Описание

Страна: Германия

Год: 1917

Истребитель

Варианты

- Fokker - D.VII / V11 / V18 / V22 / V24 - 1917 - Германия

- Fokker - C.I / C.II / C.III - 1918 - Германия

- Fokker - V34 / V36 / D.IX - 1918 - Германия

- Huffer - HSD.II / H 9 - 1924 - Германия

- В.Кондратьев Самолеты первой мировой войны

- В.Шавров История конструкций самолетов в СССР до 1938 г.

- А.Александров, Г.Петров Крылатые пленники России

- A.Weyl Fokker: The Creative Years (Putnam)

- J.Herris, J.Leckscheid Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI (A Centennial Perspective on Great War Airplanes 55)

- J.Herris, J.Leckscheid Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII (A Centennial Perspective on Great War Airplanes 55b)

- J.Herris Fokker Aircraft of WWI. Vol.6: Foreign Service (A Centennial Perspective on Great War Airplanes 56)

- C.Owers Fokker Aircraft of WWI. Vol.7: Postwar (A Centennial Perspective on Great War Airplanes 67)

- J.Forsgren Swedish Military Aircraft 1911-1926 (A Centennial Perspective on Great War Airplanes 68)

- Z.Czirok German Aircraft in Hungarian Service (A Centennial Perspective on Great War Airplanes 92)

- O.Thetford, P.Gray German Aircraft of the First World War (Putnam)

- W.Green, G.Swanborough The Complete Book of Fighters

- G.Swanborough, P.Bowers United States Navy Aircraft Since 1911 (Putnam)

- L.Andersson Soviet Aircraft and Aviation 1917-1941 (Putnam)

- P.Grosz, G.Haddow, P.Shiemer Austro-Hungarian Army Aircraft of World War One (Flying Machines)

- E.Hauke, W.Schroeder, B.Totschinger Die Flugzeuge der k.u.k. Luftfahrtruppe und Seeflieger 1914-1918

- Журнал Flight

-

Сайт - Pilots-and-planes /WWW/

Early Fokker D.VII in the factory scheme with the early style of crosses.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Fokker D.VII 262/18 of Emil Thuy

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII 382/18 of Lt. Georg von Hantelmann, flown by Lt. Kurt Wusthoff, Jasta 15, JG II, 17 June 1918. Von Hantelmann scored 25 victories and was recommended for the Pour le Merite but Germany's collapse prevented it.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII 402/18 of Vfw. Max Holtzem of Jasta 16b, summer 1918.

-

Сайт - Pilots-and-planes /WWW/

Early Fokker D.VII of Jasta 16b.

-

Сайт - Pilots-and-planes /WWW/

Early Fokker D.VII al Jasta 16b.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D. VII (Alb) 652/18 “L" of Lt. Fritz Krautheim, Jasta 23

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (Alb) 697/18 of Oblt. Robert Greim, Staffelfuhrer of Jasta 34b

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII(Alb) 817/18 Nickchen IV of Offzstv. Fritz Blumenthal, Jasta 53

-

Сайт - Pilots-and-planes /WWW/

Nickchen IV flown by Fritz Blumenthal of Jasta 53

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (Alb) 883/18 of Oblt. Robert Greim, Staffelfuhrer of Jasta 34b

-

Сайт - Pilots-and-planes /WWW/

A Fokker D.VII (1450/18) piloted by Hans Shultz when it was shot down by Lt C.H.R. Lagesse of 29 Sqdn.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (O.A.W.) 2035/18 of Lt.d.R. Rudolf Windisch, Jasta 66. Windisch scored 22 victories and was awarded the Pour le Merite.

-

Z.Czirok - German Aircraft in Hungarian Service /Centennial Perspective/ (92)

German Fokker D.VII 5146/18 captured by Hungarians coming from the Balkans with the marking of the skull and crossbones

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (Alb) 5278/18 ‘Hertha’ of 21-victory ace Lt. Friedrich Noltenius, Jasta 27, 21 total victories, 8 balloons. Original markings.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII(Alb) 5278/18 Hertha., unknown pilot, Jasta 27. Later markings.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (Alb) "RK" flown by Lt.d.R. Richard Kraut of Jasta 63

-

J.Herris - Development of German Warplanes in WWI /Centennial Perspective/ (1)

This Fokker D.VII, flown by Lt. Richard Kraut of Jasta 66, was brought to Canada as war booty after the armistice. The Fokker D.VII made a dramatic impact on the air war over the Western Front; German pilots doubled their rate of scoring victories after they started flying it. It outperformed the Albatros in all respects, especially maneuverability, and was much stronger, so structural failures were no longer a concern for the pilots, enabling them to fly the airplane to its limits. These qualities were primarily due to the innovative wing design.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII(O.A.W.) 6340/18 of Lt. Hermann Becker, Staffelfuhrer of Jasta 12, JG II.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (O.A.W.) 6372/18, Oblt. Amandus Rostock, Jasta 76

-

Сайт - Pilots-and-planes /WWW/

Fokker D.VII (OAW 8425/18), this machine was turned over to the British at the end of the war.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII(OAW) “Du doch nicht!” of Ltn. Ernst Udet, who was the highest scoring ace to survive the war with 62 victories. His fiancee’s nickname “Lo!” appeared on his aircraft from mid-1917 until the end of the war.

Interpretation of "Du doch nicht!!" showing the Jasta 4 unit marking of a black nose -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

"Du doch nicht!!" in the all-red Geschwaderfuhrer scheme

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII "U.10" of Lt. Heinz Freiherr von Beaulieu-Marconnay before capture and as now restored in the NASM.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII "U.10" of Lt. Heinz Freiherr von Beaulieu-Marconnay after capture and the insignia of the 95th Aero Squadron was applied.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (O.A.W.) of Uffz. Alfred Bader of Jasta 65. Bader scored 2 victories.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (O.A.W.) of Lt. Hans Besser of Jasta 12. Besser downed at least 2 Liberty planes.

-

R.Bennett - Last Gathering of Eagles 1918-1920 /Aeronaut/

Fokker D.VII (OAW), Fl. Abt. 418, 1919

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII of Lt.d.R. Hans Kirschstein, Jasta 6. Kirschstein scored 27 victories and was awarded the Pour le Merite before being killed in a flying accident as a passenger.

-

В.Кондратьев - Самолеты первой мировой войны

Фоккер D.VII, пилот - лейтенант У.Неккель, осень 1918г.

-

В.Кондратьев - Самолеты первой мировой войны

"Фоккер" D.VII, пилот Готтард Заксенберг из 1-й морской истребительной эскадрильи (Marine Jasta 1), лето 1918г. Капот мотора снят для улучшения охлаждения.

-

Сайт - Pilots-and-planes /WWW/

Fokker built D.VII flown by Wilhelm Hippert of Jasta 74.

-

W.Green, G.Swanborough - The Complete Book of Fighters

D VII of Ltn Veltejns, Jasta 15, summer 1918.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VIIF of Lt. Olivier Freiherr von Beaulieu-Marconnay, Jasta 19, JG II, who scored 25 victories and was nominated for the Pour le Merite.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII(O.A.W.) of Lt. Franz Buchner, Staffelfuhrer of Jasta 13, JG II, September - November 1918.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (Alb) of Lt. Carl Degelow, Staffelfuhrer of Jasta 40. Degelow scored 30 victories and was awarded the Pour le Merite.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII (OAW) in the unit colors of Jasta 18 (vermillion red forward fuselage and white rear fuselage). The additional personal markings of the black skull and crossbones and black framed fuselage are of eight victory ace Ltn. Kurt Monnington. Monnington scored 8 victories.

