Описание

Страна: Великобритания

Год: 1918

Two-seat carrier-borne Fleet Spotter and reconnaissance biplane

K.Wixey Parnall Aircraft Since 1914 (Putnam)

Parnall and Sons Limited

Aircraft Built under Contract 1914-1918

Parnall Panther

During 1917 the British Admiralty issued Specification A.D.(N.2A, which called for a two-seat reconnaissance and spotting aeroplane capable of operating with the RNAS from an aircraft-carrier.

In response designs were submitted from three sources: Handley Page with the Type 14 (R/200), the Isle of Grain (Port Victoria) Naval Experimental Station, which presented adaptations of the P.V.5 and P.V.5a types, and Parnall which entered its second design for the Admiralty, the N.2A, which was to be later named the Panther.

The N.2A was the first design for the Parnall company from the drawing board of Admiralty designer Harold Bolas. To comply with the specification's requirements, Bolas introduced something of an innovation in the structural design of his N.2A. The fuselage featured a wooden monocoque construction, a reflection of Harold Bolas's earlier experiences with the A.D. Flying-Boat and Navyplane, while another novelty was the unorthodox method employed to facilitate stowage aboard an aircraft carrier. In this instance the rear fuselage section was hinged just aft of the observer's cockpit, and could be swung to lie parallel to the starboard mainplanes. To obviate chafing, the tail unit control cables were located in a special channel on the starboard side of the fuselage.

The fuselage was built as two sections, each consisting of plywood formers to which was screwed and glued an outer skin, also formed of plywood and having fabric covering. The whole was based on a frame of four longerons, which carried the plywood formers as well as providing 'hard spots' at the fuselage folding points.

Air bags were installed in the rear fuselage section to provide buoyancy in the event of the aircraft being ditched. The instrument panel was hinged in order to provide easy access for maintenance from the rear. The pilot's cockpit was beneath the upper centre section and immediately above the main fuel tank, which had a maximum capacity of 48 gal, while two gravity tanks, installed within the upper centre-section, contained a further ten gallons. The fuel was pumped up to these tanks by means of a small wind-operated pump attacked to a short strut on the fuselage. The N.2A incorporated single-bag biplane wings of equal span and conventional construction, although the ailerons were positioned well inboard from the detachable wingtips, a combination that allowed for easier stowage. An opening in the upper centre-section provided the pilot with a rather laborious means of entry to the cockpit, a feat which also required the lowering of a centre-section trailing-edge, which was hinged to the rear spar. This aperture did have one advantage, however, in that it presented the pilot with a clear view immediately overhead. This rather cumbersome means of ingress to the pilot's cockpit, necessitated by the unusually high positioning of the two crew members (the observer entered by a more orthodox method), was compensated for when airborne by an excellent all-round view. Another great advantage for the pilot, especially in a naval aeroplane, was the exceptionally good forward view when making carrier deck landings.

The Parnall N.2A (the name Panther was applied to the sixth prototype) was powered by a 230 hp Bentley B.R.2 nine-cylinder rotary air-cooled engine, one of the most powerful rotary aero-engines ever built in quantity. This powerplant was encased in a shapely convex cowling divided radially and open at the bottom for cooling, a feature which served to improve the airflow and reduce drag.

The engine and its auxiliary components were mounted on projecting spars, and could be fitted or removed from the aircraft as a complete unit; the N.2A was one of the first aeroplanes to incorporate this feature. Large slots situated behind the engine and contained within the aircraft's fuselage profile allowed for the outlet of air and exhaust gases. The empennage was of conventional construction, but even that had a novel element m the actual layout, for the elevators and the rudder hinge lines were inclined forward in plan view.

The first N.2A prototype, N91, was ready for its initial trials in April 1918, and it appeared with an undercarriage of the cross-axle type having two V struts with widened apexes. The tailskid was attached to a strengthened former, and differed from normal practice by virtue of a special ball-type fitting designed to assist take-off procedure aboard ship. Another feature was the jettisonable wheels. These could be released by a cable and spring mechanism operated from the cockpit if a forced alighting at sea became imminent.

