Книги

Flying Machines

P.Grosz, G.Haddow, P.Shiemer

Austro-Hungarian Army Aircraft of World War One

996

P.Grosz, G.Haddow, P.Shiemer - Austro-Hungarian Army Aircraft of World War One /Flying Machines/

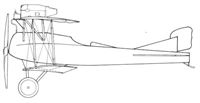

Albatros D.II(Oef) Series 53

Impressed by the successful debut of the Albatros fighters on the Western Front in August 1916 and their fine handling characteristics, the LFT and industry moved with uncommon alacrity to put the Albatros D.II and D.III fighters into production in order to meet the increasing strength of the Italians and to replace the dangerous Brandenburg D.I fighter. Oeffag, having secured license rights from the German Albatros company, had production well under way when the contract was signed on 4 December 1916, calling for 50 aircraft, originally composed of 20 D.II and 30 D.III fighters.

The Oeffag-built D.II differed but slightly from its German counterpart. The engine, a 185 hp Daimler, was more powerful. The wing chord was increased by 10mm (0.4 in) and the fuselage was slightly altered. The D.II production prototype, 53.01, first flew in January 1917. The common D.II/D.III fuselages were completed in February, but assembly of the wing cellule for both was postponed until completion of the static load tests. Flight trials were delayed by the sub-zero weather and also had to await the development of a proper radiator and selection of a suitable propeller. Finally the D.II(Oef) was released by a Flars engineering commission on 4 May 1917, whereupon 16 machines (all that were built), numbered 53.01 to 53.16, were accepted and promptly dispatched to the Front. All but two aircraft were armed with one or two machine guns fitted with the Bernatzik synchronization mechanism.

The majority of the Albatros D.II(Oef) fighters were sent to the less-active Russian Front to serve with Fliks 3, 5, 7, 10, 14, 20, 22, 25, 26, and 37. The D.II was also flown by Fliks 2, 19, 35, 41/J, 42/J, and 46 on the Isonzo Front and Fliks 21, 24, and 48 in the Tirol. Although a few victories were recorded, in general the D.II(Oef) fighter served to introduce two-seater pilots to the vagaries of handling a facile, high performance aircraft. Its operational function was well described in a Flik 37/D appreciation: "...too slow, its rapid climb has little effect because Russian aircraft practically never cross the lines; therefore the D.II mainly performs escort work." By the end of 1917, the D.II(Oef) was relegated to training duties, and two were offered for sale by the Austrian government in 1920.

Albatros D.II(Oef) Series 53 Specifications

Engine: 185 Daimler

Wing: Span Upper 8.50 m (27.89 ft)

Span Lower 8.00 m (26.25 ft)

Chord Upper 1.70 m (5.58 ft)

Chord Lower 1.70 m (5.58 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.35 m (4 43 ft)

Stagger 0.12 m (0.39 ft)

Total Wing Area 24 sq m (258 sq ft)

General Length 7.35 m (24.12 ft)

Height 2.71 m (8.89 ft)

Track 1.80 m (5.91 ft)

Loaded Weight 898 kg (1980 lb)

Maximum Speed: 170 km/hr (106 mph)

Climb 1000m (3,281 ft) in 4 min 30 sec

2000m (6,562 ft) in 7 min

3000m (9,843 ft) in 12 min 30 sec

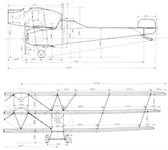

Albatros D.III(Oef) Series 53.2

Production of the Albatros D.III(Oef) had kept in step with the D.II (sharing a common fuselage, undercarriage, and tail surfaces) to enable Oeffag to switch to D.III output as soon as the static load tests of the re-designed "sequiplane" wing cellule were satisfactorily completed. Not content with the original German design, Oeffag engineers developed a stronger wing and airframe - in the process creating a tough, beautifully-built aircraft that could take increasingly more powerful engines without extensive modification. The popular Oeffag-built D.III fighter remained in production until the end of the war in three different series:

Qty Series Number Engine Order Date

34 53.20-53 185 Dm 4 December 1916

11 53.54-64 185 Dm 3 February 1917

61 153.01-61 200 Dm 3 February 1917

50 153.62-111 200 Dm 18 July 1917

100 153.112-211 200 Dm 8 October 1917

70 153.212-281 200 Dm 18 May 1918

230 253.01-230 225 Dm 18 May 1918

100 253.231-330 225 Dm August 1918

The maiden flight of the D.III(Oef) production prototype, 53.21, took place in mid-February 1917. The Flars engineering commission, after inspecting the prototype on 4 May, specified several minor modifications. Production acceptances which began on 17 May were interrupted to repeat the static load test of the wing cellule (on 26 May) as a precautionary measure triggered by reports of recurring D.III wing failures on the Western Front. The far-sighted action of Oeffag engineers was vindicated for, by refusing to copy the German wing cellule, they had made significant improvements which were outlined in an LFT report: 1) The German spars and ribs are appreciably weaker than those of the 53.2 series. 2) Ribs between the main and auxiliary spar are solid and constructed of heavier plywood. 3) Spar flange thickness is increased from 10 to 20 mm at stress points. 4) Metal reinforcing is added between the main and auxiliary spar. 5) The front auxiliary spar is prevented from twisting by a metal fixture at the fuselage juncture. The German and Oeffag-built machines were dimensionally identical, with only small variations in wingspan, gap and area. Fully loaded, the Oeffag-built D.III was heavier than the German D.III, weighing 964 kg (2126 lb) compared to the German D.Ill's weight of 912 kg (2010 lb); the difference was due to the heavier 185 hp Daimler engine. Greater power gave the D.III(Oef) series 53.2 fighter a higher rate of climb and a maximum speed of 180 km/h (112 mph), as compared with the 165 km/h of the 160 hp Mercedes-powered German fighter.

Output grew rapidly but the shortage of synchronization mechanisms, a chronic problem, forced Oeffag to manufacture precision parts to keep production moving. An enthusiastic reception met the first D.III(Oef) fighters when they reached the Front in June 1917. Finally, squadrons possessed a fighter that an average pilot could fly with relative ease and safety. By September 1917, sufficient experience had been gathered to assess the fighter's virtues and shortcomings. Although the series 53.2 and 153 were equal in speed to the Brandenburg D.I, they had a much superior rate of climb, showed excellent maneuverability and above all, were regarded as safe aircraft. Only one Flik reported lower wing vibration. At first the fighter was not fully trusted in a steep dive (nor was this recommended), but this restriction was lifted on later models. The synchronization mechanism was often unreliable, an all too common problem, and the steel-tube machine-gun supports required strengthening. A weak tail skid structure and poor quality cowling fasteners were problems quickly corrected. The 45 Albatros D.III(Oef) series 53.2 fighters were distributed among many Fliks on the Italian Front and in smaller numbers on the Russian Front. They formed the initial complement of Flik 51/J. When production ended in July 1917, the series 53.2 was replaced by the structurally identical but more-powerful D.III(Oef) series 153. With the appearance of newer fighters, the series 53.2 was used as a fighter-trainer by frontline training units.

Albatros D.III(Oef) Series 53.2 Specifications

Engine: 185 Daimler

Wing Span Upper 9.00 m (29.53 ft)

Span Lower 8.73 m (28.64 ft)

Chord Upper 1.50 m (4.92 ft)

Chord Lower 1.10 m (3.61 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.47 m (4 81 ft)

Stagger 0.22 m (0.72 ft)

Total Wing Area 20.56 sq m (221 sq ft)

General Length 7 35 m (24.12 ft)

Height 2.80 m (9.19 ft)

Track 1.80 m (5.91 ft)

Empty Weight 690 kg (1521 lb)

Loaded Weight 964 kg (1980 lb)

Maximum Speed: 180 km/hr (112 mph)

Climb: 1000m (3,281 ft) in 3 min 20 sec

3000m (9,843 ft) in 14 min 30 sec

5000m (16,405 ft) m 32 min

Albatros D.III(Oef) Series 153

As soon as it became available, the high-compression 200 hp Daimler engine was mounted in the standard production airframe and output continued under the designation Albatros D.III(Oef) series 153. Between July 1917 and June 1918 a total of 281 fighters, numbered 153.01 to 153.281, were delivered. The second production batch, starting with airframe 153.112, was designed with a rounded nose to eliminate the spinner, which was prone to fly off and damage the airframe. In addition, German wind tunnel tests had demonstrated that replacing the spinner by a simple, rounded nose improved propeller efficiency, which in this case resulted in a speed increase of some 14 km/h (9 mph). Armament consisted of two buried Schwarzlose machine guns mounted with butts projecting into the cockpit and firing through blast tubes mounted alongside the engine. The slow-firing guns and often erratic synchronization systems were universally damned by pilots, more so because the D.III was an extremely stable gun platform. When several Fliks suggested that the guns be raised to eye level, three such fighters were built by Oeffag (153.161, 153.162, 153.181) and sent to the Front for evaluation. However, raised, cowl-mounted guns were not installed on production machines until the advent of series 253 in mid-1918.

