Книги

Журнал

Flight за 1917 г.

358

Журнал - Flight за 1917 г.

Flight, April 26, 1917.

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

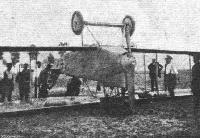

During the spring and summer of 1912 the Austrian Etrich firm built and experimented with an enclosed monoplane of the Taube type. As our illustration shows, this machine was very similar in general arrangement to the ordinary Etrich taube, with the exception that the body had been made considerably more roomy. Constructionally the body was of the girder type with a superstructure giving the covering an elliptical form in section. Windows of non-inflammable material were provided in the sides and nose, and as the engine was mounted very high up in the body, the view forward and downward was exceptionally free, considering that the machine was of the tractor type. The two seats were placed one behind the other, and the pilot occupied the rear one. Apart from the fact of it being enclosed, this monoplane was a departure from standard practice in other respects. For instance, the under-carriage was of the simple Vee type that is so popular on modern machines, but which had not become generally adopted at that time. The wings, which had the usual back swept and upturned tips characteristic of the taube, were attached to the body by a single tubular pivot, and provisions had been made for varying the angle of incidence during flight. This was accomplished by rotating a wheel mounted in the body to the right of the pilot.

For some reason no more machines of this type were built by the Etrich firm, whether this is due to the enclosed feature or to other causes. Probably the reason was that, like so many others, this new departure had too many unknown factors. On the face of it, it would appear that the centre of thrust was too high, being approximately in line with the intersection of the chord line and the resultant, while the centre of resistance of the body and that of the under-carriage were some distance below this point.

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

During the spring and summer of 1912 the Austrian Etrich firm built and experimented with an enclosed monoplane of the Taube type. As our illustration shows, this machine was very similar in general arrangement to the ordinary Etrich taube, with the exception that the body had been made considerably more roomy. Constructionally the body was of the girder type with a superstructure giving the covering an elliptical form in section. Windows of non-inflammable material were provided in the sides and nose, and as the engine was mounted very high up in the body, the view forward and downward was exceptionally free, considering that the machine was of the tractor type. The two seats were placed one behind the other, and the pilot occupied the rear one. Apart from the fact of it being enclosed, this monoplane was a departure from standard practice in other respects. For instance, the under-carriage was of the simple Vee type that is so popular on modern machines, but which had not become generally adopted at that time. The wings, which had the usual back swept and upturned tips characteristic of the taube, were attached to the body by a single tubular pivot, and provisions had been made for varying the angle of incidence during flight. This was accomplished by rotating a wheel mounted in the body to the right of the pilot.

For some reason no more machines of this type were built by the Etrich firm, whether this is due to the enclosed feature or to other causes. Probably the reason was that, like so many others, this new departure had too many unknown factors. On the face of it, it would appear that the centre of thrust was too high, being approximately in line with the intersection of the chord line and the resultant, while the centre of resistance of the body and that of the under-carriage were some distance below this point.

Flight, April 26, 1917.

THE "TOTALLY ENCLOSED" AEROPLANE.

IT has already been recorded that at the Aero Show held in Berlin in April, 1912, two enclosed machines were exhibited - the Rumpler and the Bavarian Aircraft Works monoplane. At about the same time, early in April, 1912, there arrived at Brooklands aerodrome a new monoplane from the Avro works. During the weeks that followed this machine was taken through its tests by the late Lieut. Wilfred Parke, R.-N., who put up some very good performances, and demonstrated for the first time in England the practicability of the all-enclosed aeroplane.

A good idea of the general arrangement of the Avro enclosed monoplane can be formed from the accompanying illustration. The body, which was of rectangular section, had flat sides, top, and bottom. The front part of it was fitted with celluloid windows in the sides as well as in the roof and floor. Round the windows the covering consisted of sheet aluminium, while the rear part of the body was covered with fabric. Access to the interior was obtained through an aluminium trap door in the roof, and the pilot was comfortably seated inside, with the warp and elevator lever between his knees, his feet resting on two pedals pivoting on a transverse steel tube and operating the rudder. His switch, throttle, and spark advance levers were mounted on the right-hand side of the body, and his various instruments - altitude recorder, compass, revs, indicator, watch, map holder, and inclinometer - were arranged conveniently around him.

When the machine first made its appearance at Brooklands it was generally thought that, with the respiration of the pilot inside and fine spray of oil thrown out with the exhaust of the engine, the windows would soon become clouded over, and render clear vision impossible after a few minutes' running. In practice this was not found to be the case, and after the longest flight made on this machine, the window in the floor was the only one that showed any signs of mistiness. The engine fitted was, it should be remembered, a Viale, which had no auxiliary exhaust ports in the cylinders, but on the other hand no exhaust pipes were employed to lead the gases away from the windows. Had this been done there appears to be no reason to suppose that the window underneath would have clouded over at all. As a precautionary measure a circular opening was provided in each side of the body, on a level with the pilot's head, so that if the windows should get covered with mist or rain it was possible, by looking out through these openings, to obtain a reasonably good view. After several months of very good flying the Avro monoplane was damaged through running into a wire fence that the pilot had failed to notice, and as the firm were then busy on their other machines the monoplane was put on one side, having during its short career provided quite a lot of useful data for the biplane of similar type which was being got out for the Military Trials.

<...>

THE "TOTALLY ENCLOSED" AEROPLANE.

IT has already been recorded that at the Aero Show held in Berlin in April, 1912, two enclosed machines were exhibited - the Rumpler and the Bavarian Aircraft Works monoplane. At about the same time, early in April, 1912, there arrived at Brooklands aerodrome a new monoplane from the Avro works. During the weeks that followed this machine was taken through its tests by the late Lieut. Wilfred Parke, R.-N., who put up some very good performances, and demonstrated for the first time in England the practicability of the all-enclosed aeroplane.

A good idea of the general arrangement of the Avro enclosed monoplane can be formed from the accompanying illustration. The body, which was of rectangular section, had flat sides, top, and bottom. The front part of it was fitted with celluloid windows in the sides as well as in the roof and floor. Round the windows the covering consisted of sheet aluminium, while the rear part of the body was covered with fabric. Access to the interior was obtained through an aluminium trap door in the roof, and the pilot was comfortably seated inside, with the warp and elevator lever between his knees, his feet resting on two pedals pivoting on a transverse steel tube and operating the rudder. His switch, throttle, and spark advance levers were mounted on the right-hand side of the body, and his various instruments - altitude recorder, compass, revs, indicator, watch, map holder, and inclinometer - were arranged conveniently around him.

When the machine first made its appearance at Brooklands it was generally thought that, with the respiration of the pilot inside and fine spray of oil thrown out with the exhaust of the engine, the windows would soon become clouded over, and render clear vision impossible after a few minutes' running. In practice this was not found to be the case, and after the longest flight made on this machine, the window in the floor was the only one that showed any signs of mistiness. The engine fitted was, it should be remembered, a Viale, which had no auxiliary exhaust ports in the cylinders, but on the other hand no exhaust pipes were employed to lead the gases away from the windows. Had this been done there appears to be no reason to suppose that the window underneath would have clouded over at all. As a precautionary measure a circular opening was provided in each side of the body, on a level with the pilot's head, so that if the windows should get covered with mist or rain it was possible, by looking out through these openings, to obtain a reasonably good view. After several months of very good flying the Avro monoplane was damaged through running into a wire fence that the pilot had failed to notice, and as the firm were then busy on their other machines the monoplane was put on one side, having during its short career provided quite a lot of useful data for the biplane of similar type which was being got out for the Military Trials.

<...>

The Avro Type F cabin monoplane showing the famous 35 h.p. Viale radial engine which is now preserved for all time.

Flight, April 26, 1917.

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

Probably the Avro enclosed biplane is best remembered, and will go down to history, as the machine on which the late Lieut. Wilfred Parke, R.N., had the nasty experience that became known to all the aviation world as "Parke's Dive." That the machine came out of this bad spin without breaking anything is not only an outstanding testimony to Avro design, but is of far greater significance in showing that, even with such a great amount of side area, a machine need not be uncontrollable in a bad spin, provided the pilot knows what to do. This Lieut. Parke only discovered at the last moment, but when he put her to it the machine answered the controls at once.