The prototype N.2A was armed with a fixed forward-firing .303-in Vickers machine-gun mounted on the port side of the pilot's cockpit, while the observer/ gunner in the rear cockpit was provided with a .303-in Lewis gun mounted on a pillar. The pilot's gun was later dispensed with, however, and all subsequent prototype and production Panthers were armed with just the observer's Lewis gun.

On undergoing manufacturer's trials the prototype N.2A was found to be nose-heavy, and before leaving Bristol for its official trials at the A & AEE, Martlesham Heath, in May 1918, the aircraft was modified to include horn-balanced elevators with a pronounced increase in the forward slope of the hinge lines.

The Martlesham trials proved disappointing; the N.2A's maximum speed of 108.5 mph at 2,000 ft, and climb to that altitude in 2 min 20 sec was little improvement over earlier RNAS aircraft types possessing much less power. Nevertheless it was decided to proceed with development of the Parnall machine, and the prototype was returned to the Bristol works for the installation of flotation gear. That was in June 1918, but in the following October the prototype was reported as still being at Parnall's works.

A further five N.2As were produced by Parnall, all classed as prototypes. The second machine, N92, was fitted with an identical undercarriage to the first prototype, but the third prototype, N93, was equipped with a hydrovane attachment designed to prevent the aeroplane from nosing over in the event of a forced alightning. This hydrovane was constructed of wood and steel and was adopted as standard equipment on subsequent N.2A prototypes and production machines.

By the summer of 1918 the first three prototype N.2As had been completed and were subjected to tests involving Parnall's own design flotation gear. Deemed necessary in an aeroplane expected to operate mainly over water, this gear consisted of air bags fixed beneath the lower wings, these being additional to the air bags contained in the N.2A's rear fuselage.

On 22 June, 1918, the second prototype N.2A was sent to Turnhouse (Edinburgh) for trials with the Fleet, and was eventually taken on board the battle-cruiser HMS Repulse. This was presumably for the purpose of trying out the Parnall machine in take-offs from a small platform attached to one of the ship's gun turrets, a practice then in vogue for launching naval scouting aircraft from the larger warships.

The third prototype N.2A was completed in July 1918, and after being equipped with the Parnall flotation gear was flown to the Isle of Grain Naval Experimental Station for ditching trials. While there the Parnall flotation gear was removed to be supplanted by the Isle of Grain's own system. This consisted of three inflatable air bags, one in the rear fuselage compartment, and one each stowed in tubular steel containers attached to the top of the undercarriage V-struts. These bags were inflated by means of an air bottle charged at a pressure of 1,800 psi. After undergoing successful trials, this gear was adopted as standard equipment for all production Panthers.

In general the flotation bags were constructed with several layers of rubberized fabric, and most were provided with flaps with which they could be attached to the aircraft's structure. It was normal practice for the bags to be installed relative to the aeroplane's greatest concentration of weight, but the location of bracing wires and the aircraft's centre of gravity had also to be considered. The simultaneous release of all bags was usually accomplished by means of a T-shaped handle positioned either in the upper right-hand side of the instrument panel, or in the upper wing centresection. A hand-operated pump was also often provided to top up the bags after inflation, or to replace lost air should a slow leak have occurred. The bags were capable of keeping an aeroplane afloat for about ten hours in a calm sea, but rough waters could result in the waves chafing the bags and subsequent loss of buoyancy.

The tests at the Isle of Grain were undertaken by Maj W G Moore, DSC, and after the buoyancy trials and wheel jettisoning tests, the third prototype N.2A was subjected to alighting experiments using the hydrovane. These proved satisfactory, with the aircraft alighting at a very low speed, planing along on the hydrovane and settling down on the water undamaged.

