Книги

Журнал

Flight за 1916 г.

190

Журнал - Flight за 1916 г.

Flight, January 6, 1916.

A Model Taube.

Mr. David Hay writes from Denny, Scotland, as follows :-

"I enclose two photos, of my Etrich Taube, which was built from drawings which appeared in 'FLIGHT.' Length, 5 ft. ; span, 5ft. 9 ins. propeller, 16 ins. diameter; wheels, 2 3/4 ins. diameter; fitted with pilot's and passenger's seats; and all parts workable, all planes double surfaced. I made the model for Christmas, and took the photos, before doping the machine, as I had an idea that the dope would change the colour of same. It took me three months to complete, but I made some flying models in between that time; I think that is the best way when making such a model. I can get a good 1/4 mile out of my twin-propeller monoplane, which is flying nearly every Saturday. I must say that 'FLIGHT' is the only paper that is worth reading on such a subject."

A Model Taube.

Mr. David Hay writes from Denny, Scotland, as follows :-

"I enclose two photos, of my Etrich Taube, which was built from drawings which appeared in 'FLIGHT.' Length, 5 ft. ; span, 5ft. 9 ins. propeller, 16 ins. diameter; wheels, 2 3/4 ins. diameter; fitted with pilot's and passenger's seats; and all parts workable, all planes double surfaced. I made the model for Christmas, and took the photos, before doping the machine, as I had an idea that the dope would change the colour of same. It took me three months to complete, but I made some flying models in between that time; I think that is the best way when making such a model. I can get a good 1/4 mile out of my twin-propeller monoplane, which is flying nearly every Saturday. I must say that 'FLIGHT' is the only paper that is worth reading on such a subject."

BROUGHT DOWN BETWEEN THE LINES. - As a result of many duels in mid-air between the British and German machines, enemy pilots are continually forced down between the lines, the combat being often witnessed with intense interest by both sides in the trenches. The above picture portrays one of these incidents in Flanders, in German Taube, crippled by one of the British machines, has fallen between the British and German lines, a blazing mass.

A two-seater Avro about to start for Suvla the day alter the evacuation. On the pilot's return he reported that the Turks were still shelling the empty trenches for all they were worth.

Mounting and housing of Vee-type air-cooled engines. Inset in centre, the Renault engine, showing tubular bearers.

Flight, January 13, 1916.

A Model Bristol Scout.

From South Lowestoft Mr. Lewis E. Richards sends a photo, of a beautifully-made Bristol scout, of which he says :-

"Enclosed herewith are photos, of a model Bristol Scout, Type C, 1915, constructed a few months back, which might interest your Model Section.

"Made almost entirely of mahogany and copper, to a scale of 1/12th , it was primarily intended as an exhibition working model, having in view the suggestion I put forward in your columns last February in connection with the Flying Services Fund.

"Not the least interesting features incorporated in its construction are a special copper stamping for the engine housing, and a laminated air screw, whose shafting is coupled to a motor and driven by a dry battery in the fuselage.

"Controls are functioned by levers situated in the cabane, including a device for starting up and switching off the motor. To facilitate dismantling and inspection, all members are readily and easily detachable.

"Details have engaged closest attention, and to ensure accuracy, blue prints were supplied through the courtesy of Messrs. The British and Colonial Aeroplane Co., Ltd., to whom I am greatly indebted for their kind and valued assistance.

"The planes are only shown in section, pressure of business having prevented their completion."

A Model Bristol Scout.

From South Lowestoft Mr. Lewis E. Richards sends a photo, of a beautifully-made Bristol scout, of which he says :-

"Enclosed herewith are photos, of a model Bristol Scout, Type C, 1915, constructed a few months back, which might interest your Model Section.

"Made almost entirely of mahogany and copper, to a scale of 1/12th , it was primarily intended as an exhibition working model, having in view the suggestion I put forward in your columns last February in connection with the Flying Services Fund.

"Not the least interesting features incorporated in its construction are a special copper stamping for the engine housing, and a laminated air screw, whose shafting is coupled to a motor and driven by a dry battery in the fuselage.

"Controls are functioned by levers situated in the cabane, including a device for starting up and switching off the motor. To facilitate dismantling and inspection, all members are readily and easily detachable.

"Details have engaged closest attention, and to ensure accuracy, blue prints were supplied through the courtesy of Messrs. The British and Colonial Aeroplane Co., Ltd., to whom I am greatly indebted for their kind and valued assistance.

"The planes are only shown in section, pressure of business having prevented their completion."

Mounting and housing of Vee-type air-cooled engines. Inset in centre, the Renault engine, showing tubular bearers.

Flight, July 27, 1916.

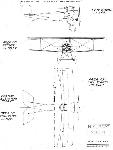

THE NEW L. AND P. FUSELAGE BIPLANE.

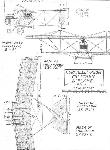

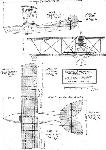

A VERY neat and clean design. This is the first impression received when viewing the new biplane built by the London and Provincial Aviation Co., of Hendon, and, as in so many other cases, closer acquaintance confirms the first impression. The designer of the machine, Mr. Fletcher, who previous to joining the L. and P. firm was associated with Messrs. Martin and Handasyde of Brooklands, has managed to incorporate into a very graceful outline design a number of cleverly thought out details, and the result is a machine combining everywhere the required, and in many places a greater, factor of safety with a minimum of weight. In this connection it might be pointed out that throughout the machine all fittings are so designed as to avoid piercing any of the important members subjected to stress, such as main wing spars, body rails, &c. It is by this means that it has been possible to cut down weight without sacrificing strength, and so well have the various fittings been thought out that nowhere has the designer had to resort to a clumsy, ungainly job to get around the objectionable drilling.

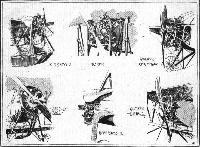

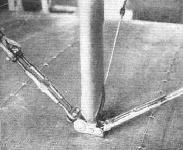

From the accompanying photographs and scale drawings a good idea can be formed of the general arrangement of the new L. and P. biplane, while some of the constructional details are shown in the various sketches. The body, which is of rectangular section, is probably of as good a streamline form as it is possible to obtain without the use of formers and stringers. It is built up of ash rails, tapering and spindled out towards the rear, and connected by vertical and horizontal struts. In the rear portion the bracing is effected by wiring, while in front where, as will be seen, the covering consists of three-ply ash bracing takes the form of diagonally placed spruce struts. The wiring plates connecting the struts to the rails in the rear part of the body are some of the most ingenious we have seen, being made up of three pieces of very light gauge, the three pieces being held together by the copper eyelets in the holes for the bracing wires. The fitting is quickly and cheaply made, being, as already mentioned, of very light gauge, and by making it in two standard sizes it can be employed irrespective of the taper of the body rails.

In front a number of the metal fittings take the form of large Duralumin plates serving a variety of purposes. Several of these plates can be seen in the illustrations. A turtle back, consisting in front of three-ply wood, and at the rear of formers and stringers, tops the body and helps to give the necessary depth for effectively enclosing the occupants, of whom nothing but the heads are seen when the machine is flying. The pilot occupies the back seat, and has in front of him a neatly fitted dashboard with all the usual instruments, including engine revolution counter, altimeter, air speed indicator, clock, petrol pressure gauge, telltale oil glass, &c. In front of the pilot, and in a separate cockpit, is installed the passenger, whose seat is placed on top of the main petrol tank, which in turn rests on the bottom of the body. From this tank the fuel is forced by means of a pressure pump to a smaller service tank in the nose of the body. The controls consist of a central lever of wood mounted on a longitudinal rocking shaft, and of a foot bar for the rudder.

The engine - an 80 h.p. Anzani - is mounted in the usual manner on a capping plate bolted to the rails of the body. In order to further stiffen the mounting, two tubes are taken from the bolts of the crank-case to the top of the inner inter-plane struts. Just behind the engine the body is covered with aluminium plates, that of the top being neatly curved to form a better entry for the air.

