В.Кондратьев Самолеты первой мировой войны

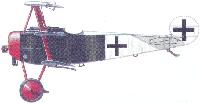

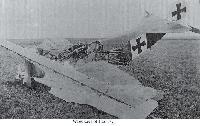

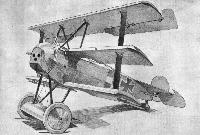

"ФОККЕР" Dr.I / FOKKER Dr.I

В июле 1917 года немцам достался трофейный английский истребитель "Сопвич триплан", совершивший вынужденную посадку на вражеской территории. Многие германские авиафирмы сразу начали работы по копированию этой удачной машины.

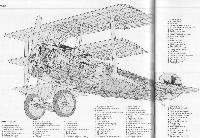

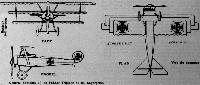

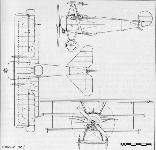

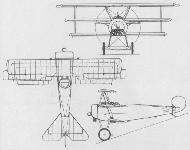

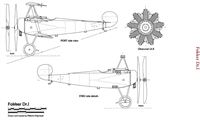

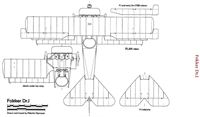

Наибольшего успеха добился авиаконструктор фирмы "Фоккер" Рейнольд Платц. Спроектированный им аэроплан во многом отличался от английского прототипа. Он имел типично "фоккеровский" фюзеляж и оперение с каркасом, сваренным из тонкостенных стальных труб и полотняной обшивкой. Важным нововведением были крылья относительно толстого профиля без наружных расчалок.

Прототипы V.3 и V.4 были быстро построены, успешно облетаны и рекомендованы к серийному производству под обозначением "Фоккер" Dr.I (Dr - сокращение от немецкого Dreidecker - "драйдеккер" - триплан).

Поначалу самолеты комплектовались 100-сильными ротативными моторами "Оберурсель" Ur.I, затем - 110-сильными Ur.II или импортными шведскими моторами "Тулин" той же мощности (копия французского двигателя "Рон" 9J). Иногда ставили трофейные 130-сильные "Клерже", с которыми самолет демонстрировал выдающиеся летные характеристики.

Вооружение - два синхронных пулемета LMG 08/15.

Первые два экземпляра машины в августе-сентябре 1917 г. успешно прошли войсковые испытания на западном фронте. В октябре новыми истребителями вооружили Первую истребительную эскадру Рихтхофена, а затем самолет начал поступать на вооружение других частей и подразделений.

Всего было построено 318 "фоккеров" Dr.I. Пик их боевого применения приходится на май 1918 года. К началу этого месяца в немецких фронтовых эскадрильях числилось 170 машин данного типа. Но в том же месяце самолет был снят с производства.

К концу войны в строю оставалось еще около 70 "драйдеккеров". К тому времени они уже считались морально устаревшими и большинство из них входило в состав тыловых эскадрилий ПВО.

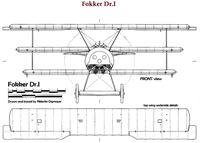

Надо отметить, что Dr.I, ставший сейчас на Западе своего рода символом авиации Первой мировой войны и образцом для постройки многочисленных летающих реплик, далеко не однозначно воспринимался немецкими боевыми летчиками. Обладая хорошей скороподъемностью и отличной горизонтальной маневренностью, он в то же время был весьма сложен в пилотировании и просто опасен для пилотов невысокой квалификации.

По скоростным данным он уступал современным ему истребителям стран Антанты (особенно - ранние машины со 100-сильным мотором). Кроме того, на фронте выявилась недостаточная прочность крыльев, из-за чего произошло несколько катастроф. В ноябре 1917-го полеты на "драйдеккерах" даже пришлось временно запретить до устранения этого недостатка. Лишь через месяц самолеты с усиленными крыльями вернулись на фронт.

Но при всех своих недостатках Dr.I был излюбленной машиной ведущих германских асов, так как он давал первоклассным пилотам наибольшие возможности в маневренном воздушном бою на близких дистанциях.

ДВИГАТЕЛЬ: "Оберурсель"Ur I, мощностью 100 л.с. (на первых серийных машинах), или "Оберурсель" Ur II, 110 л.с.

ВООРУЖЕНИЕ: 2 синхр. LMG 08/15 "Шпандау".

ЛЕТНО-ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

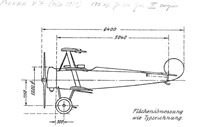

Размах, м 7,20

Длина, м, 5,76

Площадь крыла, кв.м 18,66

Сухой вес, кг 406

Взлетный вес, кг 586

Скорость максимальная, км/ч 165

Время подъема на высоту

2000 м, мин.сек 6,48

Потолок, м 6000

Показать полностью

R.Keimel Osterreichs Luftfahrzeuge (Weishaupt Verlag)

M.A.G. Fokker Dr. I 1917

После прототипов 90.01 (Berg C I) и 90.02 (Berg D I) в 1917 году на Венгерской всеобщей машиностроительной фабрике был создан прототип 90.03 - копия истребителя-триплана Fokker Dr. I. До серийного выпуска дело не дошло.

Производитель: Лицензионная постройка, Ungarische Allgemeine Maschinenfabrik AG (MAG), Будапешт.

Назначение: Прототип истребителя.

Построен: 1917

Первый полёт: 1917

Количество: 1 экземпляр

Бортовой номер: Сер. № 90.03

Экипаж: 1

Двигатель: 1 × 118 кВт (160 л.с.) Le Rhône, ротативный, двухлопастный винт.

Размеры:

Размах крыла: 8,00 м

Длина: 6,80 м

Высота: 3,20 м

Веса:

Пустой: 620 кг

Макс. взлётный вес: 880 кг

Нагрузка на мощность: 7,5 кг/кВт

Макс. скорость: 170 км/ч

Потолок: 4500 м

Дальность: 500 км

Продолжительность полёта: 3 ч

Показать полностью

A.Weyl Fokker: The Creative Years (Putnam)

Fokker's travels to the Western Front

Early in 1917 Fokker again journeyed to the front. Although the German command was far-sighted enough to encourage such activities, in the interests of exchanging technical information between industry and operational units, Fokker was one of the few executives in the German aircraft industry who regularly paid visits to front-line formations. These visits were welcomed by pilots, who were able to air grievances about their equipment unhampered by Service regulations.

Fokker had two purposes for this particular visit: he wanted to find out what kind of fighter design, in continuation of the V.1/V.2 development, would be likely to be successful; and he wanted to discuss with his pilot friends ways and means of overcoming the growing resistance of the Adlershof technicians to his aircraft. He felt that something should be done to curb the slide-rule wielders and stress experts. So he assured one and all that he, Fokker, could give them the finest fighter aircraft on earth if only the thick-headed theorists of Adlershof would let him: his advanced designs were too practical for the chair-borne brigade at Adlershof.

These arguments struck a sympathetic chord; in fact, many of the leading fighter pilots had similar ideas. They had been provided with obsolete aircraft, some proving to be complete wash-outs; the pilots therefore ought to be consulted in the selection of new fighter types. The departmental chiefs of the IdFlieg and the Flz. readily agreed to this idea: it had always been a difficult and heavy responsibility for them to choose the best available type of aircraft; time and time again the chosen type, although good at the prototype stage, did not go into operational use until too late, when it was obsolescent. In other instances, new engines had proved disappointing under operational conditions.

For these failures the technical experts were blamed, consequently they were well content to leave the task of selection to operational pilots. It was decided that all new and airworthy prototypes should be sent to Adlershof to be flown in comparative trials by competent fighter pilots. In addition, it was suggested that promising new experimental aircraft should be sent to the front, even before being submitted to a type test. This, it was thought, should help to expedite production and re-equipment with the latest and best types.

These concessions to operational units were, of course, a quite startling innovation in the German Army. It was unheard of for soldiers to be allowed to choose their own equipment: no soldier had ever been invited (officially, that is) to express his opinion on the design or handling of his rifle. But the officers responsible for the innovation, notably Thomsen, Siegert and Wagenfuehr, did not hesitate to cut red tape in this way; they were confident that the arrangement with the fighter pilots would work well. Fokker hoped so too.

While Fokker was visiting Jagdstaffel 11, commanded by Manfred von Richthofen, he was told about the sensational new Sopwith triplane that had made its appearance at the front. Fokker was shown the first specimen brought down before it was passed on to Adlershof. He was also taken to an observation post, where he saw the triplane in flight. Von Richthofen and his technical officer Leutnant Krefft told Fokker that they needed just such an aircraft. But it had to come quickly and to be at least as good as the Sopwith.