Once recovered from the water the N.2A was ready for flying again immediately. At about the time these trials were taking place, a new official system of nomenclature was introduced for British military aeroplanes, and Parnall's N.2A was named Panther, coming officially within the class known as the RAF Type 21, which applied to Fleet Reconnaissance shipborne aircraft.

Meanwhile the fourth prototype N.2A (N94) flew to the Royal Aircraft Establishment at Farnborough to undergo proof-loading tests, the fifth machine (N95) going to Turnhouse, where it flew on trials with the Fleet, at the same time participating in experiments with the Grain Flotation Gear. The sixth and final N.2A prototype (N96) was equipped with Grain Flotation Gear, a hydrovane and two extra handling positions which were embodied in the fuselage. It was this sixth machine that was officially named Panther, and which was considered equivalent to a production aircraft.

Parnall was awarded two contracts for the construction of 312 production Panthers (N7400-N7549 and N7680-N7841), but with the signing of the Armistice in November 1918, the second contract was cancelled. This annulment created friction between Avery (Parnall's controlling group) and the Air Ministry, and as a consequence both the Panther contracts were cancelled. The first order was later revised and offered to The British & Colonial Aeroplane Company at Filton, which readily accepted the Panther contract and thus helped to alleviate the rising unemployment figures in the area.

It is apparent, however, that Parnall did produce a small number of production Panthers in its Bristol works, a fact proved by a surviving photograph showing Panther N7406 in the Coliseum works, and bearing the unmistakable Parnall factory number P.877.

How many Panthers were actually completed by Parnall from the Air Ministry contract to The British & Colonial Aeroplane Company is uncertain, but fuselages for machines up to N7426 are believed to have been built in the Coliseum works by Parnall on behalf of British & Colonial before Panther production began at Filton.

The second Panther contract remained void, and work on the 162 machines (N7680-N7841) was never started. The original Air Ministry order for 150 Panthers was complied with during 1919 and 1920 at Filton, and the type entered service with the British Fleet aboard the aircraft carriers HMS Argus and Hermes whence the Panthers participated in the early development of carrier deck flying. For this purpose they were equipped with special fasteners attached to the undercarriage axle, these fasteners, or clips, engaging longitudinal wires running fore and aft along the carrier's deck. The wires themselves acted not only as guide lines and assisted in friction braking, but were also directed over a number of transverse, hinged, wooden barriers, which helped to brake the aircraft as it pushed them down during its landing roll. Under these conditions it was inevitable that a number of aircraft sustained varying amounts of damage while in the process of landing on the carrier deck. Indeed during one set training period aboard HMS Argus in 1924, it was recorded that only five landings in six escaped mishaps. This system of carrier deck landing proved so costly in damage to Fleet Air Arm aircraft that it was abandoned in favour of the old rope and weights method until a more satisfactory system was available.

Production Panthers were later modified to include large horn-balanced rudders, oleo-type undercarriage legs, a wider-track undercarriage, and improved deck-landing cable hooks.

A number of Panthers were rebuilt under contract including eighteen sent to Gloucestershire Aircraft at Cheltenham in 1923 and, although unconfirmed, it is believed a small number of Panthers were renovated by the newly formed George Parnall company at the Coliseum works, Park Row, Bristol.

Service pilots reported the Panther as pleasant to fly with few vices, the most noticeable being an adverse effect on rudder control when the aircraft was flying at low speed. It was also agreed that the Panther's Bentley engine required frequent coaxing and could become very irksome during flight. The well-known test pilot Capt Norman Macmillan spoke highly of the Panther in regard to his personal experience with the type.

In addition to serving with the carriers HMS Argus and Hermes, Panthers operated with shore-based units including, No.421 Fleet Spotter Reconnaissance Flight at Gosport, Nos.441 and 442 Fleet Spotter Reconnaissance Flights at Leuchars and, also at Leuchars, with No.406 Fleet Fighter Flight. Panthers continued to serve with the Fleet Air Arm until 1926, when those machines still serving with No.442 Flight were finally replaced by Fairey IIIDs.