The introduction of the series 153 fighters coincided with the formation of specialized fighter squadrons, such as Fliks required performance and flight characteristics to engage in successful combat with enemy aircraft of similar type. It is the best-liked fighter at the Front." In the opinion of Offizierstellvertreter Friedrich Hefty, a Flik 42/J pilot credited with five victories, the "200 hp D.III was a superbly-designed aircraft, beautifully balanced and especially suited for aerobatics. Its rate of climb was equal to the Hanriot and the Camel, but slower in level flight than the SPAD." Every Flik lauded the D.III's all-round qualities. Not only was it robustly built and well finished (an Oeffag hallmark), but also its ease of maintenance endeared it to ground personnel. As usual the rocky airfields took their toll. In January 1918, seven Flik 55/J fighters were withdrawn for two weeks to repair rear airframe damage that occurred during take-off and landing. Oeffag raised the tail-skid support by 6 cm (2.4 in) to prevent the tail from bottoming out. Due to the temporary shortage of high-grade wing-bracing wire, some series 153 fighters were delivered in late 1917 with inferior stranded cable, which stretched to such a degree that lower wings began to vibrate in flight and allowed the wings to take on a pronounced V-form.

In January 1918, Flik 42/J, a crack unit, submitted a combat summary which stated that "enemy aircraft are encountered in flights of eight or nine machines. To attack the well-coordinated enemy with inferior numbers is a hopeless task. In doing so our squadrons suffer inevitable losses without being able to control the air. The only solution is to attack the enemy in equal numbers; only then will the effectiveness of our type 153, powered by the high-compression engine (200 hp Daimler), reach its full potential. The supply of new fighters is totally inadequate." A rough indication of the combat attrition is shown by the following statistic. In August 1918, some 142 series 153 fighters were listed in the frontline inventory; three months later, the LFT's inventory was reduced to 57 machines, of which only 12 were in flyable condition. In spite of the high losses, an important fact to remember is that in terms of victories scored, the Albatros D.III(Oef) series 153 leads the list of all Austro-Hungarian fighters. This is a tribute to the aircraft and the pilots of the specialized fighter units, especially Fliks 3/J, 41 /J, 42/J, 51/J, 55/J, 56/J, 63/J, and 68/J, who fought gallantly and held their own against great numerical odds on the Italian Front.

Albatros D.III(Oef) Series 153 Specifications (With Spinner)

Engine: 200 hp Daimler

Wing: Span Upper 9.00 m (29.53 ft)

Span Lower 8.73 m (28.64 ft)

Chord Upper 1.50 tn (4.92 ft)

Chord Lower 1.10 tn (3.61 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.47 m (4.81 ft)

Stagger 0.22 m (0.72 ft)

Total Wing Area 20.56 sq m (2.2.1 sq ft)

General: Length 7.35 m (24.12 ft)

Height 2.80 m (9.19 ft)

Track 1.80 m (5.91 ft)

Empty Weight 710 kg (1566 lb)

Loaded Weight 987 kg (2176 lb)

Maximum Speed: 188 km/hr (117 mph)

Climb: 1000m (3,281 ft) in 2 min 35 sec

2000m (6,562 ft) in 6 min 35 sec

3000m (9,843 ft) in 11 min 20 sec

4000m (13,124 ft) in 18 min 50 sec

5000m (16,405 ft) in 33 min

Albatros D.III(Oef) Series 253

On 18 May 1918, Oeffag received a contract to supply 230 Albatros D.III(Oef) series 253 fighters, numbered 253.01 to 253.230, to be powered by the improved 225 hp Daimler engine that was just entering quantity production. An additional batch of 100 series 253 fighters, numbered 253.231 to 253.330, was ordered in August with delivery scheduled to end in December 1918. Requiring only minor internal modification, the series 253 began to replace the series 153 in May 1918 and continued in production until the war ended. Counting the 30-odd machines completed after the war, Oeffag built a total of 260 series 253 fighters.

The first units to receive the new 225 hp fighter were Fliks 61/J and 63/J in mid-June 1918, whose pilots were lavish with praise. Flik 61/J labelled it as "first class and superior to any fighter." Flik 63/1 considered the new fighter as "equal to all combat requirements; it is very much liked, only the squadron does not receive sufficient numbers." By July 1918, seven fighter Fliks acclaimed the series 253 as the finest fighter they had flown. Flik 56/J reported the series 253 "meets every demand, is solid and well constructed, climbs rapidly and is preferred over the Aviatik D.I because of its peerless flight characteristics." When various LFT staff officers at the Front were asked to summarize their requirements for future planning the reply was unanimous: "Unquestionably the most maneuverable and safest fighter at the Front. It has the pilots' complete trust. Because of its excellent handling and performance, it is preferred over every other fighter. Mass production is urgent." Given full priority for materials and engines, Oeffag responded by increasing average monthly output of the series 253 by 50 percent over the series 153.

Among the 24 participants that competed in the Fighter Evaluation at Aspern in July 1918, only three were standard production machines - the Aviatik D.I 338.03 and two Albatros D.III(Oef), 253.32 and 253.35. In spite of having the highest wing loading, the Albatros fighters achieved a faster rate of climb than all other contestants with exception of the Aviatik D.I and the WKF 80.10 (D.I) prototype. Oberleutnant Benno von Fiala recommended returning the raised machine guns to the buried position (as in the earlier series) because blowing gases and oil interfered with aiming. In this connection, Flik 61/J reported that pilots flying machines with raised guns were forced to sit on two cushions to use the sights properly. At least up to aircraft 253.116, series 253 fighters left the factory armed either with buried or raised guns, apparently at random. Whether raised armament was planned as standard equipment on later production aircraft is not known.

As of 1 August 1918, sixty-six series 253 fighters were at the Front, serving primarily with Fliks 3/J, 41/J, 42/J, 51/J, 55/J, 56/J, 61/J, and 63/J. By October 1918, all but 29 of the initial production batch had been accepted. After the war, Poland purchased 38 series 253 fighters (253.212-230, 232, 234-239, 243-248, 252-254, 256, and 257). So impressed was the Polish air service that in August 1919 Oeffag received a letter of commendation, praising the engineers and mechanics for the "exceptional, diligent and thorough work" done on the series 253. Several series 253 fighters took part in Austrian Volkswehr skirmishes with the troops of the new Yugoslavian state in Karnten until fighting finally ceased in June 1919.

Albatros D.III(Oef) Series 253 Specifications

Engine: 225 hp Daimler

Wing: Span Upper 9.00 m (29.53 ft)

Span Lower 8.73 m (28.64 ft)

Chord Upper 1.50m (4.92 ft)

Chord Lower 1.10 m (3.61 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.47 m (4.81 ft)

Stagger 0.24 m (0.77 ft)

Total Wing Area 20.56 sq m (221 sq ft)

General: Length 7.43 m (24.38 ft)

Height 2.64 m (8.67 ft)

Track 1.80 m (5.91 ft)

Empty Weight 722 kg (1592 lb)

Loaded Weight 995 kg (2194 lb)

Maximum Speed: 202 km/hr (125 mph)

Climb: 1000m (3,281 ft) in 3 min 5 sec

2000m (6,562 ft) in 7 min 10 sec

3000m (9,843 ft) in 11 min 20 sec

4000m (13,124 ft) in 17 min 15 sec

5000m (16,405 ft) in 27 min

Impressed by the successful debut of the Albatros fighters on the Western Front in August 1916 and their fine handling characteristics, the LFT and industry moved with uncommon alacrity to put the Albatros D.II and D.III fighters into production in order to meet the increasing strength of the Italians and to replace the dangerous Brandenburg D.I fighter. Oeffag, having secured license rights from the German Albatros company, had production well under way when the contract was signed on 4 December 1916, calling for 50 aircraft, originally composed of 20 D.II and 30 D.III fighters.

The Oeffag-built D.II differed but slightly from its German counterpart. The engine, a 185 hp Daimler, was more powerful. The wing chord was increased by 10mm (0.4 in) and the fuselage was slightly altered. The D.II production prototype, 53.01, first flew in January 1917. The common D.II/D.III fuselages were completed in February, but assembly of the wing cellule for both was postponed until completion of the static load tests. Flight trials were delayed by the sub-zero weather and also had to await the development of a proper radiator and selection of a suitable propeller. Finally the D.II(Oef) was released by a Flars engineering commission on 4 May 1917, whereupon 16 machines (all that were built), numbered 53.01 to 53.16, were accepted and promptly dispatched to the Front. All but two aircraft were armed with one or two machine guns fitted with the Bernatzik synchronization mechanism.

The majority of the Albatros D.II(Oef) fighters were sent to the less-active Russian Front to serve with Fliks 3, 5, 7, 10, 14, 20, 22, 25, 26, and 37. The D.II was also flown by Fliks 2, 19, 35, 41/J, 42/J, and 46 on the Isonzo Front and Fliks 21, 24, and 48 in the Tirol. Although a few victories were recorded, in general the D.II(Oef) fighter served to introduce two-seater pilots to the vagaries of handling a facile, high performance aircraft. Its operational function was well described in a Flik 37/D appreciation: "...too slow, its rapid climb has little effect because Russian aircraft practically never cross the lines; therefore the D.II mainly performs escort work." By the end of 1917, the D.II(Oef) was relegated to training duties, and two were offered for sale by the Austrian government in 1920.