Fokker hurried back to Schwerin. This was the chance he was waiting for. The time was late April 1917. Although he knew that other manufacturers would be invited to submit prototypes designed to counter the Sopwith triplane, he was confident that Platz would be able to get out a design more quickly than his competitors and that it would probably be better. Moreover, Fokker had a start over his rivals because he was the only manufacturer who had seen the Sopwith and knew its capabilities. He also recalled the large store of Bente Le Rhones at Adlershof: this engine would do as well as the Clerget that powered the Sopwith, and it was immediately available in quantity. There would therefore be no hold-up because of shortage of engines.

As soon as he got back to Schwerin Fokker told Platz of his discoveries and ideas. One might think that Fokker would have recorded fully all that he had learned about the Sopwith, with a technical description of the design and structural features that he might have been expected to note with care. Nothing of the kind! As Platz distinctly recalls - and he is quite emphatic about it - Fokker merely told him: “I have seen a good enemy triplane at the front. We must build one too”. And that was that. Platz gathered that the new prototype was to have a rotary engine that would be forthcoming from Adlershof almost at once.

Platz did not like the idea at all. He was all for Spartan simplicity: to him, it seemed an outrageous and retrograde complication to give an aeroplane three wings when one would be so much better: he could not understand it at all. But Fokker was the boss; to argue with such a stubborn fanatic was not easy, and Platz was very conscious of the fact that he was just beginning to find his feet as a designer. He could not help it: the triplane was an order: a triplane it had to be!

Platz is also quite certain that while he was designing the Fokker triplane he had no information whatever about the Sopwith triplane. No example of the Sopwith or any of its components came to Schwerin (contrary to the assertion made later by Dr. Sablatnig), and Platz’s only wartime visit to Adlershof did not occur until 1918. It is therefore certain that his triplane design, the Fokker V.3, was not influenced by that of the Sopwith; this is borne out by a comparison of the general arrangement and structural design of the two aircraft. How far any advice or suggestions of Fokker’s may have influenced the final development of the V.3 cannot now be ascertained, but any such advice seems to have been confined to points relating to the handling and armament of the new type.

Some small Sopwith influence might be attributed to the use, at a later stage, of a single interplane strut. Platz is emphatic that this strut was quite unnecessary when the prototype was first tested at Schwerin, but Fokker insisted on having it fitted after testing the aircraft. Platz cannot recall the reasons given by Fokker at the time. To the world Fokker let it be known that it was added because the Adlershof experts abhorred cantilever wings (which was quite untrue) and that the operational pilots did not want them either (which probably was true).

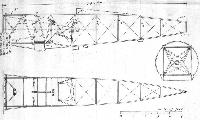

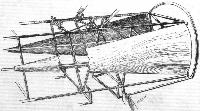

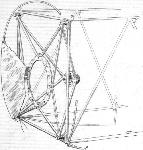

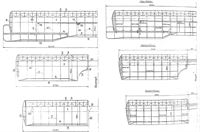

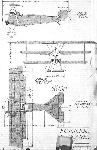

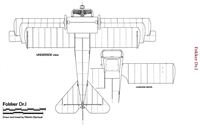

The Fokker V.3 was simpler and lighter than the V.1. With the elaborate streamlining abandoned, the slab-sided, fabric-covered fuselage saved weight and eased production and maintenance in the field. There were small plywood fairings on the fuselage sides to blend the circular cross-section of the engine cowling into the rectangular section of the fuselage structure; a rounded top decking was also fitted.

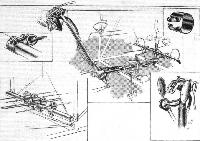

As on the Sopwith triplane, the three wings were staggered. This was neither coincidence nor imitation; it merely happened to be the best way of getting a decent view from the cockpit. All the wings had the same chord and section, but the top wing was of greater span than the other two; these were of equal span. Thus in each wing the cantilever portion was of the same length, consequently it was possible to make all the spars of the same cross-section. Platz neglected to take into account the actual lift grading over triplane systems. He assumed uniform loading everywhere. All wings were integral structures, the middle wing being attached directly to the upper longerons.

Much attention was given to the evolution of a suitable wing section. Platz thought that thick aerofoils might prove inefficient in a triplane system and that a section with no camber on the undersurface would give a high landing speed. He therefore reshaped, by eye, the V.1/V.2 section to the characteristic undercambered aerofoil of the Fok. Dr.I. This aerofoil was not tested aerodynamically in a wind-tunnel or in any other way when the V.3 and V.4 were designed. Later on, unknown to Platz, the Flz. subjected it to wind-tunnel tests at Goettingen as the Goettingen 298 aerofoil. The results of these tests were circulated by the Flz. to all German aircraft manufacturers. They were, of course, of limited value because of the low Reynolds numbers and the failure to take the turbulence of the wind-tunnel into account.

The results of British wind-tunnel tests of the Fokker aerofoil were largely ignored at the time: the leading aeronautical brains in this country were “positively certain” that thick aerofoil sections must be fundamentally bad. This being so, no-one would have been so unpatriotic as to admit that a German designer might be right with such an outlandish idea.

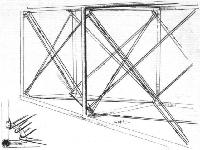

The two wing spars had to be placed as close together as possible so that the middle wing could be accommodated in front of the cockpit. But, as trials with the V.3 showed, this impaired the torsional stiffness of the wings. To put this right, the gap between the two spars was bridged, above and below, by span-wise plywood strips glued and bradded over the tops and bottoms of the spars. This produced a box structure with four vertical webs and four narrow flanges, covered by plywood flanges. This unique spar-box arrangement of the Fokker triplanes obviated the need for internal drag bracing, yet allowed the wings to be covered simply with fabric.

In such a wing the stiffness of the deep ribs with their plywood web could have been utilized to relieve the torsion strain (by compound action of the rib-spar system restraining the spars from warping). However, it was Fokker practice to make the spar gaps in the ribs large enough to allow the ribs to slide over the web splices during assembly; the ribs were subsequently attached to the spars by triangular corner pieces.

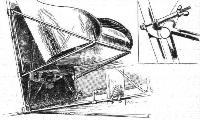

Each wing tip was formed by attaching a wing rib at right angles to the end rib. This was simple and yet gave a pleasing, rounded tip shape; it was also capable of resisting dope stresses and facilitated handling.

The cabane structure for the top wing was much simpler than that of the V.1, but was rather tall because the wing was above the level of the pilot’s head. The cabane of the V.3 (and of subsequent Fokker triplanes) consisted of two inverted-V struts with cable cross bracing in the plane of the front members. There was a wide bracket at the apex of each inverted-V strut; this attachment was fixed to both wing spars. The top wing attachment was consequently not so rigid as that of the V.1, but it was lighter, interfered less with the pilot’s view, and probably caused less interference drag than the ten-strut cabane structure of the V.1.

Seen from some angles, particularly from the front, the V.3 looked ungainly: neither Fokker nor Platz was much impressed by its lines.

In the V.3 Platz abandoned the peculiar control surfaces of the V.1 and V.2 and fitted conventional ailerons, elevators and rudder. In accordance with his views on simplicity the ailerons and elevators were not balanced surfaces. The standard comma-shaped rudder of the M types was retained. Although balanced, it was simple enough for Platz’s taste.

After flight-testing the V.3, Fokker demanded balanced ailerons and elevators. Platz disapproved of these luxuries, which he regarded as a mere fad of Fokker’s. But Fokker insisted on them, and was right to do so - every pilot who flew the Fokker triplane praised its effortless response to the controls. Platz returned to plain control surfaces in several subsequent designs. It is regrettable that he never troubled to learn to fly.

It was decided not to submit the V.3 to a type test or to an evaluation at the front. Instead, a re-design under the new designation V.4 was undertaken.

Platz realized that the appearance of the triplane could be improved by increasing the span of the middle wing so that the spans of the three wings decreased regularly from top to bottom. The increased span would mean a higher maximum bending moment at the fuselage, and Platz was not keen on fitting stronger spars to the centre wing on this account.

A new middle wing of the desired increased span was subjected to structural tests to determine whether stronger spars were needed. The results proved that the wing had an unusually high load factor for those days and needed no strengthening. Platz now realizes that the V.3 and V.4 spar flanges were generously dimensioned: when he designed the aircraft he failed to take into account the high strength of pine in tension. Had he done so he could have made the bottom flanges smaller.

Despite the favourable result of the structural tests, Platz was glad that the interplane strut was fitted, for it reduced the appreciable flexing of the wing. Although harmless enough in itself, this flexing would probably have alarmed pilots. In front elevation the interplane strut was perpendicular to the wings. Platz now recognizes that it would have been more logical to instal the strut obliquely, so as to form equal-span bays in the three wings. This might also have looked better.