-

R.Bennett - Last Gathering of Eagles 1918-1920 /Aeronaut/

Lt. d. R. Otto Weisshaar Fokker D.VII, FA Haas

-

R.Bennett - Last Gathering of Eagles 1918-1920 /Aeronaut/

Comet-marked Fokker D.VII, FA Haas

-

R.Bennett - Last Gathering of Eagles 1918-1920 /Aeronaut/

Fokker D.VII (OAW) Ltn. Richard Kraut, Fl. Abt 434 / Truppenfliegerstaffel, 9 Graudenz, 1919.

-

R.Bennett - Last Gathering of Eagles 1918-1920 /Aeronaut/

Fokker D.VII (OAW), Fliegerhorst Horst, Emscher, March 1920

-

R.Bennett - Last Gathering of Eagles 1918-1920 /Aeronaut/

Fokker D.VII (OAW) 8453/18, FA 410/Artillerie-Fliegerstaffel 120, Grenzschutz Allenstein, Deuthen, 1919

-

Сайт - Pilots-and-planes /WWW/

A Fokker built D.VII flown by the Polizerflieger (Air Police) Staffeln at Paderhorn during the early 1920s.

-

Сайт - Pilots-and-planes /WWW/

Fokker D.VII

-

Сайт - Pilots-and-planes /WWW/

Ear y Fokker D.VII belonging to Oblt Karl Bolle of JG 2. Bolle finished the war with 36 victories.

-

Z.Czirok - German Aircraft in Hungarian Service /Centennial Perspective/ (92)

German-built Fokker D.VII w/n 3867 with the early Czechoslovakian national markings after its capture. The plane served in this form from 1919 until October 1921, and the number 38.67 was painted on the fuselage at the end of 1919

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII 38.67, Czech Air Service, September 1921, Racing '16' applied for the First Air Meeting.

-

Z.Czirok - German Aircraft in Hungarian Service /Centennial Perspective/ (92)

The four-color scheme of green/ochre/brown and silver underneath with Czechoslovak flag marking was used on Fokker D.VII w/n 3867 from 3rd June 1922 until the end of its career. The number 38.67 was repainted on the fuselage; it is visible on a photo dated 29th July 1923 but was later replaced by the marking of the flying school at Cheb (white rectangle)

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Belgian D.VII bearing the thistle insignia of the 9th Escadrille.

-

W.Green, G.Swanborough - The Complete Book of Fighters

A D VII of the Belgian Aviation Militaire, Bruxelles-Evere, July 1919.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Belgian D.VII bearing the penguin insignia of the Wevelgem pilot's school.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Belgian D.VII bearing the Comet insignia of the 10th Escadrille.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VIIF 937 (ex-7716/18) after being flown to Sweden by ex-JG I leader Herman Goring. It was purchased and repainted in Swedish Air Service markings and used as a trainer. 1920.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VIIF 7716/18 Flown to Sweden by Hermann Goring

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII (OAW) sent to Canada postwar and flown by Major William G. Barker VC in the Toronto to New York air race of 1919. 50 was the roughly painted number he was assigned for the race.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Finnish D.VII (OAW) 8545/18 '1C357'

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Latvian D.VII (OAW) '4' (ex-8595/18)

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

French D.VII (OAW) 6557/18

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Netherlands D.VII LVA No. 251 with early form of national insignia.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII 265 of Netherlands LVA

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII F-302 of Netherlands KNIL.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII (O.A.W.) 22.04 (ex-8588/18), 2/Lt. Antoni Bartkowiak, 15 Eskadra Mysliwska, Lewandowka Aerodrome, Autumn 1920

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII (OAW) CWL No. 22.05 “Memento Mori" belonging to the 13th Fighter Squadron (13.EM). At that time, the planes of this squadron had personal emblems painted on the aircraft sides. The aeroplane was in original finish from the OAW factory.

-

A.Olejko - War Wings Over Galicia 1918-1919 /Aeronaut/

Fokker D.VII of the 13th Fighter Squadron, 1920. The aircraft had a characteristic pilot's personal emblem - a skull with crossbones and the inscription Memento mori.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII 502/18 flown by Lt Wojciech Bialy, 15 Eskadra Mysliwska, Lewandowka Aerodrome, August 1920

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII (SLL No. 503/18) "Bi-Ba-Bo", belonged to pilot Lt. Jozef Hendricks, 15. Fighter Squadron (15.EM), August 1920. The “Bi-Ba-Bo" cupie doll was designed specifically by Mundek Dumnicki student and graduate of the Krakow Academy of Fine Arts for instructor Adam Haber-Wtyhski pilot of the school in Lawica before the plane was sent to 15.EM at the front.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VIIF 5768/18 Polish Air Service

-

P.Grosz, G.Haddow, P.Shiemer - Austro-Hungarian Army Aircraft of World War One /Flying Machines/

Fokker D.VII(MAG) 93.07

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII 93.08, 8th Squadron, Red Hungarian Air Service Matyasfold aerodrome, April 1919

-

D.Mechin - Foreign Fronts of the French Air Force 1914-1919 /Aeronaut/

Fokker D.VII of the 8th Voros Repuloszazad in May 1919.

-

Z.Czirok - German Aircraft in Hungarian Service /Centennial Perspective/ (92)

German-built Fokker D.VII w/n 3867 with the original four-color lozenge camouflage and the Hungarian red star in May 1919

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII Nr.5, Lithuanian Air Service, 1927

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII(OAW) 2113/18 USAS, Post Field, Oklahoma, circa 1920

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Modified Fokker D.VII used for testing by the Packard Motor Company to test performance of the Packard V-12 Aero engines.

Fokker D.VII AS94034, USAS, McCook Field, 1923 -

J.Herris - Fokker Aircraft of WWI. Vol.1: Spinne - M.10 & Watercraft /Centennial Perspective/ (51)

Fokker D.VII replica at the National Museum of the USAF; the aircraft is painted in colors of Lt. Rudolf Stark, commander of Jasta 35,11-victory ace, and author of Wings of War, a noted memoir of wartime flying. The Fokker D.VII was Fokker's masterpiece. Most D.VII fighters used the 170 hp Mercedes D.IIIa engine; those powered by the over-compressed 185 hp BMW.IIIa were probably the best fighters to see combat during the Great War. The D.VII vindicated Fokker.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Reproduction Fokker D.VII displayed in authentic camouflage and markings at the USAF Museum.This D.VII is in the colors of Lt. Rudolf Stark, Jastafuhrer of Jasta 35b ('b' indicating a Bavarian unit), 11 victory-ace, and author of the postwar book Wings of War.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

The fully restored D.VII in the RAF Museum's facility at Hendon in 2012.

-

J.Herris - Fokker Aircraft of WWI. Vol.1: Spinne - M.10 & Watercraft /Centennial Perspective/ (51)

Fokker D.VII "U.10" surrendered to pilots Sewall, Curtis, and McLanahan of the 95th Aero Squadron when it landed on their airfield a few days before the war ended. It has been restored to its original colors and is on display at the NASM.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

The "Knowlton Fokker" D.VII in its museum in Canada. This is one of the most authentic original Fokker D.VII fighters in existence and shows one variation of the original printed camouflage fabric applied to the D.VII (with some patches).