Except for the fact that it had two pairs of wings the enclosed Avro biplane was very similar to the monoplane already described. The main planes were attached to the upper and lower longitudinals of the body respectively, and pilot and passenger were seated tandem fashion inside. Entrance to the body was through a triangular door in the side, this being shown in our illustration. The engine, a 60 h.p. Green, was mounted in the nose of the body, which had here a width of only 15 inches, this being made possible by the fact that the engine was of the vertical type. The radiators were mounted on the side of the body in front of the door. Forming a partition between what may be termed the "engine room" and the occupants' cockpit was a large dashboard with all the instruments. These were therefore, as the passenger sat in front, some distance away from the pilot, who had to look over the passenger's shoulders in order to read the instruments.

The number of windows had been reduced, in this machine, to a long rectangular opening in each side of the body, but the interesting fact was disclosed after a few flights, that during straight flying no draught was felt by the occupants. When the machine was turning and banking a slight wind from the side was noticed, but not sufficient to be in the slightest degree uncomfortable. Although the Avro enclosed biplane was undoubtedly very promising in many respects the authorities did not encourage the production of this type, otherwise the totally enclosed aeroplane might have been very considerably more advanced than is now the case. When the war is over and this type will once more have to be studied seriously, it is to be hoped that the Avro firm, who pioneered the type, will be among the first to take it up again.

<...>

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

Probably the Avro enclosed biplane is best remembered, and will go down to history, as the machine on which the late Lieut. Wilfred Parke, R.N., had the nasty experience that became known to all the aviation world as "Parke's Dive." That the machine came out of this bad spin without breaking anything is not only an outstanding testimony to Avro design, but is of far greater significance in showing that, even with such a great amount of side area, a machine need not be uncontrollable in a bad spin, provided the pilot knows what to do. This Lieut. Parke only discovered at the last moment, but when he put her to it the machine answered the controls at once.

Except for the fact that it had two pairs of wings the enclosed Avro biplane was very similar to the monoplane already described. The main planes were attached to the upper and lower longitudinals of the body respectively, and pilot and passenger were seated tandem fashion inside. Entrance to the body was through a triangular door in the side, this being shown in our illustration. The engine, a 60 h.p. Green, was mounted in the nose of the body, which had here a width of only 15 inches, this being made possible by the fact that the engine was of the vertical type. The radiators were mounted on the side of the body in front of the door. Forming a partition between what may be termed the "engine room" and the occupants' cockpit was a large dashboard with all the instruments. These were therefore, as the passenger sat in front, some distance away from the pilot, who had to look over the passenger's shoulders in order to read the instruments.

The number of windows had been reduced, in this machine, to a long rectangular opening in each side of the body, but the interesting fact was disclosed after a few flights, that during straight flying no draught was felt by the occupants. When the machine was turning and banking a slight wind from the side was noticed, but not sufficient to be in the slightest degree uncomfortable. Although the Avro enclosed biplane was undoubtedly very promising in many respects the authorities did not encourage the production of this type, otherwise the totally enclosed aeroplane might have been very considerably more advanced than is now the case. When the war is over and this type will once more have to be studied seriously, it is to be hoped that the Avro firm, who pioneered the type, will be among the first to take it up again.

<...>

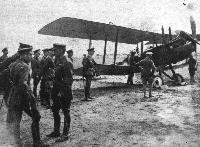

The presentation of the aeroplane "South Africa" by the London Chamber of Commerce, through the Imperial Air Fleet Committee, to the Right Hon. Lieut.-General J.C.Smuts, K.C., as representing the Union of South Africa. Lef to right, from the top: General Smuts and Lord Desborough; Lord Desborough being strapped into the machine previous to his flight with Captain Hucks. Centre: Captain Hucks just getting off. Below: the christening, and Captain Hucks with Lord Desborough about to land.

Flight, May 10, 1917.

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

Regarding what has been done in this country in the way of enclosed aeroplanes since the outbreak of war little can, of course, be said. As, however, the Germans are known to have captured one of the large Handley-Page biplanes practically intact, it may be permissible to give a few particulars of this very successful machine.

Strictly speaking the Handley-Page biplane is not a "totally enclosed" machine, as the gunner, who is placed right out in the nose, and the pilot both have their head projecting above the covering. Had it not been for the fact that this machine is being used for military purposes, there can be little doubt, however, that it would have been totally enclosed, and when machines of this type come to be employed on commercial work in peace time, the total covering in will follow as a matter of course, the general arrangement of the machine naturally lending itself to this feature. It appears probable that in this case the pilot will occupy the front seat, and windows will be provided above, below, in front and on the sides, so that the view will be practically unrestricted in all these directions. For pleasure flying in peace times it would indeed be difficult to imagine a machine offering greater possibilities in the way of comfortable accommodation of passengers, while the weight carrying capability of the machine will render possible the transportation of considerable quantities of lighter goods such as the mails, &c. With only very slight modifications the machine could be transformed from a weapon or war into a commercially useful vehicle of the air, and without any very radical changes, except as regards size, the Handley-Page can be easily pictured as a trans-continental mail carrier of the future.

<...>

Flight, November 29, 1917.

London to Constantinople.

THE Secretary of the Admiralty made the following announcement on November 22nd :- "It will be remembered that during July a successful air attack was carried out on objectives in the vicinity of Constantinople. This was accomplished by a large British bombing aeroplane of the Handley-Page type, which flew from England, where she was constructed, to one of our bases in the Mediterranean. The journey was accomplished in a series of eight flights. Among other places, stops were made at Lyons and Rome. The total distance flown was nearly 2,000 miles, the machine being actually in the air for just over 31 hours. During some parts of the flight strong winds and heavy rain-storms were experienced, and for one stretch of over 200 miles the route lay over mountainous country where it would have been impossible for any machine to land. Nevertheless the aeroplane carried out its journey practically to time table, which is believed to be easily a World's record for a cross-country journey, and also for the Weight carried for the distance, the machine being self-contained as regards engine and aeroplane spares."

IT has been stated unofficially that the machine on the journey to Constantinople was piloted by Squadron-Commander K. S. Savory, Flight Lieutenant H. Macclelland, and Engineer Lieutenant T. Rawlings. The mechanic was P.O. Benjamin Cromack.

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

Regarding what has been done in this country in the way of enclosed aeroplanes since the outbreak of war little can, of course, be said. As, however, the Germans are known to have captured one of the large Handley-Page biplanes practically intact, it may be permissible to give a few particulars of this very successful machine.

Strictly speaking the Handley-Page biplane is not a "totally enclosed" machine, as the gunner, who is placed right out in the nose, and the pilot both have their head projecting above the covering. Had it not been for the fact that this machine is being used for military purposes, there can be little doubt, however, that it would have been totally enclosed, and when machines of this type come to be employed on commercial work in peace time, the total covering in will follow as a matter of course, the general arrangement of the machine naturally lending itself to this feature. It appears probable that in this case the pilot will occupy the front seat, and windows will be provided above, below, in front and on the sides, so that the view will be practically unrestricted in all these directions. For pleasure flying in peace times it would indeed be difficult to imagine a machine offering greater possibilities in the way of comfortable accommodation of passengers, while the weight carrying capability of the machine will render possible the transportation of considerable quantities of lighter goods such as the mails, &c. With only very slight modifications the machine could be transformed from a weapon or war into a commercially useful vehicle of the air, and without any very radical changes, except as regards size, the Handley-Page can be easily pictured as a trans-continental mail carrier of the future.

<...>

Flight, November 29, 1917.

London to Constantinople.

THE Secretary of the Admiralty made the following announcement on November 22nd :- "It will be remembered that during July a successful air attack was carried out on objectives in the vicinity of Constantinople. This was accomplished by a large British bombing aeroplane of the Handley-Page type, which flew from England, where she was constructed, to one of our bases in the Mediterranean. The journey was accomplished in a series of eight flights. Among other places, stops were made at Lyons and Rome. The total distance flown was nearly 2,000 miles, the machine being actually in the air for just over 31 hours. During some parts of the flight strong winds and heavy rain-storms were experienced, and for one stretch of over 200 miles the route lay over mountainous country where it would have been impossible for any machine to land. Nevertheless the aeroplane carried out its journey practically to time table, which is believed to be easily a World's record for a cross-country journey, and also for the Weight carried for the distance, the machine being self-contained as regards engine and aeroplane spares."