Albatros D.II(Oef) Series 53 Specifications

Engine: 185 Daimler

Wing: Span Upper 8.50 m (27.89 ft)

Span Lower 8.00 m (26.25 ft)

Chord Upper 1.70 m (5.58 ft)

Chord Lower 1.70 m (5.58 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.35 m (4 43 ft)

Stagger 0.12 m (0.39 ft)

Total Wing Area 24 sq m (258 sq ft)

General Length 7.35 m (24.12 ft)

Height 2.71 m (8.89 ft)

Track 1.80 m (5.91 ft)

Loaded Weight 898 kg (1980 lb)

Maximum Speed: 170 km/hr (106 mph)

Climb 1000m (3,281 ft) in 4 min 30 sec

2000m (6,562 ft) in 7 min

3000m (9,843 ft) in 12 min 30 sec

Albatros D.III(Oef) Series 53.2

Production of the Albatros D.III(Oef) had kept in step with the D.II (sharing a common fuselage, undercarriage, and tail surfaces) to enable Oeffag to switch to D.III output as soon as the static load tests of the re-designed "sequiplane" wing cellule were satisfactorily completed. Not content with the original German design, Oeffag engineers developed a stronger wing and airframe - in the process creating a tough, beautifully-built aircraft that could take increasingly more powerful engines without extensive modification. The popular Oeffag-built D.III fighter remained in production until the end of the war in three different series:

Qty Series Number Engine Order Date

34 53.20-53 185 Dm 4 December 1916

11 53.54-64 185 Dm 3 February 1917

61 153.01-61 200 Dm 3 February 1917

50 153.62-111 200 Dm 18 July 1917

100 153.112-211 200 Dm 8 October 1917

70 153.212-281 200 Dm 18 May 1918

230 253.01-230 225 Dm 18 May 1918

100 253.231-330 225 Dm August 1918

The maiden flight of the D.III(Oef) production prototype, 53.21, took place in mid-February 1917. The Flars engineering commission, after inspecting the prototype on 4 May, specified several minor modifications. Production acceptances which began on 17 May were interrupted to repeat the static load test of the wing cellule (on 26 May) as a precautionary measure triggered by reports of recurring D.III wing failures on the Western Front. The far-sighted action of Oeffag engineers was vindicated for, by refusing to copy the German wing cellule, they had made significant improvements which were outlined in an LFT report: 1) The German spars and ribs are appreciably weaker than those of the 53.2 series. 2) Ribs between the main and auxiliary spar are solid and constructed of heavier plywood. 3) Spar flange thickness is increased from 10 to 20 mm at stress points. 4) Metal reinforcing is added between the main and auxiliary spar. 5) The front auxiliary spar is prevented from twisting by a metal fixture at the fuselage juncture. The German and Oeffag-built machines were dimensionally identical, with only small variations in wingspan, gap and area. Fully loaded, the Oeffag-built D.III was heavier than the German D.III, weighing 964 kg (2126 lb) compared to the German D.Ill's weight of 912 kg (2010 lb); the difference was due to the heavier 185 hp Daimler engine. Greater power gave the D.III(Oef) series 53.2 fighter a higher rate of climb and a maximum speed of 180 km/h (112 mph), as compared with the 165 km/h of the 160 hp Mercedes-powered German fighter.

Output grew rapidly but the shortage of synchronization mechanisms, a chronic problem, forced Oeffag to manufacture precision parts to keep production moving. An enthusiastic reception met the first D.III(Oef) fighters when they reached the Front in June 1917. Finally, squadrons possessed a fighter that an average pilot could fly with relative ease and safety. By September 1917, sufficient experience had been gathered to assess the fighter's virtues and shortcomings. Although the series 53.2 and 153 were equal in speed to the Brandenburg D.I, they had a much superior rate of climb, showed excellent maneuverability and above all, were regarded as safe aircraft. Only one Flik reported lower wing vibration. At first the fighter was not fully trusted in a steep dive (nor was this recommended), but this restriction was lifted on later models. The synchronization mechanism was often unreliable, an all too common problem, and the steel-tube machine-gun supports required strengthening. A weak tail skid structure and poor quality cowling fasteners were problems quickly corrected. The 45 Albatros D.III(Oef) series 53.2 fighters were distributed among many Fliks on the Italian Front and in smaller numbers on the Russian Front. They formed the initial complement of Flik 51/J. When production ended in July 1917, the series 53.2 was replaced by the structurally identical but more-powerful D.III(Oef) series 153. With the appearance of newer fighters, the series 53.2 was used as a fighter-trainer by frontline training units.

Albatros D.III(Oef) Series 53.2 Specifications

Engine: 185 Daimler

Wing Span Upper 9.00 m (29.53 ft)

Span Lower 8.73 m (28.64 ft)

Chord Upper 1.50 m (4.92 ft)

Chord Lower 1.10 m (3.61 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.47 m (4 81 ft)

Stagger 0.22 m (0.72 ft)

Total Wing Area 20.56 sq m (221 sq ft)

General Length 7 35 m (24.12 ft)

Height 2.80 m (9.19 ft)

Track 1.80 m (5.91 ft)

Empty Weight 690 kg (1521 lb)

Loaded Weight 964 kg (1980 lb)

Maximum Speed: 180 km/hr (112 mph)

Climb: 1000m (3,281 ft) in 3 min 20 sec

3000m (9,843 ft) in 14 min 30 sec

5000m (16,405 ft) m 32 min

Albatros D.III(Oef) Series 153

As soon as it became available, the high-compression 200 hp Daimler engine was mounted in the standard production airframe and output continued under the designation Albatros D.III(Oef) series 153. Between July 1917 and June 1918 a total of 281 fighters, numbered 153.01 to 153.281, were delivered. The second production batch, starting with airframe 153.112, was designed with a rounded nose to eliminate the spinner, which was prone to fly off and damage the airframe. In addition, German wind tunnel tests had demonstrated that replacing the spinner by a simple, rounded nose improved propeller efficiency, which in this case resulted in a speed increase of some 14 km/h (9 mph). Armament consisted of two buried Schwarzlose machine guns mounted with butts projecting into the cockpit and firing through blast tubes mounted alongside the engine. The slow-firing guns and often erratic synchronization systems were universally damned by pilots, more so because the D.III was an extremely stable gun platform. When several Fliks suggested that the guns be raised to eye level, three such fighters were built by Oeffag (153.161, 153.162, 153.181) and sent to the Front for evaluation. However, raised, cowl-mounted guns were not installed on production machines until the advent of series 253 in mid-1918.

The introduction of the series 153 fighters coincided with the formation of specialized fighter squadrons, such as Fliks required performance and flight characteristics to engage in successful combat with enemy aircraft of similar type. It is the best-liked fighter at the Front." In the opinion of Offizierstellvertreter Friedrich Hefty, a Flik 42/J pilot credited with five victories, the "200 hp D.III was a superbly-designed aircraft, beautifully balanced and especially suited for aerobatics. Its rate of climb was equal to the Hanriot and the Camel, but slower in level flight than the SPAD." Every Flik lauded the D.III's all-round qualities. Not only was it robustly built and well finished (an Oeffag hallmark), but also its ease of maintenance endeared it to ground personnel. As usual the rocky airfields took their toll. In January 1918, seven Flik 55/J fighters were withdrawn for two weeks to repair rear airframe damage that occurred during take-off and landing. Oeffag raised the tail-skid support by 6 cm (2.4 in) to prevent the tail from bottoming out. Due to the temporary shortage of high-grade wing-bracing wire, some series 153 fighters were delivered in late 1917 with inferior stranded cable, which stretched to such a degree that lower wings began to vibrate in flight and allowed the wings to take on a pronounced V-form.

In January 1918, Flik 42/J, a crack unit, submitted a combat summary which stated that "enemy aircraft are encountered in flights of eight or nine machines. To attack the well-coordinated enemy with inferior numbers is a hopeless task. In doing so our squadrons suffer inevitable losses without being able to control the air. The only solution is to attack the enemy in equal numbers; only then will the effectiveness of our type 153, powered by the high-compression engine (200 hp Daimler), reach its full potential. The supply of new fighters is totally inadequate." A rough indication of the combat attrition is shown by the following statistic. In August 1918, some 142 series 153 fighters were listed in the frontline inventory; three months later, the LFT's inventory was reduced to 57 machines, of which only 12 were in flyable condition. In spite of the high losses, an important fact to remember is that in terms of victories scored, the Albatros D.III(Oef) series 153 leads the list of all Austro-Hungarian fighters. This is a tribute to the aircraft and the pilots of the specialized fighter units, especially Fliks 3/J, 41 /J, 42/J, 51/J, 55/J, 56/J, 63/J, and 68/J, who fought gallantly and held their own against great numerical odds on the Italian Front.

Albatros D.III(Oef) Series 153 Specifications (With Spinner)

Engine: 200 hp Daimler

Wing: Span Upper 9.00 m (29.53 ft)

Span Lower 8.73 m (28.64 ft)

Chord Upper 1.50 tn (4.92 ft)

Chord Lower 1.10 tn (3.61 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.47 m (4.81 ft)

Stagger 0.22 m (0.72 ft)

Total Wing Area 20.56 sq m (2.2.1 sq ft)

General: Length 7.35 m (24.12 ft)

Height 2.80 m (9.19 ft)

Track 1.80 m (5.91 ft)

Empty Weight 710 kg (1566 lb)

Loaded Weight 987 kg (2176 lb)

Maximum Speed: 188 km/hr (117 mph)

Climb: 1000m (3,281 ft) in 2 min 35 sec

2000m (6,562 ft) in 6 min 35 sec

3000m (9,843 ft) in 11 min 20 sec

4000m (13,124 ft) in 18 min 50 sec

5000m (16,405 ft) in 33 min

Albatros D.III(Oef) Series 253

On 18 May 1918, Oeffag received a contract to supply 230 Albatros D.III(Oef) series 253 fighters, numbered 253.01 to 253.230, to be powered by the improved 225 hp Daimler engine that was just entering quantity production. An additional batch of 100 series 253 fighters, numbered 253.231 to 253.330, was ordered in August with delivery scheduled to end in December 1918. Requiring only minor internal modification, the series 253 began to replace the series 153 in May 1918 and continued in production until the war ended. Counting the 30-odd machines completed after the war, Oeffag built a total of 260 series 253 fighters.