The Fok. Dr.I was later flown experimentally without interplane struts by Adlershof test pilots: they wanted to find out what would happen if the interplane strut was hit in combat. The triplane remained manageable but the wings warped visibly and displayed an inclination to flutter during steep glides. This indicated that the interplane strut was subjected to bending fore and aft and was not a mere placebo, as Fokker had claimed. This was also proved by the official sand-loading tests; when the required ultimate load for case C (terminal nose dive) was reached, the fittings of the upper strut began to buckle, a sign of impending collapse from torsion.

The Fokker V.4 emerged with a new set of wings in which the top and bottom surfaces were of greater span than those of the V.3; the middle wing was of intermediate span in order to provide progressively reducing spans. Horn-balanced ailerons were fitted to the upper wings, and the interplane strut made its initial appearance. The horn-balances of the elevators projected outside the tailplane contours, and twin fixed machineguns were fitted. Fuselage, rudder and installation appeared to be identical with those of the V.3.

The introduction of the Fok. F.I triplane

In June 1917, as a counter-measure to combat Allied air superiority in the Flanders sector, four of the best Jagdstaffeln (Nos. 4, 6, 10 and 11) were grouped together to form the first German Fighter Wing (Jagdgeschwader Nr. 1). The new unit was mobile, for it was intended that it should be moved to any sector threatened by Allied air activity. Its command was given to Manfred von Richthofen.

On July 6 von Richthofen was shot down wounded; he returned to the aerodrome at Marcke on July 25. On the following day he announced to his officers that the unit was to be re-equipped with Fokker triplanes. These he described as being “as manoeuvrable as the devil” and capable of “climbing like monkeys”. This re-equipment had been decided upon without waiting for a Type Test.

A possible reason for this hasty adoption of the new Fokker lay in the poor opinion of German fighter aircraft held by their pilots. They were then opposed by Sopwith Pups, Triplanes, Camels, S.E.5s, Spads, Nieuports and Bristol Fighters; the F.E.s and R.E.8s were easy meat for the German fighters. The new S.E.5a was greatly superior in climb and speed. Leutnant Adam, leader of Jasta 6, regarded the S.E.5 as about equal to the Albatros D.V; he regarded the Pup and Triplane as inferior, and thought the Camel might also prove to be inferior. There was no doubt about the superiority of the S.E.5a and the 200-h.p. Spad over the Albatros.

Voss, leader of Jasta 10, differed from Adam: he regarded all contemporary British single-seaters as better than the Albatros in climb, manoeuvrability and ability to dive. Leutnant Groos, the deputy leader of Jasta 11, agreed entirely with Voss. Manfred von Richthofen himself was convinced that re-equipment with better fighters was long overdue.

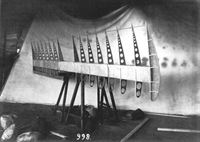

Fokker had been given an order for the supply of three experimental examples of his triplane design. The V.4 prototype (Military Order No. 101/17) was sent early in August to Adlershof for structural testing prior to operational evaluation at the front. The other two aircraft, No. 102/17 and No. 103/17, were nearing completion at Schwerin. The Flugzeugmeisterei conducted the strength tests with all speed between August 7 and 10, 1917, with Fokker present. The type was, at that early date, referred to as Fok. Dr.I.

For the first time a new Fokker aircraft passed its structural tests without major modifications. It was suggested that the rudder bar should be strengthened, and that the diameter of the steel-tube longerons in the rear fuselage should be increased to 20 mm. The tests appeared to indicate that the undercarriage strength was not up to the required standard but, as there were doubts about the testing rig (which was thought to be somewhat unrealistic), the aircraft was not grounded or retarded for this reason, and in fact no Fok. Dr.I ever gave cause for complaint about its undercarriage.

On August 11, the prototype V.4 was tested to destruction in Case A. The ultimate load factor proved to be 7-92, which was highly satisfactory. Fokker asked for the fabric to be removed from the lower wing so that structural deformation could be observed. The ribs began to buckle at a load factor of 7-75, final failure occurring with the buckling of the webs at the fuselage. Taking into account the lift from the aerofoil fairing of the undercarriage axle, the ultimate load factor could be as high as 8-38. It is doubtful whether any other operational aeroplane of the period possessed comparable strength.

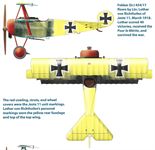

With the type designation Fok. F.I, No. 102/17 and No. 103/17 underwent acceptance flight tests at Schwerin on August 16, 1917. They were taken by Fokker to Manfred von Richthofen’s fighter wing at Courtrai on August 21. It is not known with certainty why the two aircraft were designated Fok. F.I. Perhaps the Kogenluft had decided on a new category that followed naturally on the official category letters A, B, C, D and E. But the IdFlieg had already settled on Fok. DR.I (or more correctly Fok. Dr.I) at a very early stage, as a Flz. drawing dated August 7, 1917, clearly proves. All doubt about the triplane’s official designation was removed by a Flz. order dated August 19, 1917, and signed by Muehlig-Hofmann. This order established the category Dr. for single-seat fighter triplanes; it also created the categories (CL (or Cl) and GL (or Gl) for light two-seaters and light twin-engined aircraft respectively. Thus 102/17 and 103/17 remained the only Fokker triplanes to bear the designation F.I. They differed visibly from the V.4 only in having the elevator horn balances lying within the contour of the horizontal tail surfaces.

On August 26, 1917, no less a personage than Quartermaster-General von Ludendorff, commanding the German armies in the field, came to see the new Fokker fighter. Fokker demonstrated it with his usual skill. On the evening of August 29, Leutnant Werner Voss, leader of Jasta 10, tried it for the first time. He was delighted with the little triplane and its capabilities. He made the first operational flight on F.I No. 103/17 on the following day; during this flight he shot down a British aircraft. Voss’s fighting career with the triplane was brief, but with it he scored no fewer than twenty-one victories between August 30 and September 23.

He was flying No. 103/17 when he met his death on September 23. He was flying alone on an evening patrol when he saw an S.E.5a, which he attacked. Other aircraft were attracted to the fight. These included the S.E.5a’s of “B” Flight of No. 56 Squadron, R.F.C., led by Captain J. T. B. McCudden and including Second Lieutenant A. P. F. Rhys Davids. After a long fight, in which Voss fought superbly, Rhys Davids at last placed a well-aimed burst of fire into the Fokker triplane. McCudden. who was the only witness of the triplane’s last plunge to earth, later praised Voss’s skill and courage; Rhys Davids bitterly regretted that he had been unable to take such a gallant foe alive.

Manfred von Richthofen flew a Fokker triplane for the first time on September 1, 1917: the aircraft was Fok. F.I No. 102/17. Although he was still suffering badly from his head wound and had little faith in rotary engines, he took instantly to the Fokker. Later that day, again flying the triplane, he shot down an R.E.8 near Zonnebeke. It was his sixtieth victory.

Although that particular victory was an easy one, so much did von Richthofen like the Fokker that on the following day he reported to the Kogenluft that it was distinctly superior to the Sopwith triplane and well suited to the requirements of his Jagdgeschwader. He requested complete re-equipment with triplanes with all possible speed.

Fok. F.I No. 102/17 had a shorter life than its sister machine. On September 15, Oberleutnant Kurt Wolff (Jasta 11), a frail-looking boy of great spirit who was very popular with Manfred von Richthofen and his brother officers, was shot down and killed while flying it in combat with Sopwith Camels of No. 10 Squadron, R.N.A.S.

About the middle of October 1917, six new triplanes were delivered from Schwerin, all now bearing the designation Fok. Dr.I and differing from the F.Is in some details. The only external difference was the addition of wing-tip skids under the lower wings. The order numbers of these first six Fok. Dr.Is were 104/17, 106/17, 109/17, 110/17, II1/17 and 113/17.

Eleven more arrived three days later, all with Beute Le Rhone engines. These were Nos. 107/17, 112/17, 114/17, 116/17, 118/17, 119/17, 121/17, 122/17, 123/17, 125/17 and 132/17. No. 108/17 did not go to the front: it was supplied to Adlershof for flying trials of the new 160-h.p. Goebel Goe.III engine.

Included in the next batch of triplanes was the ill-fated No. 115/17. This Fok. Dr.I was delivered to Jasta 15, on October 22, 1917, where it was taken over by the Staffelfuhrer, Leutnant Heinrich Gontermann. Bad weather delayed his first flight in the aircraft until October 28, 1917. On the following day his second flight in the new triplane ended fatally: an eye-witness description indicates that Gontermann was performing aerobatics at 1,500 ft. over the aerodrome when it became apparent that his triplane was out of control. Several parts of the top wing were seen to break away, and the aircraft crashed. Gontermann was seriously injured and died next day, twenty-one years of age and with thirty-nine victories to his credit.