IT has been stated unofficially that the machine on the journey to Constantinople was piloted by Squadron-Commander K. S. Savory, Flight Lieutenant H. Macclelland, and Engineer Lieutenant T. Rawlings. The mechanic was P.O. Benjamin Cromack.

TESTING THE ENGINES. - The two Rolls-Royce engines on the "H.P." having a trial run before the start on the London-Constantinople bombing expedition.

The successful Handley-Page biplane built in England since the outbreak of war and now doing extremely useful work.

GETTING READY. - A Handley Page biplane of a type similar to that which made the magnificent flight from London to Constantinople. A good idea of the dimensions of the machine is provided by comparison with the people in front.

THE HANDLEY PAGE TWIN-ENGINED BIPLANE. - A rear view of the engine mounting and fore part of the fuselage.

THE HANDLEY PAGE TWIN-ENGINED BIPLANE. - Lifting the tail. A similar photograph to the above was shown on the screen in connection with Mr. Handley Page's recent paper at the Aeronautical Society, and in connection with which the author explained that the tail is really quite easy to lift, the extra help seen in the photograph being rather due to the well-known fact that when a film is being taken, everybody wants to help - by getting into the photograph.

THE HANDLEY-PAGE BOMBER FLIGHT TO CONSTANTINOPLE. - On left: Flight-Commander Savory, D.S.O. and bar, who took part in this raid, with his greyhound mascot. On the right: Squadron-Commander Smyth-Piggot, D.S.O., with his mascot.

TWO VIEWS OF THE ROLLS-ROYCE ENGINES WHICH MADE THE FLIGHT POSSIBLE. - On the left, a front view of an R.R. installed in the wings of the Handley-Page. The engine housing has been removed to give a better view of the engine. On the right, a three-quarter rear view of the Rolls-Royce engine. In the space behind the engine the petrol tank is carried.

In the Hands of the Enemy. - A Handley-Page biplane shot down in Flanders by anti-aircraft guns. The machine according to Flugsport, had a crew of three and carried sixteen bombs, each weighing 50 kilogs.

DIVERTING THE CARDINAL WOLSEY RIVER AT HANWORTH PARK. - Mr. H. Sykes, on his Martinsyde, looping in a gale of wind. The machine is travelling away from the spectator, and is in the inverted position.

Flight, April 19, 1917.

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

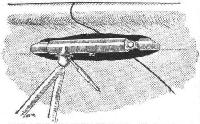

Apart from such early designs as the Henson already referred to, one of the first, if not, indeed, the very first, totally enclosed in the fuselage covering, was the Piggot monoplane exhibited at the Olympia aero show in 1911. This machine, as our illustration shows, had a stream-line body, even to a casing round the propeller boss, and it is, in point of fact, a debatable point whether the designer was primarily concerned with providing comfort for the passengers or obtaining maximum efficiency by stream-lining everything to the greatest possible extent. Be that as it may, the occupants were enclosed in the stream-line body which they entered through circular openings in the floor. Presumably these same openings served to give a view in a downward direction. An additional opening was provided under the engine near the nose, and windows on each side of the engine were to give the passenger a view directly forward. It is quite evident, in view of modern knowledge, that the pilot's range of vision was totally inadequate, and as a matter of fact, when the machine was ultimately tried, an opening was cut in the top of the body, through which the pilot's head projected. The machine was not a very great success, but we should hesitate to put this down to the fact that it was totally enclosed. Rather is it to be assumed that the chief trouble was insufficient power.

<...>

THE "TOTALLY ENCLOSED" AEROPLANE.

<...>

Apart from such early designs as the Henson already referred to, one of the first, if not, indeed, the very first, totally enclosed in the fuselage covering, was the Piggot monoplane exhibited at the Olympia aero show in 1911. This machine, as our illustration shows, had a stream-line body, even to a casing round the propeller boss, and it is, in point of fact, a debatable point whether the designer was primarily concerned with providing comfort for the passengers or obtaining maximum efficiency by stream-lining everything to the greatest possible extent. Be that as it may, the occupants were enclosed in the stream-line body which they entered through circular openings in the floor. Presumably these same openings served to give a view in a downward direction. An additional opening was provided under the engine near the nose, and windows on each side of the engine were to give the passenger a view directly forward. It is quite evident, in view of modern knowledge, that the pilot's range of vision was totally inadequate, and as a matter of fact, when the machine was ultimately tried, an opening was cut in the top of the body, through which the pilot's head projected. The machine was not a very great success, but we should hesitate to put this down to the fact that it was totally enclosed. Rather is it to be assumed that the chief trouble was insufficient power.

<...>

A pronounced example of the stream-line form body, the Piggott monoplane exhibited at the Olympia Aero Show of 1911. The entire framework of this machine is enclosed in a light fabric-covered shell, access to which is obtained from beneath. There is room for pilot and passenger inside, both of whom have an outlook through various small windows. The propeller-boss is conical, and forms a sharp point on the otherwise hemispherical head. The radiator forms a kind of crest above the forehead.

THE GREAT FLIGHT ACROSS SOUTH AFRICA. - General Smuts recently, when accepting the aeroplane subscribed for by the London Chamber of Commerce, had reason to refer to the retaining of the supremacy of the air as being the forerunner of victory. He has intimate knowledge of the activities at the front, and has also in mind the 300 miles South African flight carried out by Captain Moore in the German East African Campaign. In our photograph above, Captain Moore has arrived safely back, the aeroplane being taken, into the hangar.

Captain Moore, the pilot (on the right), studying the route map before his start on the 300 miles flight in the German East African Campaign.

AIR PATROLLING IN THE EASTERN MEDITERRANEAN. - One of our air patrols photographed in the air from another machine.

A BRITISH BOMBING MACHINE CROSSING THE LINES ON THE WAY TO AN ENEMY POSITION. - Such a scene as the above may be witnessed any fine day on the Western Front. A bombing raid carried by the R.F.C. in progress. The aeroplanes are seen maling their way over the lines under heavy anti-aircraft fire. In the lower right-hand corner a small hostile patrol has sighted the raid, and has decided that discretion in the better part of valour. A well-known sector of the lines is here shown, the woods appearing as weird dark shapes on the vast panorama. The long straight roads, so typical of France, stretch away over the wide expanse, dotted with little villages strewn, as it were, carelessly over it. As the eye follows them, fading gradually to an ill-defined horizon, it is baffled by the heavy pall of mist which hangs like a purple curtain abruptly from the sky, above which the summits of clouds appear as giant icebergs.

Flight, September 6, 1917.

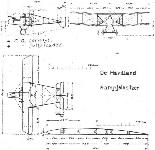

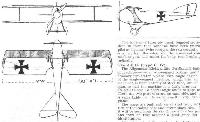

A "DE HAVILLAND" SINGLE-SEATER FIGHTER.

AN interesting illustrated description of a British biplane, appears in a German aeronautical contemporary, which we are now able to reproduce. The data relating to the "de Havilland," so described by our contemporary, are preceded by the following interesting and characteristic remarks :-

"It was difficult for the English constructors to produce a machine equal to the German aeroplanes, especially as regards the production of a single-seater fighter. The main desiderata in such a machine were high speed, maneuverability, climb and a free field for a machine gun in a forward direction. As English aeronautical engineering was somewhat backward, especially with regard to firing through the propeller, the construction of a tractor single-seater with the engine in front had to be discarded. The result was therefore necessarily a fighter, with the screw at the rear and an open framework carrying the tail, and it was the little de Havilland single-seater which was ordered in large quantities by the British Army. As our readers know, early in 1916 these machines were rushed to the English Front, where whole squadrons were smashed through accidents."