Due to the rate of attrition caused mainly by carrier deck landing damage, and despite the availability of sixteen spare Panther airframes produced at Pilton, relatively few of the type survived to be offered on the civil market. Any that did were sold privately by the Aircraft Disposal Company. One such machine, G-EBCM, was converted purely to take part in the Royal Aero Club race meeting held at Croydon on 17 April, 1922. This particular Panther (ex-N7530) had first been completed at Filton on 23 June, 1920 and first flew in its civil guise on 13 April, 1922. Four days later it flew in the Royal Aero Club race piloted by A F Muir.

The Panther did arouse the interest of some foreign observers, among them representatives of the United States Navy and the Imperial Japanese Navy. The US Navy placed an order for two Panthers which were allotted the US Naval Flying Corps serial numbers A.5751 and A.5752. Both machines were shipped to the United States during 1920, and were fitted with the 230 hp Bentley B.R.2 rotary engine, hydrovanes and the Isle of Grain flotation gear. In view of the subsequent trials that both of these aircraft underwent in the United States, the Parnall Panther can justifiably be regarded as one of the founder types of aeroplane that helped to develop naval aviation in the USA.

Meanwhile the Imperial Japanese Navy was keen to build up its naval aviation potential. During 1921 a British Air Mission, headed by Col The Master of Sempill, arrived in Japan. Their purpose was to advise on the most suitable and best equipment with which the Imperial Japanese Navy could establish its new air arm. The result was a number of British aircraft types being ordered for service with the Japanese Navy. Among these were twelve Parnall Panthers, all of which were fitted with horn-balanced rudders, and these machines served for some time with the Japanese Fleet from a base at Yokosuka.

Despite any shortcomings it possessed, there is little doubt the Parnall Panther played an important part in the development of carrier deck flying techniques, and it was an early factor in the evolution of the carrier-borne strike aircraft which were to participate so vitally in the war at sea two decades later.

Parnall N.2A Panther

Two-seat carrier-borne Fleet Spotter and reconnaissance biplane. 230 hp Bentley B.R.2 nine-cylinder air-cooled rotary engine.

Span 29 ft 6 in; length 24 ft 11 in; length folded 14 ft 6 in; height 10 ft 6 in; chord 6 ft 3 in; maximum gap 6 ft 3 in; minimum gap 6 ft 2 1/2 in; wing area 336 sq ft; aileron area (each of four) 11.3 sq ft; tailplane span 12 ft; tail plane area 18.4 sq ft; total elevator area 19.3 sq ft; fin area 6.85 sq ft; rudder area 4.4 sq ft.

Empty weight 1,328 lb; loaded weight 2,595 lb. Gross weight of civil Panther 2,369 lb.

Maximum speed 108.5 mph at 6,500 ft, 103 mph at 10,000 ft; climb to 2,000 ft, 2 min 20 sec; to 6,500 ft 9 min 20 sec, to 10,000 ft 17 min 5 sec; service ceiling 14,500 ft, endurance 4 1/2 hr. One .303-in pillar-mounted Lewis machine-gun in rear cockpit. First prototype had one fixed forward-firing .303-in Vickers machine-gun on port side of pilot's cockpit.

Production

Six prototypes.

Описание:

- K.Wixey Parnall Aircraft Since 1914 (Putnam)

- J.Bruce British Aeroplanes 1914-1918 (Putnam)

- O.Thetford British Naval Aircraft since 1912 (Putnam)

- O.Thetford Aircraft of the Royal Air Force since 1918 (Putnam)

- H.King Armament of British Aircraft (Putnam)

- G.Swanborough, P.Bowers United States Navy Aircraft Since 1911 (Putnam)

- Jane's All The World Aircraft 1919

- A.Jackson British Civil Aircraft since 1919 vol.3 (Putnam)