On October 31, two days after Gontermann’s fatal crash, Leutnant Pastor (Jasta 11) crashed in a similar manner while flying No. 121/17. In spite of the promise showed by the triplane all aircraft of the type were grounded immediately. A special commission of experts (Z.A.K. Sturz Kommission) was hastily formed and sent to the front to investigate. Its members were Oberleutnant Dr.-Ing. W. Hoff of the D.V.L., the Flugzeugmeisterei engineers Diebel and Fleckig, and - most important - Dipl.-Ing. Roland Betsch, technical officer of Bauaufsicht 13 at the Fokker works, Schwerin. A more searching structural examination of the aircraft was begun at Adlershof.

Meanwhile, the Richthofen Jagdgeschwader had to revert to Albatros D.Va and Pfalz D.IIIa, both with the 160-h.p. Mercedes and no longer competitive types in the more active sectors of the front.

Manfred von Richthofen had been a witness of Pastor’s crash. Immediately after the accident, he and his Technical Officer, Leutnant Krefft, examined all the Fokker triplanes on the strength of Jagdgeschwader 1. The result was alarming: they found extensive evidence of bad workmanship. It was obvious that production of the wings had been rushed, and that such inspection as might have been made had been sketchy. When the crash-investigation commission arrived from Adlershof, accompanied by a much-subdued Fokker, von Richthofen showed them his findings. He also impressed upon the commission the urgent need for a speedy investigation and recommendation: the Fok. Dr.I was urgently needed and had shown great promise.

Examination of the remains of both the wrecked triplanes confirmed that the workmanship had been exceedingly poor. On the other hand, the wing spars had not failed in flight; but in each case the ailerons and ribs had come off in manoeuvres that could not be called violent, and this was puzzling. Several theories were advanced. It was suggested that sideslipping might have imposed some hitherto unknown loading on the ailerons, accentuated perhaps by the horn balances. Hoff did not like those balances: might not they, at some point, have produced an abrupt overbalancing force, thus producing sudden and unexpected peak loads? If so, the attachment of the ailerons did not look strong enough to cope with such loads, nor did the ribs that might have to transmit them look substantial enough. Some redesign seemed necessary: this ought to be investigated at Adlershof.

The accidents to Gontermann and Pastor were, by coincidence, investigated on the same day, November 2, 1917, the former at La Neuville, the latter at Kortryk. One eye-witness of Gontermann’s crash, a fighter pilot of Jasta 15, had noticed that during a side-slip to port the port aileron had broken away first; immediately afterwards the ribs came off the top wing. Examination of the wreckage showed that the top-wing spar had remained intact until the impact with the ground; the rest of the wing structure was missing. The Z.A.K Sturz Kommission found similar evidence in the remains of Pastor’s aircraft. The spar of the top wing and the port aileron were examined, and it was found that all the ribs had come away in the air. The inner portion of the aileron was missing, and the surface had fractured outboard of the horn balance. The hinges were intact; a part of the auxiliary spar to which they were attached was still in place. Manfred von Richthofen stated that Pastor was gliding down. As the triplane tended to drop its port wings Pastor would have applied starboard aileron, thus producing a load on the ailerons that might have caused the failure.

For examination, von Richthofen and Krefft had selected the Fok. Dr.I that had done most flying, and had stripped the fabric from its top wing. This immediately revealed an insecure connexion between the auxiliary spar and the wing-tip former. Moreover, the interior of the wing had been badly affected by moisture: all the plywood webs had warped, and some of the cap-strips of the ribs had come away from the webs.

Removal of the fabric from the bottom wing of another triplane revealed that many ribs had pulled out of the grooves of their cap-strips, and that the triangular-section gusset pieces attaching the ribs to the spar box had come adrift, probably because of moisture and careless gluing. In this instance, disintegration of the entire wing seemed imminent.

After the Kortryk investigation, Oblt. Hoff interviewed Fokker in the presence of Manfred von Richthofen and delivered a stern warning that he would have to improve his production and inspection methods. If he did not do so, drastic measures would have to be taken. Fokker’s lame excuse - that his factory had worked day and night to expedite the delivery of the first triplanes because von Richthofen wanted them so urgently - was brushed aside.

On November 6, 1917, the IdFlieg wrote to Fokker confirming in detail “the instructions imparted to Herr Fokker by Oblt. W. Hoff at Kortryk”. This letter was agreed with the Kogenluft and was signed by Muehlig-Hofmann. It stipulated that existing Fok. Dr.I aircraft were to be provided with new and properly constructed wings without delay: the new wings must be supplied by Fokker without extra charge. All wings of existing Fok. Dr.Is must be sent to the Central Aircraft Acceptance Commission (Z.A.K.) at Adlershof. Until new wings were fitted, all Fok. Dr.Is must remain grounded.

The letter from the IdFlieg further directed that all Fok. Dr.I wings already made must be uncovered, examined thoroughly, and modified as follows:

1. Reinforcement of the tip former by adding a second rib to form a box rib.

2. A third box rib to be incorporated in the wing to provide a more solid attachment for the auxiliary spar.

3. Improvement of the joint between the auxiliary spar and the wing-tip former.

4. Omission of the cut-out at the centre of the auxiliary spar.

5. Improvement of the joint between the auxiliary spar and the capstrips of the ribs that were attached to it.

6. Improvement of the joints between the rib webs and their capstrips.

7. Stiffening of the rib webs by the addition of vertical stays.

8. Omission of the lightening holes in the rib webs to reduce moisture absorption.

9. The fabric must be sewn to the ribs; it must no longer be nailed on.

10. Provision must be made of means for supporting the fabric, especially in the centre of the upper wing.

11. The wing interior must be protected against moisture by a coating of protective lacquer.

12. The Flz. would experiment on the size of the horn balances of the ailerons: these might have to be modified.

The IdFlieg requested that these modifications should be inspected and approved by the Flz. before any wings were accepted. They also emphasized that all wings supplied in the future had to be more carefully produced and must not require further structural modifications.

The crash-investigation commission submitted its report and recommendations on November 15, 1917. It and its associated documents were signed by Roland Betsch.

Critical though the IdFlieg letter of November 6 was, Platz never saw it (until the author showed him a copy recently), nor did he learn the findings of the crash-investigation commission. Apart from Fokker’s failure to pass this information to Platz, it seems extraordinary that Betsch, who was personally acquainted with Platz, did not consider it his duty to discuss with the designer the technical details of the report. One cannot escape the feeling that at Schwerin conceptions of duty were peculiar, war or no war.

Today, having learned all these technical facts belatedly, Platz is convinced that the Fok. Dr.I could have been made safe with fewer modifications, simply by more careful production and a modification of the rib construction that he had already introduced at that time. After a test flight with a production Fok. Dr.I, the pilot had shown him that the fabric on one of the bottom wings had become loose; there had been no accident of any kind. Platz found that the rib cap-strips had come off the webs. The grooved cap-strips, a relic of the early monoplane, had been insufficiently glued and had parted company with the rib webs. Platz obviated this danger by sandwiching the web between two separate rib-contour runners: this gave a secure joint. The ribs of all subsequent Fokker aeroplanes were made in this way, regardless of whether the wings were fabric-covered or plywood skinned.

Of the other modifications demanded by the IdFlieg, Platz agrees that Nos. 1, 3, 5 and 9 were good ideas. His own independent action had met requirement No. 6. Modifications Nos. 2, 4, 7 and 8 seemed to him quite unnecessary, and his arguments against them would probably have convinced the Flz. experts if they had realized that the designer of the triplane was Platz, not the great A. H. G. Fokker who was so curiously inarticulate when questioned about design details.

The effect of the crash-investigation commission’s report and the IdFlieg letter was to bring Fok. Dr.I production to a standstill. As a scapegoat, the Schwerin works manager was dismissed. The military authorities refused to accept any further aircraft until all wings had been modified and thoroughly inspected.

All this was a considerable set-back for Fokker and his company. The initial order had been for 320 triplanes (with the numbers 101/17 to 220/17, and 400/17 to 599/17), and Fokker had been told, before the wing-failure crashes, that much larger orders might be given: this depended only on engine supplies and, most of all, on the lubricating-oil situation. But now the triplane was in disrepute, and instead of accepting growing orders Fokker had to use up his profits in having all wings stripped, examined and modified.

The original delivery programme envisaged the supply of 173 Fok. Dr.Is by December 1, 1917, the balance of the first contract to be delivered thereafter. The grounding of the type changed this drastically, as the following table indicates:

Date of report Number of operational Fokker triplanes Number supplied by Fokker during period preceding date of report

1.9.17 2 (Fok. F.I) 3 (one as type aircraft to Adlershof)

1.11.17 17 None during September; 24 during October

1.1.18 35 6 during November; 47 during December

1.3.18 143

1.5.18 171

1.7.18 118 Up to 1.7.18, 150 Fok. Dr. I were withdrawn from front-line units in the major flying sectors

1.9.18 65

1.11.18 69 Almost all with home-defence fighter formations

The modified wing, when tested at Adlershof, proved capable of withstanding more than 200 % of the maximum load specified for the aileron attachment, in spite of an adverse load grading. Being over-strength it was, of course, heavier than it need have been. On November 28, 1917, Fokker was notified by telegram from Hoff that the wing had proved satisfactory on test. The ban on the Fok. Dr.I was then lifted.