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII(Alb) 6810/18 preserved in its original finish at Knowlton.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Fokker D.VII(Alb) 6810/18 preserved in its original finish at Knowlton.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Top: Completed aircraft on display. Bottom: Aircraft during restoration.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

The Museum's facility at Flugwerft Schleissheim in Oberschleissheim, now houses the D.VII. It is seen on display in 2016 with a reproduction Otto pusher.

Другие самолёты на фотографии: Otto Doppeldecker - Германия - 1912

-

J.Herris - Development of German Warplanes in WWI /Centennial Perspective/ (1)

This D.VII replica is seen here painted in Jasta 6 markings. This D.VII was one of three reproductions built for the film, The Blue Max. Purchased by Javier Arango, it was re-sold to The Vintage Aviator, Ltd. in New Zealand and was reworked. It now is a frequent flier at airshows along with both Pfalz D.III replicas from the same film.

-

J.Herris - Development of German Warplanes in WWI /Centennial Perspective/ (1)

The greatest result of the Fighter Competitions was the iconic Fokker D.VII, widely regarded as the best WWI fighter. Here a beautiful replica in a representative color scheme is shown in its element.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Replica Fokker D.VII in the colors of one of Ernst Udet's aircraft.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

The restored ex-Mantz Fokker D.VII that is now displayed at the Nationale Militaire Museum in the Netherlands.

-

W.Green, G.Swanborough - The Complete Book of Fighters

A restored Albatros-built D VII in early Luchtvaartafdeling markings and originally one of 142 shipped to the USA in 1919.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

The restoration of LVA Fokker D.VII No. 266: This Fokker D.VII has been variously known as (Alb) 2528/18 (w/n 504); '7745/18'; N4729V and N6268. It is now resplendent in the colours of the LVA D.VII No. 266 The history of this particular machine is covered in the USA section, however, as it now resides in the Nationaal Militair Museum as a LVA machine, the restoration photographs are presented here.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

A Fokker D.VII tubular steel fuselage and tailplane survived for many years suspended in the vaulted hall at the Dubendorf military airfield. This was one of the D.VII fighters constructed by Alfred Comte. Reconstructed with new wings, etc., the restored aircraft is displayed in the Flieger Flab Museum, Dubendorf, bearing the false serial No. 640.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

Mantz's original D.VII (NX-3764) with 220-hp Hispano-Suiza engine bore this colour scheme for a number of years.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

This was the last scheme that the aircraft wore before going to the Netherlands - a tribute to Ernst Udet.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

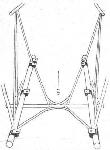

The Fokker V11, works number 1883, participated in the First Fighter Competition powered by a 160 hp Mercedes D.III engine. It is seen here in its original form with short fuselage and no fixed fin, clear indication of its Triplane heritage. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Fokker V11 in its original form. There was no central cut-out in the wing trailing edge, and the balance portions of the elevators had straight-edged tips. The short fuselage without fixed fin made the aircraft directionally unstable and challenging to fly; it was certainly not suitable for operational use.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Fokker V11 in its original form. There is slight dihedral on the upper wing and the undercarriage axle does not have an airfoil. The nose radiator was simple and effective. The wing design was excellent both structurally and aerodynamically, being strong, relatively simple, and offering exceptional stall characteristics, (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

The Fokker V11, work number 1883, in revised form with longer fuselage that imparted greater stability. (Peter M. Grosz Collection/STDB)

The modified V.11 with revised ailerons and new tail unit. The upper wing has been moved aft, necessitating a small cut-out in the trailing edge to improve the pilot’s upward view. -

A.Weyl - Fokker: The Creative Years /Putnam/

This aircraft is believed to be the second Fokker V.11, modified to production standard. It had a large exhaust manifold carrying the exhaust gases to a level above the upper wing.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

The Fokker V18 was based on the same formula as the V11 but had larger vertical tail surfaces for improved stability.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

In this front view, V18 closely resembled its sister aircraft V11. The light-colored tip of the lower left wing indicates this photo, as well as the other frontal view, were taken after the damage suffered on 25 January had been repaired.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

The Fokker V18 was based on the same formula as the V11 but had larger vertical tail surfaces for improved stability.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Fokker V18, works number 2116, at the First Fighter Competition at Adlershof in late January/early February 1918. The curved leading edge of the horizontal tailplane is in evidence. This was of a very similar shape to that seen on the Fokker F.I Triplanes. The somewhat ungainly tail fin appears to have been retro-fitted, and its shape loosely resembles a similar component seen on the earlier Fokker D.IV. Also apparent in this view is the comparatively large cut-out to the upper wing centre-section.

-

A.Weyl - Fokker: The Creative Years /Putnam/

The Fokker V.18.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Closeup of the exhaust side of Fokker V18 showing noticeable stains on the rear cabane strut. Of interest is the cut in leading edge of the metal side panel which enabled swivelling the component back into place after engine maintenance.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

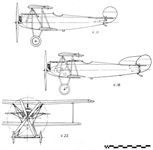

The Fokker V21 was the production prototype of the Fokker D.VII.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

The Fokker V21 was a variant of the Fokker D.VII. Old-style national insignia were applied.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

The lack of a top wing cut out would indicate that this is possibly a V.11 or V.18 that has been revised to D.VII standards. The Maltese crosses also signal its early age in D.VII production.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Front view of the Fokker V21 was essentially identical the production Fokker D.VII except for the national insignia.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Fokker V 22, Vorläufer für D.VII. Nr. 2342 (MAG 90.05). mit vierblättrigem Jaray-Propeller

Fokker V 22, предшественник D.VII. № 2342 (MAG 90.05). с четырехлопастным винтом Jaray

The V22 was a D.VII prototype with 200 hp Austro-Daimler engine and 4-bladed Jaray propeller. In an attempt to improve propeller efficiency, the blades were oriented at 70°/110° instead of the much more common 90°. The extra power of the 200 hp Austro-Daimler engine gave it much improved performance compared to the V21. It is shown here at Schwerin before shipment to Austria where it was designated 90.05. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Fokker V 22 at Schwerin in March 1918. It was powered by a 200 hp Daimler engine and armed with two synchronized Schwarzlose M16 machine guns. In all other respects the airframe was similar to the Fokker D. VII.

The V22 was a D.VII prototype with 200 hp Austro-Daimler engine and 4-bladed Jaray propeller for evaluation by the Austro-Hungarian Fliegerarsenal. The extra power of the 200 hp Austro-Daimler engine gave it significantly improved performance compared to the V21. The Austrian authorities were concerned about the lack of steel tube, but after Germany agreed to supply sufficient steel tube for production - and Lt. Mallinkrodt's demonstration of the aircraft to the LFT chief - the aircraft was chosen for Austro-Hungarian production. The all-wood Pfalz D.XII was also considered for production because Austria had plentiful supplies of wood, but the Fokker had better flying qualities. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Close-up of the Fokker V 22 showing how the Austro-Daimler engine was enclosed by a smooth, close-fitting cowling, typical of the early Fokker D.VII aircraft. The four-bladed propeller was constructed and shipped in two pieces, then bolted together on the propeller shaft.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Closeup of V22 tail assembly; Fokker D.VII 241/18 is in the background.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Tony Fokker wiping his hands after demonstrating the V 22 at Matyasfold in May 1918. A two-bladed propeller has been fitted and the standard Fokker streaked camouflage applied. In the background is the Fokker 90.03 (V7) and the Aviatik D.I(MAG) 92.14.

