats under the wings, thus creating the world's first inherently stable flying boat.

But it seemed that Dornier's second flying boat also did not want to leave the water.

Claude Dornier turned to Prof. Baumann in Gotha, since he had significantly more experience in building giant flying boats. He travelled to Gotha on May 30th, 1916 and Prof. Baumann wrote the following in a letter dated May 29th, 1916:

“[...] tomorrow Mr. Dornier will come from Friedrichshafen to get some advice, now, finally after he blew 1,000,000 Mark. His newest craft (Rs.II) travels at 20 km/h and is not even contemplating flying[...]”m

It's not clear how much Prof. Baumann could help Claude Dornier. But it was clear to all that with a flying boat of this size and design, Dipl.-Ing. Dornier was breaking completely new ground, and had to do a great deal of pioneering work first. Prof. Bauman's experience building giant aircraft such as the Gotha G-Types might be able to help.

Between May 20th and June 8th, the front of the fuselage step was laid, the redundant bomb bays were rebuilt and a spare radiator was inserted. The boat still did not take off. The elevator, including the box-shaped control unit which could be adjusted in flight, was also altered. In its final form, the vertical stabilizer was made of two movable rudders without a pre-stage, and an elevator fin.

On June 9th, the boat reached a speed of 65 km/h for the first time, rose out of the water to the step and was on the verge of lifting off for the first time. Encouraged by this progress, Dornier added one small additional aid to the hull in the middle of June. During another test on June 26th, the upper transmission bearing broke. The testing could continue after repairs were complete on June 30th. The empty weight of the aircraft had increased to 6,388 kilograms, and the take-off weight to 7,045 kilograms. Nevertheless, on this, the seventh attempt, the Rs.II lifted off from the water effortlessly, at 80 km/h.

“[...] On the third attempt, at 7:30am, the aircraft rose out of the water for the first time. It was a blissful and calm feeling as the steps got longer and longer and then ended. Finally!

We flew about three minutes, two meters above the water, and on the second flight we reached an altitude of about 25 meters, and flew for four minutes. ”

On July 1st four flights were carried out, although on the final flight of the day the starboard gear shaft broke, and the attached engine, which was running without load, blew out.

After the repairs, testing was able to begin again on July 17th. On the last flight the port propeller ruptured, and heavily damaged the other two propellers, the upper wing, the port flaps, as well as a girder in the tail section. Still, the pilot was able to glide the Rs.II to a safe landing.

The constant problems with the remote operator caused Dornier to switch to a direct drive. Instead of placing the three engines underneath the propellers, four 260 horsepower Maybach Mb IVa direct drive engines were built into the aircraft in a so-called tandem configuration. Two by two engines were placed behind each other in a single nacelle. These propellers' power unit, configured as one pull and one push propeller, proved to be significantly more efficient than a single propeller.

In order to test the tandem drive, a test facility was built behind the Seemoos hangar. The engines were placed on an iron frame, one end of which was able to be pivoted around the axis, while a scale was placed on the other end. The experiments and measurements showed that the tractor engine had only about 70% of the performance of the pusher engine. This reduction in performance stemmed from the drag created by the top of the engine and the nacelle. On the pusher engine the air could flow through unhindered. Claude Dornier had calculated the engines' output ahead of time, but still this one showed better flight performance. This was also in part due to the larger radiators from the Suddeutsche Kuhler Fabrik (SKF), which were flexibly mounted. In order to regulate the temperature, fabric curtains could be closed between the cooling surface and the engine room.

At the same time, the entire instrument panel was modernized, including four tachometers (Morell), eight temperature sensors (Morell), a circuit breaker for each of the four engines, and four signal lamps. The Bosch-built throttle, which had been salvaged from the Rs.I, was replaced by one that had been built in-house.

After the rebuild, Rs.II began flying again on November 6th, and following a short take-off run of 52 seconds, the boat took off. The craft was significantly faster following the modifications and the extra engine.

As the flying boat was brought back to shore, the stick was damaged when it collided with the landing pier. Repairs had to be completed quickly because in the meantime Lieutenant Colonel Mans and Lieutenant Tille had arrived in Seemoos to continue the flight testing.