Фотографии

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

Powered by a 230 hp Bentley B.R.2 rotary engine, the Panther was Harold Bolas's first design for Parnall. Seen here is the prototype N.91. It has the .303-m Vickers machinegun fitted to the upper port side and hydrovane had not been fitted at that time.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

The prototype Panther, N.91. On this machine the pilot's forward-firing Vickers machine-gun is fitted in the original port side position; this gun was removed later, and did not appear on subsequent models. Note the absence of a hydrovane, and the .303-m Lewis machine-gun in rear cockpit. The Parnall trade insignia appears on rear of the fuselage.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

This rare print purports to be an in-flight view of the Parnall Panther prototype N.91. It is in fact a faked picture; nevertheless it depicts well the Panther's pronounced humped profile.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

A prototype Parnall Panther with inflated Isle of Grain style flotation bags. The hydrovane forward of the wheels, the humped fuselage and the starboard side strut carrying the propeller for actuating the wind-driven fuel pump are all visible.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

One of the first three prototype Panthers is seen here at the Isle of Grain RNAS. The Parnall-type flotation bags are inflated, one under each lower wing, plus one between the undercarriage legs.

-

J.Bruce - British Aeroplanes 1914-1918 /Putnam/

Parnall Panther. The sixth prototype with hydrovanes fitted and air bags inflated.

-

Jane's All The World Aircraft 1919 /Jane's/

Three-quarter front view of the Parnall "Panther" Ship Plane (230 h.p. B.R.2 engine). The machine is here shown with air bags inflated for flotation purposes, and the hydrovanes on the chassis can be clearly seen.

-

Jane's All The World Aircraft 1919 /Jane's/

Three-quarter rear view of the Parnall "Panther", with fuselage folded for stowage on shipboard.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

The novel way in which the fuselage of the Panther was hinged to allow for stowage of the type aboard ship can be clearly seen in this photograph of the sixth and last prototype N.96 (Parnall c/n P.707). The flotation bag in the rear of the fuselage is just visible.

-

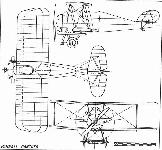

Журнал - Flight за 1919 г.

Fig.10. - Typical monocoque fuselage. Parnall Panther.

-

Jane's All The World Aircraft 1919 /Jane's/

The curious Tail Unit of the Parnall "Panther".

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

When the fuselage of the Panther was completely disconnected, it could be transported by lorry as shown here.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

A production Panther.

-

G.Swanborough, P.Bowers - United States Navy Aircraft since 1911 /Putnam/

A US Navy Parnall Panther with Grain flotation gear.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

Although contracted to the Bristol Aeroplane Co, this production Panther, N7406, (Parnall c/n P.1/10650) is under construction at the Coliseum works of Parnall & Sons, Park Row, Bristol.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

A Bristol-built Panther about to touch down on HMS Argus.

-

J.Bruce - British Aeroplanes 1914-1918 /Putnam/

This photograph of a Parnall Panther aboard HMS Argus illustrates well the longitudinal arrester wires, the hinged wooden flaps mounted transversely, the hooks on the axle and the forward hydrovane. The period was 1919-20.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

Two views of Bristol-built Panther N7425 on HMS Argus. The longitudinal wires were the cause of many damaged aircraft.

-

O.Thetford - British Naval Aircraft since 1912 /Putnam/

Panther (N7511) with non-standard oleo undercarriage.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

A Panther with the modified undercarriage struts and deck-landing hooks beneath the axle. Just visible is the lowered trailing-edge section in the upper centre-section to allow the pilot entry into the cockpit.

-

K.Wixey - Parnall Aircraft since 1914 /Putnam/

This updated Panther has a modified horn-balanced rudder and oleo undercarriage legs. A Blackburn Dart is in the background.

-

A.Jackson - British Civil Aircraft since 1919 vol.3 /Putnam/

Parnall Panther

-

O.Thetford - British Naval Aircraft since 1912 /Putnam/

Parnall Panther