V22 was camouflaged before it was sent to MAG factory and designated 90.05. In this photo it has Fokker 2-bladed propeller. Fokker triplane prototype 90.03 is in the left background. (Peter M. Grosz collection/STDB)Другие самолёты на фотографии: Aviatik (Berg) D.I - Австро-Венгрия - 1917Fokker Dr.I (Fokker Dreidecker) / V4 / V5 / V7 - Германия - 1917

-

J.Herris - Fokker Aircraft of WWI. Vol.6: Foreign Service /Centennial Perspective/ (56)

Fokker-Maschinen am MAG-Flugfeld, Fokker V 7 und Fokker V 22, im Fluge Fokker V 12

Fokker Triplane MAG 90.03 with 150 hp Steyr at center and MAG 90.05 at right.

Now designated 90.05, V22 it at right. In this photo it has Fokker 2-bladed propeller. Fokker triplane prototype 90.03 is at left.Другие самолёты на фотографии: Fokker D.VI / V9 / V12 / V13 / V33 - Германия - 1917Fokker Dr.I (Fokker Dreidecker) / V4 / V5 / V7 - Германия - 1917

-

Z.Czirok - German Aircraft in Hungarian Service /Centennial Perspective/ (92)

MAG 90.05 flys in to land; MAG 90.03 is at right. (Peter M. Grosz collection/STDB)

Im Fluge Fokker V 22, am Boden Dreidecker 90.03, Aviatik-Berg D.I 92.14, Aviatik-Berg C.I-Baureihe 91, Ufag C.I-Flugzeug 161.01Другие самолёты на фотографии: Aviatik (Berg) C.I - Австро-Венгрия - 1917Aviatik (Berg) D.I - Австро-Венгрия - 1917Fokker Dr.I (Fokker Dreidecker) / V4 / V5 / V7 - Германия - 1917UFAG C.I - Австро-Венгрия - 1917

-

A.Weyl - Fokker: The Creative Years /Putnam/

Fok. D.VII with 210-h.p. Austro-Daimler engine, photographed at Schwerin.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

V22-II with wooden fuselage & 200 hp Austro-Daimler. (Peter M. Grosz Collection/STDB)

-

P.Grosz, G.Haddow, P.Shiemer - Austro-Hungarian Army Aircraft of World War One /Flying Machines/

The second Fokker D.VII with wooden, plywood-covered fuselage photographed at the Lubeck-Travemunde factory prior to delivery on 27 August 1918.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

V22-II with wooden fuselage & 200 hp Austro-Daimler. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

V22-II with wooden fuselage & 200 hp Austro-Daimler. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

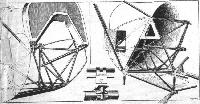

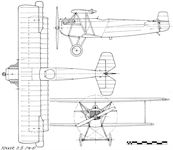

The Fokker V24 was a variant of the Fokker D.VII powered by the over-compressed 200 hp Benz Bz.IVu engine. Although offering more power, the engine was also significantly heavier, and the 185 hp BMW IIIa engine provided both better maneuverability and better performance due to its lighter weight.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Front and rear quarter views of the Fokker V24 at Schwerin before application of national insignia. Powered by the over-compressed 200 hp Benz Bz.IVu engine, it looks like a standard D.VII with more robust cowling.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Front and rear quarter views of the Fokker V24 at Adlershof after application of national insignia. The additional weight negated potential performance gains from the additional power.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

The Fokker V24 powered by the over-compressed 200 hp Benz Bz.IVu engine at Adlershof. The standard D.VII powered by the 185 hp BMW IIIa was lighter and offered better performance and maneuverability.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

Closeup view of the radiator of the Fokker V24.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

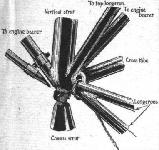

Benz Bz IVau engine in a test rig.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 1: Prototypes & D.VI /Centennial Perspective/ (55)

The Benz Bz.IV engine in the NMUSAF. (NMUSAF)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

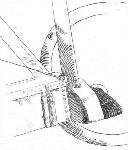

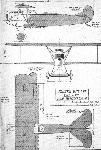

On the left side of the forward “oval” side panel, only a single rectangular service door was provided on the initial production aircraft. A small triangular access hatch, barely visible here, was installed on the upper part of the forward fabric covering of the fuselage sides. No machine gun blast tubes were fitted to this aircraft, at least when this photo was taken. These can be seen in the other photos above the engines.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Jasta 10 was most likely the first recipient of the D.VII, and it is only fitting that the earliest and lowest-numbered production D.VII known to reach the front became the plane of the Staffel commander, Lt. Erich Loewenhardt. He is seen here with his D.VII 232/18 during a visit to Jasta 19 along with fellow Jasta 10 pilot Lt. "Fritz" Friedrichs. No doubt the official reason for this was to introduce neighboring units to the new Fokker, which was actually sometimes confused with the S.E.5a. Besides the leaders streamers, only the yellow nose marking of Jasta 10 appear to have been applied to Loewenhardt's fighter, although it is possible that the rear fuselage decking and horizontal tailplane could have been yellow, too. However, no photographs showing this part of the plane clearly are available at this point, so this detail remains speculative and is based on a photo of his earlier Fokker Triplane. Detailed information about the pilot and his aeroplanes can be found in "Blue Max Airmen Volume 17".

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Seen here after arrival at the Armee-Flug-Park in the Area of the 2nd German Army, D.VII 244/18 was another example destined for Jasta 10. The Fokker works number 2329 can be read on the central "N" strut, and the military number "244" has been chalked onto the forward fuselage fabric near the wing root. Details of the Mercedes engine show well in this view. (Greg VanWyngarden)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Some of the very first Fokker-built D.VIIs carried an odd-looking hybrid version of the "Iron Cross" and "Bar Cross" national marking, which was basically an Iron Cross with straight cross arms. Most likely, this was the result of a misinterpretation of Idflieg order 41390, which regulated a new style of national marking. According to this, a straight-lined Iron Cross was to be applied in the usual positions, rather than the previous ones with curved cross arms. One can only assume that the painters at Schwerin received this order without an accompanying illustration of the new cross style, and followed the text of the order in a literal manner.

On these early planes, the bottom of the rudder was also painted in the streaked scheme of the fuselage, and the streaked camouflage applied to the fin extended up to the forward tip of the rudder. The tail cross was then centered on the white background. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

On very early D.VIIs, the forward part of the tail fin, up to the edge of the rudder, and the rudder area below the horizontal tail surfaces were also painted in the streaked scheme. On the fuselage, somewhat oddly-shaped Iron Crosses with straight cross arms are present. These may have been a result of a misinterpretation of a directive issued in March 1918 which required a change from the Iron Cross national marking to the Balkenkreuz format. The wing crosses are still the usual Iron Crosses with white outline. (Greg VanWyngarden)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Seen almost from the same perspective but almost four months later, 244/18 is seen here in the markings of Lt. Alois Heldmann. Jasta 10 upgraded to the BMW-powered D.VIIF in late July, so Heldmann's aircraft could be made available to Lt. Lothar von Richthofen when he unexpectedly returned to the Jagdgeschwader on 25 July 1918. He had recovered from a broken jaw, an injury received as a consequence of a crash in a Dr.I on 13 March 1918. (Peter M. Grosz Collection/STDB)

-

Сайт - Pilots-and-planes /WWW/

Oblt Lothar von Richthofen is standing next to his D.VII (244/18).