The future of the giant flying boats from Seemoos depended on the assessment of these two gentlemen. Until that point, all of the cost had been carried by LZ alone.

It is easy to imagine the crew's nervousness as the Rs.II was brought into the water at 7:45am on November 11th. Pilot's mate Erich Schroter also surely felt it, since Lt. Tille seemed to be unhappy with the performance so far, although Schroter was a very experienced airman.

“[...] On November 11th in the morning, I took the first flight as a guest, with the company’s aviator Schroter. I saw, by virtue of the fact that the pilot was busying himself with what seemed to me completely unnecessary work during the short, straight flight, as well as his fear of heights, that he was in no way a master of the aircraft. After a few minutes I gave him the order to land so that I could take the controls. The duration of the entire flight was about 30 minutes. The flights were interrupted by failures of the unreliable engines (these were old testing engines). The machinists on board were sometimes able to correct the irregularities in flight.

Pilot Schroter was taken out of the cockpit and replaced by the Airman First Class Fritz Dauke. He had arrived in Seemoos on November 12th from Warnemunde and on the next day he completed his first flight in the giant flying boat under the command of Lt. Tille:

“[...] On Monday, November 13th, I introduced the aviator Dauke to the aircraft. After a training flight the airman first class, whom I consider one of the most spirited aviators in my acquaintance, was able to fly the aircraft alone. ”

Until then, Dauke had only flown single-engine B- and C- floatplanes, so Lt. Tille flew with him in the Rs.II and explained the aircraft. Dauke then completed a first solo flight of the Rs.II on his own with no problem. This also was a testament to the accomplished construction of the Rs.II, despite persistent technical problems.

In their reports for the RMA the naval master builder Schmedding and Lt. Tille concluded that the Rs.II “was not quits combat-ready ... But could, with some practice, be flown by an average aviator ... and could unquestionably be developed for some long-distance military reconnaissance missions (10 hours). ”

The development or rebuild would include modifications to the shape of the hull. The fuselage was to be lengthened, so that the tail boom could be shortened and placed higher. The tail had often touched the water upon takeoff. In addition, watertight bulkheads would be built into the hull. Lt. Tille did not consider the boat combat-ready in its current form.

In the following weeks, further Rs.II test flights were interrupted by engine defects, piston damage, valve breakage, and leaky lines.

On April 28th, 1917 the central strut of the tail construction broke upon landing, so that the entire tail boom was hanging on just four cables. The pilot had not noticed the break, and wanted to take off again. The craft lifted off but was immediately pushed back into the water because the tail had shifted down, creating a nose-heavy situation. During the rough landing two further cables snapped so that the entire tail was resting on the water surface. Following a redesign of the tail boom, the Rs.II was able to take flight again in June 1917.

After all of these improvements, the Rs.II could be easily maneuvered, despite its 9.2-ton weight. After about 20-30 seconds of acceleration, she easily lifted out of the water. The top speed in horizontal flight was 128 km/h, the highest altitude reached was 1,800 meters. Although the Rs.II always was a bit tail-heavy, the flying characteristics were mature enough that a naval commission approved the Rs.II in July 1917 in Seemoos.

An accident occurred during the approval and acceptance process, which foreman Heinrich Triller described in the Dornier Post in 1936:

“[...] our giant flying boat Fs.II [Rs.II] stood in the hangar, ready to be approved. The gentlemen of the commission, naval and flight officers, were all there. The hangar doors were open and I did a short test of the four Maybach engines. Everything was well: the engines ran at about 500 rpm, and I wanted to give the signal to transport the aircraft into the water, as one of our helpers ran up from behind on the port side and waved at me. Suddenly I stopped in surprise. The man climbed up on the craft from behind, and seemed to not be aware of the running propellers. I shouted, waved the man away and reached for the ignition switch but it was too late. The machine shuddered, as if someone had hit it with a hammer. I shut my eyes tightly so that I would not see the horrifying sight, because two years earlier one of our workers was decapitated on the test rig. I breathed a sigh of relief when the man stood next to me, healthy and happy, and looked at me in surprise. He had nothing more than a bump on his head. All he wanted to do was to bring me my protective glasses, and excused himself [...]”