The main planes, which are of a section somewhat similar to the R.A.F. 6, with the exception that the lower surface is slightly more cambered, 2 1/2 in. to be exact, are characterised by heavily raked tips which tend to give the machine a "racy" appearance, and which perform the more useful function of decreasing end losses and increasing the effectiveness of the ailerons. The latter are fitted to both top and bottom planes, with the result that the machine has an ample margin of lateral control, as demonstrated a few days ago, when Mr. G. Smiles, accompanied by a passenger, put up some alarming banked turns, during which the wings were repeatedly in a vertical position.

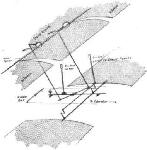

One of our sketches illustrates the attachment of the lower wing spars to short spars passing under the body.

Let into each side of the centre spars is a plate, semi-circular at its outer end and angular at the inner end. Four bolts pass through each plate and through the spar. On the inner ends of the main wing spars are two similar plates, bolted to the spars in the same manner. These latter pass outside the plates on the centre spars, and a hinged joint is formed by a long hinge-pin passing through the central hole in the end of the plates from back to front spars. One end of this pin is bent over at right angles, and is prevented from coming adrift by a small aluminium clip passed over the bent end and screwed to the inner rib of the wing. In the same sketch is shown the anchorage for the lift cables. Two magnified chain-links are secured to the spars of the centre section of the lower plane by a sturdy bolt, and as the spars themselves are at this point of generous proportions, the stresses are adequately dealt with. Another point in favour of this method of passing the spars right underneath the body is that the final point of anchorage for the lift cables is immediately below the bottom rails of the body, so that no twisting strain is imposed on the rails. At the outer ends of the chain-links referred to above is another stout bolt around which passes a plate receiving the ends of the wire strainers in the manner shown in the sketch.

One of the features of the new L. and P. biplane is the type of wiring plate and inter-plane strut socket employed. One form of these consists of a rectangular plate to which the socket is welded, provided with the necessary lips for attachment of bracing cables. At each corner of this plate is a hole for a bolt passing through the wing and through a similar plate on the other side of the spar, minus the socket, of course. The four bolts on being tightened up cause the two plates to grip the spars, and the plates are further prevented from sliding along the spars on account of the obliquity of the bracing cables by letting the bolts, into the sides of the spars to the extent of half their diameters. The fitting used for the outer struts is similar, except that here only two bolts are employed, the place of the other two being taken by two strips, of the wiring plate itself bent around the side of the spar.

The hinge for the ailerons is formed by forked eye-bolts passing through the spars, and ordinary eyebolts in the leading edge of the aileron. A long wire bolt runs right through all the eyebolts, thus doing away with the ordinary short bolt and nut for each hinge, which would be somewhat inaccessible in the narrow slot between the rear spar and the aileron. An exactly similar hinge is employed for the rudder and elevators. Regarding the various members of the tail these give the impression of being unusually large, but from the severe tests of stability carried out recently it would appear that the control organs, while being large enough to ensure that any tendency to pitching or yawing is effectively stopped, are not so large as to cause any difficulty in the way of too great or weathercock stability. The fixed tail plane is of the nonlifting type in so far as it is set at no angle of incidence to the axis of the propeller, but while its lower surface is flat its upper surface is cambered to allow for the fact that it is working in the slip stream from the propeller and in the down draft from the wings. A small swivelling skid mounted on a pyramid of steel tubes, streamlined with wood fairings, protects the tail planes against contact with the ground.

When looking casually at the machine, the chassis appears to consist of four streamline wood struts supporting the axle, but on closer examination it is found that the struts are in reality steel tubes encased in a fairing of wood. Two transverse steel tubes connect the lower apices of the Vees formed by the chassis struts, and the Duralumin tubular axle is slung from the tubular struts by rubber cord.

Altogether the London and Provincial Aviation Co. are to be congratulated on their first machine of original design. The workmanship is such as no large firm would need be ashamed of, in fact it would be difficult to improve on it, and the designer, Mr. Fletcher, has good cause to be proud of the machine from an aerodynamical as well as from a constructional point of view, seeing that it has already done some very excellent performances, including looping with two up, although the engine was far from being in concert trim, ticking, in fact, over at somewhere in the neighbourhood of 900 r.p.m. instead of the regulation 1,250. Even so the speed was something like 75 m.p.h., and when the new Lang propeller ordered for the machine arrives, this figure is expected to be considerably exceeded. The total weight "all up," including pilot, passenger, and three hours' fuel, is 1,400 lbs., which is very light for a machine of this size. We have no official figures regarding the gliding angle, but it appears to be extraordinarily good, probably in the neighbourhood of 1 in 10.

THE NEW L. AND P. FUSELAGE BIPLANE.

A VERY neat and clean design. This is the first impression received when viewing the new biplane built by the London and Provincial Aviation Co., of Hendon, and, as in so many other cases, closer acquaintance confirms the first impression. The designer of the machine, Mr. Fletcher, who previous to joining the L. and P. firm was associated with Messrs. Martin and Handasyde of Brooklands, has managed to incorporate into a very graceful outline design a number of cleverly thought out details, and the result is a machine combining everywhere the required, and in many places a greater, factor of safety with a minimum of weight. In this connection it might be pointed out that throughout the machine all fittings are so designed as to avoid piercing any of the important members subjected to stress, such as main wing spars, body rails, &c. It is by this means that it has been possible to cut down weight without sacrificing strength, and so well have the various fittings been thought out that nowhere has the designer had to resort to a clumsy, ungainly job to get around the objectionable drilling.

From the accompanying photographs and scale drawings a good idea can be formed of the general arrangement of the new L. and P. biplane, while some of the constructional details are shown in the various sketches. The body, which is of rectangular section, is probably of as good a streamline form as it is possible to obtain without the use of formers and stringers. It is built up of ash rails, tapering and spindled out towards the rear, and connected by vertical and horizontal struts. In the rear portion the bracing is effected by wiring, while in front where, as will be seen, the covering consists of three-ply ash bracing takes the form of diagonally placed spruce struts. The wiring plates connecting the struts to the rails in the rear part of the body are some of the most ingenious we have seen, being made up of three pieces of very light gauge, the three pieces being held together by the copper eyelets in the holes for the bracing wires. The fitting is quickly and cheaply made, being, as already mentioned, of very light gauge, and by making it in two standard sizes it can be employed irrespective of the taper of the body rails.

In front a number of the metal fittings take the form of large Duralumin plates serving a variety of purposes. Several of these plates can be seen in the illustrations. A turtle back, consisting in front of three-ply wood, and at the rear of formers and stringers, tops the body and helps to give the necessary depth for effectively enclosing the occupants, of whom nothing but the heads are seen when the machine is flying. The pilot occupies the back seat, and has in front of him a neatly fitted dashboard with all the usual instruments, including engine revolution counter, altimeter, air speed indicator, clock, petrol pressure gauge, telltale oil glass, &c. In front of the pilot, and in a separate cockpit, is installed the passenger, whose seat is placed on top of the main petrol tank, which in turn rests on the bottom of the body. From this tank the fuel is forced by means of a pressure pump to a smaller service tank in the nose of the body. The controls consist of a central lever of wood mounted on a longitudinal rocking shaft, and of a foot bar for the rudder.

The engine - an 80 h.p. Anzani - is mounted in the usual manner on a capping plate bolted to the rails of the body. In order to further stiffen the mounting, two tubes are taken from the bolts of the crank-case to the top of the inner inter-plane struts. Just behind the engine the body is covered with aluminium plates, that of the top being neatly curved to form a better entry for the air.

The main planes, which are of a section somewhat similar to the R.A.F. 6, with the exception that the lower surface is slightly more cambered, 2 1/2 in. to be exact, are characterised by heavily raked tips which tend to give the machine a "racy" appearance, and which perform the more useful function of decreasing end losses and increasing the effectiveness of the ailerons. The latter are fitted to both top and bottom planes, with the result that the machine has an ample margin of lateral control, as demonstrated a few days ago, when Mr. G. Smiles, accompanied by a passenger, put up some alarming banked turns, during which the wings were repeatedly in a vertical position.