The first units to receive the new 225 hp fighter were Fliks 61/J and 63/J in mid-June 1918, whose pilots were lavish with praise. Flik 61/J labelled it as "first class and superior to any fighter." Flik 63/1 considered the new fighter as "equal to all combat requirements; it is very much liked, only the squadron does not receive sufficient numbers." By July 1918, seven fighter Fliks acclaimed the series 253 as the finest fighter they had flown. Flik 56/J reported the series 253 "meets every demand, is solid and well constructed, climbs rapidly and is preferred over the Aviatik D.I because of its peerless flight characteristics." When various LFT staff officers at the Front were asked to summarize their requirements for future planning the reply was unanimous: "Unquestionably the most maneuverable and safest fighter at the Front. It has the pilots' complete trust. Because of its excellent handling and performance, it is preferred over every other fighter. Mass production is urgent." Given full priority for materials and engines, Oeffag responded by increasing average monthly output of the series 253 by 50 percent over the series 153.

Among the 24 participants that competed in the Fighter Evaluation at Aspern in July 1918, only three were standard production machines - the Aviatik D.I 338.03 and two Albatros D.III(Oef), 253.32 and 253.35. In spite of having the highest wing loading, the Albatros fighters achieved a faster rate of climb than all other contestants with exception of the Aviatik D.I and the WKF 80.10 (D.I) prototype. Oberleutnant Benno von Fiala recommended returning the raised machine guns to the buried position (as in the earlier series) because blowing gases and oil interfered with aiming. In this connection, Flik 61/J reported that pilots flying machines with raised guns were forced to sit on two cushions to use the sights properly. At least up to aircraft 253.116, series 253 fighters left the factory armed either with buried or raised guns, apparently at random. Whether raised armament was planned as standard equipment on later production aircraft is not known.

As of 1 August 1918, sixty-six series 253 fighters were at the Front, serving primarily with Fliks 3/J, 41/J, 42/J, 51/J, 55/J, 56/J, 61/J, and 63/J. By October 1918, all but 29 of the initial production batch had been accepted. After the war, Poland purchased 38 series 253 fighters (253.212-230, 232, 234-239, 243-248, 252-254, 256, and 257). So impressed was the Polish air service that in August 1919 Oeffag received a letter of commendation, praising the engineers and mechanics for the "exceptional, diligent and thorough work" done on the series 253. Several series 253 fighters took part in Austrian Volkswehr skirmishes with the troops of the new Yugoslavian state in Karnten until fighting finally ceased in June 1919.

Albatros D.III(Oef) Series 253 Specifications

Engine: 225 hp Daimler

Wing: Span Upper 9.00 m (29.53 ft)

Span Lower 8.73 m (28.64 ft)

Chord Upper 1.50m (4.92 ft)

Chord Lower 1.10 m (3.61 ft)

Dihedral Upper 0 deg

Dihedral Lower 1 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.47 m (4.81 ft)

Stagger 0.24 m (0.77 ft)

Total Wing Area 20.56 sq m (221 sq ft)

General: Length 7.43 m (24.38 ft)

Height 2.64 m (8.67 ft)

Track 1.80 m (5.91 ft)

Empty Weight 722 kg (1592 lb)

Loaded Weight 995 kg (2194 lb)

Maximum Speed: 202 km/hr (125 mph)

Climb: 1000m (3,281 ft) in 3 min 5 sec

2000m (6,562 ft) in 7 min 10 sec

3000m (9,843 ft) in 11 min 20 sec

4000m (13,124 ft) in 17 min 15 sec

5000m (16,405 ft) in 27 min

The Albatros D.II(Oef) 53.01 during flight tests in January 1917. The engine has the winter cowling installed and armament is not fitted.

Albatros D.II(Oef) 53.01 with Hauptmann Walter Lux Edler von Treurecht, CO of Flik 21/D in Pergine, June 1917. It was armed with two buried machine guns fired through blast tubes mounted alongside the engine.

Another factory photograph of Albatros D.II(Oef) 53.06 fitted with an experimental propeller for flight tests. At this stage, the aircraft was unarmed.

Albatros D.II(Oef) 53.06 photographed on the Oeffag airfield. It was flown by Flik 37/D in October-November 1917. The slanted tail-skid support differentiates the Oeffag version from the German-built D.II.

Albatros D.II 53.06 in Wr. Neustadt. Werksflugfeld, Februar 1917, aufgenommen in fabriksneuem Zustand, abweichend mit deutschem Teeves & Braun-Kühler

Albatros D.II 53.06 в Wr. Нойштадт. Заводской аэродром, февраль 1917 года, в совершенно новом состоянии, но с немецким радиатором Teeves & Braun.

Albatros D.II 53.06 in Wr. Neustadt. Werksflugfeld, Februar 1917, aufgenommen in fabriksneuem Zustand, abweichend mit deutschem Teeves & Braun-Kühler

Albatros D.II 53.06 в Wr. Нойштадт. Заводской аэродром, февраль 1917 года, в совершенно новом состоянии, но с немецким радиатором Teeves & Braun.

Albatros D.II(Oef) 53.14 with Feldwebel Franz Koudela (r) of Flik 26/D at Zastawna in August 1917. The twin blast tubes for the machine guns are mounted under the engine intake manifold. Additional engine cooling louvres have been cut in the cowling.

Albatros D.III(Oef) 53.24, delivered in June 1917, attained four victories while serving with Fliks 13 and 31, Fliegerdetachment Nikitsch, Flik 39/D, and Kampfstaffel Harja. In 1918 it was used as a trainer by the Feldfliegerschule at Campoformido.

Lineup of Flik 41/J during the visit of the Archduchess Maria Theresa on July 26, 1917 at Sesana; she is at the far left of the photo.

This D.I with the Buddhist good luck emblem, the swastika, was with Flik 41J when this photograph was taken despite the original caption stating it was taken at Flik 12. Albatros (Oef) 53.27 is seen in the background. This D.l was flown at times by Godwin Brumowski and test flown by Gottfried Banfield. Serial number unknown.

With few exceptions, an angled machine gun or a Type II VK gun canister comprised the armament on Brandenburg D.I fighters. Shown here are 28.65 and 28.64 (swastika insignia) of Flik 41/J in August 1917. The purpose of the flags extending from the canisters is not known, but could be an indication that the guns are armed.

This D.I with the Buddhist good luck emblem, the swastika, was with Flik 41J when this photograph was taken despite the original caption stating it was taken at Flik 12. Albatros (Oef) 53.27 is seen in the background. This D.l was flown at times by Godwin Brumowski and test flown by Gottfried Banfield. Serial number unknown.

With few exceptions, an angled machine gun or a Type II VK gun canister comprised the armament on Brandenburg D.I fighters. Shown here are 28.65 and 28.64 (swastika insignia) of Flik 41/J in August 1917. The purpose of the flags extending from the canisters is not known, but could be an indication that the guns are armed.

Albatros D.III(Oef) 53.30 served with Flik 6 in Albania in the summer of 1917. The small Oeffag triangular logo can be seen on the nose.

A Brandenburg C.I(U) series 67 biplane with the 4th Army in Poland, summer 1917. The slim, blunt-ended Asboth propeller design was originally developed by the propeller test facility at Fischamend. In the background is an Albatros D.III(Oef) 53.32.

Non-commissioned ace Stabsfeldwebel Josef Kiss flying Albatros D.III(Oef) 53.33 over the rugged Alpine terrain which characterized much of the combat enviroment on the Italian Front.

Accepted in July 1917, the long-lived Albatros D.III(Oef) 53.50 served with Flik 17/D (August 1917 - January 1918), Flik 27/D (April-May 1918), and Flik 54/D (June 1918) until finally ending with Flik 3/J as a trainer, which may explain why the wings and tail have been painted in a bright color. The seldom-seen strut brace to the lower-wing leading edge gives evidence of the aircraft’s age.

Eight Albatros D.lIl(Oef) fighters of Jagdstaffel Oberleutnant Elssler parading on the Pergine airfield awaiting Kaiser Karl's inspection on 14 September 1917. A Brandenburg D.I(Ph) series 28 fighter and two Aviatik C.I series 37 biplanes are in the second row. Villa Guila della Rosa is in the far right.

The mechanics of Flik 35/D on the airfield St Veit (Wippach) posing with aircraft 53.56. The top surfaces, tail and wheel have been camouflaged. The most noticeable differences from the German D.III are the engine, the radiator configuration, the fuselage access panels, and the slant of the tail skid support.

The twin Schwarzlose guns slanted to fire over the propeller and installed on the center section of the Albatros D.III(Oef) 53.57 was another frontline modification. Korporal Eugen Bonsch of Flik 51/J achieved his first combat victory in this aircraft on 1 September 1917.