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Supposedly these photos were taken on 25 July 1918, after he had scored his 30th aerial victory, which also turned out to be 500th victory credited to JG I. However, this victory was scored at around 7:50 p.m., while the lighting conditions indicate that the photos were not taken around dusk. Also visible in two of these photos is Major Albrecht von Richthofen, his father. His presence suggests that Lothar's return to the front may not have been completely surprising as was reported at the time. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Another unit that received early examples of the D.VII was Royal Wurttemberg Jagdstaffel 28w, and pictured here is 247/18 at the unit's airfield at Iseghem. All crosses on this aircraft show signs of conversion from the Iron Cross to the thick form of the Balkenkreuz marking. The Jasta 28w unit marking of a yellow horizontal tail plane with a black bar centred on each side is visible in the upper photo.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.3: Early Biplane Fighters /Centennial Perspective/ (53)

About the first 150 D.VIIs produced by Fokker were delivered with fuselages that were painted in a streaked scheme that was similar to that of the Fokker Triplane. These streaks are usually portrayed in an olive green color. However, the upper relic photographed behind glass at the"Musee de l'Air" in Paris in July 2004 shows a second color: a dark "forest" green at left. This must have been the color that resulted in the dark streaks in photos. The olive green was probably a result of the yellowing of the clear dope applied to weatherproof the fabric. The dope yellowed within a few weeks, and light green pigments mixed into the dope would result in the "olive" green pictured.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

A new pilot pointing at his pilot’s badge, standing next to a very early Fokker D.VII with Maltese crosses changed over. The partially painted fin would indicate that this is a Fokker built machine.

Following his crash of Fokker D.VII 234/18 "Fritz" Friedrichs of Jasta 10 also flew two other D.VII's, 258/18 and 309/18. However, the poor quality of this photo does not provide enough details to identify with which of these two planes he is pictured here, along with two of his mechanics. He fell victim to one of several inflight fires that destroyed numerous Fokker D.VII's in mid-July 1918 due to self-ignition of the phosphorous ammunition. In Friedrich's case, the incident occurred on 15 July 1918 at around 8:45 p.m., while he was flying 309/18. His attempt to take to his parachute in order to escape the flames failed. (Peter M. Grosz Collection/STDB) -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Lt. Emil Thuy poses next to his personal Fokker D.VII 262/18 early in its frontline career. The aircraft was accepted at Schwerin on 11 April 1918, and in this photo the fuselage and wing crosses show signs of very careful conversion to the new "midstyle" Balkenkreuz with full white outline. The photo was taken at Iseghem airfield, where the unit was stationed until June 6, 1918. Its tempting to speculate that this photo was taken to commemorate his 20th victory on May 8, 1918. (Peter M. Grosz Collection/ STDB)

Lt Emil Thuy, as commander of Jasta 28 with his Fokker D VII, 262/18. Thuy had been given Jasta 28 after learning his craft with Jasta 21. A Pour Le Merite holder, Thuy survived the war with a confirmed 32 victories. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

A later photo of the same aircraft, taken at Aniche airfield, where the unit was based between 17 August and 01 October 1918. The crosses are now converted to the "late-style" Balkenkreuz of 8:1 proportions, the order for which was issued on 04 June 1918. The white fuselage band has received a narrow dark border of unknown color, possibly red, and the rudder cross has been enlarged. The machine guns have received the addition of a telescopic gun sight and streamers are fitted to the rear interplane "N" strut. On 16 September 1918, Thuy scored his 30th victory, and he ended the war with a score of 35 confirmed aerial victories. (Peter M. Grosz Collection/ STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

We have to thank the great pioneer of German WWI aviation Alex Imrie for bringing the wartime memories and photographs of Jasta 11 pilot Willi Gabriel to public attention. Gabriel joined Jasta 11 on 17 May 1918, just after the unit converted to the D.VII, coming from Schlachtstaffel 15. Here he proudly poses with his first D.VII, 286/18, which was initially marked with the unit's red nose and his personal markings of light blue and orange stripes. The markings of this plane underwent a bit of an evolution, a lengthwise orange stripe was later added to the fuselage sides. (Alex Imrie Collection)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Five Fokker D.VIIs from Jasta 11 are preparing for a mission at Beugneux airfield in June 1918. At left is 286/18, the personal plane of 11 victory ace Vfw. Willi Gabriel, who is in the process of putting on his flying kit by the left wingtip. By now he had a lengthwise orange stripe added to the fuselage. The third plane in the lineup appears to be that of Lt. Werner Steinhauser, who is known to have had red and golden-yellow stripes applied to the tails of his aircraft. He was credited with ten victories and is thought to be the first pilot of Jasta 11 to be killed while flying the D.VII, crashing fatally at around 8:00 a.m. on 26 June 1918. (Alex Imrie)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Thanks to the research of the much-missed historian Alex Imrie, Willi Gabriel's Fokker D.VII 286/18 was the first Jasta 11 D.VII to be documented in detail. Besides the red nose marking of Jasta 11, he had the tail section painted in light blue and orange stripes. When photographed, a lengthwise orange stripe had been added to the middle of the fuselage and the fuselage decking. Gabriel was credited with ten victories while flying with the Staffel between 19 May and 18 July. Soon after, a row with the new commander of Jagdgeschwader I, a certain Hermann Goring, over the confirmation of a victory claim, caused Gabriel to be transferred to AFP 2. He would not see frontline service again. (Alex Imrie)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

On the last 60-or so Fokker D.VIIs in the streaked fuselage scheme the military number was applied in white paint. 332/18 was one of these planes, and it was operated by Jasta "Boelcke". An usual detail applied to the D.VIIs operated by this Jasta was the fact that the streaked forward section of the tail fin of their Fokker-built aircraft was overpainted white. (Peter M. Grosz Collection/STDB)

-

Сайт - Pilots-and-planes /WWW/

353/18, an early standard Fokker D.VII with a 160-hp Mercedes engine in the factory standard vertical Green streaked camouflage on the fuselage and 45 degree streaks on the horizontal top wing and tail surfaces.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII 373/18 was the personal plane flown by Uffz. Heinrich Piel, who served with Jasta 13, which was a component unit of Jagdgeschwader II. The white military number is barely visible below the blue fuselage paint, which was the Geschwader color of JG II at the time. The aircraft was accepted at Schwerin on 11 May 1918. Photographs indicate that Piel flew two different D.VIIs carrying similar stork markings, but it is not known if he was killed on 29 June 1918 while flying 373/18 or the other D.VII. The two small cooling slots, seen on the engine side panel with their openings facing forward, were an innovation of a JG II Werkmeister. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

A rare line-up of Jasta 11 BMW-powered D.VII fighters allows for a highly interesting insight into the application of military numbers on early Fokker-built aircraft. D.VII 377/18F (accepted on 15 May 1918), seen at left, is thought to have been the second-to-last aircraft carrying the white serials, and it still carries the streaked fuselage factory scheme, Right next to it, D.VII 325/18F (accepted on 04 May 1918) appears in a very similar factory scheme, and the application of the "F" behind the number was apparently limited to the planes up to D.VIIF 378/18. The third plane from left, D.VIIF 460/18 (accepted 06 June 1918), is known to have been the personal plane of Lt. Erich Just, and the "F" is now applied between "D.VII" and the military number, which was the usual style of application on all later BMW-powered machines. (Greg VanWyngarden)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Factory-fresh 379/18 was accepted at Schwerin on 10 May 1918 and had been set up to be photographed for posterity in a very careful manner. This was most likely the first D.VII to have the fuselage covered in the by then common polygon-dyed aviation fabric, in this case the four-color variation was applied. The military number has now again been applied in black, and it would continue to be applied to do in this way until production at Schwerin ceased. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

The misinterpretation of the previously mentioned order was quickly rectified, and the straight-armed "Balkenkreuz" began to appear. Also decreed by this order was that a white border measuring 15 centimeters was to be applied around the cross. Since the instructions were not very well formulated, a great deal of confusion was caused, and this resulted in the application of crosses that appeared rather "fat". Often, a far bigger white border was applied, and, from a distance, the black crosses would hardly be visible against this white background, this being especially true for the fuselage cross.