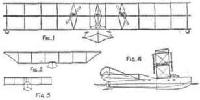

One of our sketches illustrates the attachment of the lower wing spars to short spars passing under the body.

Let into each side of the centre spars is a plate, semi-circular at its outer end and angular at the inner end. Four bolts pass through each plate and through the spar. On the inner ends of the main wing spars are two similar plates, bolted to the spars in the same manner. These latter pass outside the plates on the centre spars, and a hinged joint is formed by a long hinge-pin passing through the central hole in the end of the plates from back to front spars. One end of this pin is bent over at right angles, and is prevented from coming adrift by a small aluminium clip passed over the bent end and screwed to the inner rib of the wing. In the same sketch is shown the anchorage for the lift cables. Two magnified chain-links are secured to the spars of the centre section of the lower plane by a sturdy bolt, and as the spars themselves are at this point of generous proportions, the stresses are adequately dealt with. Another point in favour of this method of passing the spars right underneath the body is that the final point of anchorage for the lift cables is immediately below the bottom rails of the body, so that no twisting strain is imposed on the rails. At the outer ends of the chain-links referred to above is another stout bolt around which passes a plate receiving the ends of the wire strainers in the manner shown in the sketch.

One of the features of the new L. and P. biplane is the type of wiring plate and inter-plane strut socket employed. One form of these consists of a rectangular plate to which the socket is welded, provided with the necessary lips for attachment of bracing cables. At each corner of this plate is a hole for a bolt passing through the wing and through a similar plate on the other side of the spar, minus the socket, of course. The four bolts on being tightened up cause the two plates to grip the spars, and the plates are further prevented from sliding along the spars on account of the obliquity of the bracing cables by letting the bolts, into the sides of the spars to the extent of half their diameters. The fitting used for the outer struts is similar, except that here only two bolts are employed, the place of the other two being taken by two strips, of the wiring plate itself bent around the side of the spar.

The hinge for the ailerons is formed by forked eye-bolts passing through the spars, and ordinary eyebolts in the leading edge of the aileron. A long wire bolt runs right through all the eyebolts, thus doing away with the ordinary short bolt and nut for each hinge, which would be somewhat inaccessible in the narrow slot between the rear spar and the aileron. An exactly similar hinge is employed for the rudder and elevators. Regarding the various members of the tail these give the impression of being unusually large, but from the severe tests of stability carried out recently it would appear that the control organs, while being large enough to ensure that any tendency to pitching or yawing is effectively stopped, are not so large as to cause any difficulty in the way of too great or weathercock stability. The fixed tail plane is of the nonlifting type in so far as it is set at no angle of incidence to the axis of the propeller, but while its lower surface is flat its upper surface is cambered to allow for the fact that it is working in the slip stream from the propeller and in the down draft from the wings. A small swivelling skid mounted on a pyramid of steel tubes, streamlined with wood fairings, protects the tail planes against contact with the ground.

When looking casually at the machine, the chassis appears to consist of four streamline wood struts supporting the axle, but on closer examination it is found that the struts are in reality steel tubes encased in a fairing of wood. Two transverse steel tubes connect the lower apices of the Vees formed by the chassis struts, and the Duralumin tubular axle is slung from the tubular struts by rubber cord.

Altogether the London and Provincial Aviation Co. are to be congratulated on their first machine of original design. The workmanship is such as no large firm would need be ashamed of, in fact it would be difficult to improve on it, and the designer, Mr. Fletcher, has good cause to be proud of the machine from an aerodynamical as well as from a constructional point of view, seeing that it has already done some very excellent performances, including looping with two up, although the engine was far from being in concert trim, ticking, in fact, over at somewhere in the neighbourhood of 900 r.p.m. instead of the regulation 1,250. Even so the speed was something like 75 m.p.h., and when the new Lang propeller ordered for the machine arrives, this figure is expected to be considerably exceeded. The total weight "all up," including pilot, passenger, and three hours' fuel, is 1,400 lbs., which is very light for a machine of this size. We have no official figures regarding the gliding angle, but it appears to be extraordinarily good, probably in the neighbourhood of 1 in 10.

AT HENDON AERODROME . - Mr. W. T. Warren, jun., on the L. and P. biplane returning to the 'drome after a looping-the-loop bout.

LOOPING WITH SMILES IN THE L. AND P. BIPLANE AT HENDON. - What a broadside view from a looping biplane looks like. As each loop is made the horizon line revolves round the centre of vision in a clockwise direction.

ATTACHMENT OF L. AND P. WING SPAR TO CENTRE SECTION OF LOWER PLANE. - Inset analytical sketch of the anchorage for the main lift cables.

Flight, March 9, 1916.

DESIGNING AND BUILDING A BIPLANE.

THE STORY OF A SUCCESSFUL EXPERIMENT.

By ROBERT P. GRIMMER.

[In the following story Mr. Grimmer has given a detailed summary of the ups and downs to which an experimenter in aviation has to be prepared to submit. He has adopted a very light style in handling his subject, and treats his firm's misfortunes in an almost Mark Tapley spirit, worthy of admiration. The mistakes made and the difficulties encountered should be helpful to new workers in the same direction, a suggesting what to avoid. Mr. Grimmer's views as to the comparative merits of twin-propeller and chain pusher machines as opposed to direct driven tractor machines are worth careful consideration., although it must not be taken that we necessarily are in agreement with all the author sets forth. Altogether the story is both amusing and instructive, and we heartily wish the Mann firm the success which Mr. Grimmer foretells in his concluding paragraph in connection with M.2 now under construction. - ED.]

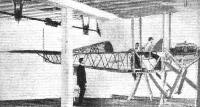

THE Mann Gun-Carrying Biplane is probably familiar enough to the average reader of "FLIGHT," but very few people seem to know the raison d'etre of its existence. The general opinion would appear to be that the transmission was put in for a joke, or else was a misguided attempt to make the 'bus dissimilar to the ordinary type of fuselage machine. Nothing could possibly be more erroneous than these views, and I am now attempting to explain the exact reason why M.1 came into being.

The great majority of aeroplanes belong to the tractor type - that is, with the airscrew in front drawing the machine forward. The other type with the propeller behind are known as "pushers." Previous to the war, the "pusher" type had been greatly neglected, owing to the fact that its design and construction from a "performance" point of view presented great difficulties. The tail booms caused a certain amount of resistance, and there was always the possibility of their being broken by fragments of a damaged propeller. Further, there was the objection against the placing of the engine and tanks behind the crew, which, any way in theory, were liable to break loose and crush the pilot and passenger in the event of a bad landing. Whether this objection has always been substantiated by facts I am not prepared to say, but on paper the "engine-behind" machine certainly does look unhealthy.

Until the war broke out, all the best aeroplanes, without except ion, were of the tractor biplane type, and the most successful of these were single-seaters or "scouts.'' Both the British and French Governments possessed a few "pushers," but it is very doubtful if the best of these had a speed much in excess of 65-70 miles per hour, with a climb of some 300 ft. per minute. The Service value of the "pusher" consists in the excellent view obtained by the crew and the ideal gun emplacement afforded by the projecting body or nacelle. But the "tractor" scored at that time (1914) by virtue of its superior speed and climb. If by a stroke of a magic wand the Allied Governments could have transformed their "tractors" into "pushers," retaining at the same time the superior performance of the former type, there is very little reason to doubt that this would have been done at the beginning of the war. It was not until some time afterwards that the device of firing through the tractor screw was introduced by Garros. This device has the great disadvantage that the gun cannot be properly aimed, as it is on a fixed mounting. The Huns were even worse off as regards "pushers" than ouselves, as they had pinned their faith entirely to the "performance tractor."