Deliveries of the modified triplanes started again early in December. By that time, however, the type had lost its temporary superiority and, especially in those sectors where aerial fighting was most intense, something better than the Fok. Dr.I was wanted.

The official report on the strength tests of the modified Fok. Dr.I wing was dated November 28, 1917. It included a description of the way in which the Fokker works had complied with the detailed requests of the IdFlieg. The points in the IdFlieg letter of November 6 had been dealt with thus:

1, 2, 9 and 10: modifications effected as requested.

3 and 5: the auxiliary spar was joined to all ribs by a triangular gusset piece of plywood; this was glued and pinned in place. Finally, a strip of fabric was cemented over it as a moisture protection.

4: the cut-out had been retained, but local reinforcement had been provided by gluing an additional piece of wood aft of the spar.

6: the joint had been improved by cementing on fabric.

7: web stiffeners had been added; over each of these, a strip of fabric had been cemented reaching over the cap-strip.

8: had been disregarded; this was accepted.

11: all wooden and metal parts in the wing had been given a protective coating of lacquer.

The structural modifications increased the wing weight by 3-5 kg.; that is, 4-25% over the original wing-structure weight of 84-5 kg. (187 lb.).

In the loading tests of the strengthened wing, the lift contributed by the undercarriage aerofoil was neglected, as before. The modified airframe withstood the specified safe loads in Cases A and B without any permanent or excessive deformation. The upper wing deflected by 135 mm. at the tips under a load factor of 5 in Case A, whereas the deflection in the original airframe had been only 127 mm. This was not investigated, possibly because the deflection was wholly elastic.

The aileron strength was tested under a negative load of 150 kg./sq. m. (30-8 Ib./sq. ft.) with the control column fixed; simultaneously the wing in front of the loaded aileron was sand-loaded to 200 kg./sq. m. (41 lb./ sq. ft.). Again no excessive deformation was observed, but splintering began to occur at the strut ends under this exceptionally severe load.

The auxiliary spar was stressed from a chordwise load of 150 kg./sq. m. on the ailerons; but even at twice this load no failure or permanent deformation occurred.

Finally an overload was applied to the wing tips. In the Case A test the sand was first applied uniformly along the span. When this load (2,345 kg., or 5,160 lb.) proved safe, additional loading was applied, rising triangularly to the wing tips. At 65% of this unrealistic tip load, the spar of the bottom wing failed at a distance of 75 cm. (30 in.) from the port side of the fuselage.

The report concluded that failure of wings or ailerons was unlikely in service unless glued joints were badly affected by moisture. The Bauaufsicht was instructed to exercise greater care in supervising the production of these aircraft.

After this unhappy interlude the Fok. Dr.I was relatively trouble-free. Two wing failures that occurred early in 1918 might have been attributable to combat damage. On February 3, 1918, Leutnant Wolff (Jasta 11) had to crash-land No. 155/17 after failure of the top wing: the aft spanwise stringer and ribs of the wing had broken. On March 13, 1918, Leutnant Lothar von Richthofen lost his top wing while diving almost vertically from an unfavourable combat position; he managed to crashland and escaped with minor injuries.

Two days later, on March 15, 1918, following a crash report, the modified Fok. Dr.I ribs were again strength-tested at Adlershof. The rib was fixed at its spar gap and a concentrated lift load applied to it. Failure occurred by buckling of the web under a load of 55 kg. (121 lb.). Two plywood reinforcing pieces were bradded to the web on both sides of the lightening holes. The rib now supported a load of 75 kg. (165 lb.). The test arrangement was far from being realistic: when the report was shown to Platz he considered the reinforcing pieces to be quite unnecessary.

The bogey of wing failure was not completely exorcised: on May 9, 1918, Leutnant Wenzel (Jasta 11) had five ribs fail in the top wing of his Fok. Dr.I during violent combat manoeuvres. He managed to land unharmed, and the failure was found to have been caused by poor workmanship.

Concurrently with the structural testing, the Fok. Dr.I was subjected to flying tests at Adlershof. There, on November 10, 1917, Fok. Dr.I No. 141/17 was evaluated as a typical example of the type. During the final meeting of the test committee and the discussion of the results, the Fokker company was represented by Dr.-Ing. Koner. The standing practice was for the designer of the aircraft to represent his firm at such discussions. The unsuitability of Koner as the Fokker representative has already been commented on.

No attempt was made to measure performance during the November trials: the performance figures that had been obtained during the acceptance tests of No. 141/17 on October 15, 1917, were incorporated in the report. These figures had been established with a military load of 145 kg. (320 lb.), 55 litres of petrol (12-2 gals.), and 8 kg. (17-6 lb.) of oil. Climbing times were:

To 1-0 km. (3,300 ft.) 1-6 minutes

2-0 km. (6,600 ft.) 4-2 minutes

3-0 km. (9,900 ft.) 8-0 minutes

5-0 km. (16,400 ft.) 20-6 minutes

The take-off run was 45 m. (50 yd.); the landing run 50 m. (55 yd.). The top speed was stated to be no less than 190 km./hr. (118 m.p.h.), but this was in fact an over-optimistic figure. Careful speed measurements were made in April 1918 at Rechlin: these established a maximum speed of only 156 km./hr. (97 m.p.h.) at an altitude of 2-75 km. (9,200 ft.), decreasing to 138 km./hr. (86 m.p.h.) at 448 km. (13,800 ft.).

Thus, D.H.9 pilots were not exaggerating when they claimed that they had been able to run away from the Fokker triplane with ease. In fact, the Fok. Dr.I was appreciably slower than the Albatros D.V, which it was supposed to supersede. But it had a much superior rate of climb at medium altitudes, and it manoeuvred superbly, its instant response to its highly sensitive controls demanding no effort from the pilot.

During the evaluation tests, various minor details were adversely criticized. These included better sealing of the entry of the aileron cables into the wing to minimize moisture absorption; poor attachment of the wing-tip skids (the need for them was not questioned!); the use of coloured anti-rust lacquer; defective cowling attachment; compass badly placed and not easily seen (it was unreliable anyhow); wheel track too narrow; front attachment nuts of the middle wing inaccessible; and so on.

More serious criticism was levelled against the shoddy crash-protection padding in front of the pilot; this should have been of 10-cm. (4-in.) diameter. The aircraft was found to be 25 kg. (55 lb.) heavier than the weight inscribed on the fuselage side (but the Fok. Dr.I was not by any means unique in this respect). The aileron cables were considered to be poorly arranged, for they chafed in places. The rudder should have had three bearings instead of only two; and the ailerons were of such a length that they should have had one more hinge.

The petrol cock was criticized for being too small, and for allowing petrol to drip into the fuselage. It was thought that the fuel tank should be made of brass, and that its mounting should be more substantial. There was some doubt about the effectiveness of engine cooling and - a curious criticism - the accessibility of the engine installation was queried. This last point was somewhat startling in view of the fact that all other operational German fighters had their engines deep within plywood fuselages.

The triplane’s exceptional manoeuvrability was praised. But the type could be recommended for Service use only after the wing and aileron design had been passed as airworthy.

At the final meeting no fewer than twenty-seven officers and high-ranking engineering experts of the specialist departments of the Flz. were present. Among them was Roland Betsch of the Bauaufsicht. It could not be said that the final judgment had been lightly or hastily reached.

The detailed report of this test failed to reach Platz, despite the fact that one copy was sent to the Fokker firm and another to the Bauaufsicht for action. Thus he, the designer, remained in ignorance of all the criticisms, suggestions and new requirements; nor did he know that the report was accompanied by a reminder that the required stress analysis of the aircraft was still outstanding and should be submitted forthwith. Apparently Bauaufsicht 13 at the Fokker Works had their own ideas about liaison between a manufacturer and the IdFlieg!

The Fok. Dr.I at the front

When the new Fokker made its appearance on the Western Front, most of the German fighter pilots took to it instantly and were full of praise for its flying qualities: it was everything they wanted a fighter aircraft to be. Even after the set-back caused by the wing failures and the subsequent suspicion of structural weakness, the operational pilots demanded that the ban on its use should be raised as quickly as possible. When similar difficulties beset some other fighter types the pilots fervently hoped that the suspect aircraft would not be seen again.

Allied pilots soon had the measure of the Fok. Dr.I. They discovered that it was rather better than the obsolete Sopwith triplane but that it was too slow. The drag of the triplane wing system deprived it of the ability to make swift, surprise diving attacks. As the test results quoted on page 241 indicate, the Germans had overrated the Fokker triplane’s speed. Yet it was not lack of speed that was its major shortcoming, even though that allowed the D.H.4, D.H.9, Bristol Fighter and Spad to run away from the Fok. Dr.I if they chose to do so: it was the poor all-round performance at the steadily increasing combat altitudes that mattered most. All Allied aircraft could now fly and fight at substantially greater heights.