Series 153 production deliveries were delayed until the correctly matching propeller was empirically determined by means of flight tests performed with the Albatros D.III(Oef) 153.01 prototype in June 1917. The prototype was assigned to Flek 6 as an advanced trainer. A Sottoscope is mounted front of the cockpit.

Albatros D.III(Oef) 153.24 of the Jagdstaffel Galanestie, airfield Galanestie (Bukovina) in the winter of 1917. In the cockpit is Oberleutnant Hans Fischer, commander of the Jagdstaffel.

Aircraft 153.31 on the Oeffag firing range to adjust the synchronization mechanism. The long blast tubes can be seen under the exhaust headers. A supplementary radiator provides for proper engine cooling.

By the time this Albatros D.III(Oef) 153.41 was delivered to Flik 2/D in September 1917, these machines were generally flown without the spinner. If the attachment was faulty, the spinner could separate and cause fatal damage. This aircraft, one of the few to survive the war, was listed as stored in damaged condition in March 1919.

Albatros D.III(Oef) 153.95 of Flik 2/D on the Pianzano airfield in the fall of 1917. The markings are believed to be those of Oberleutnant Fritz Losert.

Flik 59/D mechanics posing with 153.104 on the San Gaicomo airfield in early 1918. The twin machine gun blast tubes project from the fully-cowled engine.

Leutnant Otto Schrimpl of Flik 61/J with his Albatros D.III(Oef) series 153 on the airfield at Motta di Livenza in March 1918.

Beginning with aircraft 153.112, the Oeffag-built Albatros D.III fighters were delivered with a rounded nose. The experimental hexagonal camouflage was adopted from a similar German pattern. This fighter served with Flik 41/J before being assigned to the Feldfliegerschule at Campoformido.

Zugsfuhrer Eugen Bonsch of Flik 51/J was credited with five victories between March and June 1918 while flying 153.140.

Albatros D.III(Oef) 153.181 of Flik 61/J was armed with raised machine guns. Although most pilots preferred this arrangement for aiming and accessibility, some objected to the blow-back of gases, powder particles, and especially the chamber lubricating oil which hampered their vision.

Albatros D.III(Oef) 153.255 was assigned to Flik 63/J in May 1918. In the autumn of 1918, it was modified as a single-seat photo-reconnaissance fighter and served with Flik 46/P.

The unarmed Albatros D.III(Oef) 253.01 production prototype was employed for engine and propeller evaluation at Aspern. Compared to the series 153, the overall length was increased slightly and the introduction of wire trailing edges on the ailerons and elevators gave them a scalloped appearance.

Flik 56/J being dressed for combat in front of his Albatros D.III(Oef) 253.36 that has raised guns. Aircraft 253.30, in the background, has buried guns.

Korporal Geza Keisz of Flik 42/J made a successful forced landing in aircraft 253.64 after the lower-wing fabric peeled off during air combat on 28 August 1918. Owing to the aircraft shortage, Keisz used Hefty's aircraft, whose markings it carries. The swirled camouflage pattern was a printed fabric.

Albatros D.III(Oef) 253.120 being assembled at the factory. Owing to the rubber shortage, wheels with wood and steel-band “tires” were used to move the aircraft about the factory. The aircraft was flown by Zugsfuhrer Kurt Steidl of Flik 3/J when he participated in shooting down Sopwith Camel E.1498 of 66 Squadron on 7 October 1918.

A formidable lineup of seven Albatros D.III(Oef) series 253 fighters during acceptance testing at the factory. The furthest aircraft is the Oeffag 50.13 prototype.

The rather sombre Albatros D.III(Oef) 253.08 of Oberleutnant Stefan Stec of Flik 3/J. The red and white checkerboard was the insignia of Pilsudski's Polish Legion that fought on the Austro-Hungarian side. The aircraft is armed with buried machine guns.

Lacking synchronization, pilots sometimes took matters into their own hands. Stabsfeldwebel Kurt Gruber of Flik 41/J in an Albatros D.III(Oef) fighter that is armed with a Schwarzlose gun mounted on a pillar and angled to fire forward outside of the propeller arc. This arrangement was also seen on a number of two-seater machines.

The buried machine gun installation was standard on Albatros D.III(Oef) fighters until the introduction of cowl-mounted guns. Here aircraft 53.22 shows the blast tube, the perforated gun jacket, and the engine decompression handle in front of the windscreen. The synchronization mechanism was adjusted with the aid of a plywood disc mounted in front of the propeller.

The Oeffag 50.09 prototype during final assembly in June 1917. Here it shares the large assembly hangar with the Oeffag K 423 flying boat and early production Albatros D.III(Oef) series 153 fighters.

The neat arrangement in the assembly hall reflects the craftsmanship for which Oeffag aircraft were renowned. In the far left, the Albatros D.III(Oef) 53.21 production prototype awaits propeller installation, while in the far right the D.II(Oef) 53.06 and D.III(Oef) 53.20 are nearing completion. In the foreground, Oeffag C.II series 52.5 biplanes under assembly. The date is February 1917.

One of the three Albatros D.III(Oef) series 153 fighters armed with twin raised Schwarzlose machine guns was aircraft 153.162 that was dispatched to Flik 42/J for frontline evaluation in February 1918. The altimeter on the left is supported in a shockproof mounting. In the center is the Phylax tachometer and on the right, a bank indicator.

After serving as the series 153 prototype, the Albatros D.III(Oef) 153.01 was based at Flek 6 to investigate remote-camera installation. The Sottoscope was mounted on the right side of the cockpit. The handle in the foreground is used to decompress the 200 hp Daimler engine for starting. The machine guns are mounted internally below the two cowling access doors.

Installation of a remotely-controlled camera behind the pilot's seat (removed) of an Albatros D.III(Oef) fighter. The negative-changing handle is connected to the wooden box holding the glass plate negatives. The ring opens the fuselage aperture. The camera shutter release is not yet installed. Mounted on the fuselage are a spirit level and an Oeffag plate counter. The black box on the left is for the Bordbuch (aircraft logbook).

Asboth Helicopter

In late 1917, Oscar von Asboth left Fischamend to become a director of the Ungarische Luftschraubenfabrik GmbH, the former propeller manufacturing subsidiary of UFAG. At his own expense, Asboth commissioned UFAG to build a model helicopter followed by a man-carrying version based on the designs he had discussed with Balaban at Fischamend and for which he received Austrian patents 76,184 and 79,539 dated April 1917. His was a four-rotor helicopter tethered by a single cable attached to the airframe by a gimballed yoke that allowed the airframe to move about all axes. The four wooden rotors each had a diameter of 3 meters. Unfortunately, before any tests were run the model version, powered by a French 20 hp rotary engine, and the virtually completed full-sized airframe were destroyed in a fire at the UFAG factory on 9 September 1918. Five months of effort had come to naught.

In late 1917, Oscar von Asboth left Fischamend to become a director of the Ungarische Luftschraubenfabrik GmbH, the former propeller manufacturing subsidiary of UFAG. At his own expense, Asboth commissioned UFAG to build a model helicopter followed by a man-carrying version based on the designs he had discussed with Balaban at Fischamend and for which he received Austrian patents 76,184 and 79,539 dated April 1917. His was a four-rotor helicopter tethered by a single cable attached to the airframe by a gimballed yoke that allowed the airframe to move about all axes. The four wooden rotors each had a diameter of 3 meters. Unfortunately, before any tests were run the model version, powered by a French 20 hp rotary engine, and the virtually completed full-sized airframe were destroyed in a fire at the UFAG factory on 9 September 1918. Five months of effort had come to naught.

The Asboth helicopter frame with rotary engine and fuel tank installed at the UFAG factory shortly before it was destroyed by fire on 9 September 1918. Initially it had been planned to install a 230 hp in-line engine.

Asboth’s helicopter as patented on 30 April 1917. There are crew and machine-gun positions above and below the rotor plane.

Aviatik 30.14

The 30.14 prototype is significant in that it was the first fighter designed and built entirely in the Dual Monarchy. On 8 June 1916, Berg proposed to the LFT a biplane fighter powered by a 160 hp Daimler engine, armed with a fixed machine gun, and having a calculated top speed of 185 km/h (115 mph). Concurrently, Berg also proposed a light reconnaissance monoplane powered by a 120 hp Daimler engine. Neither project was approved by Flars because Aviatik was barred from engaging in prototype work in order devote full effort to the Knoller program. When Uzelac got wind of the fighter project in August 1916, he fortunately intervened to support the Aviatik proposal.

Construction of the 30.14 fighter prototype started in August. The uncovered airframe was inspected on 26 September by Flars engineers who listed various shortcomings for correction, especially strengthening the steering controls and flying surfaces. On 16 October 1916, the 30.14 stood ready for its maiden flight at Aspern. It was a clean biplane of pleasing lines, marred only by the tail assembly which appears undersized in relation to the airframe. The high center-section struts provided an unobstructed field of view. It was the first step towards the more compact D.I fighter, to which it bore an unmistakable family resemblance.

Feldwebel Ferdinand Konschel, an experienced Flars test pilot, was carefully briefed for the maiden flight. Ingenieur Julius Kolin recalled warning Konschel to exercise caution, but his counsel was shrugged off by Berg. According to Kolin's theoretical calculations, Berg's experimental airfoil could demonstrate an extreme center of pressure shift under certain flight conditions. Berg had adopted a Knoller-type airfoil whose rib section had a pronounced reflex curvature at the very narrow trailing-edge section. Although the airfoil was judged efficient for high speeds, little was known about its low speed and stall characteristics.