I have explained the virtues and vices of the "tractor" and "pusher" types; the one gave good performance, medium view and a bad gun platform, and the other bad performance, good view and a super excellent gun platform. Mr. Mann and I had been connected with aviation in various capacities since its inception in 1908, and we had for some time previously recognised what we considered the disabilities of the contemporary types for Service work. The first really successful flying machine was the Wright, which in its time (1908-09) put up some quite astonishing performances, including a double crossing of the Channel with an engine giving only approximately the same horse-power (20) as the Ford tin-can car! The great characteristic of the Wright was its twin geared-down propellers driven by chains. It is an undeniable fact that propellers of large pitch rotating slowly are more efficient than propellers of small pitch rotating at very high speeds. Propeller speeds of anything up to 1,000 r.p.m. are regarded as being slow, anything approaching 2,000 r.p.m. is very fast. High speed propellers have a very large percentage of "slip," and they lack the grip on the air of the slow speed variety. There are other objections as well, the chief being the tendency to disintegrate, owing to the terrific velocity of the tips, but this latter is worse in theory than in practice, though cases are reported from time to time. At one time the Wright machine was supreme, but as the designers made no real attempt to keep pace with the times by installing really high-power engines, their "twin-pusher" was in course of time completely eclipsed by single-propeller types, chiefly of the "tractor" variety. Mr. Mann and I always recognised the possibilities of the "twin-pusher," properly developed, and we had always wished to construct such a machine on modern lines. But in those days we never secured the weighty financial backing necessary for so great a project.

Just before the outbreak of the great war Mr. Mann and I were fortunate enough to secure the interest of Mr. W, H. Bonham-Carter in our project, with the result that we were able to commence construction in September, 1914, Mr. Mann having got out the rough designs in August. I must here pay a tribute to the magnanimity and the disinterested patriotism of Mr. Bonham-Carter, who at the time of writing has tome the greater part of the burden of financing our experimental work for a period of over eighteen months, and who at the outset had no guarantee whatever that he was backing the right horse.

M.1 was designed and built at great pressure in the hope that she might be used against the Huns early in 1915. Mature reflection inclines me to the view that we should have done better if we had advanced at a more leisurely pace. The design and construction of such an experimental machine was a very big contract, so big indeed that no established constructor would have risked his reputation by taking it on. Having no reputation as constructors to lose, we took the risk - there was a distinct risk, although we were unaware of it at the time - and boldly grasped the bull by the horns. The only building we had available for the purpose was a disused tin church 20 ft. by 40 ft., with a vestry that we converted into two offices. This building had the reputation of being haunted, and it certainly had been standing empty for many years before we got possession of it. A particularly gruesome story is told about this epoch, but the episode occurred so many years ago that it is impossible to verify it. Such was the reputation of the building where M.1 was built.

M.1 was a fuselage biplane with twin chain-driven propellers. Mr, Mann, who was solely responsible for the design, was actuated by the desire to combine in one machine the virtues of the tractor and pusher without any of their vices. The wings were heavily cambered with the front edges sloped back partly for stability and partly to enable the Lewis automatic gun to be fired sideways. A 100 h. p. Anzani engine, hereafter sometimes known as the "Starfish," was mounted at the extreme prow, and the power was transmitted by means of a shaft and universal couplings to a gearbox behind the observer's seat. The gearbox was installed for the purpose of reversing one of the driving chains that emerged from it, and it weighed over 100 lbs. By the way, the reversing of one chain by any method otherwise than the Wright system of crossing it is a task sufficient to daunt the boldest designer, and is by far the biggest problem to be tackled in a chain driven aeroplane. The two chains emerging from the gearbox ran on two sprockets attached to the propeller-shafts, which were supported by means of diamond-shaped brackets and tubes and wires at the sides of the inner pair of struts. The propellers, of course, revolved in opposite directions for the sake of stability.

On September 7th, 1914, we possessed a works indifferently equipped with tools, but with neither staff nor materials, and the designs of the machine itself only roughly worked out. Yet we only allowed ourselves three months in theory to get the "steamroller" - as she was afterwards called - completed. In practice, and for the best of reasons, the construction represented five months of hard work, for it was not till the end of January, 1915, that the "steamroller" appeared at Hendon. I have never worked so hard in my life as during that five months, and the toil was so arduous, and the difficulties so numerous and complex, that the end of the period brought me a severe nervous breakdown, from which I did not finally recover until I took a month's holiday in the spring. The first difficulty we encountered was the problem of getting together an adequate staff. The next difficulty was the question of materials. The unprecedented demand for wood, fabric, sheet-steel, aluminium, tubing, nuts and bolts, wire strainers, &c., had created a veritable famine in these articles, and in some cases one had to wait months for delivery. Such material as we did get had mainly to be obtained by making personal visits to the various manufacturers and cadging - that is the only appropriate word - a sheet of steel here, a few lengths of tubing there, a dozen wire strainers, and so forth. Then there was the problem of drawings. It was well into October before we were able to get even one "stress merchant," and the middle of November before we could lay our hands on two more. In the meantime the foreman had to extemporise drawings of a kind on the back of sheets of emery paper, that being the time-honoured method employed in the early days of aviation in practically all shops.

The overtime worked during this period was something cruel; it was no uncommon thing to start work at 7 a.m. and to go on, with intervals for meals, till midnight. We frequently worked right through Friday night till noon on Saturday, and on these occasions it was not an uncommon thing for fillers to fall asleep at their vices until aroused by the fireman. On all our night shifts a pint of light ale was served out to each man at the firm's expense every two hours, and we found it very efficacious in keeping the men up to the mark. I should like here to pay a tribute to the energy and zeal of the average British workman, who has been so much decried by those who do not know him. We have never known the meaning of labour troubles, and it is my experience that in the aeroplane trade at least the average workman will deal with you as you deal by him. My far the most arduous task that fell to my personal lot was that of keeping a drawing office staff awake on the night shifts. I have sat up many a night doping the "stress merchants" with strong coffee at intervals, but in spite of this and other drastic methods more than once they were compelled to surrender to Morpheus. I recollect that on one occasion a "stress merchant" collapsed from his stool on to the floor at 3 a.m.

This particular man was a Sunday school teacher and a prominent church member, and had never been known to utter even the mildest "cuss word" on any other occasion, but when the wall was banged close to his head to arouse him, he responded with such a torrent of bad language in his sleep as shocked our most hardened fitters. We let him sleep on till breakfast, as he was obviously too muddled to distinguish "pi" from "cos," or "sine" from "tan."

With much labour the "steam-roller," was completed at the end of January, 1915, and duly transported to Hendon, permission having finally been obtained from the somewhat reluctant authorities.

It was erected early in February, and no sooner was she ready for her maiden flight when the pilot we had engaged to fly her discovered that he had more pressing business elsewhere. After same delay we made arrangements with Mr. W. R. Ding, and on Friday, (Friday is regarded by pilots, both aviation and marine, as a very unlucky day) February 19th, the machine was pushed out and the engine run preliminary to a flight. Strong as was my faith in the old "'bus," I shivered with terror when the engine was started and the chains began to run round the sprockets and scream through their guides.

The chains, instead of running smoothly round the sprockets as all self-respecting chains should, progressed in a series of leaps and bounds and appeared to be animated with the desire of moving sideways as well as forward. A tinny clanging noise emanated from the transmission gear, and the wires in the propeller brackets vibrated until they resembled bird cages. The propellers gave one the impression that they wanted to come forward through the inter-plane struts. However, Ding said he would make a flight, and we all let go. The "steam-roller" ran along the ground, duly lifted amid a cloud of smoke from the engine, made a short straight flight and landed somewhat abruptly. It transpired that the pilot's seat had collapsed owing to the "wood butcher" responsible for its fixing having been called away to a prayer meeting and thus forgetting to finish his job. The following day, Saturday, Ding made another flight, partially across country, but this latter quite against his wish and inclination. On attempting to turn, he discovered that the steadying effect of the twin propellers was so great that the rudder had very little effect, and he was compelled to edge the "'bus" round very gradually in order to get back. As the propellers did not suit the engine, and the throttle had jambed at two-thirds open, he had the unexpected pleasure of flying low over Collindale Avenue and only just clearing trees and houses. However, he got back all right, and had sufficient presence of mind left to fly hands off before he landed. A speed of 60 m.p.h. was attained, which was not so bad under the circumstances.