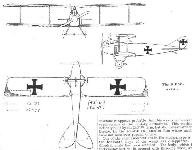

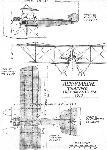

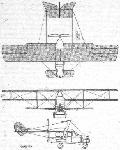

"The de Havilland single-seater consists, as the accompanying illustrations show, of a central portion of 3.5 metres span, to which the wings are attached at a dihedral angle. There are two pairs of inter-plane struts on each side. To the point where occur the first pair of struts the tail booms are attached. Ailerons of 3.31 metres length are fitted to both planes. The ailerons are held flush with the trailing edge by rubber cords on the upper surface. The power plant consists of a 100 h.p. monosoupape driving a four-bladed screw of 2.34 metres diameter. In front of the motor are the petrol and oil tanks and the pilot's seat, and in front of the seat is a pivot for the movable machine gun. The weight of the machine empty is 476 kilogrammes, and with 2 1/2 hours' fuel, pilot and machine gun, it is 722 kilogrammes. The loading is thus 35.6 kilogrammes per square metre. In spite of the great resistance of the wing bracing, the machine attains a speed of 150 kilometres per hour."

Chief Characteristics of "De Havilland" Fighter.

Power plant, 100 h.p. Gnome Monosoupape; fuel, petrol 120 litres, oil 22 litres. Area of planes (inclusive of ailerons): Top plane, 10.7 sq. m.; bottom plane, 9.6 sq. m.; total, 20.3 sq. m. Ailerons, 4 x 1.47 sq. m.; elevators, 1.19 sq. m.; rudder, 0.67 sq. m. Angle of incidence: Main planes, 4.5°; tail plane, 0.8°. Weight, empty, 476 kg.; useful load, 246 kg.; total, 722 kg. Armament, one movable machine gun.

A "DE HAVILLAND" SINGLE-SEATER FIGHTER.

AN interesting illustrated description of a British biplane, appears in a German aeronautical contemporary, which we are now able to reproduce. The data relating to the "de Havilland," so described by our contemporary, are preceded by the following interesting and characteristic remarks :-

"It was difficult for the English constructors to produce a machine equal to the German aeroplanes, especially as regards the production of a single-seater fighter. The main desiderata in such a machine were high speed, maneuverability, climb and a free field for a machine gun in a forward direction. As English aeronautical engineering was somewhat backward, especially with regard to firing through the propeller, the construction of a tractor single-seater with the engine in front had to be discarded. The result was therefore necessarily a fighter, with the screw at the rear and an open framework carrying the tail, and it was the little de Havilland single-seater which was ordered in large quantities by the British Army. As our readers know, early in 1916 these machines were rushed to the English Front, where whole squadrons were smashed through accidents."

"The de Havilland single-seater consists, as the accompanying illustrations show, of a central portion of 3.5 metres span, to which the wings are attached at a dihedral angle. There are two pairs of inter-plane struts on each side. To the point where occur the first pair of struts the tail booms are attached. Ailerons of 3.31 metres length are fitted to both planes. The ailerons are held flush with the trailing edge by rubber cords on the upper surface. The power plant consists of a 100 h.p. monosoupape driving a four-bladed screw of 2.34 metres diameter. In front of the motor are the petrol and oil tanks and the pilot's seat, and in front of the seat is a pivot for the movable machine gun. The weight of the machine empty is 476 kilogrammes, and with 2 1/2 hours' fuel, pilot and machine gun, it is 722 kilogrammes. The loading is thus 35.6 kilogrammes per square metre. In spite of the great resistance of the wing bracing, the machine attains a speed of 150 kilometres per hour."

Chief Characteristics of "De Havilland" Fighter.

Power plant, 100 h.p. Gnome Monosoupape; fuel, petrol 120 litres, oil 22 litres. Area of planes (inclusive of ailerons): Top plane, 10.7 sq. m.; bottom plane, 9.6 sq. m.; total, 20.3 sq. m. Ailerons, 4 x 1.47 sq. m.; elevators, 1.19 sq. m.; rudder, 0.67 sq. m. Angle of incidence: Main planes, 4.5°; tail plane, 0.8°. Weight, empty, 476 kg.; useful load, 246 kg.; total, 722 kg. Armament, one movable machine gun.

Some unique sketches of aircraft at work overseas by Captain K. H. Riversdale Elliot, Scottish Rifles and R.F.C.. The drawings are particularly accurate and full of movement, and carry the greater weight as from an active pilot.

Some unique sketches of aircraft at work overseas by Captain K. H. Riversdale Elliot, Scottish Rifles and R.F.C.. The drawings are particularly accurate and full of movement, and carry the greater weight as from an active pilot.

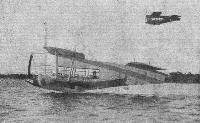

A Short Type 184 seaplane with 225 h.p. Sunbeam engine, beached on the bank of the Tigris for repairs, during the operations against Kut-el-Amara.

WITH THE BRITISH FORCES IN MESOPOTAMIA. - A seaplane returning to the slipway at Bazra after trials.

A seaplane, in what was German East Africa, about to start a flight over the German cruiser "Konigsberg," for the purpose of "spotting" for artillery work.

A Sopwith single-seater lands on its back, apparently with never a fracture, after a fight over the German lines.

Some unique sketches of aircraft at work overseas by Captain K. H. Riversdale Elliot, Scottish Rifles and R.F.C.. The drawings are particularly accurate and full of movement, and carry the greater weight as from an active pilot.

AT THE RECENT SOPWITH SPORTS AT NORBITON. - A snap of a Sopwith "Camel" during an exhibition flight.

Some unique sketches of aircraft at work overseas by Captain K. H. Riversdale Elliot, Scottish Rifles and R.F.C.. The drawings are particularly accurate and full of movement, and carry the greater weight as from an active pilot.

A three-decker in the hands of the enemy . - Another view of the machine "standing'' on its nose which was reproduced in "FLIGHT" on page 920, September 6th. We reproduce the illustration exactly as it appears in an enemy newspaper, and it will be noticed that emphasis is laid upon the fact that the machine is uninjured, which appears to be correct subject to the propeller and very minor details.

Flight, July 19, 1917.

A NEAT SCHOOL MACHINE.

IN the training of a Service pilot it would often be an advantage if a machine were available on which, after having got to feel quite at home in the ordinary training machine, he could put in a little extra practice before making the admittedly somewhat long step to the high-powered fast Service aeroplane. It was with this object in view that the small biplane illustrated in the accompanying photographs was built. This machine, which was designed for the Wright Forge and Engineering Co., Ltd., of Tipton, Staffs., by Mr. W. West wood, is a light two-seater, fitted with a 40-45 h.p. Anzani engine. It is stated by the designer to have a speed range of from 30 to 65 m.p.h., and its climb, although not measured, appears to be quite good.

The upper and lower planes are of the same span, and both are fitted with ailerons interconnected in the usual manner. The top plane is built up in three sections - a centre section and the two outer main sections. The bottom planes are, as in the majority of modern biplanes, attached to the sides of the body. Structurally the wings are built up of ash spars reinforced with steel, and of ribs having spruce flanges and three-ply webs. The leading and trailing edges are of spruce, except for the tips, which are steam-bent ash. As will be seen from the illustrations, there is only one pair of inter-plane struts on each side, the machine following in this respect the lines of a fast single-seater scout.

As regards the wing bracing, this is effected by a somewhat unusual combination of steel tubes and stream-line wires. The lift "wires" consist of streamline steel tube measuring 1/2 in. in width by about 3/16 in. thick, and of R.A.F. wires. The landing "wires" are steel tubes only. External drift wires run to the nose of the body, and assist the internal wing bracing, which is in the form of stranded cable.

A flat non-lifting tail plane is secured to the top of the body and stayed with stream-line steel tubes. To the trailing edge of the tail plane is hinged the divided elevator, which is operated by means of stranded cables from an external crank lever on the side of the body. The rudder is hinged to the stem post of the body, and is partly balanced by a forward projection as shown in the illustrations.

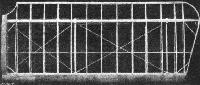

Aerodynamically the body is of the ordinary flat-sided rectangular section type, but constructionally it differs somewhat from the majority of other aeroplane bodies. The designer argues - quite rightly, we think - that for a school machine, which is subject to many and frequently rough landings, it is important that the body should be a strong one. This end is attained in the present machine by an internal construction of the ordinary girder type, with four ash booms and ash and spruce struts in front and rear respectively, the whole being braced with piano wire, supplemented by a covering of three-ply extending the whole length of the body and screwed to rails and struts so as to minimise the danger of short breaks in the rails. A similar body has, we understand, stood up to a nose dive into the ground from a height of about 100 ft. This happened to a monoplane having a similar body.