In the face of unpredictable wind gusts, Konschel had intended to perform only a few preparatory hops. Witnesses reported that after some 30 meters of low hops, Konschel unexpectedly lifted off - involuntarily according to some. With the engine at low rpm, he wove a wobbly flight path and executed a flat turn at 100 meters height. As Konschel throttled back to land, the prototype plunged straight into the ground. The crash protocol blamed Konschel's death on "a nose-heavy aircraft and inadequate control surfaces." The official inquest, however, attributed the crash to control-pulley failure. Nevertheless, Kolin remained certain that the center of pressure shift was the real culprit. With Knoller's assistance, Kolin designed a new airfoil for use on future Aviatik aircraft. Though beset by misfortune, the 30.14 prototype was the progenitor of the Aviatik D.I fighter that remained in service until the end of the war.

Aviatik 30.14 (Single-Seat Fighter) Specifications

Engine: 160 hp Daimler

Wing: Span Upper 8.00 m (26.25 ft)

Chord Upper 1.60 m (5.25 ft)

Chord Lower 1.50 m (4.92 ft)

General: Length 6.86 m (22.51 ft)

Loaded Weight 715 kg (1577 lb)

Aviatik 30.19, 30.20, and 30.21

On 25 September 1916, Flars approved three fighter prototypes based on the 30.14 design and incorporating some 40 improvements specified by Flars. Three prototypes, designated Aviatik 30.19 to 30.21, were built; one for flight evaluation, one for static tests, and one as a spare. Aviatik was directed to proceed with all possible speed.

Originally scheduled to start flight tests in November 1916, the 30.19 airframe inspection by Flars was delayed until 28 December, and the maiden flight took place on 24 January 1917. The Aviatik 30.19, prototype for the Aviatik D.I, here retro-fitted with a one-piece upper wing, during flight evaluation at Aspern.

LFT pilots were cleared to fly the 30.19, powered by a 185 hp Daimler engine, on 13 February. Flars test pilot Oberleutnant Oskar Fekete reported on 31 March 1917 that the 30.19 had flight characteristics similar to the Aviatik C.I but was superior all around. Fie emphasized the fighter's "fabulous climb and enormous maneuverability" and felt that any competent two-seater pilot should be able to fly the type without prior schooling. On 15 May 1917, the 30.19 prototype (retro-fitted with a one-piece upper wing) and the first production Aviatik D.I, 38.01 were dispatched to Fluggeschwader I (later renamed Flik 101/GJ on the Isonzo Front for evaluation under frontline conditions. Armed with a free-firing machine gun mounted on the upper wing, the 30.19 was flown at the Front by Hauptmann Karl Sabeditch from 18 May until July 1917, when it was badly damaged and written-off. On 23 May 1917, Sabeditch downed a Caproni bomber, thereby achieving the first victory both for himself and an Aviatik fighter aircraft (30.19).

The 30.20 prototype failed the load test on 17 March. A one-piece wing was designed to replace the two-piece upper wing and cabane center-section. As soon as the 30.20 passed the third load test on 28 April 1917, the design was released for production as the Aviatik D.I series 38 fighter. The 30.20 prototype was written-off after the load tests.

The 30.21 was used for flight trials until February 1917, when, after a minor landing mishap, the airframe was modified by Aviatik as the prototype for the Aviatik D.II and renumbered 30.22.

Aviatik 30.19 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 8.00 m (26.25 ft)

Span Lower 7.84 m (25.72 ft)

Gap 1.35 m (4.43 ft)

General: Track 1.80 m (5.91 ft)

Aviatik 30.20 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 8.00 m (26.25 ft)

Span Lower 7.92 m (25.98 ft)

Chord Upper 1.45 m (4.76 ft)

Chord Lower 1.30 m (4.27 ft)

Dihedral Upper 0 deg

Dihedral Lower 0 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.35 m (4.43 ft)

Stagger 0.25 m (0.82 ft)

Total Wing Area 20.4 sqm ( sq ft)

General: Length 6.86 m (22.51 ft)

Height 2.50 m (8.20 ft)

Track 1.80 m (5.91 ft)

Empty Weight 734.5 kg (1620 lb)

Loaded Weight 854.5 kg (1884 lb)

The 30.14 prototype is significant in that it was the first fighter designed and built entirely in the Dual Monarchy. On 8 June 1916, Berg proposed to the LFT a biplane fighter powered by a 160 hp Daimler engine, armed with a fixed machine gun, and having a calculated top speed of 185 km/h (115 mph). Concurrently, Berg also proposed a light reconnaissance monoplane powered by a 120 hp Daimler engine. Neither project was approved by Flars because Aviatik was barred from engaging in prototype work in order devote full effort to the Knoller program. When Uzelac got wind of the fighter project in August 1916, he fortunately intervened to support the Aviatik proposal.

Construction of the 30.14 fighter prototype started in August. The uncovered airframe was inspected on 26 September by Flars engineers who listed various shortcomings for correction, especially strengthening the steering controls and flying surfaces. On 16 October 1916, the 30.14 stood ready for its maiden flight at Aspern. It was a clean biplane of pleasing lines, marred only by the tail assembly which appears undersized in relation to the airframe. The high center-section struts provided an unobstructed field of view. It was the first step towards the more compact D.I fighter, to which it bore an unmistakable family resemblance.

Feldwebel Ferdinand Konschel, an experienced Flars test pilot, was carefully briefed for the maiden flight. Ingenieur Julius Kolin recalled warning Konschel to exercise caution, but his counsel was shrugged off by Berg. According to Kolin's theoretical calculations, Berg's experimental airfoil could demonstrate an extreme center of pressure shift under certain flight conditions. Berg had adopted a Knoller-type airfoil whose rib section had a pronounced reflex curvature at the very narrow trailing-edge section. Although the airfoil was judged efficient for high speeds, little was known about its low speed and stall characteristics.

In the face of unpredictable wind gusts, Konschel had intended to perform only a few preparatory hops. Witnesses reported that after some 30 meters of low hops, Konschel unexpectedly lifted off - involuntarily according to some. With the engine at low rpm, he wove a wobbly flight path and executed a flat turn at 100 meters height. As Konschel throttled back to land, the prototype plunged straight into the ground. The crash protocol blamed Konschel's death on "a nose-heavy aircraft and inadequate control surfaces." The official inquest, however, attributed the crash to control-pulley failure. Nevertheless, Kolin remained certain that the center of pressure shift was the real culprit. With Knoller's assistance, Kolin designed a new airfoil for use on future Aviatik aircraft. Though beset by misfortune, the 30.14 prototype was the progenitor of the Aviatik D.I fighter that remained in service until the end of the war.

Aviatik 30.14 (Single-Seat Fighter) Specifications

Engine: 160 hp Daimler

Wing: Span Upper 8.00 m (26.25 ft)

Chord Upper 1.60 m (5.25 ft)

Chord Lower 1.50 m (4.92 ft)

General: Length 6.86 m (22.51 ft)

Loaded Weight 715 kg (1577 lb)

Aviatik 30.19, 30.20, and 30.21

On 25 September 1916, Flars approved three fighter prototypes based on the 30.14 design and incorporating some 40 improvements specified by Flars. Three prototypes, designated Aviatik 30.19 to 30.21, were built; one for flight evaluation, one for static tests, and one as a spare. Aviatik was directed to proceed with all possible speed.

Originally scheduled to start flight tests in November 1916, the 30.19 airframe inspection by Flars was delayed until 28 December, and the maiden flight took place on 24 January 1917. The Aviatik 30.19, prototype for the Aviatik D.I, here retro-fitted with a one-piece upper wing, during flight evaluation at Aspern.

LFT pilots were cleared to fly the 30.19, powered by a 185 hp Daimler engine, on 13 February. Flars test pilot Oberleutnant Oskar Fekete reported on 31 March 1917 that the 30.19 had flight characteristics similar to the Aviatik C.I but was superior all around. Fie emphasized the fighter's "fabulous climb and enormous maneuverability" and felt that any competent two-seater pilot should be able to fly the type without prior schooling. On 15 May 1917, the 30.19 prototype (retro-fitted with a one-piece upper wing) and the first production Aviatik D.I, 38.01 were dispatched to Fluggeschwader I (later renamed Flik 101/GJ on the Isonzo Front for evaluation under frontline conditions. Armed with a free-firing machine gun mounted on the upper wing, the 30.19 was flown at the Front by Hauptmann Karl Sabeditch from 18 May until July 1917, when it was badly damaged and written-off. On 23 May 1917, Sabeditch downed a Caproni bomber, thereby achieving the first victory both for himself and an Aviatik fighter aircraft (30.19).

The 30.20 prototype failed the load test on 17 March. A one-piece wing was designed to replace the two-piece upper wing and cabane center-section. As soon as the 30.20 passed the third load test on 28 April 1917, the design was released for production as the Aviatik D.I series 38 fighter. The 30.20 prototype was written-off after the load tests.

The 30.21 was used for flight trials until February 1917, when, after a minor landing mishap, the airframe was modified by Aviatik as the prototype for the Aviatik D.II and renumbered 30.22.