After a month spent in sundry alterations, chiefly to the transmission gear, with a view to steadying the jumping chains, a further flight of ten minutes was made on March 20th. A larger rudder and improved propellers had been designed, and this time the throttle was induced to go wide open. The improvement was quite marked, and a speed of 70 m.p.h. attained. An altitude of 1,000 ft. was reached without difficulty in a 30 m.p.h. wind. Unfortunately, however, one of the wires in the diamond supporting a propeller bracket came adrift, and the great weight of the "'bus" caused her to burst a tyre on landing. Jumping chain trouble was still prevalent, and the tail skid was not satisfactory. A week was spent in further slight modifications.

( To be concluded.)

Flight, March 16, 1916.

DESIGNING AND BUILDING A BIPLANE.

THE STORY OF A SUCCESSFUL EXPERIMENT.

By ROBERT P. GRIMMER.

(Concluded from page 206.)

ON March 38th, Ding made two further flights of 15 minutes each, taking Mr. Mann as passenger in the second one. The chains jumped worse than ever, and two of Hans Renold's experts were absolutely horrified at their extraordinary behaviour. The speed was about 70 m.p.h., but the general performance was so short of Mr. Mann's expectation that it was decided to make very drastic alterations and to install a 125 h.p. Anzani in place of the original 100 h.p. In the light of subsequent knowledge I regard the substitution of engines as a very great mistake, as it materially increased the loading and head resistance, and thus nullified the extra power. Later, I shall give a short list of the alterations, and point out the defects in the original machine, and the reasons that led to these defects. It is worthy of note that in this first Hendon period we only got in less than an hour's flying. On April 1st (of all days) we moved back to Surbiton with the "'bus" and all our impedimenta.

Now, our troubles were two in number: (1) lack of rigidity in the transmission, chiefly in the diamond-shaped stays supporting the propeller shafts, of which stays the front pair were wires and the rear pair steel tubes, and (2) the excessive weight of the machine necessary to secure a high factor of safety in so experimental a "'bus." The original machine with crew and fuel on board weighed over a ton, and the loading approximated to 9 lbs. to the square foot, but in spite of the manifest defects, its early performance of 70 m.p.h. speed and its 400-500 ft. per min. climb, put it in the very front ranks of "pushers." Had the transmission gear been as reliable as it afterwards became, there is very little doubt but that the machine would have been at once purchased by the Government, but the alterations occupied so long a period that by the time they were completed we had to face a rival in the shape of the twin-engined gun 'bus, of which more anon. When the "steamroller" was dissembled after the flight of March 28th, it was discovered that the gearbox and its plate had been moving about and bashing the petrol tank, which would assuredly have burst had the flight, in which Mr. Mann went up as passenger, been prolonged a few more minutes. Furthermore, each radius rod had sheared through its bolt at the gearbox end, with the result that the chains had each been pulling to the extent of a thousand pounds or so against the wing spars. Owing to the jambing of the safety valve in one of the petrol tanks, not the one "strafed" by the gearbox, it was on the point of bursting with the volume of air pumped into it by our automatic pump and was distorted completely out of shape. By way of climax the chains had only kept on their sprockets by a miracle. A period of drastic alterations now commenced, including a new chassis, larger wheels, new propellers to absorb the increased power, a still larger rudder, more forward stagger, and the complete elimination of wires from the transmission. The new engine necessitated heavier shafts, sprockets, chains, radius rods, bridge pieces and gearbox. The difficulty in obtaining material was so great that it was not until the end of June that we saw Hendon again.

During part of our first visit to Hendon we had been housed in one of the L. and P. sheds, but we were soon moved from this to the large Navy shed. When we returned at the end of June, we were unable to get a shed of any kind either from the Navy or the Grahame-White Co., so we were compelled to import a tent, which was pitched near the Hall School. Ding made his sixth flight on Tuesday, June 29th, and the general show the "'bus'' put up was inferior to her March form, and necessitated further experiment with propellers to recover the lost speed and climb. The ill-luck that had haunted us in the spring was still in evidence, for a serious accident was only narrowly averted during Ding's seventh flight on July 3rd, The "steamroller" had been up several minutes at a height of 1,500 feet, and was on the point of landing on vol plane, when a pupil on a Caudron taxied right in front of him. With great presence of mind Ding switched the engine on again, and had it not picked up immediately the Caudion would have been smashed to matchwood by over a ton of "steamroller'' moving through the air at 70 m.p.h. However, he was just able to jump over the "louse," the embryo pilot of which was in great need of a substantial dose of phospherine. On Sunday, July 4th, Ding made his eighth and ninth flights, in the latter of which a very interesting episode occurred. The old '"bus" was in great form and travelling at 73 m.p.h. Ding had just passed a "box-kite" to confute a rumour that the Mann was slower than machines of that type, and was banking to turn, when suddenly a shower of objects flew out behind the left rear of the machine and simultaneously everybody on the aerodrome heard a crashing report. At the same time the right-hand propeller was observed to increase its revolutions, but the "bank" grew no worse and Ding switched off, got the machine at a level keel, and landed without accident. Investigations showed that one of the steel stay tubes supporting the left hand propeller shaft had broken, and falling back into the propeller, had caused it to disintegrate. This incident was really a blessing in disguise, for it demonstrated the utter fallacy of the theory that any accident to one of the propellers of a twin-propeller machine must inevitably "crash" the '"bus."

A fortnight was spent in making a new propeller and strengthening up the propeller brackets, and on Sunday, July 18th, the "steamroller'' was again pushed out. Jupiter Pluvius had been busy during that fortnight, and the whole machine had been saturated with water which had percolated through the roof of the tent. The result of all this soaking was a shocking attack of "nonstarteris" on the part of the "starfish," which was not improved by the confusion of high tension wires 6 and 9 by a careless mechanic. The figures on the Anzani crank case, it transpired, were to be read upside down, which is somewhat embarrassing. M. Hagons, the Anzani expert, seemed greatly amused at our contusion of 6 and 9. During the following week short flights were made on July 19th, 20th and 21st, but trouble developed with both the petrol system and the air speed indicator, which restricted us to 10 minute flights at an alleged speed of 50 m.p.h. On the last day of July and August 1st some more or less "dud" flights were put up, and then Ding returned to Windermere in disgust, having flown the "'bus" altogether about three hours.

Having in the meantime secured that rara avis, a petrol pump that pumps petrol, we induced Mr. Sydney Pickles to try the machine on August 4th. For once in a way the "steamroller" was on her best behaviour, and climbed without any forcing to 3,000 ft. in ten minutes, remaining in the air the record time for her of half an hour. On the following night, Thursday, August 5th, Pickles took up Mr. Mann as passenger for an hour's flight, climbing the first 5,000 feet in less than 20 minutes. After the transmission gear had been overhauled and found quite satisfactory, Pickles took up the writer on August 21st, and Mr. Jones, of "FLIGHT," on the same day. The climb had by this time been increased to 500 ft. per minute and the speed to 75-80 m.p.h. All our troubles seemed to be over, and the machine, now highly successful, was about to be re-offered to the Government when the thunderbolt fell. Pickles was forbidden by an American firm, with which he had just completed a contract, to fly any machine but their own particular make. The fatal day was August 22nd. Pickles had flown the "'bus" almost as long as Ding, i.e., 3 hours.