After this accident, the final acceptance flight had to be delayed for a few days, until replacement propellers were delivered. The metal-covered wooden propeller had split along its entire length, the crack was about 10 millimeters wide. Low-quality fuel forced further delays. After the Rs.II's 23rd flight in July 1917, engine performance declined significantly, with each engine delivering 50-80 rpm less than normal, and it took an hour to reach an altitude of 2,000 meters. Since there was no technical defect on the flying boat structure or its engines, the fuel was tested in a laboratory. These tests confirmed the initial suspicion. Both LZ and Maybach had also received this inferior fuel. A test using 2/3 benzene and 1/3 gasoline did not improve the engine performance, causing immediate soot soiling. Many phone calls later, the Rhenania-Benzinwerke in Ludwigshafen was able to deliver appropriate fuel to Seemoos.

The combat readiness of the Rs.II would take place at the naval air station in Norderney. In order to simulate the flight to Norderney, Dipl.-Ing. Dornier ordered a six-hour test flight over Lake Constance on August 13th, 1917. The Rs.II would be fully armed, including a four-man crew, and outfitted as it would be in war. After 2 hours and 17 minutes of flight time, the aft port propeller, built and delivered by the company Behrend-Rugebrecht, broke. Flying parts smashed into the aft starboard propeller as well. Two struts on the tail boom were separated and spars and fabric covers were also damaged. The supports for the engine base as well as the trays of the rear engines were also torn open.

Despite this accident the pilot, Lt. Lech, was able to slowly glide and land the plane.

The heavy damage on the Rs.II prompted the Reichs Naval Department on August 21st, 1917 to order the craft to be scrapped, and to salvage the parts that could be re-used. The testing phase of the 1 1/2 year-old design was complete, and the development of the successor model, Rs.III, was already fairly advanced. Also, the obsolete lattice construction was finally retired. Engineers in Seemoos used parts of the Rs.II, such as spars, empennage and rudders for stress testing in order to gain knowledge for the new Rs.III. The SVK in Warnemunde used parts of the Rs.II, which the Navy had allocated the number 1433, such as the fuselage, for further testing. It was finally destroyed on June 3rd, 1918 during a stress test in Warnemunde.

In the meantime, the financial questions between ZWL and the Reichs Naval Department were cleared up and the purchase and development costs of 300,000 Reichs Mark were transferred to the Abt. Do. The RMA's decision to stop construction of the Rs.II likely included the consideration that the company-internal competitor, Zeppelin-Werke GmbH Staaken, had flown its Staaken L aircraft from Staaken to Potsdam for delivery on August 10th 1917. It was assigned the Naval number 1432. This naval R-aircraft was on the verge of acceptance. At the Potsdam hangar, its wheels were replaced with floats. The design of the aluminum floats was developed together with the ZWL and the naval master constructor Schmedding, and were built in the hangar in Staaken. The carriage upon which the 12-meter-long floats were fastened for ground transport was a special construction. The engineers Scholler and Welker designed a "float bay" which had air chambers and floated on the water surface. In this way the yokes could be pushed over the floats and tightened with bolts.

The first water take-off of the Staaken L was on September 5th from Lake Havel. The aircraft was to be transferred to Warnemunde on November 12th, 1917, but was forced to land on the Saaler Lagoon due to an engine failure. After the repairs, she was flown to Warnemunde on November 14th. As the craft was fastened to the buoy, the specially built carriage could be attached, despite winds of 8-10 meters per second, and the Staaken rolled onto land and into the hangar under its own power. This was proof that large aircraft with massive measurements and weight that had until now been unknown, could be stationed and employed at the front.

In the following weeks, the aircraft was equipped with a radio and mast for the antenna. Larger fuel tanks extended its range to 10 hours. In addition, a lighting and a heating system were added. The aircraft went through rigorous testing in Warnemunde in the months that followed. The focus of these were long-distance flights as well as landing performance in various sea conditions. The maximum flight range of 10 hours could be extended when one of the engines was shut off.