Aviatik 30.19 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 8.00 m (26.25 ft)

Span Lower 7.84 m (25.72 ft)

Gap 1.35 m (4.43 ft)

General: Track 1.80 m (5.91 ft)

Aviatik 30.20 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 8.00 m (26.25 ft)

Span Lower 7.92 m (25.98 ft)

Chord Upper 1.45 m (4.76 ft)

Chord Lower 1.30 m (4.27 ft)

Dihedral Upper 0 deg

Dihedral Lower 0 deg

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.35 m (4.43 ft)

Stagger 0.25 m (0.82 ft)

Total Wing Area 20.4 sqm ( sq ft)

General: Length 6.86 m (22.51 ft)

Height 2.50 m (8.20 ft)

Track 1.80 m (5.91 ft)

Empty Weight 734.5 kg (1620 lb)

Loaded Weight 854.5 kg (1884 lb)

Feldwebel Ferdinand Konschel posing with the Aviatik 30.14 prototype shortly before his fatal crash on 16 October 1916.

The first Austrian Aviatik fighter prototype, the 30.14 which crashed in October 1916.

The first Austrian Aviatik fighter prototype, the 30.14 which crashed in October 1916.

The Aviatik 30.19, prototype for the Aviatik D.I, here retro-fitted with a one-piece upper wing, during flight evaluation at Aspern.

Aviatik 30.19, Prototyp für Berg D.I. Aspern Mai 1917, im Juni zur Fronterprobung beim FIG I

Aviatik 30.19, прототип Berg D.I. Асперн, май 1917 г., фронтовые испытания в июне в FIG I.

Aviatik 30.19, Prototyp für Berg D.I. Aspern Mai 1917, im Juni zur Fronterprobung beim FIG I

Aviatik 30.19, прототип Berg D.I. Асперн, май 1917 г., фронтовые испытания в июне в FIG I.

The Aviatik 30.21 was slightly damaged at Aspern in the course of testing. It was subsequently rebuilt with a wireless wing cellule and redesignated 30.22, to become the prototype of the Aviatik D.II.

Aviatik 30.24

An Aviatik proposal for a two-seat triplane was rejected by Flars in July 1917 but development of a single-seat version continued. Drawings submitted on 17 September 1917 showed a triplane cellule fitted to a standard Aviatik D.I fuselage and tailplane. In September 1917, Aviatik received a contract to build four experimental triplane fighters to be powered by 185/200 hp Daimler engines. The first triplane fighter, designated 30.24, began flight testing in October 1917. Powered by a 185 hp Daimler engine, the Aviatik 30.24 had inferior performance compared with a similarly-engined Aviatik D.I.

The 30.24 was returned to the factory for installation of a 200 hp Daimler engine and twin machine guns. It reappeared at Aspern on 26 February 1918 for further tests that showed little improvement. The triplane was transferred to Flek 8 and then to Flek 6 in Wiener-Neustadt, where a variety of experimental radiators were installed as part of the program to improve forward view of the Aviatik fighters. 30.24 was accepted in September 1918. The remaining three prototypes (designations unknown), completed but disassembled, were accepted at the end of October 1918. The 30.24 was offered for sale to the Czechoslovakian government in April 1920.

Aviatik 30.24 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 7.23 m (23.70 ft)

Span Middle 7.13 m (23.38 ft)

Span Lower 7.00 m (22.97 ft)

Gap Upper 0.85 m (2.79 ft)

Gap Lower 0.85 m (2.79 ft)

Total Wing Area 22.73 sq m (245 sq ft)

General: Length 6.25 m (20.51 ft)

Height 2.75 m (9.02 ft)

Empty Weight 730 kg (1610 lb)

Loaded Weight 900 kg (1985 lb)

Maximum Speed: 174 km/hr (108 mph)

Climb: 1000m (3,281 ft) in 2 min 40 sec

An Aviatik proposal for a two-seat triplane was rejected by Flars in July 1917 but development of a single-seat version continued. Drawings submitted on 17 September 1917 showed a triplane cellule fitted to a standard Aviatik D.I fuselage and tailplane. In September 1917, Aviatik received a contract to build four experimental triplane fighters to be powered by 185/200 hp Daimler engines. The first triplane fighter, designated 30.24, began flight testing in October 1917. Powered by a 185 hp Daimler engine, the Aviatik 30.24 had inferior performance compared with a similarly-engined Aviatik D.I.

The 30.24 was returned to the factory for installation of a 200 hp Daimler engine and twin machine guns. It reappeared at Aspern on 26 February 1918 for further tests that showed little improvement. The triplane was transferred to Flek 8 and then to Flek 6 in Wiener-Neustadt, where a variety of experimental radiators were installed as part of the program to improve forward view of the Aviatik fighters. 30.24 was accepted in September 1918. The remaining three prototypes (designations unknown), completed but disassembled, were accepted at the end of October 1918. The 30.24 was offered for sale to the Czechoslovakian government in April 1920.

Aviatik 30.24 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 7.23 m (23.70 ft)

Span Middle 7.13 m (23.38 ft)

Span Lower 7.00 m (22.97 ft)

Gap Upper 0.85 m (2.79 ft)

Gap Lower 0.85 m (2.79 ft)

Total Wing Area 22.73 sq m (245 sq ft)

General: Length 6.25 m (20.51 ft)

Height 2.75 m (9.02 ft)

Empty Weight 730 kg (1610 lb)

Loaded Weight 900 kg (1985 lb)

Maximum Speed: 174 km/hr (108 mph)

Climb: 1000m (3,281 ft) in 2 min 40 sec

Aviatik 30.24 during flight testing at Aspern in October 1917. The fuselage and tail were adapted from the Aviatik D.I design. The lower wing is suspended below the fuselage by four small struts.

The Aviatik 30.24 in front of the company hangar at Aspern. The aerodynamically-balanced ailerons on the top wing were unique for Berg-designed fighters. Cellon panels in the middle wing enhanced the pilot’s view downward. To the left are an Aviatik D.II 39.01 and a D.I 138.17.

Fitted with a 200 hp Daimler engine, an experimental radiator and twin machine guns, the 30.24 was inspected by ace Feldwebel Josef Kiss (middle) during a visit to Aspern in 1918. The rigging wires run through the middle wing panel.

Aviatik 30.24, nach Kühlerumbau und Waffeneinbau, Erprobung in Aspern. 2. von links Feldpilot Offzstv Kiss

Авиация 30.24, после переделки радиатора и установки вооружения, испытания в Асперне. 2-й слева пилот Offzstv Kiss

Aviatik 30.24, nach Kühlerumbau und Waffeneinbau, Erprobung in Aspern. 2. von links Feldpilot Offzstv Kiss

Авиация 30.24, после переделки радиатора и установки вооружения, испытания в Асперне. 2-й слева пилот Offzstv Kiss

The octagonal radiator tested on the Aviatik 30.24 prototype was an attempt to improve aerodynamic characteristics.

Aviatik C.I (Lo) Series 114 and 214

Lohner was given a contract for 50 Aviatik C.I biplanes, drawn down from an open order for 72 aircraft signed on 27 January 1917. Work began in April. The first airframe was static tested at Aspern in July, releasing the type for delivery in August 1917. Virtually all aircraft left the factory without armament, which was installed at the Front. The contract had scheduled 24 Aviatik C.I (Lo) series 114 aircraft powered by the 185 hp Daimler engine and 26 series 214 aircraft powered by the 200 hp Daimler. However a critical shortage of the latter engine forced a change in production quantities to 32 series 114 aircraft (114.01 to 114.32) and 18 series 214 aircraft (214.01 to 214.18). Even so, eight series 214 machines were accepted without engines. In the field, aircraft 214.06, 14, 15, and 18 were fitted with used 185 hp Daimler engines.

As of October 1917, the series 114 was supplied singly to Fliks 2/D, 4/D, 8/D, 10/F, 16/D, 19/D, 23/D, 27/F, 46/D, 47/D, 49/D, 50/D, 53/D, 57/F, and 58/D, but were soon replaced by other aircraft. The series 214 formed the first equipment of Fliks 22/D, 38/D, 40/P, 49/D, and 52/D. Series 114 and 214 were flown as trainers by Fleks 6 and 8, and the Feldfliegerschule Campoformido. The Lohner-built Aviatik C.I machines did not gain the full confidence of frontline personnel. In general, the Aviatik-built version was preferred because of superior workmanship and performance. Some series 114 and 214 aircraft were modified as single-seat, photoreconnaissance fighters by covering the rear seat and replacing the observer with a sack of sand to balance the aircraft. The frontline inventory of 1 August 1918 listed eleven Aviatik C.I (Lo) series 114 and five series 214 aircraft.