On Fokker-built aircraft, the forward part of the tail fin was left in four- or five-color aircraft fabric, only the rear part of the fin was painted white. On all Schwerin-built VIIs marked with the tail Balkenkreuz, this marking was applied in the position shown in the photo, very close to the rudder/tail fin hinge line.

The style of application of the military number is interesting, it reads "Fok.D VII 379/18." on this aircraft. Barely visible at the bottom of the rudder, hidden in the shadow cast by the horizontal tailplane, is the Fokker factory serial number 2466. The aircraft was accepted on 10 May 1918. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Lt. Gustav Fraedrich poses next to Mercedes-powered Fokker D.VII 383/18, which is the third aircraft seen in the line-up.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Ten Fokker-built D.VII's of Jasta 72s are lined up perfectly for the benefit of the photographer at Bergnicourt airfield in July 1918. Closest to the camera is D.VII 401/18 "M"(accepted 17 May), the Mercedes-powered aircraft flown by the unit commander and Pour le Merite ace Lt. Karl Menckhoff. At the time, Menckhoff also had BMW-powered D.VIIF 502/18 (accepted 19 June) at his disposal, this plane being marked in an almost identical way as 401/18. For some reason, it is now seen in this line-up shot. The fourth aircraft from the end of the line-up is D.VIIF 494/18 "F"(accepted on 17 June), which was the BMW-powered D.VII flown by Lt. Gustav Fraedrich. He would take command of the unit on 23 October 1918 and survived the war with a total of six confirmed victories.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Two-thirds of production Fokker D.VII fighters were powered by the Mercedes D IIIa and one third by the over-compressed BMW IIIa. Here is a lineup of D.VII fighters at Jasta 72 with the Staffelfuhrer's aircraft at left. Carl Menckhoff, the Staffelfuhrer, achieved 39 victories and won the Pour le Merite.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VII 402/18 is seen here at the local Armee-Flugpark before delivery to a Jagdstaffel. The aircraft was accepted on 21 May 1918, and it is covered in five-color dyed fabric. At the time, the thick white "Balkenkreuze" were applied at the factory to both the fuselage and wings. On the rear fuselage, below the tailplane, a chalked marking reading "X gut" is visible. This indicated that the aircraft had been checked and was ready to be picked up by a Jagdstaffel pilot. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

The recipient of this aircraft was Vzfw. Max Holtzem, who flew with Jasta 16b. Holtzem added his personal marking of a comet to the fuselage sides, which symbolized "Good Hope" to him. The nose was painted Bavarian blue, barely visible in this view, and a white-black-white band was added to the tailplane, these two details being the unit markings. This was one of several D.VIIs which featured an "open" application of the fuselage military number, i.e. the gaps left by the stencil were not filled in with black paint. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Vfw. Max Holtzem is pictured here looping his Fokker D.VII 402/18 over the Jagdstaffel 18 airfield. Holtzem earned his flying license in 1913, served as a test pilot with the Pfalz company in 1915 and eventually joined Jasta 16b in September 1917. He was born in Elberfeld (now Wuppertal) in Prussia, but since his mother was born in Wurzburg, he could claim to be half-Bavarian, enough to join a Bavarian Staffel. While he was not credited with a single confirmed victory, he remained with the Staffel until the end of the war, no doubt due to being a highly skilled pilot. After the war, he became a test pilot for Fokker in America, often flying with Anthony Fokker himself in the 1920s. Holtzem passed away in 1980. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

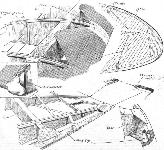

One of the greatest services Manfred von Richthofen did for Germany was instigating the fighter competitions, and the Fokker D.VII was the greatest result of those competitions. Arriving at the front days after Richthofen's death in his Fokker Triplane, he was not able to fly the D.VII in combat himself. Initially using the 170 hp Mercedes D.IIIa engine, when fitted with the superb 185 hp BMW IIIa it was arguably the best all-around fighter of the war. Here D.VII 406/18, accepted on 18 May 1918, and other D.VIIs are shipped to the front by rail two days later, on Monday, 20 May. (Peter M. Grosz Collection/STDB)

Fok. D.VII aircraft on their way to the front on railway flat wagons, June 1918. The recess in the fuselage underside that accommodated the lower wing can be seen.

Disassembled for transportation, this train load of early Fokker built D.VIIs are being shipped from the Schwerin factory to the front. One of the requirements of the Idflieg was that an aircraft could be easily and quickly disassembled for transporting. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

A mix-up of components can be seen on some D.VIIs, and the nose of D.VIIF 460/18 seen here is a good example. This was a late aircraft from the initial batch (227/18 - 526/18) featuring the same trio of louvres seen above on 507/18. The upper panel is an organ transplant donated by an aircraft from the 4250/18 - 4300/18 military numbers sequence. Originally, this aircraft also featured the “low” collector exhaust as seen above. The opening for this exhaust has been carefully faired over, the patch being just visible in the picture. A new exhaust of the “saxophone” design has been fitted as a replacement item, and the replaced upper panel may simply have been a leftover from an aircraft which had this item removed during the summer months and which been lost in combat.

-

R.Kosin - The German Fighter since 1915 /Putnam/

Fokker D.VII

-

M.Dusing - German Aviation Industry in WWI. Volume 2 /Centennial Perspective/ (85)

"Фоккер" D.VII №461/18 на испытаниях в Адлерсхофе.

A Fokker built D.VIIF with BMW IIIa(O) in the lozenge type camouflaged fabric. The lozenge pattern was printed on the fabric after it was made and before it was applied to the airframe. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