The pilot's and passenger's seats are arranged tandem fashion, the pilot occupying the rear ore. The instruments comprise: Altimeter, revolutions counter, air speed indicator, switch, throttle and air control.

In the preliminary tests, which were carried out by Mr. Rene Desoutter at Dunstall Park, Wolverhampton, the machine did not show any tendency to spin, and refused, we are informed, to do a tail-slide when stalled to a vertical attitude in the air, the machine coming out in a nose-dive from this attitude. The following are the chief characteristics of the machine :-

Length, 22 ft.; span, 26 ft.; chord, 5 ft.; gap, 5 ft.; weight empty, 720 lbs.; area of wings, 245 sq. ft.; area of tail, 15 sq. ft.; area of elevators, 10 sq. ft.; area of rudder, 6,75 sq. ft.; engine, 40-45 Anzani; propeller, Lang; speed, 30 to 65 m.p.h.

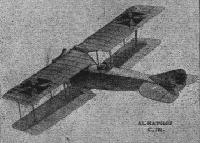

A NEAT SCHOOL MACHINE.

IN the training of a Service pilot it would often be an advantage if a machine were available on which, after having got to feel quite at home in the ordinary training machine, he could put in a little extra practice before making the admittedly somewhat long step to the high-powered fast Service aeroplane. It was with this object in view that the small biplane illustrated in the accompanying photographs was built. This machine, which was designed for the Wright Forge and Engineering Co., Ltd., of Tipton, Staffs., by Mr. W. West wood, is a light two-seater, fitted with a 40-45 h.p. Anzani engine. It is stated by the designer to have a speed range of from 30 to 65 m.p.h., and its climb, although not measured, appears to be quite good.

The upper and lower planes are of the same span, and both are fitted with ailerons interconnected in the usual manner. The top plane is built up in three sections - a centre section and the two outer main sections. The bottom planes are, as in the majority of modern biplanes, attached to the sides of the body. Structurally the wings are built up of ash spars reinforced with steel, and of ribs having spruce flanges and three-ply webs. The leading and trailing edges are of spruce, except for the tips, which are steam-bent ash. As will be seen from the illustrations, there is only one pair of inter-plane struts on each side, the machine following in this respect the lines of a fast single-seater scout.

As regards the wing bracing, this is effected by a somewhat unusual combination of steel tubes and stream-line wires. The lift "wires" consist of streamline steel tube measuring 1/2 in. in width by about 3/16 in. thick, and of R.A.F. wires. The landing "wires" are steel tubes only. External drift wires run to the nose of the body, and assist the internal wing bracing, which is in the form of stranded cable.

A flat non-lifting tail plane is secured to the top of the body and stayed with stream-line steel tubes. To the trailing edge of the tail plane is hinged the divided elevator, which is operated by means of stranded cables from an external crank lever on the side of the body. The rudder is hinged to the stem post of the body, and is partly balanced by a forward projection as shown in the illustrations.

Aerodynamically the body is of the ordinary flat-sided rectangular section type, but constructionally it differs somewhat from the majority of other aeroplane bodies. The designer argues - quite rightly, we think - that for a school machine, which is subject to many and frequently rough landings, it is important that the body should be a strong one. This end is attained in the present machine by an internal construction of the ordinary girder type, with four ash booms and ash and spruce struts in front and rear respectively, the whole being braced with piano wire, supplemented by a covering of three-ply extending the whole length of the body and screwed to rails and struts so as to minimise the danger of short breaks in the rails. A similar body has, we understand, stood up to a nose dive into the ground from a height of about 100 ft. This happened to a monoplane having a similar body.

The pilot's and passenger's seats are arranged tandem fashion, the pilot occupying the rear ore. The instruments comprise: Altimeter, revolutions counter, air speed indicator, switch, throttle and air control.

In the preliminary tests, which were carried out by Mr. Rene Desoutter at Dunstall Park, Wolverhampton, the machine did not show any tendency to spin, and refused, we are informed, to do a tail-slide when stalled to a vertical attitude in the air, the machine coming out in a nose-dive from this attitude. The following are the chief characteristics of the machine :-

Length, 22 ft.; span, 26 ft.; chord, 5 ft.; gap, 5 ft.; weight empty, 720 lbs.; area of wings, 245 sq. ft.; area of tail, 15 sq. ft.; area of elevators, 10 sq. ft.; area of rudder, 6,75 sq. ft.; engine, 40-45 Anzani; propeller, Lang; speed, 30 to 65 m.p.h.

Flight, July 12, 1917.

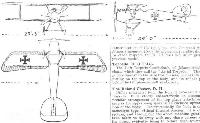

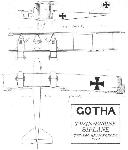

SOME 1917 TYPE GERMAN AEROPLANES.

The A.E.G. (Type C. IV).

The Allgemeine Elektrizitats Gesellschaft build two types of machines - one a twin-engined biplane and the other an ordinary two-seater biplane with single engine. The wings of the single-engined machine, which, like all the A.E.G. machines, is built entirely of steel tube, are of 42 ft. 6 ins. span, so that the machine is a fairly large one. The wings are set at a small dihedral angle and also slope back slightly. There are two pairs of struts on each side, and the machine is remarkable for its exceptionally large gap between the planes.

The wings are built entirely of steel tube, with the exception of the leading edge and intermediate ribs. The ailerons, it will be seen from the sketch, are of rather peculiar shape, and form on that account a good guide for purposes of identification.

Like the rest of the machine, the body is built of steel tube, and is flat-sided except in front, where it is covered with three-ply and slightly rounded. The engine, a 175 h.p. Mercedes, is mounted on two longitudinal bearers of square section steel tube. The petrol service tank and radiator are incorporated with the centre section of the top plane, which is straight. The armament consists of two machine guns, the front one fixed and synchronised, the rear one on a gun ring, and of four bombs placed on top of one another inside the body, to the right of the passenger.

SOME 1917 TYPE GERMAN AEROPLANES.

The A.E.G. (Type C. IV).

The Allgemeine Elektrizitats Gesellschaft build two types of machines - one a twin-engined biplane and the other an ordinary two-seater biplane with single engine. The wings of the single-engined machine, which, like all the A.E.G. machines, is built entirely of steel tube, are of 42 ft. 6 ins. span, so that the machine is a fairly large one. The wings are set at a small dihedral angle and also slope back slightly. There are two pairs of struts on each side, and the machine is remarkable for its exceptionally large gap between the planes.

The wings are built entirely of steel tube, with the exception of the leading edge and intermediate ribs. The ailerons, it will be seen from the sketch, are of rather peculiar shape, and form on that account a good guide for purposes of identification.

Like the rest of the machine, the body is built of steel tube, and is flat-sided except in front, where it is covered with three-ply and slightly rounded. The engine, a 175 h.p. Mercedes, is mounted on two longitudinal bearers of square section steel tube. The petrol service tank and radiator are incorporated with the centre section of the top plane, which is straight. The armament consists of two machine guns, the front one fixed and synchronised, the rear one on a gun ring, and of four bombs placed on top of one another inside the body, to the right of the passenger.

A captured German (A.E.G.) biplane with 175 h.p. Mercedes engine. Note the peculiar shape of the ailerons.

Flight, July 12, 1917.

SOME 1917 TYPE GERMAN AEROPLANES.

Twin-Engine A.E.G., 450 h.p.

It has already been mentioned that the Allgemeine Elektrizitats Gesellschaft make a twin-engine biplane. This machine, which is built entirely of steel, is fitted with two Benz or Mercedes engines of 225 h.p. each, placed in nacelles between the wings. The radiators are in the nose of the nacelles, as are also, in contradistinction to the Gotha, the air screws. The fuselage, which has seating accommodation for three occupants, projects a considerable distance ahead of the main plane.

Flight, November 1, 1917.

THE TWIN-ENGINE A.E.G. BOMBING BIPLANE.