Aviatik C.I(Lo) Series 114 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 8.40 m |27.56 ft)

Span Lower 8.40 m (27.56 ft)

Chord Upper 1.70 m (5.58 ft)

Chord Lower 1.60m (5.25 ft)

Total Wing Area 24.8 sq m (267 sq ft)

General: Length 7.68 m (25.20 ft)

Height 2.96 m (9.71 ft)

Track 1.80 m (5.91 ft)

Empty Weight 650 kg (1433 lb)

Loaded Weight 990 kg (2183 lb)

Climb: 1000m (3,281 ft) in 3 min 50 sec

3000m (9,843 ft) in 17 min 12 sec

Aviatik C.I(Lo) Series 214 Specifications

Engine: 200 hp Daimler

Wing: Span Upper 8.40 m |27.56 ft)

Span Lower 8.40 m (27.56 ft)

Chord Upper 1.70 m (5.58 ft)

Chord Lower 1.60 m (5.25 ft)

General: Length 7.68 m (25.20 ft)

Height 2.96 m (9.71 ft)

Empty Weight 732 kg (1614 lb)

Loaded Weight 1045 kg (2304 lb)

Maximum Speed: 178 km/hr (110.5 mph)

Climb: 1000m |3,281 ft) in 3 min 46 sec

3000m (9,843 ft) in 14 min 5 sec

Aviatik 30.14 (new), 30.15, and 30.16

Based on the design experience gained with the 30.14 prototype, Aviatik engineers proposed an improved fighter (30.19) and a derivative two-seat biplane. On 26 September 1916, Flars ordered three, two-seat prototypes numbered 30.14, 30.15, and 30.16. (After the destruction of the 30.14 fighter, the number was re-assigned). The 30.14 reconnaissance prototype, powered by a 185 hp Daimler engine, came to Aspern for flight tests on 26 November. It was similar to the production version (designated C.I) except that the upper wing consisted of two panels and a separate center section. Details regarding the flight trials are lacking but the severe 1917 winter certainly retarded progress. On 9 February 1917, the 30.14 broke its back in a collision with a trainer on the ground. A new fuselage was provided. When Uzelac flew the machine on 22 February, he was impressed by "its fighter-like handling characteristics" and instructed Flars to push the development program with all possible speed.

Construction of the 30.15 prototype began in October 1916 and it appeared at Aspern in January 1917. The overall flight performance was reported excellent. The fuselage was damaged on 23 January when the tail skid collapsed while landing. Aviatik chief pilot, Stabsfeldwebel Fritz Wurbel was unable to fly the repaired machine on 10 February because it had been sabotaged. The elevator had been incorrectly wired and the tires slashed. The 30.15 was released for evaluation by Flars pilots on 13 February 1917.

During the first load test on 22 February, the rear spar of the third prototype, 30.16, collapsed at a 3.7 load factor. A strengthened wing, tested on 5 March, again failed. The upper wing, re-designed as a single structure, was tested on 23 March 1917 with satisfactory results.

On 29 April 1917, Uzelac demanded top priority to bring the promising two-seater, now designated C.l, into production. The 30.15 and 30.16 prototypes were repaired, brought up to production standard, and entered LFT service under the designations Aviatik C.l 37.02 and 37.03. Some sources claim that prototype 30.14 became 37.01, but this is inconsistent with the fact that the 30.14 prototype was written-off on 21 March 1918 as was the 37.01 on 22 April 1918.

Aviatik 30.15 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 8.40 m (27.56 ft)

Chord Upper 1.75 m (5.74 ft)

General: Length 6.83 m (22.41 ft)

Track 1.80 m (5.91 ft)

Aviatik C.I Series 37 and 137

According to Graf Sternberg, if Berg's two-seater proposal of 8 June 1916 had been given priority instead of the Knoller program, the Aviatik C.I could have been operational in the autumn of 1916 and not, as it happened, a year later. Only after Uzelac's intervention in August 1916 was Aviatik allowed to proceed with construction of three C.I prototypes (30.14-30.16). When these were test flown, there was little doubt that Aviatik had produced a very fine aircraft.

In March 1917, Flars ordered 96 Aviatik C.I aircraft (including three prototypes 37.01-37.03 (ex-30.15, 30.16, and possibly 30.14 new) and four pre-production machines for evaluation (37.04-37.07, delivered in March and April 1917). Provided the tests were successful, Aviatik was to deliver 49 C.I series 37, numbered 37.08 to 37.56, powered by a 185 hp Daimler engine and 40 C.I series 137, numbered 137.01 to 137.40, powered by a 200 hp Daimler engine. Oberleutnant Oskar Fekete, an expert test pilot who flew the pre-production 37.04 under ideal conditions at Wiener-Neustadt, wrote on 31 March 1917:

An exceedingly easy-to-fly machine. Stability in all axes very good. Reacts fully to the rudder. Very good climb rate and great speed. Glide flat and pleasant. Landing easy. View in all directions very good. An ideal observation type, suited to mountainous terrain and small airfields.

On 29 April 1917, Uzelac requested top priority for the C.I and prepared for license manufacture at Lohner, Lloyd, MAG, and WKF that raised the production total to 255 C.I aircraft.

Prior to general squadron release, a few machines were assigned to Flek 6 for instructional purposes and to Flik 19 for frontline evaluation. Flik 19 soon reported structural problems (12 May 1917), causing Uzelac to halt production and ground the C.I biplanes for inspection and modification. The structural report issued on 11 July 1917 specified strengthening the engine bearers, aileron supports, center-section struts, tail skid, control surfaces, wing leading edges, and lower-wing attachment fixtures. Given the added weight of the modifications, the C.I failed to achieve the contractual climb rate, but the penalty was waived since the required speed was exceeded. When the Aviatik C.I appeared at the Front in August 1917, aircrew reaction was unexpectedly negative. Both Flik 23 and 46 found the C.I unsatisfactory because of the fragile airframe and sloppy workmanship. Flik 46, perceiving the C.I "impossible as a two-seater," changed 37.46 into a single-seat fighter by installing twin synchronized machine guns, decking over the rear cockpit and removing 30 kg (66 lb) surplus equipment. The C.I single-seat conversion, especially the photo-reconnaissance version, was to become very popular in 1918.

Unfavorable assessments continued. In October 1917, Flik 32 reported the C.I as unsuitable for photo work because aircraft instability caused photos to blur. Complaints were received about the cramped observer's cockpit and the inability to carry cameras larger than 30cm focal length. Flik 34 wrote in October 1917 that the C.I, greeted with high hopes because of its performance, was soon grounded because of structural problems. Even after strengthening, the squadron "had little confidence in the type." To place these statements into the proper perspective, it must be remembered that pilots, accustomed to flying heavy, stable aircraft such as the Brandenburg C.I, found the sensitivity of the Aviatik C.I strange and disconcerting. With time frontline personnel came to appreciate its qualities. Pilot Philipp Vacano recalled that "the C.I was light on the controls and had to be flown with a certain touch. Unfortunately, not every pilot had it. The C.I responded to small gusts and even the motion of an observer swinging the machine gun would induce oscillations." Max Hesse, in his memoirs, reckoned the C.I was "suitable only for daredevils." The wheel control was cumbersome but a stick control was never fitted. The unusual rudder pedals - similar to automobile pedals - prompted so much criticism that they were replaced by a customary rudder bar beginning with aircraft 37.25.

Armament consisted of a fixed machine gun mounted on the center-section, firing at a 15 degree angle over the propeller, and a gun for the observer. In general, the machine guns were not installed at the factory due to the shortage of guns and interrupter mechanisms. In June 1917, aircraft 37.21 was sent to Fischamend for installation of a wooden rotating turret that became production standard beginning with aircraft 37.49. Aircraft 37.13 was tested with twin, forward-firing machine guns.

The Aviatik C.I series 37 saw operational service on the Italian Front, where it was assigned to Fliks 17/D, 21/D, 24/F, and 48/D in the South Tirol and to Fliks 2/D, 5/D, 12/Rb, 19/D, 22/D, 23/D, 32, 34/D, 35/D, 46/P, and 58/D on the Isonzo Front. In the spring of 1918, the C.I series 37 was slowly being replaced by aircraft of greater range, durability, and load-carrying ability.

Aviatik C.I Series 37 Specifications

Engine: 185 hp Daimler

Wing: Span Upper 8.40 m (27.56 ft)

Span Lower 8.25 m (27.07 ft)

Chord Upper 1.70 m (5.58 ft)

Chord Lower 1.70 m (5.58 ft)

Sweepback Upper 0 deg

Sweepback Lower 0 deg

Gap 1.52 m (4.99 ft)

Stagger 0.36 m (1.18 ft)

Total Wing Area 24.8 sq m (267 sq ft)

General: Length 6.86 m (22.51 ft)

Height 2.26 m (7.41 ft)

Track 1.80 m (5.91 ft)

Empty Weight 653 kg (1440 lb)

Loaded Weight 976 kg (2152 lb)

Maximum Speed: 178 km/hr (111 mph)

Climb: 1000m (3,281 ft) in 3 min 52 sec

Aviatik C.I Series 137

After aircraft 37.01 was evaluated with a 200 hp Hiero engine, the engine was replaced by a 200 hp Daimler in June 1917. As such the 37.01 became the prototype for the Aviatik C.I series 137. Acceptances began in September 1917 and ran concurrent with the series 37 until June 1918, when the last of 40 C.I series 137 aircraft was accepted. Because fighters were given priority for the 200 hp Daimler engine, most of the series 137 machines were delivered with rebuilt 185 hp Daimler engines, and 13 left the factory without engines due to the engine shortage.

When the Aviatik C.I series 137 biplanes arrived at the Front in November 1917, aircrews appreciated the good performance but criticized the shoddy workmanship. Such a lightly-designed aircraft required materials and a level of craftsmanship that Aviatik seemed unable to meet. The rocky airfields encountered on the Italian Front played havoc with the airframe, particularly the plywood-covered fuselage. Responding to aircrew complaints, the fuselage of 137.32 was load tested on 5 January 1918 and corrective measures taken. As a two-seater, the C.I series 137 saw operational service with Fliks 5/D, 17/D, 21/D, 23/D, 27/D, 39/D, 47/D, 49/F, 50/D, 53/D, 58/D, 59/D, and 73/D.

Aviatik C.I Single-Seat Conversion