To commemorate special occasions, group photos were taken, and here pilots of Jagdstaffel 15 gather in front of Georg von Hantelmann's plane. He scored his 20th victory on 9 October 1918 at 4:15 p.m., and the lighting indicates that the photo was most likely taken on the next day. Very likely, the aircraft seen behind the men is D.VIIF 465/18, which was one of six BMW-powered D.VIIs delivered to Jasta 15 in July. Von Hantelmann was nominated for the Pour-le-Merite on 30 October but failed to receive the award due to the end of the war. Depending upon source, was credited with 25-26 confirmed and 4-5 unconfirmed victories, all of which were scored while flying D.VIIs.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Being born on 14 April 1883, Oblt. Carl Menckhoff was 35 years of age when these photos were taken in July 1918. He was given command of Jagdstaffel 72 when the unit was formed in early 1918, and was decorated with the Pour-le-Merite on 23 April 1918. The Jasta received the D.VII at an early stage, and Menckhoff had two at his disposal. By early July 1918 he was credited with 35 confirmed victories, and he then had the luxury of having two identically-marked fighters at his disposal: D.VII 401/18 and D.VIIF 502/18, seen behind him in both photos. Menckhoff was brought down on 25 July 1918 after his engine was disabled, and crashed into a tree. He was taken into captivity unharmed, with a total of 39 victories to his credit. Under his command, the Staffel was credited with 33 victories while only a single pilot was killed. (Dr. Hannes Tager)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Two views of D.VII 507/18 show the aircraft in partially-completed factory finish, the metal nose parts and the wheel covers lack paint at this stage. The machine guns also remain to be fitted, and the mix of crosses (fully outlined fuselage cross and wing crosses with 5:4 cross arm proportions) indicated that these components did not receive their national markings at the same time. This aircraft was accepted at Schwerin on 19 June 1918 and was powered by a Mercedes D.IIIa engine with the serial number 41747. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Although slower than many of its competitors, the Fokker V II prototype's easy handling and reluctance to spin endeared the aircraft to the trials pilots, unanimously adjudging it the overall winner of the first of the 1918 Alderhof fighter trials. As there was an urgent need for an initial 400 of these single seat fighters, a figure beyond Fokker's ability to meet on time, contracts were placed simultaneously with Fokker and Albatros, with AEG being drawn in later. Given the military designation Fokker D VII, the machine was powered initially by a 160hp Mercedes D III, this being soon replaced by the 185hp BMW IIIa. This latter engine pushed the top level speed up by 7mph, to 124mph at sea level and had an even more dramatic effect on the fighter's rate of climb, with the time to reach 3,280 feet dropping to 2.5 minutes from 3.8 minutes for the earlier Mercedes powered examples. Rapid as it was, with first operational deliveries being made in April 1917 to JG I, the Fokker DVII's passage into service appears to have been essentially trouble-free. Even more significantly, no subsequent fatal flaws, such as those experienced with Fokker's Dr I, were to emerge. At last Anthony Fokker and his chief designer, Reinhold Platz, had produced a real winner that would not only keep the factory full, but would soon come to earn the respect of the all the Allied pilots who encountered it. Armed with the standard twin 7.92mm Spandaus, over 800 examples of the D VII had been delivered to 48 operational Jastas by the start of September 1918. Showing off its well proportioned lines, Fokker D VII, 507/18, seen here, reportedly served with the famed Jasta Boelcke.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

The last 70-or-so examples of the first Fokker production batch received a trio of cooling louvres that were initially positioned relatively far up, as seen here on D.VII 507/18. Plastic kit manufacturers have constantly gotten this detail wrong, showing these openings in the later “low” position that was typical for the final production version. Note that the initial collector exhaust, which exited via an opening in the side panel, was actually slanted backwards. A small rectangular access hatch is positioned below the exhaust.

The rear of the chin panel was now deepened somewhat compared to the photo on the left. In the top two photos the metal nose sections were still unpainted when the photographs were taken. Before shipment to the front, these were painted dark green. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Accepted on 19 June 1918. D.VII 507/18 exhibits a fuselage cross with the correct 15 centimeter border. However, this was outdated by then, since two new orders concerning the application of national crosses had been issued in the meantime. The first, dated 15 May, only concerned the wing crosses, which were now to be applied with 5:4 proportions, resulting in a marking resembling a grave cross. Likely it was this similarity let to the issue of the third - and final - order specifying the application of national markings on 4 June 1918. According to this, the crosses were now to be marked with cross arms of equal proportions, and this resulted in the slim "Balkenkreuz" marking known from the many late-war photos of German aircraft.

Both 379/18 and 507/18 were covered in four-color polygon fabric, but this type of fabric was not applied to all aircraft of the first Fokker D.VII batch (227/18-153/18). Several aircraft were covered in five-color dyed aviatipn fabric, and sometimes fuselages, wings and ailerons were covered in either of these colors. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

The second Schwerin production batch was numbered 4250/18 to 4449/18, and pictured here is the most famous aircraft in this batch. Fokker D.VIIF 4253/18, accepted on 04 July, was the personal plane of Ernst Udet, the leader of Jagdstaffel 4, and it was photographed here when elements of Jagdgeschwader I landed at Epinoy airfield on 21 August 1918. The works number 2954 can be read on the bottom of the rudder.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

A right-side view of Ernst Udet's Fokker D.VIIF 4253/18 is pictured earlier in this book, and this photo of the plane, taken at FEA 2 in Furth in early October 1918, shows a view of the left side. Eagle-eyed readers will note that the "LO!" monogram was applied further aft on the left side, and the upper cowling panels had not been put back in place after the hot summer period had come to an end. The lower wing crosses remain in the factory-applied 5:4 proportions; nobody deemed it necessary to convert them to the equal proportions that were required for about three months. (Peter M. Grosz Collection/STDB)

Oblt Ernst Udet, seen here standing in front of his Fokker D VII 'Lo' was born on 26 April 1896 and was to become the last commander of Jasta 4, having previously served with Jastas 15, 37 and 11. At the time of the Armistice, Udet was a Pour Le Merite holder, with 62 confirmed victories, which makes him Germany's second highest scoring ace of the war after Baron Manfred von Richthofen. Udet remained prominent in post-war German aviation circles, particularly as an aerobatic pilot and lent his name to an aircraft manufacturer during the 1920s. Along with a number of other former prominent military fliers, Udet rejoined the Luftwaffe in 1935 with the rank of Generaloberst, the equivalent of a four-star general or Air Chief Marshal. Subsequently blamed for shortfalls in aircraft production, Udet took his own life on 17 November 1941. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

The first fifty-or-so aircraft from the second production batch mounted upper engine cowlings that featured six to eight cooling louvres. These can be seen here on the two Jagdstaffel 10 aircraft at Metz-Frescaty in late September/early October 1918. The machine nearest to the camera is possibly D.VIIF 4264/18, which was the personal mount of Lt. Alois Heldmann.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Jagdstaffel 4 received BMW-powered Fokkers in September, and seen here is D.VIIF 4275/18 from this batch. While out of the photo, the upper nose cowling panels would have looked very similar to the ones seen in the photo above. This was one of several Jasta 4 D.VIIs marked with colored fuselage longerons, as well as a broad fuselage band. The forward part of the tail fin, which was covered in polygon fabric on Fokker-build machines, has been overpainted in white, with a thin stripe of an unknown light color acting as a division line. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Three days after the death of Jasta 10 commander Oblt. Erich Loewenhardt on 10 August 1918, Lt. Arthur Laumann, who had previously served with Jasta 66, took command of the unit. His personal plane at Jasta 10 became Fokker D.VIIF 4282/18, and he is seen in the cockpit of this plane in this photo, which was published as a "Sanke" card.The fuselage was covered in four-color fabric.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Hermann Goring liked to use white as his personal color on many of his planes, and on Fokker D.VIIF 4283/18 the rear fuselage was painted in this color. The forward fuselage and upper wing surfaces were painted red, in order to ensure easy recognition of the JG I commander in the air, even though he flew very few combat sorties from August 1918 until the end of the war. Again, the cooling louvres in the upper cowling part can be seen. This plane has previously been misidentified as D.VIIF 4253/18, and some writers have concluded that Udet and Goring shared this plane. This is wrong, however, as the Fokker works number 2984 can be clearly seen on the bottom of the rudder in the original print. (Alex Imrie)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Names were fairly often applied to German fighter aircraft, and D.VII 4301/18 "OttO", seen here, flew with Jagdstaffel 71. This was a Mercedes-powered aircraft, accepted at the Schwerin factory on 15 July 1918, and reportedly was the personal mount of Vzfw. Otto Baurose, who served with the unit from 6 February to the end of the war. The photo was taken at Habsheim airfield. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Another unidentified Jasta 10 D.VIIF is seen here in American hands. This photo allows a better view at the cooling louvres described previously, but readers must be warned that the fuselage fabric with the small Balkenkreuz was not original. Apparently, some of the fuselage fabric was "souvenired" after capture and later replaced by the fabric seen in the photo. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

This aircraft from the second batch illustrates a shortlived addition of cooling louvres on the upper metal panel. These are noted in photos of aircraft in the military number sequence 4250/18 - 4300/18. In this photo six louvres can be seen, but this was not always the case. Other photos show eight louvres on the left and/or right side.