A weary, discouraging wait ensued, for it was not until October 2nd that we were able to secure another pilot in the person of Mr. A. E. Bans, invalided from the Royal Flying Corps. All the intervening six weeks the poor old "steamroller" was steadily deteriorating in our damp tent, the fabric getting slacker and slacker daily, and rust collecting on all the metal parts despite paint and grease After two excellent preliminary flights of 18 minutes and 9 minutes respectively, during the second of which he carried a passenger, on the following day, October 3rd, he ascended with another passenger to the height of 5,000 ft., but as the weather was misty he decided to go no higher, and remained at that altitude for 40 minutes. After tea he took up a third passenger for 15 minutes and performed some astonishing evolutions, including heavily banked right and left-hand turns with hands off the controls, a feat that the exceptional stability of the Mann biplane renders quite easy. During all these flights the "steamroller" attained a speed of 80m.p.h., which at that time was a record pace for a two-seated "pusher" machine, and surpassed by very few two-seater "tractors". Unfortunately, after landing and taxiing some distance, the wheels became embedded in a filled-in trench, with the result that the chassis and one propeller were broken. This, however, was in no way the fault of the machine. We had a lovely job getting the "'bus" to our tent in the dark. To lift a dead weight of over a ton on to a trolley at night with only six pairs of hands and no mechanical appliances is "some" feat. Still, it was done with much pinching of ringers and uttering of strange oaths, and we "teedled" the trolley for home with one mechanic leading the way as guide and steering by the stars, a task for which his former experience in the Navy would seem to render him specially suitable. After we had been pushing and shoving for half an hour or so without any sign of the home fires in the tent, the ground seemed so very familiar that we stopped to investigate. Enquiries showed that our guide, who had that day been treated to a special "joy" ride in the "steamroller," had been celebrating the occasion to such an extent that he had been travelling in a circle. On being remonstrated with by the foreman, he immediately took that worthy's left eye between his finger and thumb with the apparent intention of plucking it out. He may have been a Bible student anxious to add practice to theory. Anyway, he and the foreman rolled about in the mud under the trolley, the old "'bus" trying to fall off on top of them in the meantime, using most horrible language, the foreman continually repeating "Leave go of my - eye, you - Hun!" Eventually the Bible student let go and staggered away into the darkness. It transpired later that he found a nice comfortable bed in the damp grass from which he only emerged to frighten Langridge with his dishevelled appearance at dawn. He had forgotten about the whole episode, which indeed would afford a fine text for a temperance lecturer. We freely forgave him, and he is one of our very best men at the present time. By the way, we had to serve out frequent rations of rum in the leaky tent to keep the staff from catching pneumonia, but this is the only time I have ever seen one of our men the worse for drink.

The damage to the "'bus" was soon repaired, and the critics of the Mann biplane were treated to six weeks of consistent flying without a mishap of any kind. During this period Bans flew the machine over 10 hours at an average speed of 80 m.p.h. and a maximum of 85, he ascended on 30 occasions and carried no fewer than 18 different passengers without any untoward incident. He secured with ease a low speed of 40 m.p.h. in spite of the exceptional heavy loading. The only direction in which the "'bus" might be held defective was the "climb." The falling off in this respect since August was simply due to the slackening off of the wing fabric caused by exposure in the damp and dripping tent. But in spite of her "soggy" wings the machine repeatedly climbed with five hours' fuel, gun and ammunition and two up to 3,000 ft. in 8 minutes, and that with a dead weight of over a ton and the wings loaded to 10 pounds per square foot. She frequently ascended to 5,000 ft., once to 7,000 ft., and once to nearly 9,000 ft. All the old faults had long since been eradicated, and the transmission gear gave no trouble at all. The Mann was undoubtedly the fastest two-seater "pusher" in existence, and the improvement since February was generally commented upon in aviation circles. It is my opinion that single-seater "scouts" cannot be regarded as serious "gun 'buses" from which proper aim can be taken, as the pilot is too occupied with his controls to give adequate attention to his gun. Such makeshift gun-carriers are only effective at pointblank range, and fall easy victims to a two-seater of distinctly less "performance."

How this improvement had been effected is a long story, but I will give my readers a few details. Contrary to general expectation, the chains by themselves gave very little trouble, the stretch was negligible, and we never had a single broken roller. Their vibration, however, was the cause of the acutest anxiety to us in the early days. This vibration proceeded from a variety of causes - wires in the original propeller brackets, too long chain guides which compelled the chain to take its slack on the sprockets themselves, insufficiently rigid radius rods, and last, but by no means least, a critical period of vibration in the engine. By sheer process of elimination we eventually succeeded in inducing the chains not to jump, and a photograph in "FLIGHT" of October 29th last illustrates their smooth running. In this photograph the chains are as rigid as bars of steel. This photograph, by the way, was taken by Karrs himself from the pilot's seat, he having left go of the controls for that purpose. The bias against chains that one is constantly meeting with is surprising. There is an altogether fallacious and erroneous impression that they break! Our shafts and couplings gave no trouble at all, and we only had trouble with a propeller bracket on one occasion. Some pseudo-experts have expressed the opinion that the resistance of chains, guides and sprockets prevent high speeds from being obtained, but the fact that we were able to attain a speed of 85 m.p.h. with a crude experimental "'bus," weighing over a ton, would seem to show that there is some fallacy here. The design of the propellers involved a great deal of experiment, and we must have tried nearly a dozen pairs. The best results were obtained from the 125 h.p. engine by a pair of propellers that had proved utterly hopeless on a 100 h.p. engine. They were extremely crude in appearance, having been designed by a "wood butcher" more in joke than anything else. But with the 125 h.p. engine they pushed like elephants, giving a combined thrust of one-third the weight of the machine and licking into the proverbial cocked hat the best productions of professional propeller designers. The various propellers to Mr. Mann's own design gave excellent results, but invariably slowed the "'bus" from 5 to 10 miles per hour, while the propellers designed by the professionals pave much poorer performance.

The speed and climb of the '"bus" were worked up principally in three ways - (1) propeller experiment, (2) diminishing chain vibration, which absorbed quite a lot of power, and (3) streamlining transmission tubes and stays. Experiments with struts, both chassis and interplane, produced good results, as also did lessening the weight, but the initial ponderosity of the "steamroller" was so great that any attempt to diminish it was like sandpapering an elephant. It is the opinion of both Mr. Mann and myself that the admittedly good performance of the "'bus" was entirely due to its twin propellers, for how else could a machine weighing nearly a ton and a quarter and loaded 10 lbs. to the square foot, be induced to climb at the rate of 500 ft. per minute as actually happened when she was in good form? It is very much to be doubted if any single propeller or tractor screw would have got her off the ground at all.

Our long and protracted experimental period, which really ended in August, for Barrs had merely picked up the broken thread that Pickles had dropped, had given the mysterious "technical advisers" to the Admiralty and War Office a distinct bias against the Mann. Why, I am not prepared to say, for the practical experiments that are necessary before one can standardise a new type of aeroplane had been amply justified by the results obtained. Rehearsals are always needed before a successful public performance, and aviation is no exception to the rule. It is only on paper and in drawing offices that one designs a new type that requires neither alteration nor experiment.

However, finally, we were on the point of obtaining permission to fly the "'bus" for official trials, when she was "crashed" in an altogether unexpected manner. On November 16th Burrs had ascended with a passenger in an attempt to break the British altitude record. In about three-quarters of an hour he had ascended to a height of between 8,000 and 9,000 feet, and was still climbing strongly. Suddenly the gearbox seized up dead and the momentum of the whirling propeller broke the chain on the right-hand side. Please note that the propeller broke the chain and not the chain the propeller. The chain flew out between the two end interplane struts and vanished, as I had always prophesied it would do in the very unlikely event of a breakage, and Barrs switched off his engine and commenced a glide which lasted 21 minutes. Mr. J. G. Woodley, the passenger, was so little concerned that he calmly went on making entries in his diary, which was reproduced at the time in the pages of "FLIGHT." On nearing the ground, the poor old "'bus" was caught by a strong downward current which brought her down just outside the aerodrome in a small field. She taxied into some trees, felling three of them, but although the chassis and wings were smashed to atoms, such was the strength of the fuselage that neither Barrs nor Woodley sustained the slightest injury. The passenger's escape in particular was due to the main shaft connecting the engine and gearbox making his compartment extremely rigid and unyielding. Such a smash on an engine-behind machine would have probably left no survivors to tell the tale. The initial cause of the "crash'' was the negligence of a mechanic to put grease in the gearbox, though but for that wretched remou at the last moment the '"bus" would have landed in the aerodrome without breaking a wire. Extremely lurid and misleading accounts of the accident appeared in the pages of the contemporary daily press. Such was the end of the "steamroller" after some nine months of strenuous life.