IN the early days of the war it was the habit of the lay Press to use the name Taube generically for all military machines of German origin, and this caused some confusion in sometimes spreading the impression that the machines which figured in reports of fights in the air were of the Taube monoplane type, when, as a matter of fact, this type of aeroplane had long since been abandoned by the Germans. In the same manner there would at the present moment appear to be the possibility of causing some confusion by assigning to all German aeroplanes carrying out bombing raids on this country the designation "Gotha." As a matter of fact, it must not be assumed that these raiders are necessarily always of the Gotha type, as Germany possesses others which would in all probability be capable of raids on England, for which they with some amount of probability may be assumed to have been used. We are referring to the large twin-engine biplanes built by the Allgemeine Elektrizitats Gesellschaft, and known as A.E.G. biplanes.

The A.E.G. firm was, perhaps, one of the first in Germany to turn its attention to machines of large dimensions, although not to such extent as the Capronis in Italy or the Handley-Pages in this country. One of the first A.E.G. twin-engine biplanes to become known to our pilots on the western front made its appearance during 1916, and was briefly described by M. Jean Lagorgette in our French contemporary l'Airophile of August, 1916. This machine had a long convered-in fuselage providing accommodation for the pilot and gunners, while the two engines were placed on the wings, sufficiently far out for the two tractor screws to clear the nose of the fuselage. The planes, of which the upper was slightly longer than the lower, were set at a dihedral angle, and were also swept back in the manner beloved by German aeroplane designers. Little was known of these machines, except that they were believed to be made almost entirely of steel.

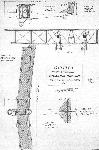

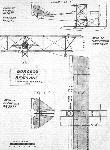

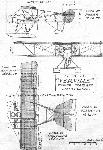

The following particulars of the 1917 type A.E.G. bombers may be of interest, since, as already mentioned, there is a possibility of these being employed for raids on this country as well as the Gothas. The general arrangement will be clear from the accompanying perspective views and scale drawings, which latter should not be very far wrong in any dimension, although we cannot guarantee that they are absolutely correct. They have been plotted with the aid of the perspective views, with which they tally fairly accurately.

Fundamentally the A.E.G. bomber resembles the Gotha biplanes, illustrated descriptions of which were published in our issues of July 12th and August 9th, 1917. In dimensions, however, the two machines differ considerably, the Gotha being somewhat larger. Also the A.E.G. has its two airscrews placed in front of the main planes, whereas in the Gotha they are "pusher" screws. As in the Gotha, the wings of the A.E.G. are swept back, and are also placed at a dihedral angle, which appears to be greater in the bottom than in the top plane. The span, it will be seen from the scale drawings, is the same for both planes, and amounts to 57 ft., while the overall length is about 30 ft. The ailerons, which are of a peculiar shape, are fitted to the top plane only, and are operated by a crank lever working in a slot in the plane as shown in one of the accompanying sketches. This arrangement, which will be familiar to our readers from descriptions of Albatros biplanes, would appear to be in general favour with German designers, whereas it is rarely or never met with in Allied machines.

The tail planes, which are of the monoplane type, consist of fixed stabilising planes and a vertical fin, to which are hinged the elevators and rudder respectively. Both elevators and rudder have forward projections in order to partly balance them, thus relieving the pilot of a certain amount of the strain of working the controls. A tail skid is fitted under the stern of the fuselage, and is sprung, not by means of rubber shock absorbers as is usually the case with our machines, but by means of coil springs. The same is the case with the landing chassis, where coil springs are also used instead of rubber. Whether this "indicates a shortage of rubber" in Germany, or whether, for machines of such large dimensions and heavy weight, it has been found more suitable, it is not possible to say.

As already mentioned, the material used in the construction is, with very few exceptions, steel, practically the only parts made of wood being the ribs of the main planes. The main spars are in the form of steel tubes, which is rather surprising in view of the fact that about the worst use to put a circular or tubular section to is to employ it as a beam laterally loaded, since much of the material of such a section will be situated at or near the neutral axis, where it is adding weight without contributing greatly towards the strength. Possibly the tube has been chosen, in this instance, for reasons connected with the manufacture rather than from considerations of structural suitability. The method of attaching the root of the main spar to the centre section of the top plane is shown in one of our sketches. The short length joining the centre section spar and root of wing appears to be turned from the solid, hollowed out at one end to receive the centre section spar, and having machined on the other a forked end to receive the root of the main spar. The strut socket, which resembles those usually found on German machines, is attached to it by welding.

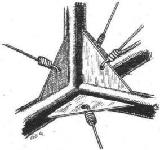

Like the rest of the machine, the fuselage of the A.E.G. bomber is built up of steel tubes, this material being used for longerons as well as for struts and cross members. These are connected by welding and the joints are stiffened and anchorage provided for the cross bracing wires by triangular pieces of sheet steel welded to longerons and struts. The arrangement will be better understood by reference to one of the accompanying sketches.

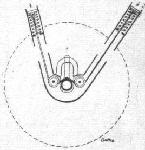

With regard to the accommodation for the occupants, this is divided into three divisions. In the front cockpit - in the extreme nose of the body - is a seat for the bomber, who views the ground below and obtains his sights through a circular opening in the floor. On his right the bomber has a rack holding bombs; these are presumably not of a very heavy calibre. Under the centre of the body there is another bomb rack carrying the heavier projectiles. Near the inner ends of the lower plane there are fittings for an additional supply of bombs. The majority of the bombs, however, are not, so far as it is possible to ascertain, carried under the body and wings, but inside the body.

In the centre cockpit there are two seats, side by side, occupied by two pilots, or presumably by two pilot-gunners, one relieving the other at the controls during a long flight. The two seats, although placed side by side, do not extend the whole width of the body, but are placed a little to the left of the centre line, leaving room on the right-hand side for a bomb rack holding about 10 or 12 bombs. Behind the pilot's cockpit is that of the gunner, who operates a machine-gun mounted on a turntable, which allows of firing the gun laterally as well as upwards and to the rear. On the left-hand side in the gunner's cockpit there is another bomb rack carrying a similar store of bombs to that in the pilot's cockpit. In the floor of the bay to the rear of the gunner's cockpit there is a trap door, hinged along its rear edge. By lifting up this trap door, which may be held in its open position by a, catch, the gunner is enabled to fire in a downward and rearward direction when being chased and attacked from behind. A small gun pivot mounted on the floor forms the support for the gun when firing through the trap door.

The engines - which are generally of the 260 h.p. Mercedes type - are placed one on each side on the centre section of the lower plane. They are enclosed in engine housings, with the radiator mounted near the nose. The main petrol tank is not carried in the engine housings, but in the pilot's cockpit, where it forms, as a matter of fact, the support for the two seats. A service petrol tank is fitted in each engine housing, these service tanks being replenished from the main tank by means of a pump. The mounting of the engines on the lower plane centre section is somewhat unusual, and may be best understood by an examination of the scale drawings and general views. It should, of course, be studied in conjunction with the undercarriage, since much of the at first sight cumbersome and unnecessary strutting is dependent upon the design of the chassis. This, it will be seen, has been so designed that the outer wheel on each side occurs directly underneath the corresponding engine, while the inner wheel is supported on another Vee from the lower plane. The object is plainly to let the inner wheels take part of the load of the central fuselage, but the manner of carrying out the idea does not strike one as particularly ingenious. The weight of the body is during a landing primarily supported on the inner ends of the centre section of the bottom plane. Struts are taken, it is true, to the top longerons of the body from the point of attachment of the inner chassis strutts, but even so there is a considerable length of spar between this point and the sides of the body. Altogether the strutting of engines and undercarriages appears clumsy and complicated, and must, it would appear, present a great amount of head resistance. The two axles are slung from the apex of the Vees by coil springs, and not by rubber bands or cords. The speed is not known, but a rough estimate would appear to indicate as a reasonable figure about go m.p.h. The resistance appears to be excessive as regards certain portions, otherwise we should have estimated the speed to be slightly higher.

SOME 1917 TYPE GERMAN AEROPLANES.

Twin-Engine A.E.G., 450 h.p.