On January 14, 1918, the Kogenluft ordered a drastic reduction of the load to be carried by all operational single-seat fighters. The fuel load was cut to provide a maximum endurance of only If hours; during acceptance tests, fuel for only one hour needed to be carried. This load reduction for all fighters in the D and Dr categories was also to apply to all new designs. This was an admission of the serious consequences of the mismanagement of aero-engine development in the immediate past.

In spite of the relief provided by this order, the main combat weakness of the Fok. Dr.I continued to be the low power and low compression ratio of its 110-h.p. Le Rhone engine. The Allies had largely withdrawn the Le Rhone from operational use a year or so earlier. A programme with the aim of re-equipping the Fok. Dr.I with more powerful engines of better altitude performance was therefore initiated. None of these variants was put to the test of operational flying before the Fok. Dr.I was withdrawn from first-line units.

Typical of the opinions of the pilots who flew the triplane in its operational heyday are those of von Tutschek and Ernst Udet. Hauptmann von Tutschek claimed that the Fok. Dr.I was superior in dog-fighting to any contemporary Allied fighter, better even than the 200-h.p. Spad single- seater. He himself had dived the Fokker triplane until its terminal velocity was reached in a near-vertical dive: this he claimed to be in excess of 240 km./hr. (150 m.p.h.), which is just possible but not very probable.

Ernst Udet stated, early in 1918, that to him the Fokker triplane seemed to be the ideal fighter aeroplane; he regarded it as superior to the Sopwith Camel in manoeuvrability and rate of climb. He was so fond of the triplane that shortly after the war he wanted a similar aircraft designed for him for exhibition flying.

Less enthusiastic were those pilots who were built on more generous lines than the average mortal. The Fok. Dr.I was no aeroplane for long-legged pilots: E. A. Marquard has recounted the agonies he endured in the triplane’s cockpit; a contemporary cartoon depicted him with his legs protruding through the bottom of the triplane's fuselage, his feet resting on a rudder bar mounted on the undercarriage axle. Marquard also criticized the poor view from the cockpit during take-off and when touching down. This was certainly true, because the fuselage was short and the undercarriage tall.

Most pilots of the Richthofen Jagdgeschwader flew the Fok. Dr.I until April 1918; from then onwards it was progressively replaced by the Fok. D.VII biplane. During the first big air battle over Le Cateau, on March 18, 1918, sixty German single-seat fighters took part: the majority were Fokker triplanes, one of which, No. 152/17, was flown by Manfred von Richthofen.

Contrary to all the sensational claims in Allied newspapers during the war and in certain American magazines published since then, Manfred von Richthofen’s triplanes were perfectly standard and carried no more than the two regulation machine-guns. He, however, had the privilege of having two or even three reserve aircraft. These were all alike and were always kept ready for immediate operational use in case his usual triplane was unserviceable for any reason.

Occasionally the red wings of his Fok. Dr.I bore leader’s streamers similar to those used in British squadrons. He adopted these after a shotdown British pilot had said that during the fight he had looked in vain for the legendary Red Baron as the most desirable target. A Prussian officer could not let this pass.

Production of the Fok. Dr.I ceased during May 1918; after that, no more production triplanes were accepted.

The Fokker triplane seen through Allied eyes

Examples of the Fokker triplane soon fell into Allied hands. One of the best specimens was No. 144/17, which came down in British-held territory in near-perfect condition, its pilot (Leutnant Stapenhorst of Jasta 11) having been wounded by anti-aircraft fire. This Fok. Dr.l had been despatched from Schwerin on December 12, 1917; its engine was apparently an Oberursel-built Le Rhone, or had been given an Oberursel nameplate.

The design features of the triplane were critically studied by Allied experts. At this remove it is difficult to know whether some were so strongly prejudiced that they thought that anything produced by the enemy was inevitably no good, or considerations of national security or propaganda required their reports to imply that that was the case. Others evaluated the Fokker intelligently, but took care not to hurt the tender feelings of the authorities and aircraft designers in this country.

In March 1918, Ministry of Munitions report No. I.C. 620 was published. It was brief, incomplete and inaccurate, its tone being set by the statement “It was felt the machine exhibits few instructive features”. The report asserted that the Fok. Dr.I was “one of the poorest of modern German designs”, emphasized “the grave structural weakness” of the airframe, and made it abundantly clear that the “expert” who wrote the report had been either insufficiently conscientious to make a rough paper check on the airframe strength or incapable of doing so: it would have cost less than an hour’s work. The report must have made remarkable reading for British pilots who had experienced the combat qualities of the Fokker triplane.

But British experts in less official positions thought somewhat differently. In particular, Flight took great pains to discuss the design objectively and in great detail: no doubt this description was written by C. M. Poulsen, who was the journal’s technical editor at that time. This excellent private effort allowed Allied aircraft designers to judge for themselves the merits of the Fokker triplane.

The Flight report criticized the fact that welded joints were stressed in tension. In comparison with other German fighters, the triplane's cockpit seemed cramped and spartan; the seat upholstery and padding were described as of inferior quality, like the rest of the furnishing. This criticism was justified: indeed, the poor finish and workmanship of the Fok. Dr.I may have been partly responsible for the poor impression it created among the British technicians.

The critic erred in objecting to the seemingly weak attachments of the undercarriage struts. This arrangement was intentional and in conformity with German official requirements.

On the whole, Flight's appraisement was not only intelligent and accurate; it was remarkably fair and far-sighted.

Immediately after the Armistice, the Allies discovered a number of serviceable Fok. Dr.Is in two fighter training establishments at Valenciennes and Nivelles. At Nivelles in particular, British and American officers had ample opportunity to make trial flights before these triplanes were scrapped. They were all astonished by the aircraft’s sensitivity, instant control responses, and the effortless ease with which it could be thrown about in the air. They now understood why their erstwhile German opponents had been so disconcertingly agile and elusive in combat. The Allied pilots were the more impressed because, during the war, the British authorities had not troubled to make proper flight tests of any of the captured triplanes. (Captured Fok. Dr.Is had been test-flown in France early in 1918, but the reports of these tests cannot now be traced.)

None of the officers who now had an opportunity of trying out the Fok. Dr.I found any real difficulty in mastering it. Although the specimens they flew were somewhat past their best and their engines were running on a low-grade castor-oil substitute, the triplanes still impressed with their spectacular climbing ability.

A few years after the war, one or two triplane single-seaters were built in Germany. These were more or less variations of the Fok. Dr.I and had Le Rhone-type rotary engines. Max Schueler, a veteran pilot and designer, flew one all over Germany advertising Sarotti chocolate. It had a Thulin-built engine, and its career ended in an unfortunate forced landing in 1926. It seems that no genuine Fok. Dr.I exists anywhere today.

Non-standard versions of the Fok. Dr.I

Towards the end of 1917 the Oberursel UR.II engine passed the official acceptance test; it was the Fokker-sponsored copy of the Le Rhone. Engines of this type were from then on installed in the Fok. Dr.I, but the pilots at the front preferred the Beute engines, and all kinds of subterfuges were employed to replace the UR.II. Both engines were practically identical, but the Thulin-built version embodied better materials and the workmanship was excellent.

Siemens und Halske had now completed their new eleven-cylinder counter-rotating engine, the 160-h.p. Sh.3. As it had not then passed its type test it remained experimental. This engine was more powerful than the Le Rhone and, owing to its higher compression ratio, had a better altitude performance. The large, slow-running propeller had a high propulsive efficiency.

Fokker received an order for an experimental triplane to be powered by this engine. The Sh.3 needed a different engine mounting embodying a front bearing; the cowling also had to be modified. Even when a four- blade airscrew was fitted it was still of such a diameter that a taller undercarriage was necessary. This not only made the aircraft ungainly in appearance but impaired its handling characteristics on or near the ground. It was also heavier. Although otherwise virtually identical with the standard Fok. Dr.I, the triplane with the Sh.3 engine was given the new designation Fokker V.7. Later versions of this triplane had the fuselage lengthened by as much as 55 cm. (21 -7 in.).

A. Zeithammer, the Siemens engineer in charge of the field trials with the Sh.3 engine, complained bitterly of Fokker’s uncooperative attitude. Fokker persistently found fault with the engine during test flights, yet Zeithammer was unable to trace any trouble. Fokker, of course, was not anxious to see the Siemens-Halske engine achieve success and be adopted. He had instructed his Oberursel firm to develop with all speed an eleven-cylinder Le Rhone development for a more powerful variant of the Fok. Dr.I.

It seems that the IdFlieg finally decided to take the experiments with the Sh.3 out of Fokker’s hands. One or two further Fok. Dr.Is with the Sh.3 were sponsored by Adlershof, but these were modifications of existing Dr.I airframes made in the Flz. workshops and by the Siemens und Halske firm.