The "crash," however, got us out of one difficulty. Our canvas hangar had become almost uninhabitable owing to the heavy rains, and a miniature river was flowing through the tent from side to side. Any further flying of the "steamroller" at Hendon had become well-nigh impossible, but the remou that brought the "'bus" down just on the wrong side of the fence effectually cut the Gordian Knot. It is worthy of note that the "steamroller" was flown three hours by Ding, three by Pickles, and 12 by Barrs, 18 hours in all, and she must have covered in that time a distance of nearly 1,500 miles.

At the time of writing, some ten weeks afterwards, we have half finished the "steamroller's" successor, M.2, who, I will venture to say without any risk of boasting, will regain for Mr. Mann the "pusher" supremacy he lost in November. M.1 all but completely vindicated the principle of chain-drive and geared down propellers; M.2, with her loading reduced to half, hundreds of pounds less in weight, will completely do so. M.1 was built in the typical "Middle Ages" manner with great clumsy fitting and full of unnecessary weight and head resistance. M.2 will be in every way an up to-date 1916 machine with transmission added. Her performance will astonish the few remaining critics of the type.

Invidious comparisons have recently been made between twin-engine and transmission machines, to the detriment of the latter. To my mind, the twin-engine machine weighs much more than a transmission machine, its head resistance is much greater, and it has more vulnerable points, e.g., two engines afford a better target for hostile fire than one, also they obviously require more attention. The twin-engine machine can fly after a fashion with one propeller, so can the transmission machine. On a transmission machine you can put your propellers where you like and run them at any desired speed. On a twin-engine machine you mutt place your engines in two particular spots, or the efficiency will suffer, and your propeller revolutions are arbitrarily fixed. Twin-engines usually indicate twin-chassis, which are not necessary on a transmission machine. The only point where the twin-engine machine scores is in simplicity, but an aeroplane transmission, once the experimental stage is passed, requires no more attention than that of a car.

My tale is told. I have made it clear to my readers why we have persevered with the Mann biplane so long, and also that the path of the experimenter is by no means easy and pleasant, though it may easily lead him to destruction. Ridicule and calumny are poured on him at every step, and all men wish him ill. He has to tight rigid conservatism and wrestle with invincible ignorance. His sole assets are the courage of his convictions and a saving sense of humour. But we forget the toil and danger of the past as we daily watch the Mann biplane rise like the Phoenix from the ashes of its predecessor. And perhaps this true story of how we wrested success from apparent failure may encourage others among the readers of "FLIGHT" to follow in our footsteps. Per Ardua ad Astra !

DESIGNING AND BUILDING A BIPLANE.

THE STORY OF A SUCCESSFUL EXPERIMENT.

By ROBERT P. GRIMMER.

[In the following story Mr. Grimmer has given a detailed summary of the ups and downs to which an experimenter in aviation has to be prepared to submit. He has adopted a very light style in handling his subject, and treats his firm's misfortunes in an almost Mark Tapley spirit, worthy of admiration. The mistakes made and the difficulties encountered should be helpful to new workers in the same direction, a suggesting what to avoid. Mr. Grimmer's views as to the comparative merits of twin-propeller and chain pusher machines as opposed to direct driven tractor machines are worth careful consideration., although it must not be taken that we necessarily are in agreement with all the author sets forth. Altogether the story is both amusing and instructive, and we heartily wish the Mann firm the success which Mr. Grimmer foretells in his concluding paragraph in connection with M.2 now under construction. - ED.]

THE Mann Gun-Carrying Biplane is probably familiar enough to the average reader of "FLIGHT," but very few people seem to know the raison d'etre of its existence. The general opinion would appear to be that the transmission was put in for a joke, or else was a misguided attempt to make the 'bus dissimilar to the ordinary type of fuselage machine. Nothing could possibly be more erroneous than these views, and I am now attempting to explain the exact reason why M.1 came into being.

The great majority of aeroplanes belong to the tractor type - that is, with the airscrew in front drawing the machine forward. The other type with the propeller behind are known as "pushers." Previous to the war, the "pusher" type had been greatly neglected, owing to the fact that its design and construction from a "performance" point of view presented great difficulties. The tail booms caused a certain amount of resistance, and there was always the possibility of their being broken by fragments of a damaged propeller. Further, there was the objection against the placing of the engine and tanks behind the crew, which, any way in theory, were liable to break loose and crush the pilot and passenger in the event of a bad landing. Whether this objection has always been substantiated by facts I am not prepared to say, but on paper the "engine-behind" machine certainly does look unhealthy.

Until the war broke out, all the best aeroplanes, without except ion, were of the tractor biplane type, and the most successful of these were single-seaters or "scouts.'' Both the British and French Governments possessed a few "pushers," but it is very doubtful if the best of these had a speed much in excess of 65-70 miles per hour, with a climb of some 300 ft. per minute. The Service value of the "pusher" consists in the excellent view obtained by the crew and the ideal gun emplacement afforded by the projecting body or nacelle. But the "tractor" scored at that time (1914) by virtue of its superior speed and climb. If by a stroke of a magic wand the Allied Governments could have transformed their "tractors" into "pushers," retaining at the same time the superior performance of the former type, there is very little reason to doubt that this would have been done at the beginning of the war. It was not until some time afterwards that the device of firing through the tractor screw was introduced by Garros. This device has the great disadvantage that the gun cannot be properly aimed, as it is on a fixed mounting. The Huns were even worse off as regards "pushers" than ouselves, as they had pinned their faith entirely to the "performance tractor."

I have explained the virtues and vices of the "tractor" and "pusher" types; the one gave good performance, medium view and a bad gun platform, and the other bad performance, good view and a super excellent gun platform. Mr. Mann and I had been connected with aviation in various capacities since its inception in 1908, and we had for some time previously recognised what we considered the disabilities of the contemporary types for Service work. The first really successful flying machine was the Wright, which in its time (1908-09) put up some quite astonishing performances, including a double crossing of the Channel with an engine giving only approximately the same horse-power (20) as the Ford tin-can car! The great characteristic of the Wright was its twin geared-down propellers driven by chains. It is an undeniable fact that propellers of large pitch rotating slowly are more efficient than propellers of small pitch rotating at very high speeds. Propeller speeds of anything up to 1,000 r.p.m. are regarded as being slow, anything approaching 2,000 r.p.m. is very fast. High speed propellers have a very large percentage of "slip," and they lack the grip on the air of the slow speed variety. There are other objections as well, the chief being the tendency to disintegrate, owing to the terrific velocity of the tips, but this latter is worse in theory than in practice, though cases are reported from time to time. At one time the Wright machine was supreme, but as the designers made no real attempt to keep pace with the times by installing really high-power engines, their "twin-pusher" was in course of time completely eclipsed by single-propeller types, chiefly of the "tractor" variety. Mr. Mann and I always recognised the possibilities of the "twin-pusher," properly developed, and we had always wished to construct such a machine on modern lines. But in those days we never secured the weighty financial backing necessary for so great a project.

Just before the outbreak of the great war Mr. Mann and I were fortunate enough to secure the interest of Mr. W, H. Bonham-Carter in our project, with the result that we were able to commence construction in September, 1914, Mr. Mann having got out the rough designs in August. I must here pay a tribute to the magnanimity and the disinterested patriotism of Mr. Bonham-Carter, who at the time of writing has tome the greater part of the burden of financing our experimental work for a period of over eighteen months, and who at the outset had no guarantee whatever that he was backing the right horse.