It has already been mentioned that the Allgemeine Elektrizitats Gesellschaft make a twin-engine biplane. This machine, which is built entirely of steel, is fitted with two Benz or Mercedes engines of 225 h.p. each, placed in nacelles between the wings. The radiators are in the nose of the nacelles, as are also, in contradistinction to the Gotha, the air screws. The fuselage, which has seating accommodation for three occupants, projects a considerable distance ahead of the main plane.

Flight, November 1, 1917.

THE TWIN-ENGINE A.E.G. BOMBING BIPLANE.

IN the early days of the war it was the habit of the lay Press to use the name Taube generically for all military machines of German origin, and this caused some confusion in sometimes spreading the impression that the machines which figured in reports of fights in the air were of the Taube monoplane type, when, as a matter of fact, this type of aeroplane had long since been abandoned by the Germans. In the same manner there would at the present moment appear to be the possibility of causing some confusion by assigning to all German aeroplanes carrying out bombing raids on this country the designation "Gotha." As a matter of fact, it must not be assumed that these raiders are necessarily always of the Gotha type, as Germany possesses others which would in all probability be capable of raids on England, for which they with some amount of probability may be assumed to have been used. We are referring to the large twin-engine biplanes built by the Allgemeine Elektrizitats Gesellschaft, and known as A.E.G. biplanes.

The A.E.G. firm was, perhaps, one of the first in Germany to turn its attention to machines of large dimensions, although not to such extent as the Capronis in Italy or the Handley-Pages in this country. One of the first A.E.G. twin-engine biplanes to become known to our pilots on the western front made its appearance during 1916, and was briefly described by M. Jean Lagorgette in our French contemporary l'Airophile of August, 1916. This machine had a long convered-in fuselage providing accommodation for the pilot and gunners, while the two engines were placed on the wings, sufficiently far out for the two tractor screws to clear the nose of the fuselage. The planes, of which the upper was slightly longer than the lower, were set at a dihedral angle, and were also swept back in the manner beloved by German aeroplane designers. Little was known of these machines, except that they were believed to be made almost entirely of steel.

The following particulars of the 1917 type A.E.G. bombers may be of interest, since, as already mentioned, there is a possibility of these being employed for raids on this country as well as the Gothas. The general arrangement will be clear from the accompanying perspective views and scale drawings, which latter should not be very far wrong in any dimension, although we cannot guarantee that they are absolutely correct. They have been plotted with the aid of the perspective views, with which they tally fairly accurately.

Fundamentally the A.E.G. bomber resembles the Gotha biplanes, illustrated descriptions of which were published in our issues of July 12th and August 9th, 1917. In dimensions, however, the two machines differ considerably, the Gotha being somewhat larger. Also the A.E.G. has its two airscrews placed in front of the main planes, whereas in the Gotha they are "pusher" screws. As in the Gotha, the wings of the A.E.G. are swept back, and are also placed at a dihedral angle, which appears to be greater in the bottom than in the top plane. The span, it will be seen from the scale drawings, is the same for both planes, and amounts to 57 ft., while the overall length is about 30 ft. The ailerons, which are of a peculiar shape, are fitted to the top plane only, and are operated by a crank lever working in a slot in the plane as shown in one of the accompanying sketches. This arrangement, which will be familiar to our readers from descriptions of Albatros biplanes, would appear to be in general favour with German designers, whereas it is rarely or never met with in Allied machines.

The tail planes, which are of the monoplane type, consist of fixed stabilising planes and a vertical fin, to which are hinged the elevators and rudder respectively. Both elevators and rudder have forward projections in order to partly balance them, thus relieving the pilot of a certain amount of the strain of working the controls. A tail skid is fitted under the stern of the fuselage, and is sprung, not by means of rubber shock absorbers as is usually the case with our machines, but by means of coil springs. The same is the case with the landing chassis, where coil springs are also used instead of rubber. Whether this "indicates a shortage of rubber" in Germany, or whether, for machines of such large dimensions and heavy weight, it has been found more suitable, it is not possible to say.

As already mentioned, the material used in the construction is, with very few exceptions, steel, practically the only parts made of wood being the ribs of the main planes. The main spars are in the form of steel tubes, which is rather surprising in view of the fact that about the worst use to put a circular or tubular section to is to employ it as a beam laterally loaded, since much of the material of such a section will be situated at or near the neutral axis, where it is adding weight without contributing greatly towards the strength. Possibly the tube has been chosen, in this instance, for reasons connected with the manufacture rather than from considerations of structural suitability. The method of attaching the root of the main spar to the centre section of the top plane is shown in one of our sketches. The short length joining the centre section spar and root of wing appears to be turned from the solid, hollowed out at one end to receive the centre section spar, and having machined on the other a forked end to receive the root of the main spar. The strut socket, which resembles those usually found on German machines, is attached to it by welding.

Like the rest of the machine, the fuselage of the A.E.G. bomber is built up of steel tubes, this material being used for longerons as well as for struts and cross members. These are connected by welding and the joints are stiffened and anchorage provided for the cross bracing wires by triangular pieces of sheet steel welded to longerons and struts. The arrangement will be better understood by reference to one of the accompanying sketches.

With regard to the accommodation for the occupants, this is divided into three divisions. In the front cockpit - in the extreme nose of the body - is a seat for the bomber, who views the ground below and obtains his sights through a circular opening in the floor. On his right the bomber has a rack holding bombs; these are presumably not of a very heavy calibre. Under the centre of the body there is another bomb rack carrying the heavier projectiles. Near the inner ends of the lower plane there are fittings for an additional supply of bombs. The majority of the bombs, however, are not, so far as it is possible to ascertain, carried under the body and wings, but inside the body.

In the centre cockpit there are two seats, side by side, occupied by two pilots, or presumably by two pilot-gunners, one relieving the other at the controls during a long flight. The two seats, although placed side by side, do not extend the whole width of the body, but are placed a little to the left of the centre line, leaving room on the right-hand side for a bomb rack holding about 10 or 12 bombs. Behind the pilot's cockpit is that of the gunner, who operates a machine-gun mounted on a turntable, which allows of firing the gun laterally as well as upwards and to the rear. On the left-hand side in the gunner's cockpit there is another bomb rack carrying a similar store of bombs to that in the pilot's cockpit. In the floor of the bay to the rear of the gunner's cockpit there is a trap door, hinged along its rear edge. By lifting up this trap door, which may be held in its open position by a, catch, the gunner is enabled to fire in a downward and rearward direction when being chased and attacked from behind. A small gun pivot mounted on the floor forms the support for the gun when firing through the trap door.

The engines - which are generally of the 260 h.p. Mercedes type - are placed one on each side on the centre section of the lower plane. They are enclosed in engine housings, with the radiator mounted near the nose. The main petrol tank is not carried in the engine housings, but in the pilot's cockpit, where it forms, as a matter of fact, the support for the two seats. A service petrol tank is fitted in each engine housing, these service tanks being replenished from the main tank by means of a pump. The mounting of the engines on the lower plane centre section is somewhat unusual, and may be best understood by an examination of the scale drawings and general views. It should, of course, be studied in conjunction with the undercarriage, since much of the at first sight cumbersome and unnecessary strutting is dependent upon the design of the chassis. This, it will be seen, has been so designed that the outer wheel on each side occurs directly underneath the corresponding engine, while the inner wheel is supported on another Vee from the lower plane. The object is plainly to let the inner wheels take part of the load of the central fuselage, but the manner of carrying out the idea does not strike one as particularly ingenious. The weight of the body is during a landing primarily supported on the inner ends of the centre section of the bottom plane. Struts are taken, it is true, to the top longerons of the body from the point of attachment of the inner chassis strutts, but even so there is a considerable length of spar between this point and the sides of the body. Altogether the strutting of engines and undercarriages appears clumsy and complicated, and must, it would appear, present a great amount of head resistance. The two axles are slung from the apex of the Vees by coil springs, and not by rubber bands or cords. The speed is not known, but a rough estimate would appear to indicate as a reasonable figure about go m.p.h. The resistance appears to be excessive as regards certain portions, otherwise we should have estimated the speed to be slightly higher.

Flight, December 13, 1917.

THE AGO - AN INTERESTING ENEMY AEROPLANE.