While these experiments were proceeding, experience with the Sh.3 elsewhere left no doubt that the engine was still a long way from being sufficiently serviceable for operational use. Piston trouble was experienced, and the only available oil was not suitable. Hence, in spite of its magnificent climbing performance and amazing ceiling, the Siemens-engined Fok. Dr.I never reached the front. Besides, as Kurt Student relates, this version was slightly unstable and too sensitive for the average fighter pilot of the time. The approach and landing needed care: the wing-like axle fairing had been omitted in order to reduce the tendency to float near the ground. The torque reaction from the large airscrew was felt powerfully because the wing span was so short; and the blip-switch had to be used with great care when flying close to the ground.

The IdFlieg had intended to prolong the operational life of the Fok. Dr.I by fitting more powerful engines. One of the earliest of these experimental installations was of the first Goebel Goe.III engines (Works No.1) of 170 nominal horse-power. This engine was fitted to one of the earliest production triplanes, No. 108/17, which was test-flown by Schuetzenmeister at Goerries on October 30, 1917. It was fitted with an Axial airscrew of 270-cm. (8 ft. 10| in.) diameter and 255-cm. (8 ft. 4-4 in.) pitch: this gave 1,260 r.p.m. on the stand and 1,300 r.p.m. in level flight near the ground. At 5-0 km. altitude (16,500 ft.) the engine speed dropped to 1,130 r.p.m.

Carrying ballast of 60 kg. (132 lb.), 55 litres (12 gals.) of petrol and 10 kg. (22 lb.) of oil, the Goebel-powered triplane climbed to 5-0 km. altitude in only 14-3 minutes. This was an excellent performance for that time and far better than that of the standard Fok. Dr.I. The Goe.III, which was then some way from developing all the power of which it was capable, had an hourly fuel consumption rate of 90 litres (20 gals.) of petrol and 9 kg. (20 lb.) of oil; the latter was ersatz castor oil. This was greater than the consumption of the Sh.3 engine for about the same power output.

The Goe.III was a promising development of the Gnome, with a half-controlled, half-automatic inlet valve, a high compression ratio, and (later) oversized cylinders. Final versions (Goe.IIIa) could produce over 200 h.p. for short periods. This engine was the first to have a separate gear for an auxiliary drive; this was supplied as part of the engine’s light alloy mounting.

Some of the Fok. Dr.Is delivered from January 1918 onwards were supplied with this Goebel engine, about thirty aircraft in all. It is improbable, but by no means impossible, that one or other of these triplanes may have been flown on the Western Front. Most of them went to home-defence fighter formations and training units, and experience of the Goe.III was favourable.

When the new 145-h.p. Oberursel UR.III Le Rhone development came out late in December 1917, one of the first examples to complete its bench test was quickly installed in Fok. Dr.I No. 469/17 and demonstrated by Fokker. This variant was not officially adopted, but the aircraft was flown extensively as an engine test-bed for the development of the UR.III.

Three Fok. Dr.Is (Nos. 485/17, 527/17 and 562/17) were fitted with captured 130-h.p. Clerget engines: the engine numbers were 953, 1072 and 1503, the airframes Factory Nos. 2111, 2232 and 2195, respectively. The three aircraft made their acceptance flights on April 24, 1918, at Goerries, flown by Neisen, Grosse and Schuetzenmeister respectively. These Clerget-powered triplanes were not intended for operational purposes, but were used for an investigation into the Clerget engine’s behaviour.

This investigation almost certainly arose out of the serious difficulties experienced by Germany in trying to obtain lubricating oil for rotary engines. Castor oil had become so scarce on the German side that it could no longer be supplied even for the few rotary-powered German aircraft that were then operational. A German substitute (Voltol) had been developed; it was produced by a polymerization of ordinary mineral oil under electric discharges. This substitute was certainly less soluble in petrol than ordinary oil, but its lubricating qualities fell far short of those of castor oil. Worst fault of all, its quality was not consistent. Some at least of the troubles that afflicted German-built rotaries could be blamed on their oil, consequently there was good reason for subjecting captured engines with well-known performance to the torture of running on German ersatz lubricants.

During 1918, Fok. Dr.I aircraft were used in a special series of experiments instigated by the IdFlieg. The object of this work was the evolution of a supercharger for rotary engines in order to maintain constant power output up to altitudes of 6-5 km. (22,000 ft.) and higher; service ceilings of 9-0 km. (30,000 ft.) were envisaged for 1919, and were within reach when the Armistice supervened.

As a first step, a UR.II was installed in an otherwise standard Fok. Dr.I and fitted with a Schwade gear-driven compressor weighing 47-5 kg.(105 lb.). This was mounted behind the cylinders, alongside the crankshaft and carburettor. For the drive, Schwade had designed a suitable gear and a coupling embodying elastic clutches. When running at 10,500 r.p.m. the compressor absorbed about 20 b.h.p.

This was the first German direct-coupled aero-engine compressor to fly. Details of the flight tests have never become known, but the results were highly satisfactory. Had the war continued into 1919, Schwade would have received a large production order for a fully developed version to be used in a Fok. D.VIII variant: this would have given these single-seaters a marked superiority early in the year.

A compressor had also been developed by Siemens und Halske for the Sh.3 engine. This had already been flown in an obsolete Siemens-Schuckert D.I, in which it was mounted under the carburettor; the aircraft was turned over to the Flz. in October 1918 for further trials. The IdFlieg wanted comparative trials with a more modern aircraft and engine, however. The Siemens people would have preferred such trials to have been made in one of the later Siemens-Schuckert fighters, but none of the modern types could accommodate the compressor.

It was therefore decided to install the three-stage Siemens compressor in a Fok. Dr.I with Sh.3 engine. The compressor weighed 38 kg. (84 lb.) and ran at 8,600 r.p.m. The Fokker works obtained all installation details from Siemens in September 1918. Apparently in addition to the IdFlieg experiments with the supercharged Sh.3, the Fokker works intended to apply the Siemens compressor to an Oberursel UR.II in a Fok. Dr.I. This installation was never completed, however.

Показать полностью

J.Herris, T.Phillips Fokker Aircraft of WWI. Vol.4: V.1-V.8, F.I & Dr.I (A Centennial Perspective on Great War Airplanes 54)

Despite not achieving production status, the Fokker V.1, V.2, and V.3 were significant steps. With them Fokker introduced the new, cantilever wooden wing technology and combined the most advanced aeronautical concepts. However, these aircraft more closely resembled armed racing planes than production fighters.

Most significantly, future Fokker designs would use conventional flight controls, a more conventional configuration, and a new, lighter, second-generation wing design.

The original cantilever wooden wing was too thick and too heavy. It was replaced in subsequent designs by a new, second-generation cantilever wooden wing. This more advanced wing had a better airfoil section that was thinner for reduced drag and better flying characteristics. It was also more advanced structurally. Fabric replaced wood in areas that did not need the strength of wood, reducing the weight. The new wing design used a box spar for greater strength with less weight. Verneer covered the leading edge of the wing to maintain the more advanced airfoil section. The new structure was more efficient at the cost of greater complexity.

At this juncture fate, in the form of Idflieg, stepped in. In the spring of 1917 Idflieg was ait the beginning of its Triplane Craze and asked Fokker (and other manufacturers) to build a triplane fighter in the mistaken belief that the triplane configuration offered some unique advantages for a fighter. Just at the point Fokker was on the verge of excellent designs, he responded to Idflieg’s request with the V.4 triplane prototype, that lead to the V.5 and production Dr.I. The Dr.I possessed exceptional climb and maneuverability, qualities not possessed by frontline German fighters at the time.

What the Dr.I did not have was good speed, and that was a result of the extra drag of its triplane configuration and low-powered engine. The later D.VI was essentially a biplane derivative of the Dr.I triplane. Powered by the same 110 hp Oberursel Ur.II rotary as the Dr.I, the lower drag D.VI offered notably better speed and slightly better climb than the Dr.I at the cost of a slight increase in its rolling moment of inertia that caused a small decrease in roll rate. The qualities and appearance of the Dr.I made it famous, while the later, better, and less distinctive D.VI biplane is nearly unknown.

Fokker V.4

Although the V.1, V.2, and V.3 showed admirable turning and handling qualities and benign stall characteristics, overall performance was little better than the Albatros sesquiplane fighters currently equipping the Luftstreitkrafte. The problem was weight to power ratio (W/P), which was too high due to heavy, plywood covered wings and heavy, streamlined fuselages. For the V.1 W/P was 4.02 kg/hp (kilogram per horsepower), for the V.2 it was 4.14 and for the V.3 it was 4.25. Note that each horsepower was carrying more weight as the early V series aircraft evolved. Except for speed, the V.1 actually had superior performance, especially climb, to the later V.2 and V.3. The streamlined fuselages also compromised downward vision on all three types.