On June 3rd, 1918, the Staaken L crashed during a radio testing flight over land near Warnemunde, and the entire crew was killed.

Specifications of Zeppelin-Lindau Aircraft

Type Length, m Span, m Height, m Chord, m Propeller Manufact. Armament

(guns) Weight, kg Motor Crew

Rs.I 29.00 43.50 7.20 4.60 Garuda/Reschke 1 flexible 6,475 Maybach Mb IVa 240 hp 5

Rs.II 28.88 33.20 7.60 6.50 Lorenz 3.70 1 flexible 6,388 Maybach Mb IV/IVa 6

Rs.III 22.74 37.00 8.10 6.50 versch. 4 flexible 7,865 Maybach Mb IVa 6

Rs.IV 22.30 37.00 8.55 6.50 versch. 4 flexible 6,980 Maybach Mb IVa 6

Military Numbers of Dornier-ZWL Aircraft

Military Designation Manufact. Type Class Engine Notes

M.N.1433 LZ (Do) Rs.II RC4MG Mb IVa x 4 Destroyed in Sep. 1917

The Rs.II before its maiden flight on May 17th, 1916. (Airbus Group)

The single Zeppelin-Lindau Rs II giant, long range flying boat is seen here in its initial form with biplane tail. First flown on 30 June 1916 with its three 240hp Maybach Mb IVs buried within its short, broad-beamed hull, the problem of power losses in the transmission must have been serious, leading to the Rs II's beaching for modifications. Centred around the engines, this work saw the replacement of the three buried units by four similar engines, now mounted between the hull and the parasol wing in twin push/pull nacelles, with each engine driving its propeller directly. The opportunity was also taken, at this time, to modify the machine's tail unit. In this later form and known as the Rs IIb, the flying boat got airborne once more on 6 November 1916.

The single Zeppelin-Lindau Rs II giant, long range flying boat is seen here in its initial form with biplane tail. First flown on 30 June 1916 with its three 240hp Maybach Mb IVs buried within its short, broad-beamed hull, the problem of power losses in the transmission must have been serious, leading to the Rs II's beaching for modifications. Centred around the engines, this work saw the replacement of the three buried units by four similar engines, now mounted between the hull and the parasol wing in twin push/pull nacelles, with each engine driving its propeller directly. The opportunity was also taken, at this time, to modify the machine's tail unit. In this later form and known as the Rs IIb, the flying boat got airborne once more on 6 November 1916.

The Rs.II on the dock in Seemoos. For the stability of the hull in the water, two assistive floats were attached to the lower wings. (Airbus Group)

After the first test run, vents were built into the hull. It had become almost impossible for the machinists to do their jobs due to the enormous heat of the engines located in the hull. (Airbus Group)

The propeller's power unit, through tubular shafts and angular gearboxes, stemmed from airship construction.

The Rs.II takes off after the modifications to the tandem engines on November 6th, 1916. The engine nacelles had not yet been installed, so that any problems in the cooling or fuel lines could be immediately repaired. (Airbus Group)

The Zeppelin Rs.II flies past the hangar in Seemoos in 1916 (Airbus Group).

The Zeppelin-Lindau Rs IIb, seen here in almost final form and only awaiting its four 240hp Maybachs to be encased in drag-reducing engine nacelles. Capable of reaching 81 mph top level speed at sea level, the Rs IIb had, by now, elicited sufficient naval interest to have been bought and issued with the serial 1433. Following flight testing, the machine was dismantled so that parts could be used in its successor, the Rs III.

The Zeppelin-Lindau Rs IIb, seen here in almost final form and only awaiting its four 240hp Maybachs to be encased in drag-reducing engine nacelles. Capable of reaching 81 mph top level speed at sea level, the Rs IIb had, by now, elicited sufficient naval interest to have been bought and issued with the serial 1433. Following flight testing, the machine was dismantled so that parts could be used in its successor, the Rs III.

The Rs.II during testing by naval aviator Lt. Tille in mid-November 1916. He complained about the shape of the hull, which, in his opinion, caused too much drag. The tail construction was also criticized, because it touched the water during a steep take off.