M.1 was designed and built at great pressure in the hope that she might be used against the Huns early in 1915. Mature reflection inclines me to the view that we should have done better if we had advanced at a more leisurely pace. The design and construction of such an experimental machine was a very big contract, so big indeed that no established constructor would have risked his reputation by taking it on. Having no reputation as constructors to lose, we took the risk - there was a distinct risk, although we were unaware of it at the time - and boldly grasped the bull by the horns. The only building we had available for the purpose was a disused tin church 20 ft. by 40 ft., with a vestry that we converted into two offices. This building had the reputation of being haunted, and it certainly had been standing empty for many years before we got possession of it. A particularly gruesome story is told about this epoch, but the episode occurred so many years ago that it is impossible to verify it. Such was the reputation of the building where M.1 was built.

M.1 was a fuselage biplane with twin chain-driven propellers. Mr, Mann, who was solely responsible for the design, was actuated by the desire to combine in one machine the virtues of the tractor and pusher without any of their vices. The wings were heavily cambered with the front edges sloped back partly for stability and partly to enable the Lewis automatic gun to be fired sideways. A 100 h. p. Anzani engine, hereafter sometimes known as the "Starfish," was mounted at the extreme prow, and the power was transmitted by means of a shaft and universal couplings to a gearbox behind the observer's seat. The gearbox was installed for the purpose of reversing one of the driving chains that emerged from it, and it weighed over 100 lbs. By the way, the reversing of one chain by any method otherwise than the Wright system of crossing it is a task sufficient to daunt the boldest designer, and is by far the biggest problem to be tackled in a chain driven aeroplane. The two chains emerging from the gearbox ran on two sprockets attached to the propeller-shafts, which were supported by means of diamond-shaped brackets and tubes and wires at the sides of the inner pair of struts. The propellers, of course, revolved in opposite directions for the sake of stability.

On September 7th, 1914, we possessed a works indifferently equipped with tools, but with neither staff nor materials, and the designs of the machine itself only roughly worked out. Yet we only allowed ourselves three months in theory to get the "steamroller" - as she was afterwards called - completed. In practice, and for the best of reasons, the construction represented five months of hard work, for it was not till the end of January, 1915, that the "steamroller" appeared at Hendon. I have never worked so hard in my life as during that five months, and the toil was so arduous, and the difficulties so numerous and complex, that the end of the period brought me a severe nervous breakdown, from which I did not finally recover until I took a month's holiday in the spring. The first difficulty we encountered was the problem of getting together an adequate staff. The next difficulty was the question of materials. The unprecedented demand for wood, fabric, sheet-steel, aluminium, tubing, nuts and bolts, wire strainers, &c., had created a veritable famine in these articles, and in some cases one had to wait months for delivery. Such material as we did get had mainly to be obtained by making personal visits to the various manufacturers and cadging - that is the only appropriate word - a sheet of steel here, a few lengths of tubing there, a dozen wire strainers, and so forth. Then there was the problem of drawings. It was well into October before we were able to get even one "stress merchant," and the middle of November before we could lay our hands on two more. In the meantime the foreman had to extemporise drawings of a kind on the back of sheets of emery paper, that being the time-honoured method employed in the early days of aviation in practically all shops.

The overtime worked during this period was something cruel; it was no uncommon thing to start work at 7 a.m. and to go on, with intervals for meals, till midnight. We frequently worked right through Friday night till noon on Saturday, and on these occasions it was not an uncommon thing for fillers to fall asleep at their vices until aroused by the fireman. On all our night shifts a pint of light ale was served out to each man at the firm's expense every two hours, and we found it very efficacious in keeping the men up to the mark. I should like here to pay a tribute to the energy and zeal of the average British workman, who has been so much decried by those who do not know him. We have never known the meaning of labour troubles, and it is my experience that in the aeroplane trade at least the average workman will deal with you as you deal by him. My far the most arduous task that fell to my personal lot was that of keeping a drawing office staff awake on the night shifts. I have sat up many a night doping the "stress merchants" with strong coffee at intervals, but in spite of this and other drastic methods more than once they were compelled to surrender to Morpheus. I recollect that on one occasion a "stress merchant" collapsed from his stool on to the floor at 3 a.m.

This particular man was a Sunday school teacher and a prominent church member, and had never been known to utter even the mildest "cuss word" on any other occasion, but when the wall was banged close to his head to arouse him, he responded with such a torrent of bad language in his sleep as shocked our most hardened fitters. We let him sleep on till breakfast, as he was obviously too muddled to distinguish "pi" from "cos," or "sine" from "tan."

With much labour the "steam-roller," was completed at the end of January, 1915, and duly transported to Hendon, permission having finally been obtained from the somewhat reluctant authorities.

It was erected early in February, and no sooner was she ready for her maiden flight when the pilot we had engaged to fly her discovered that he had more pressing business elsewhere. After same delay we made arrangements with Mr. W. R. Ding, and on Friday, (Friday is regarded by pilots, both aviation and marine, as a very unlucky day) February 19th, the machine was pushed out and the engine run preliminary to a flight. Strong as was my faith in the old "'bus," I shivered with terror when the engine was started and the chains began to run round the sprockets and scream through their guides.

The chains, instead of running smoothly round the sprockets as all self-respecting chains should, progressed in a series of leaps and bounds and appeared to be animated with the desire of moving sideways as well as forward. A tinny clanging noise emanated from the transmission gear, and the wires in the propeller brackets vibrated until they resembled bird cages. The propellers gave one the impression that they wanted to come forward through the inter-plane struts. However, Ding said he would make a flight, and we all let go. The "steam-roller" ran along the ground, duly lifted amid a cloud of smoke from the engine, made a short straight flight and landed somewhat abruptly. It transpired that the pilot's seat had collapsed owing to the "wood butcher" responsible for its fixing having been called away to a prayer meeting and thus forgetting to finish his job. The following day, Saturday, Ding made another flight, partially across country, but this latter quite against his wish and inclination. On attempting to turn, he discovered that the steadying effect of the twin propellers was so great that the rudder had very little effect, and he was compelled to edge the "'bus" round very gradually in order to get back. As the propellers did not suit the engine, and the throttle had jambed at two-thirds open, he had the unexpected pleasure of flying low over Collindale Avenue and only just clearing trees and houses. However, he got back all right, and had sufficient presence of mind left to fly hands off before he landed. A speed of 60 m.p.h. was attained, which was not so bad under the circumstances.

After a month spent in sundry alterations, chiefly to the transmission gear, with a view to steadying the jumping chains, a further flight of ten minutes was made on March 20th. A larger rudder and improved propellers had been designed, and this time the throttle was induced to go wide open. The improvement was quite marked, and a speed of 70 m.p.h. attained. An altitude of 1,000 ft. was reached without difficulty in a 30 m.p.h. wind. Unfortunately, however, one of the wires in the diamond supporting a propeller bracket came adrift, and the great weight of the "'bus" caused her to burst a tyre on landing. Jumping chain trouble was still prevalent, and the tail skid was not satisfactory. A week was spent in further slight modifications.

( To be concluded.)

Flight, March 16, 1916.

DESIGNING AND BUILDING A BIPLANE.

THE STORY OF A SUCCESSFUL EXPERIMENT.

By ROBERT P. GRIMMER.

(Concluded from page 206.)

ON March 38th, Ding made two further flights of 15 minutes each, taking Mr. Mann as passenger in the second one. The chains jumped worse than ever, and two of Hans Renold's experts were absolutely horrified at their extraordinary behaviour. The speed was about 70 m.p.h., but the general performance was so short of Mr. Mann's expectation that it was decided to make very drastic alterations and to install a 125 h.p. Anzani in place of the original 100 h.p. In the light of subsequent knowledge I regard the substitution of engines as a very great mistake, as it materially increased the loading and head resistance, and thus nullified the extra power. Later, I shall give a short list of the alterations, and point out the defects in the original machine, and the reasons that led to these defects. It is worthy of note that in this first Hendon period we only got in less than an hour's flying. On April 1st (of all days) we moved back to Surbiton with the "'bus" and all our impedimenta.