Since Fokker had a controlling interest in the Oberursel engine factory, it became obvious any fighter using the 110 hp Oberursel Ur.II copy of the Le Rhone 9J rotary would have to be both small and lightweight, with a weight to power ratio in the 3.0-3.5 kg/hp range. The Oberursel Ur.II was actually a copy of the Le Rhone 9Jb, which with its aluminum pistons, produced 120 hp vs the 110 hp of the steel piston 9J. The Ur.II also had aluminum pistons and British tests of a captured Ur.II showed a maximum horsepower of 127. This was excellent considering the low octane US gasoline being used by the Entente air forces, but was also achieved with good quality castor oil lubricant. The Royal Navy blockade of Germany prevented the Germans from obtaining castor oil relatively early in the war and an inferior substitute lubricant was developed. This T50 substitute lubricant (50% Voltol rapeseed and fish oil and 50% mineral oil) had a very negative effect on German rotary engine operations during the last two years of the war.

Fokker had a contract to provide the Austro-Hungarian Luftfahrtruppe a fighter aircraft through Fokker Magyar Atalanos Gepgyar (MAG) in Matyasfold, Hungary. A triplane fighter was ordered from the Fokker experimental shop on 13 June 1917 with internal designation D.VI, Werknummer 1661, Kommission Nummer 7623. Originally conceived as a biplane, the German triplane craze caused by the success of the Sopwith Triplane, resulted in the design being changed to a triplane.

From the start, Fokker knew he had to keep the design as small and lightweight as possible for use with his Ur.II powerplant. Starting with the fuselage, a short, flat-sided design using very thin steel tubing trussed together with wire at the joints was developed. Thin plywood fillets were sparingly used, as were aluminum cover panels. The flat sides also aided lateral stability compared to the round fuselages of the V.1-V.3 designs and aided downward vision. The Le Rhone 9Jb engine, used until availability of the Ur.II, was covered by a simple aluminum cowl with two ventilation holes designed to force castor or T50 oil fumes out the slot in the bottom of the cowl. This cowl had a full front face, into which the two ventilation holes, propeller shaft hole, and a slot for cylinder rotation and oil vapor exit flow were cut. The Ur.II had passed its tests early in 1917 using castor oil, but modifications for the use of the T50 castor oil substitute meant final approval did not occur until August 1917. This meant most early triplanes were fitted with captured Le Rhone 9Jb engines.

Instead of using plywood covered wings for stiffness like the V.1-V.3, lightweight, fabric-covered wings were developed with a single, very stiff and strong double box spar to maintain the cantilever configuration. This box spar carried through the fuselage for the bottom two wings, which were all in one piece. A thin plywood, almost a veneer, was used on the leading edge of the wings and there was a wire trailing edge. Fabric shrinkage on covering caused the wire to form the familiar scalloped trailing edge. The bottom and middle wings had the same span, while the top wing had a much greater span. Ailerons were only fitted to the top wing, unlike the Sopwith Triplane with its 3 sets of ailerons. For ease of construction, a common rib design and box spar cross section were used for all three wings. The bottom, middle, and center of the top wing had a common chord of 980 mm (millimeters). The wings featured the thick cross section Fokker had come to believe in since his semi-forced partnership with Junkers. Unbalanced ailerons and elevator were matched with a comma shaped rudder with no vertical fin. The only external wires on the aircraft were in an X configuration between the upper wing and fuselage and another X between the landing gear struts. No interplane struts between the wings were used and a small airfoil wing was incorporated around the landing gear axle for extra lift. This actually resulted in some early Idflieg documents referring to Fokker triplanes as vierdeckern (quadraplanes) instead of dreideckern (triplanes).

Construction and testing of the V.4 took place at a very rapid pace, with the V.4 likely flying by 25 June 1917, only 12 days after Fokker ordered the biplane fighter under construction to be completed as a triplane. By 2 July, the English already had an intelligence report that a new triplane fighter was flying. The V4 data table shows the dimensions and other characteristics of the V.4.

From the start, the performance and handling qualities of the V4 were excellent in the hands of an expert pilot. Stall characteristics of the V.4 were relatively benign, like the V.1-V.3. Pitch, roll, and yaw were all relatively unstable, making for a very maneuverable aircraft, with aileron and roll control being one of the primary criticisms of the design. This was likely caused by flexing of the upper wing, due to lack of interplane struts, limiting effectiveness of the ailerons. Top speed was exceptional at 200 km/hr kilometers per hour (124 mph), especially considering the relatively low power of the rotary engine. Climb rate was better than the Albatros V-strutters, but not as good as Fokker had hoped. Werner Voss flew the V.4 and fell in love. The maneuverability of the triplane was phenomenal, with unprecedented rudder authority, and good climb rate. With no dihedral and no vertical fin, the V.4 could happily fly along at ridiculous yaw angles. Flat yaw turns were possible with complete control and the large propeller allowed the triplane to hang on its propeller while pointing the nose in any direction the pilot desired. All of this performance was helped by the much improved weight to power ratio of 3.15 kg/hp, especially when compared to the V.1-V.3, all of which exceeded 4 kg/hp. Details are in the V.4 performance table. Testing was done without the twin machine gun armament, hence the 165 kg payload.

According to Fokker records, Fokker V.4, WN 1661, was painted and shipped to the Ungarische Machinenfabrik, Budapest without an engine or machine guns in August 1917 and received on 3 September 1917 with its cowling missing. It was assigned Austro-Hungarian designation 90.02 and was tested extensively with A-H license built engines. Austro-Hungary received a further triplane for testing, V.7R, WN 1781, at a later date, but decided to go with a version of the simpler V.12/Fokker D.VI biplane fitted with an A-H license built version of the 145 hp, 11 cylinder, Le Rhone rotary.

Fokker V.4 Specifications

Engine: 120 hp Le Rhone 9Jb

Wing: Span Upper 6.21.m

Chord Bottom, Middle, Center top 0.980 m

Wing Area 14.0 m2

General: Length 5.75 m

Height 2.95 m

Empty Weight 346 kg

Loaded Weight 528 kg

Fuel capacity 751

Oil capacity 121

Power to Wt. Ratio Empty 3.15 kg/hp

Maximum Speed: 200 km/h

Climb: 1000m 2.5 min

2000m 5.5 min

3000m 10 min

4000m 17 min

5000m 28 min

Performance with 165 kg load

Fokker V.5 / Idflieg El 101/17

Although V.4, WN 1661, performance and handling characteristics already exceeded that of his Albatros rival's fighters, Fokker could immediately see that changes needed to be made to make aircraft handling more suitable for the average pilot, to increase roll rate, to improve climb rate, and to damp the fluttering of the top wing attached only by the fuselage struts. This would result in a modified design ordered on 5 July 1917, variously identified as a V.4 (Alex Imrie's modified V.4) and V.5 for the same airframe in Fokker sources. The same dichotomy would be found in the two later F.I triplanes, F.I 102/17, WN 1729, and F.I 103/17, WN 1730, also identified as both V.4 and V.5 triplanes, when they were all three V.5 types.

Fokker knew there was a trade-off to be made between climb rate and maximum speed. His observations at the front with Jasta 11 made him think climb rate was more important in summer 1917. This would change in 1918, when maximum speed would become considered most important. Unlike many units, Jagdgeschwader I did not usually fly standing patrols, but used forward airfields to quickly climb after enemy formations were spotted. Warnings came from forward anti-aircraft artillery batteries and other frontline observers, as well as JG I's own observations using binoculars and other optic devices. To increase climb rate Fokker knew the easiest way was to increase wing area and thus decrease wing loading. The spans of the middle and top wings were increased to give an overall wing area of 16 m2 (square meters) compared to the 14 m2 of V.4, WN 1661. This also gave a pleasing symmetry to the wings with their graduated span increase.

To increase roll rate and decrease roll sensitivity, balanced ailerons were fitted with long chord horn balances. To prevent the wing from vibrating and flexing and thus decreasing roll rate, thin wood interplane struts were fitted. The horizontal stabilizer leading edge was less rounded than on V.4, WN 1661, and a balanced elevator with rounded, rectangular horn balances was fitted. This also made the V.5, WN 1697, less sensitive in pitch response and easier to fly.

V.5, WN 1697, was fitted with a Le Rhone 9Jb (120 hp), even though noted in some Fokker sources as an Oberursel Ur.II of 110 hp, others show a 120 hp Le Rhone. The cowling was identical to that on V.4, WN 1661. This design, with a slot in the bottom plate for cylinder rotation, tended to pool castor oil/T50 synthetic substitute oil in the bottom of the cowl and would eventually be changed on the production Dr.I aircraft. Unlike V.4, WN 1661, which was never fitted with machine guns in Germany, V.5, WN 1697, was fitted with two standard, air-cooled, Maxim LMG 08/15 machine guns manufactured by the Spandau Arsenal. Each of these LMG 08/15s carried 500 rounds of ammunition.