The opening seen below the radiator and the prop mounting were a modification carried out at Jasta level, as was the barely visible hole in the forward part of the chin panel. -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

While the military number of Fokker D.VIIF "5" serving with Jasta 26 cannot be made out, visible details suggest that is was also a plane from the 4250/18 - 4449/18 range. It appears that the fuselage band onto which the "5" has been applied was not white but of some other color that photographs light on orthochromatic film. Visiting nurses take a keen interest in the aircraft, while the Staffel's German shepherd tries to escape the summer heat in the shadow cast by the left lower wing. One must assume the nurses forgot to bring along treats for the dog since the animal seems not to be bothered by the visitors. (Greg VanWyngarden)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VIIF 4330/18, accepted on 25 July 1918, was also assigned to Jagdstaffel 4. The pilot seated in the cockpit might be Lt. Egon Koepsch, who was photographed sitting on the left wheel of this aircraft, thus it was likely his personal plane. The fuselage of this aircraft was covered in five-color dyed fabric. By this time the upper cowling panels were smooth without any factory-applied louvres, which remained the standard for the rest of the Fokker production aircraft. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

A blurred view of the same aircraft, taken at Metz-Frescaty, in late September/early October 1918. The stripes seen on the fuselage longerons of this plane were similar to the ones seen on D.VIIF 4275/18 and some other planes from the same unit. This may have been a Kette marking, although this is speculative at this point.

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VIIF 4332/18, accepted on 25 July 1918, was another Jasta 4 aircraft, being the personal mount of Lt Julius Bender. Here two of his mechanics pose next to the plane. Bender joined JG I on 31 January 1918 and was not credited with any victories. He served with Jasta 4 until the end of the war, and was described in "Jagd In Flanderns Himmel" as being one of the backbone pilots of the unit. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Ernst Udet and his groundcrew are pictured here at "Grand Metz" airfield in late September 1918. Just behind them Bender's D.VIIF 4332/18 can be seen, sporting a two-color fuselage band, most likely yellow-red-yellow, the colors of his native Grand Duchy Baden. The fuselage longerons and tailplane are also painted in a dark color, most likely either red or black. (Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VIIF 4348/18, Werknummer 3049, was accepted on 2 August 1918 and flew with Jagdstaffel "Boelcke" up until the end of the war. The identity of the pilot is not confirmed, but the personal marking of the coat of arms of Berlin was applied to the fuselage sides and decking, behind the cockpit, so one may assume that the pilot, had a connection to the German capitol. The aircraft was one of several Fokker fighters of this unit that were handed over to the RAF at Nivelles after the armistice. (Upper photo: Greg VanWyngarden, lower photo: Peter M. Grosz Collection/STDB)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

The oblique black and white stripes on the horizontal tail surfaces identify this as a former Jasta 37 machine, now in British hands after the armistice. The fuselage fabric was obviously covered in a single dark color since the fabric polygons and the military number are covered completely, but the letter "Z", painted in an even darker color shows clearly. Barely visible on the fin is the Fokker works number, which appears to read 3095. This would equate to D.VII 4394/18, accepted on 1 August 1918. The tires have been removed, and the fuselage fabric has been cut open below the cockpit, allowing a glimpse at some of the welded fuselage structure. (Greg VanWyngarden)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Fokker D.VIIF 5124/18"K" was another ex-Jagdstaffel "Boelcke" aircraft, seen here in British hands at Nivelles after the Armistice. Both the"K"and the arrow were applied in a somewhat crude manner, the style of both markings being slightly different on both sides. This aircraft was accepted on 20. September 1918 and was powered by a BMW IIIa engine with the serial number 1263. Keeping in mind that shipping time to the front was at least two weeks it can only have seen around a month of frontline service with Jasta "Boelcke" before it was handed over to the RAF. (Upper photo: Peter M. Grosz Collection/STDB, lower photo : Greg VanWyngarden)

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Командир 1-й истребительной эскадры Герман Геринг в кабине своего "Фоккера" D.VII с фюзеляжем, окрашенным в белый цвет, лето 1918 г.

Anthony Fokker was very keen to maintain good relationships with frontline pilots, even more so if they held key positions. This was apparently the reason why Fokker D.VIIF 5125/18, accepted on 10. September 1918, received such an immaculate paintjob at the factory, being painted completely in Goring's favorite color, white. The neat spinner fitted to this aircraft was manufactured be the Rupp company and was only seen on BMW-powered aircraft. This photo was taken at Marville airfield in October 1918. (Peter M. Grosz Collection/STDB) -

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

A close-up photo of this aircraft proves that it showed very little signs of use. In the closing months of the war Goring few very few (if any) combat sorties, claiming that "only from the ground he was able to see all events taking place in the air". By then, he was commanding Jagdgeschwader I, Germany's most elite fighter unit, and had been decorated with the "Pour le Merite". There was nothing more he could achieve, and that would be the more logical explanation why he avoided exposing himself to the risks of aerial combat.

-

R.Bennett - Last Gathering of Eagles 1918-1920 /Aeronaut/

Paul Aue seated on Fokker D.VII F 5136/18, apparently about to conduct a wreath dropping. The ribbon on the floral wreath bears the words "Fliegerstaffel" and "Maercker". The occasion may have been Defense Minister Noske's visit. Aue wears a looped chevron, indicating his rank of Offizier-stellvertreter in the Provisional Reichswehr. (Greg VanWyngarden)

-

Z.Czirok - German Aircraft in Hungarian Service /Centennial Perspective/ (92)

German Fokker D.VII 5146/18 with Karoly Kaszala at Matyasfold. Note the marking of the skull and crossbones. (Laszlo Winkler & Petr Lukes)

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

William Barker, with his left arm in a sling, besides Fokker D.VII F 7728/18 on Hounslow airfield on 20 April 1919. The fighter retains its twin Maxim 08/15 machine guns.

-

C.Owers - Fokker Aircraft of WWI. Vol.7: Postwar /Centennial Perspective/ (67)

7729/18 photographed at Coblenz post-Armistice

-

J.Herris, J.Leckscheid - Fokker Aircraft of WWI. Vol.5: 1918 Designs Part 2: D.VII & E.V/D.VIII /Centennial Perspective/ (55)

Many factory-fresh D.VIIs were handed over to the Entente nations following the armistice, and seen here is D.VIIF 7729/18, along with several curious American servicemen. This plane was accepted on 29 October 1918, and it was probably still on the way to one of the German Armee Flugparks when the hostilities ended. The engine powering this plane was BMW IIIa # 1626. (Peter M. Grosz Collection/STDB)

-