A MOVE in the right direction has undoubtedly been made by the Air Ministry, in collecting a number of enemy aeroplanes, aeroplane parts, and engines at a London depot, and to grant facilities to aeroplane designers and representatives of responsible firms to view this collection. The query might be raised why the collection has not been thrown open to the public, but the various exhibits are of such a nature that they appeal more particularly to the trained engineer than to the general public, arranged as they are to show every constructional detail of the different machines. For the purpose for which the collection is intended the machines and parts are most admirably arranged. Thus, in the case of complete machines, these are shown with one side stripped, up to the centre line of the fuselage. The other side is left uncovered. In this way it is possible to obtain on the one side an impression of the general arrangement of the machine, while, by merely walking over to the other side, one can inspect, at leisure, every spar, strut, wire and fitting, Great care and foresight has been shown, also, in the manner in which various parts, such as spars, &c, have been cut through in places, to allow of inspecting sections and internal construction. In this manner there are practically no component parts of which the general design and detail construction are not instantly clear from a very brief inspection. We do not propose to give, in this issue, a complete list of the exhibits, since, in any case, these change from time to time, but we hope later on to be able to publish sketches and descriptions of other machines.

For the present we will confine ourselves to dealing with one captured enemy aeroplane - the Ago - which, thanks to the courtesy of the Air Board officials, our representatives have had the opportunity of examining in detail.

The first impression one receives on being suddenly confronted with the captured Ago biplane is apt to be one in which surprise mingles with curiosity. As regards its general lines, the Ago is of a strikingly unusual appearance, mainly, no doubt, due to the fact that its wings are tapered very pronouncedly from root to tip. This is very unusual in any modern machine, and when it is suddenly met with in a German machine of comparatively recent date - from various marks on the machine one gathers the impression that it was built certainly no longer ago than the first months of this year - the question that first comes to mind is naturally enough related to the raison d'etre of this unusual design.

In the first place, it is obvious that whatever it was the designer was aiming at, he was prepared to go to considerable trouble to obtain it, since the construction of such tapered wings as those of this Ago are not by any means an attractive proposition commercially, entailing, as it does, the separate construction of half the ribs, no two of which are alike from root to tip in one wing. Also, as the spars converge to a point at the tip, they intersect the ribs at varying distances from root to tip, which again means extra work in manufacture. As for the spars themselves, they also taper from root to tip, again more trouble and expense.

What, then, are the reasons which have led a designer to sacrifice so much from a manufacturing point of view, in order to obtain his end? A walk round the machine soon furnishes the reply to the question. When standing in front of the machine one is at once struck by the peculiar bracing of the front spar. Instead of the usual interplane strut there is on the Ago only a single solid wire running from the front lower spar to the front top spar, while no lift or landing cables of any sort are employed between the two front spars.

This feature, then, will probably be found to contain the solution of the peculiar design. By doing away with the front bracing, a much freer field of firing is obtained; and there can be little doubt that this was the object for which the designer was striving.

Owing to the backward slope of the leading edge of the planes, the outer inter-plane struts are farther back than they would be in a machine with straight wings, and also owing to the taper, closer together and therefore obstructing the field to a smaller extent. The narrower chord near the tip will result in a smaller travel of the centre of pressure, hence possibly the twist on the wings may become less, and the absence of front bracing be a less serious defect than one is inclined to imagine at first.

When we say absence of front bracing, this is not quite correct, since, as already indicated, a single solid wire runs from top to bottom front spar. As is well known, in biplanes, with top and bottom planes of the same area, and with the conventional spacing of gap about equal to chord, the top plane carries about 30 per cent, more load than the bottom one, or roughly, 4/7 and 3/7 respectively. By running a wire from the top to the bottom front spar, the latter is therefore made to carry a certain share of the top spar's load, thus relieving, to a certain extent, the enormous bending moment that must be present on a comparatively heavily loaded machine, whose front spars have a distance of some 13 ft. 6 in. between supports.

So much for the general design of the Ago. As regards the construction there is much detail work that is interesting and unusual. The fuselage, which is, as in the majority of German aeroplanes, of very, roomy proportions, as regards occupants' accommodation, is covered with fabric except the front around the engine, which is covered in with three-ply. The floor of the fuselage is of three-ply from the stern to the gunner's (rear) cockpit. From there to the nose the floor is three-ply, covered with aluminium. In section, the fuselage is rectangular, a light and comparatively flat structure forming a turtle back over the top of the main fuselage framework. This turtle back is built up as a separate unit, and is easily detachable by means of a neat and very simple clip. In case of severe stresses being put on the fuselage, it is therefore an easy matter to detach the top covering and examine and adjust the internal bracing.

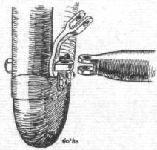

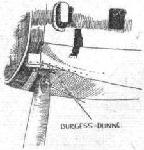

The four longerons, which are of square section, are pine, from the rear cockpit to the stern, while in front they are made of ash. The struts are in the form of steel tubes, and the solid wire bracing is attached to the struts in the manner shown in one of the accompanying sketches. A small socket, apparently machined out of the solid steel bar, has holes drilled in its edges, through which the bracing wires pass. This socket is slipped over the end of the tube, which has small dents in its end to give more room for the loop of the wire, and the socket, with its strut, is secured to the longeron by a bolt passing through it, with the nut and a spring washer inside the socket, as shown in section in one of our sketches. Except for the fact that the longerons are pierced by two holes - the horizontal and vertical fuselage struts are staggered in relation to one another - close to one another, this arrangement appears to be very neat, and certainly takes up very little space.

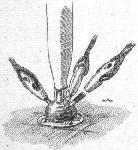

In front, the fuselage bracing is in the form of diagonal steel tubes, no wires being employed. The rear cockpit is occupied by the machine gunner, who 'is seated on a small seat built up of a framework of steel tubing, over which is stretched canvas. This seat is so hinged and sprung that immediately the gunner stands up the seat springs into a vertical position out of his way in case he wishes to do his shooting in a standing position. When horizontal, the seat is supported by a slanting steel tube, pivoted at its lower end to the floor, and having its upper end running in a steel guide, bolted to the under side of the seat. The principle will be better understood by reference to one of the accompanying sketches. The gun is mounted on a swiveling bracket, which, in turn, is supported on a rotatable gun ring of wood, forming, in effect, a turntable, by means of which the gun may be traversed in any desired direction. To prevent damaging the nose of the machine and the propeller, a stop is provided for the gun in the form of two small frames clipped to the rear legs of the cabane, which prevents the gun barrel from travelling too far inboard.

The pilot's seat, which is in the front cockpit, is placed on top of the main petrol tank resting on the floor of the fuselage. A service petrol tank is carried in and mounted flush with the top plane just to the left of the cabane. In the corresponding opening in the upper right hand wing, is carried the radiator, and in connection with these two it is interesting to note that the water and petrol is led through the right and left cabane legs respectively, thus saving a certain amount of piping, which would otherwise be exposed to the air.

The controls are, more or less, of the usual German type, with a vertical lever terminating at the top in a double handled grip, and mounted - via a universal joint - on a longitudinal rocking shaft, having at its other (rear) end crank levers for the attachment of the aileron cables. On the machine in question, no guns were mounted, but from the various fittings it appeared that there were at one time two machine guns mounted above the engine, and with the usual interrupting gear for clearing the propeller blades.

The large engine - a 230 h.p. Benz - is mounted on two longitudinal bearers, which are in turn supported from the fuselage by three direct supports - at the rear a sloping panel of ply-wood, in the middle by tubes sloping up from the junction of the rear panel to the lower longerons, and at the front by another panel of ply-wood, this a vertical one. In addition to these direct supports, the engine mounting is further braced by tubes to the upper longerons, and by diagonal tubes from top to bottom longerons. It has already been mentioned that the main petrol tank is placed on the floor of the pilot's cockpit, while the petrol service tank is mounted in an opening in the top plane. The oil tank, which is comparatively small, is carried under the engine housing on the right-hand side of the crank chamber. The propeller, which was not in place on the machine inspected, probably had a "spinner," or hemispherical nosepiece over the boss, as this would appear to go well with the nose of the fuselage, which is of rounded section at this point.